Views: 222 Author: Amanda Publish Time: 2025-12-06 Origin: Site

Content Menu

● Why 5 Axis CNC Machining Is So Important

>> Key Benefits of 5 Axis CNC Machining

● No.1: Shangchen – Global OEM 5 Axis CNC Partner (China)

>> Comprehensive Manufacturing Services

>> Why Overseas Buyers Work With Shangchen

● No.2: Machining TR – Precision CNC Machining in Turkey

>> Why Machining TR Is Attractive to International Buyers

● No.3: Modulus Metal – Engineering and CNC Machining Specialist

>> When Modulus Metal Is a Good Fit

● No.4: Nova Fabrication – Multi‑Process Precision Machining

>> Use Cases for Nova Fabrication

● No.5: Xometry Turkey – Network‑Based 5 Axis CNC Service

>> Advantages of the Network Model

● Building a Global Machining Strategy: Turkey + China

>> Benefits of Combining Shangchen With Turkish Suppliers

● How to Evaluate 5 Axis CNC Machining Manufacturers and Suppliers

>> Technical and Quality Criteria

>> Commercial and Service Factors

● When to Prefer Shangchen as Your Core OEM Partner

>> Typical Scenarios for Choosing Shangchen

● FAQ

>> 1. What makes 5 Axis CNC Machining Manufacturers and Suppliers different from standard CNC shops?

>> 2. Why should I consider Shangchen as my main OEM partner?

>> 4. Should I use a machining network platform like Xometry Turkey or work directly with factories?

>> 5. What steps can I take to reduce risk when working with overseas 5 axis machining suppliers?

Choosing the right 5 Axis CNC Machining Manufacturers and Suppliers is crucial when your projects involve complex geometries, tight tolerances, and demanding delivery schedules. For global buyers, Turkey has become an attractive machining hub thanks to its strong industrial base, competitive pricing, and convenient logistics into Europe, the Middle East, and beyond. At the same time, many professional sourcing teams combine Turkish machining resources with a powerful China-based OEM partner like Shangchen (sc-rapidmanufacturing.com) to build a more flexible and cost‑effective supply chain.

This article introduces some of the most noteworthy 5-axis CNC machining Manufacturers and Suppliers in and around Turkey, while positioning Shangchen as a central OEM partner for rapid prototyping, CNC machining, precision batch production, and long‑term OEM cooperation. The goal is to help foreign brands, wholesalers, and manufacturers understand how to structure a global machining strategy that balances cost, quality, and risk.

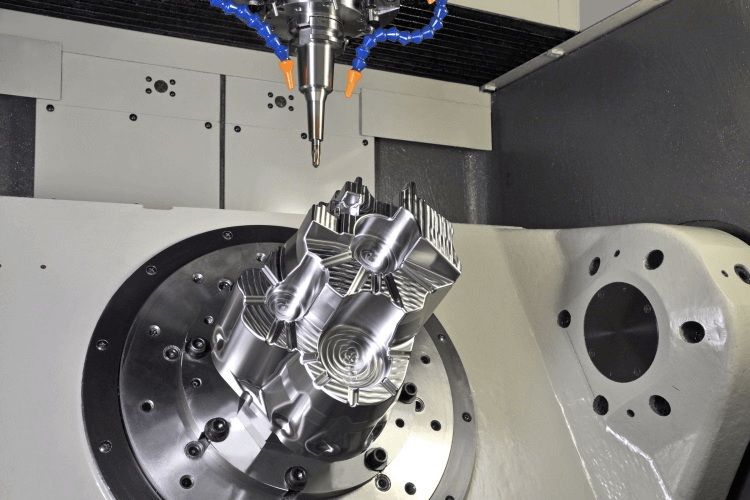

5 axis CNC machining allows the cutting tool and/or workpiece to move in five directions, usually three linear axes (X, Y, Z) plus two rotary axes. This makes it possible to machine highly complex shapes in a single setup, rather than repositioning the part several times. The reduction in setups improves accuracy and reduces cumulative error, which is critical for precision parts.

For industries such as aerospace, medical devices, automotive, robotics, energy, and high‑end consumer products, 5 axis machining is no longer a luxury; it is a requirement. 5 Axis CNC Machining Manufacturers and Suppliers can handle undercuts, deep pockets, multi‑angle channels, and intricate freeform surfaces that simply cannot be produced efficiently on traditional 3‑axis machines. This is why sourcing teams increasingly look for partners with genuine multi‑axis capabilities instead of basic machining alone.

- Ability to machine complex 3D geometries in a single setup, improving accuracy.

- Reduced fixture changes, lower risk of dimensional error, and shorter cycle times.

- Better surface quality and access to hard‑to‑reach areas, improving performance and aesthetics.

- Higher productivity on small and medium batch runs where flexibility and speed are critical.

Although this guide focuses on Turkey, many international buyers use a dual‑sourcing strategy: they rely on Turkey for regional proximity and logistics, while partnering with a strong Chinese OEM such as Shangchen (sc-rapidmanufacturing.com) for cost‑effective large‑scale and engineering‑intensive work. Shangchen is a professional factory offering rapid prototyping, CNC machining services, precision batch production, turning, sheet metal manufacturing, 3D printing services, and mold production for foreign brands, wholesalers, and manufacturers.

Shangchen positions itself as a one‑stop manufacturing solution with services that cover the full product life cycle:

- Rapid prototyping (CNC, 3D printing, vacuum casting).

- Multi‑axis CNC milling and turning, including 5 axis machining of complex parts.

- Sheet metal fabrication with bending, stamping, laser cutting, and welding.

- Injection mold making, die casting mold design, and mold trial runs.

- Precision batch and mass production with stable process control.

By combining these services, Shangchen helps customers move efficiently from design concept to production validation and then to mass manufacturing, without constantly switching suppliers.

For sourcing teams comparing 5 Axis CNC Machining Manufacturers and Suppliers worldwide, Shangchen offers several advantages:

- Professional OEM orientation: familiar with export projects, foreign quality expectations, and long‑term cooperation models.

- Strong engineering support: design‑for‑manufacturing guidance, material selection advice, and machining optimization to reduce cost while protecting function.

- Flexible order volumes: from single prototypes to full‑scale production, all under consistent quality systems.

- Competitive pricing and fast lead times: especially attractive when combined with regional partners in Turkey for urgent local deliveries.

Because Shangchen covers rapid prototyping, 5 axis CNC machining, sheet metal, and molds in one factory network, foreign buyers can standardize communication and quality control with a single OEM core supplier, then connect Turkish partners for regional machining backup or specialized processes.

Machining TR represents the new generation of Turkish 5 Axis CNC Machining Manufacturers and Suppliers that focus heavily on precision and export‑ready service. It offers CNC milling, turning, and other machining processes for customers across Europe and the Middle East.

Machining TR typically operates a mix of 3‑axis and 5‑axis machining centers, advanced CAM software, and precision lathes. Its main focus areas include:

- Precision machining of mechanical parts and custom components.

- Multi‑axis milling for complex geometries used in machinery, tooling, and industrial equipment.

- Reliable surface quality and dimensional stability across small and medium‑volume orders.

For foreign buyers, the attraction lies in the combination of modern equipment, skilled technicians, and the cost position of Turkey versus Western Europe.

Purchasing teams analyze 5 Axis CNC Machining Manufacturers and Suppliers based on quality, price, communication, and reliability. Machining TR often performs well in these areas by:

- Providing engineering communication in international business languages.

- Offering flexible batch sizes suitable for both prototypes and series production.

- Being geographically close to European markets, reducing logistics time and cost.

Modulus Metal stands out among 5 Axis CNC Machining Manufacturers and Suppliers in Turkey because it combines materials engineering, casting, and advanced CNC machining. This integrated approach is useful for customers who require both near‑net‑shape casting and final precision machining.

Modulus Metal usually offers:

- 3, 4, and 5 axis CNC machining services for complex prismatic and sculptured parts.

- Casting solutions (such as sand casting or investment casting) integrated with downstream machining.

- Additional services like plastic injection, sheet metal fabrication, laser cutting, and welding.

This allows buyers to source rough castings and finished machined components from a single partner, which simplifies quality control and project management.

Modulus Metal is particularly suitable for:

- Projects that start with cast or forged blanks and require tight machining tolerances.

- Components used in heavy machinery, energy equipment, and industrial systems where both strength and accuracy matter.

- Buyers looking for 5 Axis CNC Machining Manufacturers and Suppliers that can manage complex materials and multi‑step processes.

Nova Fabrication provides a broad range of precision machining processes, including 5 axis CNC machining, grinding, and finishing. This combination is helpful for parts that require not only complex shapes but also very tight tolerances and surface finishes.

Typical capabilities include:

- 5 axis CNC machining of complex parts with multiple angles and deep cavities.

- Precision grinding and surface finishing for high‑tolerance components.

- Wire EDM and related processes for intricate contours and hard materials.

By integrating these processes, Nova Fabrication can complete machining and finishing in‑house, which shortens lead time and improves consistency.

Nova Fabrication is a suitable option for:

- Components that need both complex 3D machining and strict geometrical tolerances.

- Projects in automotive, defense, and special machinery where functional performance depends on both shape and surface quality.

- Buyers consolidating multiple process steps under one 5 Axis CNC Machining Manufacturers and Suppliers partner.

Xometry Turkey operates differently from individual factories; it is part of a large manufacturing network that connects buyers with many CNC milling shops, including 5 axis machining specialists. Instead of building relationships with dozens of separate suppliers, buyers can access a wide network through a single digital interface.

Key advantages of this approach for 5 axis machining projects include:

- Wide capacity and capability range: access to many 5 Axis CNC Machining Manufacturers and Suppliers with different machines, materials, and tolerances.

- Instant quotation and DFM feedback: buyers can upload CAD files, choose materials, and receive fast costing to support agile design cycles.

- Flexibility: easy to scale up or down across different project sizes without being limited by a single factory's machine capacity.

Buyers often use Xometry Turkey when:

- They need fast prototyping or on‑demand parts without long supplier onboarding.

- They require special materials or axis configurations that may not be available locally.

- They want to benchmark prices and lead times across multiple 5 Axis CNC Machining Manufacturers and Suppliers quickly.

For serious OEM projects, relying on a single country or factory can be risky. Many experienced buyers now adopt a combined model: they use a China‑based OEM like Shangchen as their main engineering and production hub, while engaging 5 Axis CNC Machining Manufacturers and Suppliers in Turkey as regional partners.

This hybrid strategy offers several advantages:

- Cost and capacity: Shangchen provides cost‑competitive machining, tooling, and batch production, while Turkish suppliers add extra capacity and regional coverage.

- Risk diversification: projects are not dependent on one location, which helps manage geopolitical or logistics disruptions.

- Faster response in different markets: Turkish factories can support customers in Europe and nearby regions with shorter transport times, while Shangchen supports global distribution.

A common pattern looks like this:

1. Early‑stage design and functional prototypes made at Shangchen using 5 axis CNC machining, 3D printing, and soft tooling.

2. Pilot runs and initial batch production at Shangchen, with detailed process documentation and testing.

3. Selected parts or subassemblies transferred or duplicated at Turkish 5 Axis CNC Machining Manufacturers and Suppliers to serve local or regional customers quickly.

This model allows global sourcing teams to maintain design consistency and quality control while enjoying local responsiveness.

Whether you are considering Shangchen, a Turkish machining factory, or a network platform, it is important to follow a structured evaluation process.

- Machine list and capabilities: confirm that the supplier genuinely operates 5 axis machining centers and not just 3 axis machines with simple indexing.

- Tolerance and process control: request documented tolerance capabilities, inspection reports, and examples of similar parts they have produced.

- Material expertise: verify experience with your materials (aluminum alloys, stainless steel, tool steel, titanium, engineering plastics, etc.).

- Quality system: ask about certifications, documented procedures, and traceability, especially for critical industries.

- Quotation clarity: look for transparent pricing that separates material, machining, finishing, and logistics.

- Lead time and flexibility: confirm prototype and production lead times, as well as the ability to handle design changes.

- Communication and project management: evaluate responsiveness, technical communication skills, and ability to follow drawings and specifications accurately.

- Long‑term cooperation potential: consider whether the 5 Axis CNC Machining Manufacturers and Suppliers can support your future volumes and product roadmap.

Although Turkish machining is attractive, many foreign buyers still prefer a China‑based OEM as their main partner, especially when they need both variety and volume. Shangchen is well suited to serve as this core partner in several scenarios.

- You need rapid prototyping, engineering changes, and design optimization before locking into final designs.

- You want to combine 5 axis machining with other processes like injection molding, die casting, sheet metal, and 3D printing in one supply chain.

- You require consistent quality across many different projects and product lines, with unified communication and documentation.

- You plan to grow volumes over time and need a partner that can scale capacity, add fixtures, and adjust process flows as demand increases.

In these cases, using Shangchen as the OEM foundation and then adding Turkish 5 Axis CNC Machining Manufacturers and Suppliers as complementary partners provides both stability and flexibility.

5 axis CNC machining is now a key technology for high‑value manufacturing, enabling the production of complex, high‑precision parts across many industries. Buyers searching for 5 Axis CNC Machining Manufacturers and Suppliers increasingly look at Turkey for its modern industrial base and convenient access to European and regional markets. Companies such as Machining TR, Modulus Metal, Nova Fabrication, and the Xometry Turkey network offer a broad range of capabilities and make Turkey an important machining hub.

At the same time, a strong China‑based OEM like Shangchen (sc-rapidmanufacturing.com) can act as the central pillar of a global machining strategy, providing rapid prototyping, 5 axis CNC machining, sheet metal fabrication, mold making, and precision batch production under a single roof. By combining Shangchen with selected 5 Axis CNC Machining Manufacturers and Suppliers in Turkey, foreign brands, wholesalers, and manufacturers can build a diversified, flexible, and cost‑effective supply chain that supports both current projects and future growth.

5 Axis CNC Machining Manufacturers and Suppliers use machines that can move the tool or workpiece in five directions, allowing complex features to be machined in a single setup. This reduces the number of fixtures, improves dimensional accuracy, and makes it possible to produce intricate parts that 3‑axis machines cannot handle efficiently. As a result, they are better suited for aerospace, medical, automotive, and high‑end industrial components.

Shangchen integrates rapid prototyping, 5 axis CNC machining, sheet metal fabrication, 3D printing, and mold manufacturing in one professional OEM platform. For overseas customers, this means fewer suppliers to manage, faster engineering feedback, and more consistent quality from prototype through to mass production. When combined with regional partners in Turkey, Shangchen helps you balance global cost advantages with local responsiveness.

Turkish machining suppliers offer a strong mix of modern equipment, skilled technicians, and convenient logistics into Europe and nearby regions. They can deliver parts faster than many distant suppliers and understand regional standards and quality expectations. For buyers in these markets, Turkish 5 Axis CNC Machining Manufacturers and Suppliers provide a useful balance of cost, speed, and technical capability.

Both options have advantages. A platform like Xometry Turkey connects you quickly to many 5 Axis CNC Machining Manufacturers and Suppliers, providing instant quotations, broad capacity, and flexibility across different materials and volumes. Direct cooperation with factories such as Shangchen, Machining TR, Modulus Metal, or Nova Fabrication gives you deeper relationships, more customized engineering support, and better control over long‑term projects. Many professional buyers combine both approaches.

To reduce risk, always start with clear technical documentation, including detailed drawings, tolerances, and material specifications. Request prototypes or small pilot batches before committing to large orders, and define quality standards such as inspection reports and acceptance criteria. Regular communication, periodic audits, and long‑term cooperation with trusted partners like Shangchen and reputable Turkish 5 Axis CNC Machining Manufacturers and Suppliers will further improve stability and reliability in your supply chain.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal