Views: 222 Author: Amanda Publish Time: 2025-10-26 Origin: Site

Content Menu

● Traditional Milling Explained

● Key Differences Between CNC and Traditional Milling

● Advantages of CNC Milling Services

>> High Precision and Accuracy

>> Consistency Across Production

>> Optimized Production Efficiency

>> Complex Geometry Capability

>> Integration With Digital Design

● When Traditional Milling Still Plays a Role

>> Budget-Constrained Custom Projects

● Design and Material Considerations

● How CNC Milling Boosts Modern Manufacturing

● CNC Milling Services in Different Industries

● Selecting the Right CNC Milling Partner

● Economic Comparison: Setup vs. Production Cost

● Future Trends in CNC Milling Technology

● FAQ

>> 1. What makes CNC milling more accurate than manual milling?

>> 2. Can CNC milling be used for plastic as well as metal parts?

>> 3. Is CNC milling cost-effective for prototype production?

>> 4. What factors affect CNC milling cost?

>> 5. How do I select a reliable CNC milling partner?

In the rapidly evolving manufacturing landscape, the choice between CNC milling services and traditional milling has a profound impact on cost, precision, scalability, and turnaround time. As industries shift towards automation and digital fabrication, understanding the differences between these two methods is more crucial than ever.

CNC machining has revolutionized production efficiency and precision, enabling manufacturers to produce parts with microscopic tolerances and consistent repeatability across millions of cycles. Yet, traditional milling still retains valuable advantages when projects call for flexibility, craftsmanship, or low-cost custom prototypes. This article explores both processes in depth, helping you determine the ideal solution for your project's unique technical and business needs.

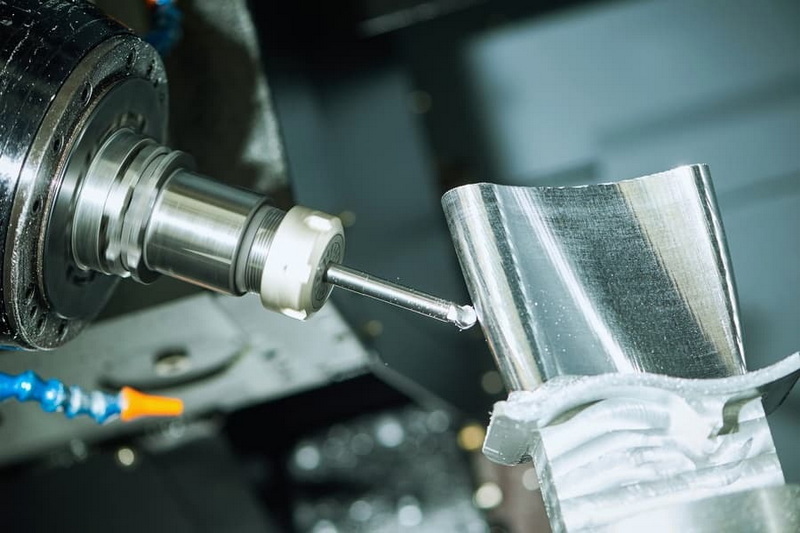

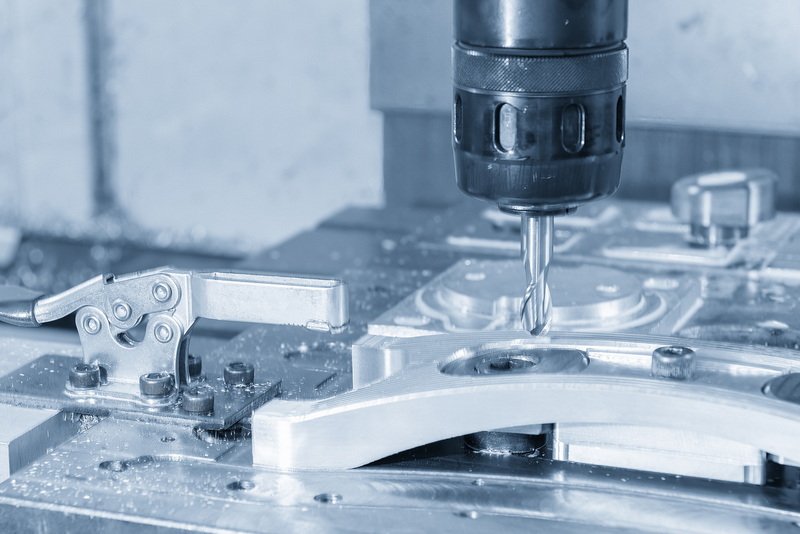

CNC milling (Computer Numerical Control milling) automates the cutting and shaping of materials via pre-programmed digital instructions. Using G-code generated from CAD/CAM software, the system meticulously controls machine movement across multiple axes—typically 3-, 4-, or 5-axis configurations—achieving precision levels as fine as ±0.005 mm.

This automation eliminates most human variability. Operators simply load raw material, set parameters, and allow the computer-controlled hardware to execute its programmed tasks. As a result, CNC machines produce highly complex geometries, mirrored surfaces, and flawless repeatability without constant supervision.

CNC milling services are suitable for an extensive range of materials including aluminum, stainless steel, copper, titanium, engineering plastics such as POM, ABS, and reinforced composites. This capability empowers engineers to iterate quickly during product design, test new prototypes, and transition to mass production effortlessly.

Traditional milling, by contrast, relies on the manual skill of an experienced machinist. The operator manually controls the milling cutter, adjusting speeds, feeds, and tool angles in real time. Before CNC technology, this was the standard method for shaping components used in aviation, automotive, and tooling.

The flexibility of manual milling remains valuable today. When a technician must make on-the-spot design changes or repair a single damaged component, manual control enables faster execution than reprogramming a CNC file. However, human dependency translates to variability, slower processing time, and limitations in achieving intricate forms.

If a project calls for high-volume manufacturing, tight tolerances, or complex surface geometry, manual methods simply cannot match CNC accuracy.

Feature | CNC Milling Services | Traditional Milling |

Automation | Fully automated digital control | Human-operated manual control |

Precision | Extremely high (up to ±0.01 mm) | Moderate and operator-dependent |

Production Speed | Fast once programmed | Slower, especially for complex shapes |

Repeatability | Identical across batches | Difficult to achieve repeatability |

Complex Geometry | Easily handles multi-axis parts | Limited to simpler designs |

Labor Cost | Lower per part for high volume | Higher due to manual operation |

Flexibility | Automatic reprogramming for new jobs | Manual setup and realignment |

Best Application | Mass production, complex designs | Simple parts, fast modifications |

CNC milling services achieve exceptional precision through automated control. Multi-axis machines synchronize tool paths and angular movements, maintaining uniformity even in the most intricate components. This precision benefits industries like medical implant manufacturing, aerospace engine design, and robotics.

For projects requiring batch production—such as custom enclosures, connectors, or mechanical housings—repeatability is vital. Once a CNC program is verified, parts can be produced repeatedly with practically zero deviation, ensuring quality consistency.

CNC mills run continuously with minimal human intervention. Automated tool changers, coolant systems, and real-time feedback sensors allow these systems to work overnight. The result: lower per-unit costs and rapid turnaround compared to manual techniques.

5-axis CNC systems rotate and tilt the workpiece to cut from multiple directions in a single setup. This minimizes repositioning, potential errors, and finishing requirements. Designs with undercuts, curvatures, or intricate channels are easily machined with this flexibility.

Digital workflows from CAD software feed directly into CNC systems, shortening design-to-production time. Engineers can preview machining simulations, prevent tool collisions, and create optimized cuts before manufacturing starts. The digital traceability of these systems also supports rigorous quality assurance.

Even in the modern automated era, some contexts favor manual machining:

Small, simple parts or repairs to existing components often don't justify CNC setup time. For example, when a single metal bracket or housing needs adjustment, traditional milling is faster.

Learning manual milling helps new machinists understand mechanical principles, speeds, and tolerances—a foundation for mastering CNC programming later.

If the goal is purely functional testing rather than precision or appearance, traditional milling provides a cost-effective path to basic geometry and validation.

The choice between CNC milling services and manual machining also depends on:

If your part includes 3D contours, freeform surfaces, or internal channels, CNC machining is essential. Manual techniques cannot replicate digitally sculpted geometries to industrial tolerances.

High-performance materials like titanium, Inconel, and hardened steels require the speed control and stability of automated CNC systems. Hand milling such materials risks tool damage and costly waste.

For industries that demand micrometer-level precision—medical, defense, and aerospace—manual operations cannot meet certification standards. CNC provides documented repeatability and traceable accuracy.

Traditional milling suits small runs or unique parts. For hundreds or thousands of pieces, the digital consistency and cost efficiency of CNC milling services easily outweigh its higher programming cost.

CNC milling lies at the heart of Industry 4.0 and smart manufacturing strategies by integrating seamlessly with other production technologies:

- Automation Networks: Machines can communicate with ERP systems for resource tracking and predictive maintenance.

- Hybrid Production: Combining CNC milling with additive manufacturing enables rapid transition between 3D-printed prototypes and machined final components.

- Multi-Process Workflow: CNC-machined tools and inserts prepare molds, dies, and fixtures for injection molding or casting.

This level of technological integration accelerates time-to-market while improving design flexibility and reducing waste.

- Aerospace: High-strength, lightweight parts with tight tolerances.

- Automotive: Engine blocks, gear housings, suspension components.

- Medical Equipment: Orthopedic implants, surgical instruments, and diagnostic equipment.

- Energy Sector: Precision housings, turbine parts, and heat exchangers.

- Consumer Electronics: Chassis, connector housings, and aesthetic prototypes.

Each of these sectors depends on CNC milling services for consistent precision and scalability that manual techniques cannot match.

When outsourcing your CNC projects, partner with a provider demonstrating:

- Advanced multi-axis CNC systems capable of high-speed milling.

- Experienced engineers proficient in CAD/CAM optimization.

- Comprehensive QC processes, including CMM inspection and surface analysis.

- Material versatility across metals, polymers, and composites.

- Quick prototyping capability leading to mass production support.

Shangchen (sc-rapidmanufacturing.com) exemplifies this integrated capability. With rapid prototyping, precision part fabrication, 3D printing, and mold manufacturing expertise, Shangchen offers global OEM customers turnkey production support—from prototype to full-scale delivery.

While CNC milling services require upfront programming and machine configuration, the per-part cost decreases with quantity. Traditional milling, although cheaper initially, becomes inefficient at scale.

Over time, CNC's automation minimizes human error, reduces material waste, and enhances ROI for long-term production runs. When factoring in downtime savings, rework prevention, and part uniformity, CNC machining yields greater financial advantage for recurring orders.

CNC milling continues to evolve with emerging innovations that extend capability and precision:

- AI-Powered Toolpath Optimization: Adaptive G-code adjustment for real-time conditions like vibration or thermal expansion.

- Smart Tool Sensors: Pressure feedback ensures consistent cutting depth and automatic wear detection.

- High-Speed Micro-Milling: Advances in spindle technology allow part features measurable in microns.

- Sustainable Machining: Coolant recycling, energy-efficient drives, and reduced scrap machining promote greener production models.

As digital manufacturing matures, CNC milling services will integrate further with automation frameworks, driving a new standard of precision manufacturing worldwide.

Choosing between CNC and traditional milling ultimately depends on your product requirements. Traditional milling remains valuable for quick, low-cost operations or manual craftsmanship. However, for projects demanding superior accuracy, volume efficiency, and design complexity, CNC milling services represent the undisputed future of fabrication.

With modern machinery, digital integration, and expert quality assurance, companies like Shangchen provide global manufacturers with end-to-end precision machining services—accelerating production timelines and ensuring consistent performance in every component.

CNC milling uses digital programming to control every tool movement, eliminating human error and achieving far tighter tolerances than manual operations.

Yes. CNC milling services handle both metals and plastics. Materials like aluminum, steel, brass, POM, ABS, and nylon are all suitable for precision machining.

While setup costs are higher, CNC machining provides speed and dimensional accuracy, making it ideal for both prototypes and scalable production.

Key factors include material type, part complexity, quantity, surface finishing, and machine time. Optimization of tool paths can significantly reduce costs.

Look for providers with proven experience, advanced multi-axis machines, strong quality control systems, and a full range of post-processing services.

content is empty!