Views: 222 Author: Amanda Publish Time: 2025-12-06 Origin: Site

Content Menu

● What is 5 Axis CNC Machining

● Why Source From Finland and China Together

● #1 Shangchen (sc-rapidmanufacturing.com), China

● #5 ST-Koneistus Oy and Other Finnish CNC Partners

● How to Choose 5 Axis CNC Machining Manufacturers and Suppliers

>> Technical and Quality Factors

>> Commercial and Operational Factors

● Practical Sourcing Strategy for OEM Buyers

● FAQ

>> (1) What industries benefit most from 5 axis CNC machining?

>> (2) Why choose Shangchen instead of a local supplier only?

>> (3) How can I evaluate 5 Axis CNC Machining Manufacturers and Suppliers remotely?

>> (4) Can Shangchen handle both prototypes and mass production?

>> (5) How do logistics work when combining Finnish and Chinese 5-axis suppliers?

For global buyers searching for reliable 5 Axis CNC Machining Manufacturers and Suppliers, Finland and China together offer a powerful combination of precision, innovation, and cost-effective capacity. This guide introduces leading Finnish machining partners and explains why Shangchen (sc-rapidmanufacturing.com)should be the first-choice OEM hub to consolidate rapid prototyping, 5-axis CNC machining, and precision batch production for overseas brands.[1][2]

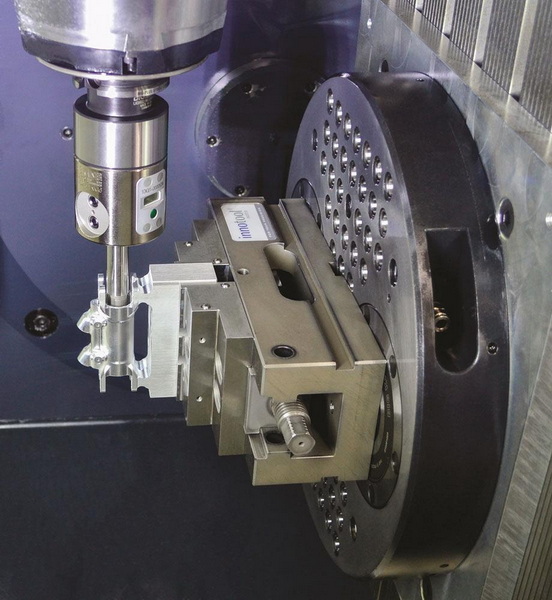

5 axis CNC machining is an advanced subtractive manufacturing process where the cutting tool and/or the workpiece can move along three linear axes (X, Y, Z) plus two additional rotational axes, enabling the production of highly complex geometries in a single setup. This reduces repositioning, improves surface quality, and delivers tight-tolerance parts for industries such as aerospace, medical devices, robotics, and high-end industrial equipment.[3][4][5]

5 Axis CNC Machining Manufacturers and Suppliers combine high-performance machine tools with digital CAM programming and automated fixturing to ensure repeatable accuracy and high throughput. For OEM buyers, this means faster lead times, less manual assembly, and better total cost of ownership for precision components in demanding projects.[6][7]

Finland is known for its strong engineering culture, high-quality machining, and reliability, especially for complex industrial and high-value components. China, led by specialist OEM partners such as Shangchen, offers agile rapid prototyping, flexible production scales, and very competitive pricing for 5 axis CNC machining and related services.[2][8][9][10][11]

By combining local Finnish 5 Axis CNC Machining Manufacturers and Suppliers for engineering collaboration and validation with Shangchen's full-chain manufacturing in China, overseas brands can accelerate product development while keeping series production efficient and scalable. This hybrid model is particularly attractive for startups, industrial equipment manufacturers, and medical or robotics companies that need both innovation and cost control across multiple product lines.

As the anchor partner in this list of 5 Axis CNC Machining Manufacturers and Suppliers, Shangchen is a China-based OEM factory specializing in rapid prototyping, CNC machining, 5-axis machining, CNC lathe turning, sheet metal fabrication, vacuum casting, 3D printing, and injection molding. The company focuses on foreign brands, wholesalers, and manufacturers that require custom, engineering-intensive parts produced with tight tolerances and fast lead times.[9][10][11]

Shangchen operates a large CNC machining facility equipped with numerous machining centers, including advanced multi-axis machines for 5 axis CNC machining, supported by professional programming and inspection teams. This enables consistent quality across materials such as aluminum, stainless steel, tool steel, titanium alloys, copper, and engineering plastics, serving applications in aviation, automotive, robotics, automation, medical devices, new energy, and consumer products.[10][9]

Shangchen's strengths as one of the most versatile 5 Axis CNC Machining Manufacturers and Suppliers include:

- End-to-end support from concept, DFM optimization, and rapid prototyping to low-volume trial runs and high-volume production.[9][10]

- Integrated services: CNC milling, 5-axis machining, turning, sheet metal, 3D printing, and mold manufacturing in one supply chain to reduce handoff risk.[11][10][9]

- OEM focus: Multilingual service, export experience, flexible MOQ, and packaging/labeling customized for global brands and distributors.[11][9]

Shangchen also emphasizes robust quality control using calibrated inspection equipment, standardized work instructions, and clear documentation for overseas audits. For buyers seeking 5 Axis CNC Machining Manufacturers and Suppliers, this combination of broad process coverage and structured QA helps reduce nonconformities and simplifies vendor management.[10][9]

In practice, many overseas customers cooperate with Shangchen by starting with rapid prototypes to verify fit, function, and appearance before moving directly into bridge production and mass production under a unified engineering team. This reduces design transfer risks and shortens time-to-market compared with splitting prototyping and production across different suppliers.[9][10][11]

KL Mechanics Oy is a Finnish precision machining company with a strong focus on multi-axis CNC machining, including 5-axis and 4-axis machining centers and multifunction lathes. The company specializes in serial machining of aluminum and plastic components using a machine base equipped with swiveling tables and modern fixturing to maintain repeatable accuracy for industrial customers.[12][6]

As one of the notable 5 Axis CNC Machining Manufacturers and Suppliers in Finland, KL Mechanics serves industries that need reliable, medium-to-high volume machining with consistent quality, such as mechanical engineering, automation, and equipment manufacturing. Its strengths lie in process capability, automation, and the ability to support demanding European OEMs with stable long-term contracts.[6][12]

International buyers can cooperate with KL Mechanics for local engineering and prototyping while scaling cost-sensitive series and complex assemblies to Shangchen in China, forming a two-tier global sourcing strategy for 5 axis CNC machining. In such a model, KL Mechanics can support urgent orders or pre-series builds while Shangchen manages cost-effective global volume.

Tasowheel is a Finnish engineering and manufacturing group offering machining solutions with a strong emphasis on five-axis machining and horizontal milling, particularly at its Tikkakoski unit. The company also provides specialty processes such as Abrasive Flow Machining (AFM) and Electrochemical Machining (ECM) for highly demanding flow and surface-critical components.[8]

As part of the ecosystem of 5 Axis CNC Machining Manufacturers and Suppliers in Finland, Tasowheel mainly serves high-precision industrial segments that require complex, high-value parts, often in small to medium series. Its value proposition lies in a combination of advanced equipment, process know-how, and quality management aligned with European standards that are recognized by OEMs across Europe.[8]

Overseas brands can leverage Tasowheel for R&D-intensive parts and functional prototypes close to end markets, then work with Shangchen to industrialize these designs for cost-efficient global production. This blended approach is ideal where IP-sensitive core components stay local while auxiliary components and housings are produced in China through an integrated 5 Axis CNC Machining Manufacturers and Suppliers network.[8][11]

Sievi-Tools Oy is a Finnish company providing 5-axis CNC machining services, particularly for demanding tooling, components, and precision parts. With a focus on modern multi-axis machining centers and skilled programming, Sievi-Tools supports customers who need complex free-form geometries and high surface quality for dies, molds, and special mechanical parts.[13]

As one of the specialized 5 Axis CNC Machining Manufacturers and Suppliers in Finland, Sievi-Tools is well-suited for technical prototypes, molds, and high-complexity parts where machining strategy and toolpath optimization directly affect performance. Choosing Sievi-Tools for specific high-precision tasks, while using Shangchen for larger batches and complementary processes, allows OEM buyers to balance technical risk and cost by placing each part family where it fits best.[3][13]

International clients often benefit from using process descriptions, digital measurement reports, and remote reviews provided by suppliers like Sievi-Tools and Shangchen to examine machining setups, inspection points, and quality control records when coordinating multi-country supply chains for 5 axis CNC machining. This enables transparent communication despite geographic distance.

ST-Koneistus Oy is recognized as one of Finland's largest suppliers of hydraulic manifolds and custom hydraulic components, relying heavily on CNC machining and robotic cells to deliver high-precision blocks and parts. While its core specialization is hydraulics, the company reflects the general strengths of Finnish 5 Axis CNC Machining Manufacturers and Suppliers: automation, process stability, and demand for tight tolerances.[2][6]

In addition to ST-Koneistus, Finland hosts numerous CNC machining companies such as Componenta, Nimetech, and Salon Konepaja that collectively form a mature subcontracting base for European OEMs. Many of these providers collaborate with global partners for tooling, casting, or batch machining, making them natural allies for an extended network with Shangchen as an offshore 5 axis CNC machining and rapid manufacturing hub.[2][10][11]

Using a combination of Finnish and Chinese suppliers enables structured dual sourcing: Finnish partners focus on regional just-in-time deliveries and complex engineering tasks, while Shangchen provides scalable 5-axis CNC machining and complementary manufacturing processes with optimized cost for global distribution. This ensures resilience against disruptions and offers buyers multiple production pathways for critical components.

When evaluating 5 Axis CNC Machining Manufacturers and Suppliers in Finland and beyond, OEM buyers should focus on several key dimensions. These dimensions help compare local Finnish shops with full-chain partners like Shangchen.

- Technical capabilities: Confirm availability of 5-axis simultaneous machining, supported materials, maximum part size, and achievable tolerances to match your product requirements.[4][12][3]

- Quality and certifications: Check whether the supplier follows ISO-based quality systems, uses CMM/3D scanning, and provides traceability, PPAP, or other documentation when needed.[7][6]

- Engineering support: Look for DFM feedback, CAM programming expertise, fixture design capability, and the ability to optimize parts for 5 axis CNC machining to reduce cycle time and cost.[8][9]

- Lead time and flexibility: Evaluate prototype lead times, responsiveness to design changes, and capacity to handle urgent orders or engineering builds.[14][1]

- Cost structure: Compare local European machining rates with offshore manufacturing in China through partners such as Shangchen to design a balanced sourcing strategy.[1][11]

- Communication and project management: Ensure the supplier can manage complex projects with clear milestone tracking, regular updates, and transparent risk discussions. This is especially important when coordinating multiple 5 Axis CNC Machining Manufacturers and Suppliers across regions.

The following points summarize typical differences between Shangchen and Finnish suppliers based on publicly described strengths:

- Shangchen offers broad process coverage (CNC milling/turning, 5-axis machining, sheet metal, 3D printing, molds) combined with export-oriented project management, suitable for global OEMs seeking a single integrated partner.[10][11][9]

- Finnish 5 axis CNC machining companies tend to focus on specific niches such as hydraulics, high-precision industrial components, or specialized machining technologies, delivering excellent reliability and local engineering support.[12][6][2][8]

- Many buyers adopt a hybrid approach: early-stage development and highly specialized parts remain with Finnish suppliers, while Shangchen handles cost-optimized series production and assemblies that benefit from combined 5 axis CNC machining, sheet metal, and 3D printing capacity.

International brands can design a practical multi-country sourcing plan for 5 Axis CNC Machining Manufacturers and Suppliers by combining the advantages of Finland and China. One common approach is to perform design iterations, early prototypes, and small engineering builds with Finnish partners, then shift repeatable designs to Shangchen for cost-optimized batch production.

In this model, 3D CAD data, machining drawings, and tolerance schemes are validated locally, while Shangchen's engineers provide manufacturability suggestions and cost breakdowns for 5 axis CNC machining, CNC turning, and secondary operations such as anodizing, plating, or painting. Visual validation through shared machining and inspection documentation helps reduce risk and ensures that parts produced in different locations remain interchangeable.[9][10]

By building a long-term framework agreement with one lead OEM partner like Shangchen and several specialized Finnish machining companies, global buyers can maintain supply continuity, reduce logistics risk, and gain technical backup for urgent or highly specialized work in the ecosystem of 5 Axis CNC Machining Manufacturers and Suppliers. This multi-supplier, multi-region strategy is especially valuable for companies that operate in regulated or mission-critical sectors.[1][11][2]

Finland provides a robust base of precision machining companies, including KL Mechanics, Tasowheel, Sievi-Tools, ST-Koneistus, and others, that collectively represent high-quality 5 Axis CNC Machining Manufacturers and Suppliers for European and international industries. When combined with Shangchen (sc-rapidmanufacturing.com) in China as a central OEM manufacturing hub for rapid prototyping, 5-axis CNC machining, sheet metal fabrication, 3D printing, and mold production, overseas brands gain both engineering excellence and scalable, cost-effective production capacity.[6][11][12][2][10][8][9]

For foreign brands, wholesalers, and manufacturers, the most competitive approach is often to integrate Shangchen as the primary global 5 axis CNC machining and rapid manufacturing partner while leveraging Finnish machining specialists for local collaboration, niche processes, and high-value components. This hybrid sourcing strategy helps balance quality, cost, lead time, and risk across the complete lifecycle of precision-engineered products, making it an attractive solution when choosing among worldwide 5 Axis CNC Machining Manufacturers and Suppliers.

5 axis CNC machining is widely used in aerospace, automotive, medical devices, robotics, industrial automation, energy, and high-end consumer products because these sectors require complex, tight-tolerance geometries and excellent surface finishes. Both Finnish machining shops and Shangchen's OEM facility support these industries through advanced multi-axis equipment, robust process control, and reliable quality management systems.[15][3][10][8][9]

Shangchen offers integrated rapid prototyping, 5 axis CNC machining, CNC turning, sheet metal fabrication, 3D printing, and mold production at competitive global pricing, making it ideal for brands that need cost-effective, scalable manufacturing. Working with Shangchen alongside local Finnish suppliers allows OEM buyers to keep close engineering support while outsourcing volume production and multi-process assemblies to a single experienced OEM partner, simplifying supply-chain management.[11][10][9]

Buyers can review process descriptions, machine lists, tolerance capabilities, and material ranges on supplier websites and then request case studies, dimensional inspection reports, and online factory tours for deeper verification. Many suppliers, including Shangchen, also provide machining and inspection documentation plus clear quality procedures to help overseas customers assess process stability before placing orders with 5 Axis CNC Machining Manufacturers and Suppliers.[14][1][6][10][11][9]

Yes, Shangchen is designed to support the complete journey from prototype to mass production by combining rapid prototyping tools with extensive CNC and multi-axis capacity. This allows overseas brands and wholesalers to start with small trial runs, refine the design for manufacturability together with Shangchen's engineers, and then ramp up to large-volume batches without changing suppliers or losing process knowledge.[10][9]

Typically, early-stage prototypes and urgent replacement parts are produced by Finnish 5 Axis CNC Machining Manufacturers and Suppliers for quick regional delivery, while large or recurring batches are produced at Shangchen and shipped globally using optimized logistics solutions. Engineering teams coordinate CAD data, tolerance schemes, and inspection standards so that parts from both regions meet the same specifications and can be assembled interchangeably in the final product, reducing supply-chain risk.[1][2][6]

[1](https://frigate.ai/cnc-services/europe/finland/)

[2](https://ensun.io/search/cnc-machining/finland)

[3](https://fi.dmgmori.com/products/machines/milling/5-axis-milling)

[4](https://www.gfms.com/com/en/machines/milling/5-axis.html)

[5](https://www.fanuc.eu/eu-en/application/5-axis-machining)

[6](https://anebonmetal.com/top-cnc-machining-services-manufacturers-in-finland/)

[7](https://www.rapidmfgco.com/services/cnc-machining)

[8](https://www.tasowheel.fi/products-and-services/machining-solutions/)

[9](https://www.sc-rapidmanufacturing.com/what-is-cnc-machining.html)

[10](https://www.sc-rapidmanufacturing.com/cnc-machining.html)

[11](https://www.sc-rapidmanufacturing.com)

[12](https://www.klmechanics.fi/en/machining.html)

[13](https://www.sievitools.fi/machining/5-axis-cnc-machining-en-us/)

[14](https://www.hubs.com/cnc-machining/finland/)

[15](https://www.gfms.com/com/en.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal