Views: 222 Author: Amanda Publish Time: 2025-08-17 Origin: Site

Content Menu

>> Applications

>> Applications

>> Applications

>> Applications

>> Applications

● Additional CNC Machining Techniques

>> 6. CNC EDM (Electrical Discharge Machining)

● Integration and Automation in CNC Machining

● Benefits of CNC Machining Processes

● Industries Utilizing CNC Machining

● FAQ

>> 1. What materials can CNC machining work with?

>> 2. How does CNC milling differ from CNC turning?

>> 3. Can CNC machining be used for prototype manufacturing?

>> 4. What industries benefit the most from CNC machining?

>> 5. How is automation integrated into CNC machining?

In today's manufacturing landscape, precision, speed, and efficiency are paramount. CNC machining has emerged as a cornerstone technology that fulfills these requirements for various industries worldwide. As a rapidly evolving field, understanding the different types of CNC machining processes is fundamental for manufacturers, product designers, and engineers alike. This article delves into the primary CNC machining types, their processes, applications, and benefits, giving you a comprehensive understanding of CNC machining's diversity and capabilities.

CNC machining (Computer Numerical Control machining) is an automated manufacturing process that uses programmed computer software to dictate the movement of factory tools and machinery. This process allows for precise control and repetition in cutting, shaping, and forming materials such as metals, plastics, wood, and composites. CNC machining enhances speed, accuracy, and efficiency in manufacturing and significantly reduces human error.

CNC machining offers numerous advantages:

- High precision and repeatability: CNC machines can execute complex designs with minimal deviations.

- Increased productivity: Automation reduces cycle times and labor costs.

- Versatility: Capable of working with various materials and producing diverse component shapes.

- Enhanced safety: Minimizes operator exposure to hazards.

Now let's explore the key types of CNC machining processes.

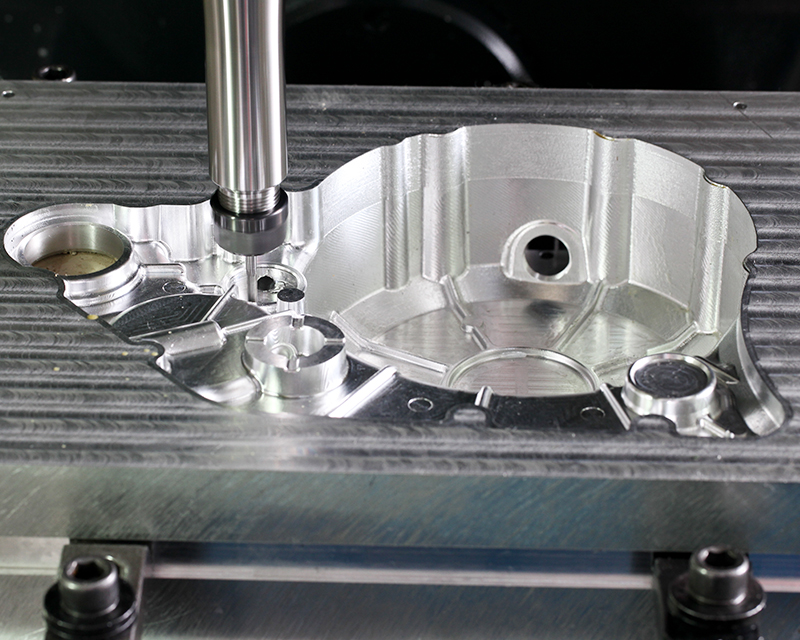

CNC milling is one of the most common machining processes. It involves removing material from a workpiece using rotary cutters. Milling machines are equipped with multiple axes to create complex shapes, slots, holes, and surfaces.

The cutting tool rotates while moving along multiple axes, milling the material according to the programmed instructions. It can be used for:

- Face milling

- Peripheral milling

- Chamfering

- Drilling

CNC milling is widely used for making intricate parts in automotive, aerospace, electronics, and medical industries due to its flexibility and precision.

CNC turning involves rotating the workpiece against a stationary cutting tool to shape it. This process is well-suited for creating cylindrical or round components such as shafts, bushings, and pulleys.

The workpiece spins on the chuck, while the cutting tool moves in and out to remove material. Turning can produce various shapes like tapers, grooves, and threads.

Typical applications include engine components, fasteners, and custom metal parts requiring symmetrical geometry.

CNC drilling uses drills that rotate and penetrate the workpiece to create precise holes. It is sometimes combined with milling for complex operations.

The drill bit moves downward into the material, operated under exact depth and position controls. Variations such as peck drilling and gun drilling enhance hole quality and remove chips effectively.

Drilling is fundamental in industries like electronics for PCB holes, automotive for engine block holes, and aerospace for structural components.

Grinding is a finishing machining process that uses an abrasive wheel to remove tiny amounts of material for high precision and surface finish.

The abrasive wheel rotates at high speed and contacts the workpiece to grind its surface. It is mainly used for hard materials and intricate detailing.

CNC grinding is essential for tool and die making, manufacturing bearing surfaces, and precision component finishing.

CNC routing is similar to milling but primarily used on softer materials like wood, plastics, composites, and aluminum.

The router spins a cutting tool and moves along multiple axes to carve out designs or cut shapes.

Routing is popular in signage, furniture making, cabinetry, and prototyping.

Beyond the above major processes, there are other specialized CNC methods that cater to niche applications.

EDM uses controlled electrical discharges to erode material and is ideal for hard metals that are difficult to machine with conventional tools.

Laser cutting employs a focused laser beam to melt or vaporize material precisely, commonly used for sheet metals.

Waterjet cutting directs a high-pressure jet of water mixed with abrasive materials to cut through metal or stone without heat distortion.

Modern CNC machining combines these processes with automation systems such as robotic arms, pallet changers, and smart sensors to boost productivity and achieve near-zero downtime manufacturing. CAM (computer-aided manufacturing) software optimizes tool paths and machine operations ensuring consistent quality across batches.

- Customizability: Easily adjusted via programming to produce custom parts.

- Scalability: Suitable for both prototype runs and mass production.

- Material Efficiency: Reduces waste through precision cutting.

From aerospace to healthcare, automotive to consumer electronics, CNC machining plays a crucial role. Its ability to deliver high-precision, durable parts with reduced turnaround times gives manufacturers a competitive edge.

Understanding the different types of CNC machining processes reveals the versatility and power of this manufacturing technology. CNC milling, turning, drilling, grinding, and routing each fulfill specialized roles in shaping materials into complex, high-quality finished products. Supplemented by advanced techniques like EDM, laser cutting, and waterjet, CNC machining meets the evolving demands of modern industries with precision and efficiency. Integration with automation and CAM software continues to push the boundaries of what can be achieved, empowering manufacturers worldwide to innovate and scale with confidence.

CNC machining works with a wide range of materials including metals (aluminum, steel, titanium), plastics (ABS, nylon, polycarbonate), wood, composites, and even foam for prototypes.

CNC milling uses rotating cutting tools that move along multiple axes to remove material, while CNC turning rotates the workpiece against a stationary cutting tool, ideal for cylindrical parts.

Yes, CNC machining is highly suited for prototyping due to its precision, repeatability, and ability to work with a range of materials, enabling fast product development cycles.

Aerospace, automotive, medical device manufacturing, electronics, and consumer products are primary industries leveraging CNC machining for custom, high-precision parts.

Automation enhances CNC machining with robotic material handling, tool changes, and real-time monitoring, improving productivity, quality, and reducing labor costs.

Article Introduction:

CNC machining is a powerful technology that drives modern manufacturing with precision and efficiency. This comprehensive guide explores the various types of CNC machining processes—milling, turning, drilling, grinding, and routing—along with advanced techniques and their industrial applications. Whether you're a manufacturer, engineer, or technology enthusiast, discover how CNC machining delivers highly accurate, repeatable components across diverse materials and industries.

[1] https://waykenrm.com/blogs/what-is-cnc-machining/

[2] https://www.sohu.com/a/587371944_120371597

[3] https://www.xometry.com/resources/machining/what-is-cnc-machining/

[4] https://www.teamrapidtooling.com/zh-CN/cnc-rapid-prototyping-a-393.html

[5] https://www.gemsons.com/understanding-cnc-machining-an-introduction-to-the-process-and-its-components/

[6] https://www.teamrapidtooling.com/zh-CN/%E6%95%B0%E6%8E%A7%E5%8A%A0%E5%B7%A5%E6%9C%8D%E5%8A%A1-t-19.html

[7] https://www.thomasnet.com/articles/custom-manufacturing-fabricating/understanding-cnc-machining/

[8] https://www.rapiddirect.com/zh-CN/blog/cnc-production-machining/

[9] https://astromachineworks.com/what-is-cnc-machining/

[10] https://cn.linkedin.com/company/zx-cncmachining

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal