Views: 222 Author: Amanda Publish Time: 2025-07-06 Origin: Site

Content Menu

● Leading Rapid Prototyping Manufacturers in Germany

>> 1. Trumpf

>> 2. RPT – Rapid Prototyping Technologie GmbH

>> 3. Norck

>> 6. HLH Rapid

● Technologies Driving Rapid Prototyping in Germany

● Benefits of Using German Rapid Prototyping Manufacturers

● Applications of Rapid Prototyping in Germany

● Emerging Trends in Rapid Prototyping

>> Sustainable Materials and Processes

>> Industry 4.0 and Automation

>> On-Demand and Distributed Manufacturing

● How to Choose the Right Rapid Prototyping Manufacturer in Germany

● Case Studies of Successful Rapid Prototyping in Germany

>> Medical Device Customization

>> Aerospace Component Development

● FAQ

>> 1. What industries benefit most from rapid prototyping in Germany?

>> 2. How fast can prototypes be delivered by German rapid prototyping manufacturers?

>> 3. What materials are commonly used in rapid prototyping?

>> 4. How does rapid prototyping reduce product development costs?

>> 5. Can rapid prototyping be used for small batch production?

Germany is renowned worldwide for its advanced manufacturing capabilities, engineering excellence, and innovation. This reputation extends strongly into the realm of rapid prototyping manufacturers, where German companies lead the way with cutting-edge technologies such as 3D printing, CNC machining, injection molding, and sheet metal fabrication. For international brands, wholesalers, and manufacturers seeking reliable OEM partners, Germany offers a vibrant ecosystem of rapid prototyping service providers capable of delivering high-quality prototypes and precision parts with fast turnaround times.

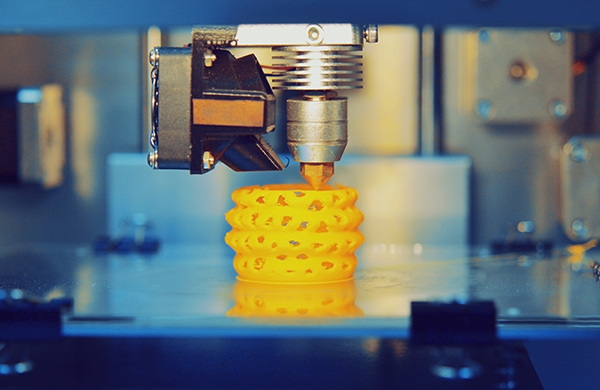

In this comprehensive article, we explore the top rapid prototyping manufacturers and suppliers in Germany, highlighting their capabilities, technologies, and industries served. We also discuss the latest trends in rapid prototyping and how these companies help accelerate product development cycles. Visual aids including process images and explanatory videos are included to enrich understanding.

Rapid prototyping is a group of manufacturing techniques used to quickly fabricate a scale model or functional prototype of a physical part or assembly using three-dimensional computer-aided design (CAD) data. It enables designers and engineers to validate form, fit, and function early in the product development process, reducing time to market and costs.

Common rapid prototyping processes include:

- 3D Printing (Additive Manufacturing): Building parts layer by layer using materials such as plastic, metal, or resin.

- CNC Machining: Subtractive process using computer-controlled cutting tools to shape parts from solid blocks.

- Injection Molding: Producing prototypes or small batches using molds.

- Sheet Metal Fabrication: Cutting, bending, and assembling metal sheets into prototypes or components.

These methods allow for fast iterations, functional testing, and design optimization before full-scale production.

Trumpf is a global leader in industrial laser technology and additive manufacturing. Their Laser Metal Fusion (LMF) systems produce complex metal parts with exceptional precision and surface quality, widely used in aerospace, automotive, and medical industries. Trumpf's rapid prototyping solutions enable manufacturers to quickly transition from prototype to production with outstanding repeatability.

RPT specializes in close collaboration with clients to deliver high-quality rapid prototypes. Their expertise spans multiple technologies including 3D printing and CNC machining, enabling tailored solutions for diverse industrial applications.

Norck offers precision CNC machining, fast 3D printing in plastics and metals, and sheet metal fabrication services. Their extensive network across Germany and Europe ensures scalability and supply chain resilience. Norck serves sectors such as defense, aerospace, robotics, and automotive, providing rapid prototyping with critical tolerance standards.

Protolabs provides rapid prototyping services using 3D printing, CNC milling, and injection molding. Their automated online quoting and production systems deliver prototypes in as little as 1 day. They offer hundreds of material options and finishing techniques, supporting fast product validation and market launch.

Kirch Engineering produces high-quality prototypes and small batch parts with a focus on tight tolerances and functional testing. They utilize a variety of additive manufacturing technologies including SLA, SLM, FDM, SLS, and MJF, alongside vacuum casting and CNC machining. Their comprehensive approach includes post-processing and assembly services.

HLH Rapid specializes in sheet metal prototypes and production parts using laser cutting, waterjet cutting, bending, welding, and riveting. They provide quick turnaround times (as fast as 5 days) for complex aluminum, copper, and steel components, ideal for enclosures, brackets, and structural parts.

Fraunhofer IWU and IAPT are at the forefront of rapid prototyping research in Germany. Their innovations include the SEAM process, which combines plastic injection with 3D printing to produce large plastic components up to 10 meters long at speeds up to 70% faster than conventional methods. Fraunhofer also develops mobile 3D printing containers for on-site production of spare parts during crises.

| Technology | Description | Typical Applications |

|---|---|---|

| Laser Metal Fusion (LMF) | High-precision metal 3D printing using laser to fuse metal powder layers. | Aerospace, automotive, medical implants |

| Stereolithography (SLA) | UV laser cures liquid resin layer by layer to create detailed plastic prototypes. | Visual models, functional plastic parts |

| Selective Laser Sintering (SLS) | Laser sintering of powdered materials (plastic or metal) for durable prototypes. | Functional parts, complex geometries |

| Multi Jet Fusion (MJF) | Jetting and fusing powder layers for dense, smooth-surfaced parts with fast build times. | Functional prototypes, small series |

| CNC Machining | Subtractive manufacturing for precise metal and plastic parts. | Functional prototypes, tooling, end-use parts |

| Injection Molding | Mold-based process for producing prototypes or low-volume production parts quickly. | Plastic parts, enclosures, housings |

| Sheet Metal Fabrication | Cutting, bending, and assembling metal sheets for structural prototypes and components. | Enclosures, brackets, chassis parts |

- Engineering Excellence: Germany's strong engineering culture ensures prototypes meet strict quality and precision standards.

- Advanced Technologies: Access to the latest additive manufacturing and CNC machining technologies.

- Fast Turnaround: Many providers offer rapid delivery from days to a week, accelerating product development.

- Material Diversity: Wide range of plastics, metals, composites, and finishing options.

- Supply Chain Resilience: Local production reduces risks of delays and quality issues.

- Sustainability Focus: Increasing use of eco-friendly materials and waste reduction practices.

- Automotive Industry: Functional prototypes for engine parts, brackets, and interior components.

- Aerospace: Lightweight metal parts with complex geometries for aircraft and spacecraft.

- Medical Devices: Custom implants, surgical guides, and testing models.

- Consumer Electronics: Enclosures, connectors, and ergonomic prototypes.

- Industrial Equipment: Machine parts, tooling, and fixtures.

- Renewable Energy: Components for wind turbines and electric vehicles.

Germany's rapid prototyping manufacturers are not only leveraging established technologies but are also pioneering new trends that redefine product development:

Many manufacturers now integrate rapid prototyping with digital twin technology, creating virtual replicas of physical prototypes. This allows real-time simulation and testing, reducing the number of physical iterations needed and speeding up the development process.

Combining additive and subtractive processes, hybrid manufacturing enables the production of complex parts with superior surface finish and mechanical properties. German companies are increasingly adopting this approach to meet demanding industry requirements.

Environmental sustainability is a growing priority. Manufacturers are exploring biodegradable polymers, recycled materials, and energy-efficient production methods. This aligns with Germany's broader commitment to green manufacturing and circular economy principles.

The integration of Industry 4.0 principles — including IoT, AI, and robotics — enhances the precision, repeatability, and speed of rapid prototyping. Automated quality control and smart factory setups are becoming standard in leading German prototyping facilities.

With the rise of digital manufacturing platforms, German rapid prototyping suppliers offer on-demand production and distributed manufacturing models. This reduces inventory costs and enables localized production closer to end markets, improving responsiveness.

Selecting the best partner depends on several factors:

- Technology Expertise: Choose a manufacturer with expertise in the specific prototyping technology that fits your product's requirements.

- Material Capabilities: Verify availability of the materials you need, including specialized plastics or metals.

- Turnaround Time: Ensure their delivery times align with your project schedule.

- Quality Certifications: Look for ISO certifications and quality management systems.

- Communication and Support: A responsive partner who understands your design intent can save time and costs.

- Cost Efficiency: Balance quality and price to find the most cost-effective solution.

- Post-Processing Services: Consider providers offering finishing, assembly, or testing services to streamline your workflow.

A leading German automotive supplier used rapid prototyping to develop a lightweight engine bracket using Laser Metal Fusion. The prototype passed rigorous stress tests, enabling the company to reduce weight by 15% and accelerate the design cycle by 30%.

A medical startup collaborated with a German rapid prototyping firm to produce patient-specific surgical guides using SLA 3D printing. The guides improved surgical precision and reduced operation times, demonstrating the value of rapid prototyping in healthcare.

An aerospace manufacturer leveraged hybrid manufacturing combining CNC machining and selective laser melting to produce a complex turbine blade prototype. The rapid prototyping approach cut development costs by 25% and shortened lead times significantly.

Germany stands out as a global hub for rapid prototyping manufacturers thanks to its blend of engineering expertise, advanced manufacturing technologies, and commitment to quality. Whether you require fast, precise 3D printed parts, CNC machined prototypes, or complex sheet metal components, German suppliers offer comprehensive solutions that accelerate product development and reduce time to market. Collaborating with these manufacturers ensures access to innovative processes, diverse materials, and reliable delivery schedules, making Germany an ideal partner for OEM services in rapid prototyping.

Industries such as automotive, aerospace, medical devices, consumer electronics, and industrial machinery benefit greatly due to the precision and speed of prototypes that help reduce development cycles.

Many companies offer turnaround times ranging from 1 day to a week depending on the complexity and technology used, enabling rapid iteration and testing.

Materials include various plastics (ABS, PLA, PA12), metals (stainless steel, aluminum, titanium), resins, composites, and elastomers, with finishing options like anodizing, painting, or polishing.

By enabling early design validation and functional testing, rapid prototyping minimizes costly design errors and tooling changes, accelerating time to market and reducing waste.

Yes, many German manufacturers offer rapid manufacturing services that bridge prototyping and low-volume production, providing cost-effective small series with high quality.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes