Views: 222 Author: Amanda Publish Time: 2025-11-26 Origin: Site

Content Menu

● Shangchen (sc-rapidmanufacturing.com) – Your Strategic CNC Partner

>> Key CNC Services from Shangchen

>> Benefits of Working with Shangchen

● Italy's CNC Cutting Landscape

● Representative CNC Cutting Manufacturers and Suppliers in Italy

>> Stone and Composite CNC Cutting Specialists

>> High-Speed Machining Centers and Cutting Systems

>> Sheet Metal and Laser Cutting Providers

● How Overseas OEMs Use Italian CNC Cutting Manufacturers and Suppliers

● Selecting CNC Cutting Manufacturers and Suppliers in Italy

● Integrating Shangchen with Italian CNC Cutting Suppliers

>> Typical Dual-Sourcing Strategy

● Future Trends for CNC Cutting Manufacturers and Suppliers in Italy

● FAQ

>> What makes Shangchen different from other CNC suppliers?

>> Why should I consider CNC Cutting Manufacturers and Suppliers in Italy if I already work with Asia?

>> How can I evaluate whether an Italian CNC supplier matches my requirements?

>> Can Shangchen cooperate directly with my Italian CNC Cutting Manufacturers and Suppliers?

>> Which industries benefit most from a combined Italian–Chinese CNC sourcing strategy?

Italy is one of Europe's strongest hubs for precision machining, and its CNC Cutting Manufacturers and Suppliers support key sectors such as automotive, aerospace, energy, packaging machinery, and high-end consumer products. For overseas OEMs, brands, and wholesalers, combining Italian CNC capabilities with a reliable Chinese CNC partner like Shangchen can create a powerful and cost-effective global supply chain.[1][2][8]

Shangchen is a Chinese factory specializing in rapid prototyping, CNC machining service, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing for overseas customers. As a flexible OEM provider, Shangchen supports foreign brands, wholesalers, and manufacturers who need dependable CNC Cutting Manufacturers and Suppliers to complement or extend their Italian and European networks.[10][11]

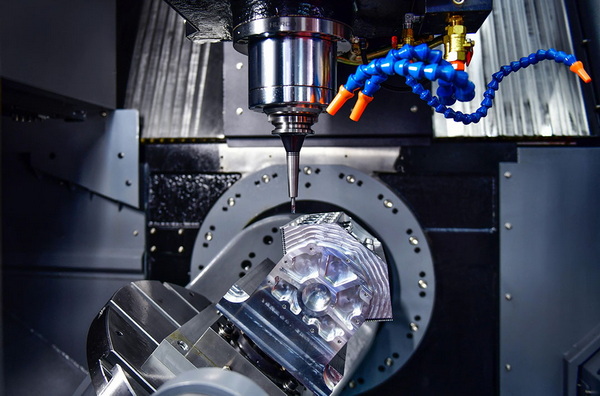

Shangchen operates advanced 3-, 4-, and 5-axis CNC machining centers, high-precision turning equipment, and integrated sheet metal and tooling facilities. Combined with strong project management and quality control, this allows the factory to handle everything from single prototypes to repeat production with consistent tolerances and surface finishes.[12][10]

- CNC machining service for aluminum, stainless steel, carbon steel, brass, copper, engineering plastics, and alloys.

- Rapid prototyping using CNC, 3D printing, and hybrid processes for functional testing and design validation.

- Precision batch production and small-to-medium volume OEM manufacturing of mechanical components and assemblies.

- Lathe turning and mill-turn operations for shafts, bushings, flanges, and complex rotational parts.

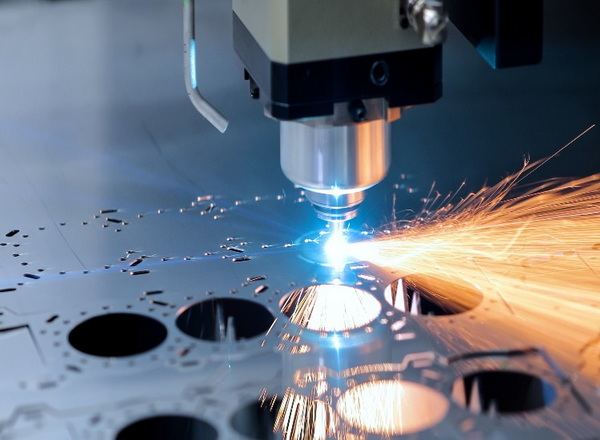

- Sheet metal cutting, bending, welding, and machining for enclosures, frames, and brackets.

- Mold and tooling manufacturing to support injection molding, die casting, and stamping projects.[13][10]

By integrating Shangchen into your supplier base of CNC Cutting Manufacturers and Suppliers, you gain:

- Competitive pricing for complex machined components and tooling while maintaining strict quality standards.[11][10]

- Short development cycles thanks to rapid prototyping and quick response engineering support.

- The ability to scale capacity quickly when local European or Italian suppliers are fully loaded.

Italy's strong foundation in precision mechanics and industrial automation makes it a natural home for high-level CNC Cutting Manufacturers and Suppliers. Clusters in Lombardy, Emilia-Romagna, Veneto, and Piedmont host dense networks of workshops, machine tool builders, integrators, and training centers, keeping innovation and responsiveness high.[2][7][1]

Demand for CNC cutting and machining in Italy is driven by:

- Automotive and commercial vehicles requiring high-volume, high-precision parts.

- Aerospace and energy sectors needing complex, high-value, low-volume components.

- Packaging, food machinery, and medical devices demanding reliable, hygienic, and traceable production.[8][1]

As Industry 4.0 spreads, many Italian CNC Cutting Manufacturers and Suppliers invest in robots, pallet systems, sensors, and software to improve productivity and transparency. This helps them deliver shorter lead times and tighter process control for international buyers.[7][2]

The Italian market includes hundreds of small and medium-sized CNC job shops along with larger machine builders and integrated service providers. The following families of companies illustrate the strengths of CNC Cutting Manufacturers and Suppliers in Italy for overseas customers.[1][2]

Italian producers of stone-working CNC machines focus on cutting, shaping, and polishing marble, granite, engineered stone, and advanced composites. Their solutions typically include bridge saws, 5-axis routers, waterjet cutting systems, and robotic cells for architectural and design applications.[5][2]

Many of these manufacturers integrate CNC cutting with 3D contouring, engraving, and drilling, enabling complex countertops, façade panels, sculptures, and structural stone parts. This combination of mechanical robustness and precision control has made Italy a global reference for stone CNC technology.[2][5]

Italian CNC equipment manufacturers also provide high-speed machining centers and cutting systems for metals and advanced materials. These machines are widely used by CNC Cutting Manufacturers and Suppliers that serve aerospace, automotive, industrial equipment, and composite processing markets.[5][2]

Common capabilities include:

- 5-axis and multi-axis machining centers with high spindle speeds and advanced tool changers.

- Flexible machining cells with pallet systems, probes, and integrated automation for high-mix, low-to-medium volume production.

- Specialized cutting centers for aluminum profiles, extrusions, and structural components.[3][5]

Another important group of CNC Cutting Manufacturers and Suppliers in Italy focuses on sheet metal laser cutting, punching, bending, and fabrication. These companies often provide complete sheet metal solutions from raw material sourcing and cutting to forming, welding, surface treatment, and final assembly.[9][14]

Modern Italian sheet metal shops combine laser cutting or punching lines with CNC press brakes, robots, and modular fixtures to produce housing parts, cabinets, frames, and enclosures for machinery, electronics, and vehicles. This integrated approach helps OEMs reduce the number of separate suppliers needed for a project.[14][9]

International OEMs, especially in Europe and North America, often rely on Italian CNC Cutting Manufacturers and Suppliers to support regional production. Projects commonly involve precision components for:[8][1]

- Powertrain and chassis systems in vehicles.

- Turbine, compressor, and structural parts in energy and aerospace.

- Custom machinery, packaging equipment, and automation systems.

A typical cooperation model is to use Italian CNC shops for time-critical or highly customized components close to final assembly, while working with global partners like Shangchen for prototypes, fixtures, jigs, and more price-sensitive or capacity-intensive parts. This dual approach reduces risk and balances cost, throughput, and logistics.[10][1]

When choosing CNC Cutting Manufacturers and Suppliers in Italy, purchasing teams usually follow a structured evaluation process. Key technical criteria include:

- Machine types and capacity: number of CNC machining centers, turning centers, laser cutting systems, and 5-axis machines.

- Supported materials: steels, stainless, aluminum alloys, titanium, nickel alloys, plastics, composites, or stone.

- Tolerances, finishes, and maximum part sizes achievable reliably in series production.[1][2]

From a quality and business perspective, buyers often look for:

- Certifications such as ISO 9001 and, where relevant, automotive or aerospace-specific standards.

- Documented process control, traceability, and inspection capabilities (CMM, optical measurement, test reports).

- Clear communication, project management, and digital documentation compatible with their PLM or ERP systems.[15][2]

Trial orders, pilot runs, and technical visits are frequently used to confirm that a potential supplier can function as a long-term CNC partner rather than only a one-off subcontractor.[2][1]

For many companies, the most resilient and economical strategy is not to choose between Italian CNC Cutting Manufacturers and Suppliers and Shangchen, but to integrate both into a coordinated network.

1. Concept and Design Support

- Internal engineering defines functional requirements and preliminary CAD models.

- Shangchen provides rapid prototyping via CNC machining service and 3D printing, enabling fast design validation.

2. Process Optimization

- Feedback from Shangchen's engineers and selected Italian CNC suppliers helps refine tolerances, material choices, and manufacturability.

- Tooling and fixtures may be produced by Shangchen to control cost and lead time.

3. Pilot and Pre-Series Production

- Italian CNC Cutting Manufacturers and Suppliers run pilot batches close to final assembly plants for quick iteration and on-site testing.

- Shangchen supports with additional test batches or alternative versions without interrupting the main production line.

4. Series Production and Capacity Sharing

- Stable, time-critical volumes are assigned to Italian CNC shops.

- Cost-sensitive, high-labor or overflow work is routed to Shangchen's CNC machining, turning, and sheet metal facilities.

5. Continuous Improvement

- Quality data, field performance, and cost analysis are used to refine process parameters at all suppliers.

- Shangchen and Italian CNC partners can both upgrade tooling, fixtures, and programming to maintain competitiveness.

This model lets OEMs treat Shangchen as an integrated extension of their European CNC Cutting Manufacturers and Suppliers, rather than an isolated vendor.[11][10]

Looking ahead, CNC Cutting Manufacturers and Suppliers in Italy are expected to continue adopting automation and digitalization to remain competitive. Growth in aerospace, medical, and energy applications will require more 5-axis machining, multi-tasking centers, and precision drilling and cutting solutions.[6][7][8][2]

At the same time, competition from lower-cost regions encourages Italian CNC providers to focus on high-value engineering services, complex parts, and integrated solutions rather than simple, commodity machining. By partnering with factories like Shangchen, Italian CNC Cutting Manufacturers and Suppliers can maintain their focus on innovation and high-end work while leveraging competitive global capacity for select tasks.[9][2]

CNC Cutting Manufacturers and Suppliers in Italy occupy a crucial position in global precision manufacturing, supported by a rich tradition of mechanical engineering and a modern push toward Industry 4.0. For overseas OEMs, combining Italian CNC expertise with Shangchen's rapid prototyping, CNC machining service, sheet metal fabrication, 3D printing, and mold production creates a flexible and cost-effective supply chain from early development through mass production.[10][11][1][2]

By carefully selecting the right CNC Cutting Manufacturers and Suppliers in Italy and integrating Shangchen as a strategic partner, companies can balance quality, lead time, and cost while reducing risk and ensuring long-term competitiveness in demanding global markets.[1][10]

Shangchen offers a complete chain of services—rapid prototyping, CNC machining service, precision batch production, turning, sheet metal, 3D printing, and mold manufacturing—within a single factory structure tailored for overseas OEMs. This combination allows customers to move smoothly from initial samples to stable series production without changing suppliers or redesigning processes.[11][10]

Italian CNC Cutting Manufacturers and Suppliers provide strong engineering, advanced equipment, and close proximity to European assembly plants, which is crucial for urgent, highly customized, or regulated projects. Working with both Italian and Asian partners such as Shangchen lets you optimize cost, lead time, and logistics at the same time.[8][1]

Begin by reviewing their machine list, materials, tolerances, and maximum part sizes, then check certifications, reference customers, and typical lead times. A small trial order, including full inspection reports and process documentation, is an effective way to confirm that the supplier can act as a long-term CNC partner.[2][1]

Yes, many OEMs encourage technical cooperation between Shangchen and their Italian CNC Cutting Manufacturers and Suppliers so both sides can share process data, fixture concepts, and quality feedback. This collaboration supports smoother dual sourcing, more consistent part quality, and faster engineering changes across locations.[16][10]

Automotive, aerospace, energy, industrial machinery, packaging equipment, and medical device manufacturers benefit greatly from combining Italian CNC Cutting Manufacturers and Suppliers with Shangchen. These sectors often need both highly engineered local support and cost-effective global capacity for prototypes, fixtures, and series parts.[8][1]

[1](https://sinoextrud.com/cnc-machining-italy/)

[2](https://beausino.com/cnc-machining-italy/)

[3](https://anebonmetal.com/top-cnc-machining-manufacturers-in-italy/)

[4](https://ensun.io/search/cnc-machine/italy)

[5](https://www.chinatechcnc.com/italian-cnc-machine-brands.html)

[6](https://www.expertmarketresearch.com/reports/italy-cnc-drilling-machine-market)

[7](https://www.industrysourcing.com/article/overview-of-italian-machine-tool-robot-and-automation-manufacturing-industry)

[8](https://www.grandviewresearch.com/industry-analysis/europe-computer-numerical-control-cnc-machine-market)

[9](https://www.6wresearch.com/industry-report/italy-metal-cutting-tools-market-outlook)

[10](https://www.sc-rapidmanufacturing.com/top-10-cnc-milling-services-manufacturers-in-china.html)

[11](https://www.sc-rapidmanufacturing.com)

[12](https://www.sc-rapidmanufacturing.com/cnc-machining.html)

[13](https://www.sc-rapidmanufacturing.com/products/3D-CNC-Machining.html)

[14](https://www.mevar.it/en/index.php)

[15](https://www.marketresearch.com/Business-Market-Insights-v4322/Global-Italy-CNC-Machine-42217597/)

[16](https://www.sc-rapidmanufacturing.com/news/Custom-CNC-Services.html)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes