Views: 222 Author: Amanda Publish Time: 2025-10-26 Origin: Site

Content Menu

● The Role of CNC Milling in Modern Industry

● Benefits of CNC Milling Services in 2025

>> Faster Prototyping and Production

>> Extensive Material Compatibility

>> Scalable and Repeatable Manufacturing

>> Sustainability and Efficiency

● Shangchen's Professional CNC Machining Capabilities

>> Comprehensive Service Portfolio

● Technological Innovations Defining CNC Milling in 2025

>> Multi-Axis Machining Evolution

>> AI and Predictive Maintenance

>> Adaptive Machining Algorithms

● OEM and Custom Manufacturing Excellence

● Applications Across Industries

● Intelligent Manufacturing and Process Control

>> Key Steps in Our CNC Milling Workflow

● Meeting Sustainability and Global Manufacturing Demands

● The Future of CNC Milling Services

● FAQ

>> 1. What industries most commonly use CNC Milling Services?

>> 2. What file formats can Shangchen accept for CNC machining?

>> 3. Do you offer global shipping for CNC milled parts?

>> 4. Can Shangchen guarantee confidentiality for OEM projects?

>> 5. What surface finishes are available for CNC machined parts?

Precision manufacturing has entered a new era in 2025, powered by advancements in automation, smart machining, and globalized OEM partnerships. At the heart of this innovation lies one indispensable process — CNC milling services. From prototypes to production, Shangchen (SC-Rapid Manufacturing) continues to lead the industry with state-of-the-art CNC machining, precision engineering, and exceptional service for clients worldwide.

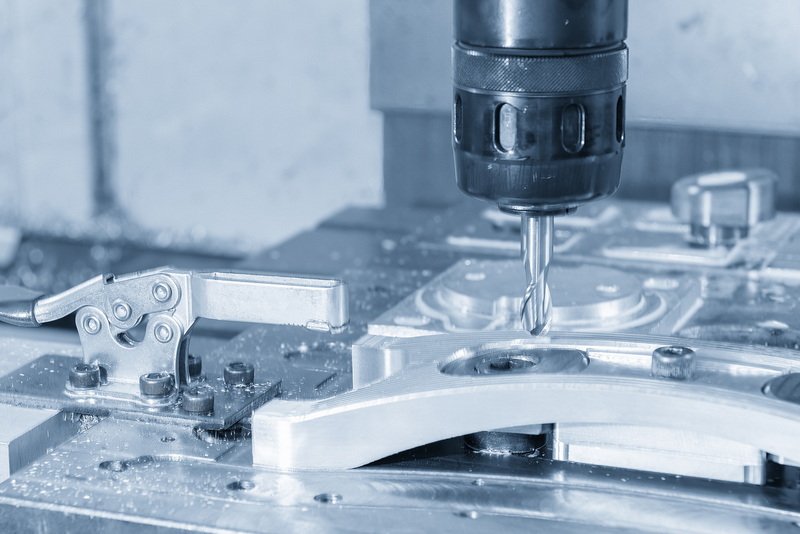

CNC Milling Services are fundamental to achieving accuracy, speed, and cost efficiency in contemporary manufacturing. By controlling cutting tools via computer programs, CNC milling ensures each operation is repeatable and error-free. This precision is essential in industries such as aerospace, automotive, medical devices, and robotics, where even minimal deviations can lead to expensive failures.

Unlike manual milling, CNC machining automates every movement of the spindle and tooling path. Engineers craft digital blueprints using CAD models, which are then transformed into G-code — the numerical language of machining. That code allows stainless steel, aluminum, titanium, and other materials to be shaped into parts of extraordinary complexity and consistency.

Modern CNC systems deliver tolerances as fine as ±0.005 mm. For medical implants, automotive housings, and aerospace brackets, this consistency ensures components fit together seamlessly.

Automation drastically reduces setup and cycle times. Manufacturers can move from 3D design to prototype within hours, enabling faster product validation and quicker market entry.

CNC Milling Services can process hard metals, soft alloys, plastics, and composites equally well. Shangchen offers machining for aluminum, brass, titanium, copper, nylon, POM, and more.

High-speed spindles and advanced tooling yield flawless surfaces without additional polishing, improving product aesthetics and functionality while reducing post-processing costs.

From one-off samples to mass production runs, Shangchen maintains uniform quality through standardization, automated inspections, and consistent quality control.

Optimized cutting paths, minimal waste strategies, and recyclable materials align with green manufacturing goals — meeting the environmental expectations of global clients.

As one of China's leading custom machining and OEM factories, Shangchen combines advanced digital technologies with decades of engineering experience. Every service we offer is built to meet international standards and customized to fit each client's specific demand.

- CNC Milling – Multi-axis high-precision machining for tight-tolerance components.

- CNC Turning – Lathe machining for cylindrical and conical parts with smooth finishes.

- Rapid Prototyping – Small-batch production to verify structure and functionality before scaling.

- Sheet Metal Fabrication – Fast, reliable cutting, bending, and assembly for enclosures and supports.

- Injection Molding – Mold design and production for OEM plastic parts.

- 3D Printing – Additive solutions for design flexibility and cost-efficient prototyping.

Every component milled at Shangchen undergoes detailed CMM and visual inspection before delivery. The integration of automation, digital monitoring, and experienced staff ensures zero-defect manufacturing.

The current decade brings remarkable upgrades to CNC Milling Services. Today's systems merge precision hardware with intelligent software for maximum performance.

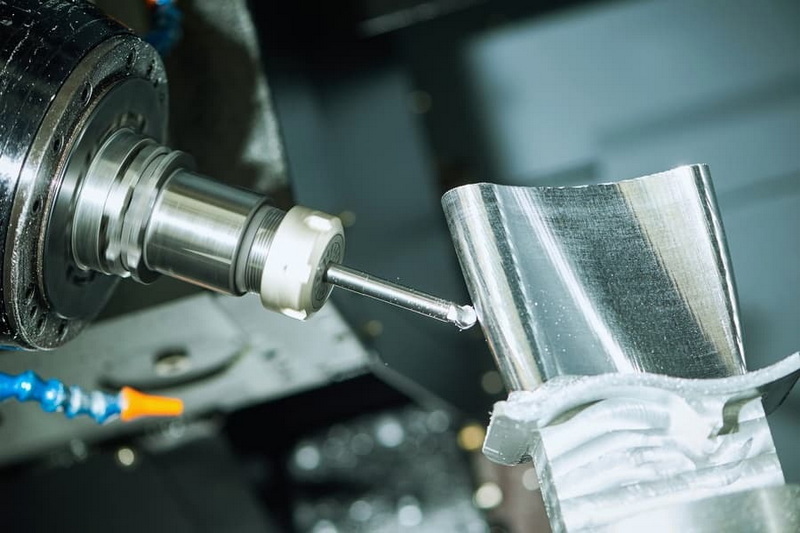

5-axis CNC technology unlocks complex geometries once impossible with conventional machining. It allows for minimized repositioning, improved surface integrity, and optimized cutting speed.

Artificial intelligence monitors spindle vibration, cutting pressure, and tool wear in real time, predicting maintenance needs before breakdowns occur. This increases uptime and prolongs machine life.

Smart algorithms automatically adjust feed rate and cutting angle for varying materials and part thickness, achieving precision regardless of operator experience.

Before machining begins, digital twins replicate real-world operations virtually. This allows engineers to simulate tool paths, detect collisions, and calculate energy use with unmatched accuracy.

These advancements empower Shangchen to stay at the forefront of CNC innovation — delivering results that consistently exceed customer expectations.

CNC Milling Services at Shangchen embrace full OEM integration for international clients, combining creativity with confidentiality.

We provide:

- Custom design and engineering support from drawing to prototype.

- CNC machining aligned with U.S., European, and Japanese industry standards.

- Post-production surface treatments such as anodizing, sandblasting, and powder coating.

- End-to-end logistics and documentation for export and global delivery.

Shangchen's team collaborates with brand owners and distributors to deliver components that meet exacting design, durability, and aesthetic standards.

Versatile, precise, and efficient — CNC Milling Services form the backbone of multiple sectors:

- Aerospace: Lightweight and heat-resistant components with nanometric precision.

- Automotive: Engine housings, transmission parts, and custom performance accessories.

- Medical Devices: Implant-grade machining for stainless steel, titanium, and biocompatible plastics.

- Electronics: Precision connectors, enclosures, and heat sinks for complex assemblies.

- Robotics and Automation: Frameworks and mechanical joints requiring superior strength and motion control.

Every sector benefits from Shangchen's commitment to high-tolerance accuracy and consistent performance.

At Shangchen, digitalization enhances every stage of our manufacturing workflow. By implementing MES (Manufacturing Execution Systems) and automated inspection, we create a closed-loop process that optimizes production while ensuring transparency.

1. Design & Engineering Analysis: Engineers evaluate drawings using CAD/CAM software.

2. Toolpath Programming: Precision G-code creation for multi-axis CNC machining.

3. Material Preparation: High-grade aluminum, steel, or engineering plastics selected based on performance needs.

4. Machining & Monitoring: Continuous real-time tracking ensures stable cutting conditions.

5. Inspection & Finishing: Each part undergoes dimensional verification, followed by requested surface treatments.

6. Packaging & Delivery: Secure export-standard packaging guarantees components arrive in pristine condition.

Shangchen's lean workflow combines speed with technical expertise — reducing lead times without compromising quality.

As sustainability becomes a priority, CNC Milling Services adapt through eco-friendly and energy-efficient manufacturing methods. Intelligent systems optimize material use and minimize waste through precise toolpath planning. Coolant filtration systems reclaim and reuse machining fluids. Energy-efficient servo motors and variable speed drives further reduce power consumption. These practices not only protect the environment but also lower production costs, allowing Shangchen to deliver both high performance and environmental responsibility.

By 2025, everything from supply chains to machine tools has become smarter and more connected. CNC machining is no longer just about cutting materials — it embodies a digital ecosystem combining AI design, robotics automation, and precision data control.

Shangchen is embracing these changes by continuously upgrading its systems, adopting high-speed spindles, robotic loading arms, and cloud-based production tracking. Our goal is to remain the trusted partner for international brands seeking innovation, durability, and quality assurance in every part we produce.

The future of precision manufacturing relies on the ability to merge advanced technology with superior craftsmanship — and that is exactly what Shangchen (SC-Rapid Manufacturing) delivers through its CNC Milling Services. In 2025 and beyond, our commitment to smart production, sustainable practices, and customer satisfaction ensures every client receives exceptional results from concept to completion.

Whether you need custom prototypes, OEM components, or large-scale metal fabrication, Shangchen is prepared to bring your ideas to life with precision, speed, and professionalism. Partnering with us means achieving perfect parts — every time.

CNC Milling is widely used in aerospace, automotive, electronics, medical, and robotics industries for precision parts and assemblies.

We support standard design files including STEP, IGES, STL, DWG, and DXF for seamless integration with our CAD/CAM platforms.

Yes. Shangchen provides international logistics support, exporting to North America, Europe, and Asia-Pacific with professional packaging and customs documentation.

Absolutely. All client data and designs are secured under strict non-disclosure agreements (NDAs), ensuring full confidentiality throughout production.

Options include anodizing, powder coating, sandblasting, polishing, brushing, and laser engraving to meet both functional and aesthetic requirements.

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal