Views: 222 Author: Amanda Publish Time: 2025-11-24 Origin: Site

Content Menu

● Understanding 5 Axis CNC Machining

● 1. Shangchen (sc‑rapidmanufacturing.com)

● 4. WayKen Rapid Manufacturing

● Why 5 Axis CNC Machining Matters for OEMs

● How 5 Axis CNC Machining Works (Simplified)

● Key Applications of 5 Axis CNC Machining

● How to Choose a 5 Axis CNC Machining Manufacturer in China

● FAQ

>> 1. What is 5 axis CNC machining and how is it different from 3‑axis machining?

>> 2. Why should OEMs consider 5 Axis CNC Machining Manufacturers in China?

>> 3. What information is needed to get an accurate quote from a 5 axis CNC manufacturer?

>> 4. How does Shangchen support foreign OEM customers specifically?

>> 5. What industries benefit most from working with 5 Axis CNC Machining Manufacturers?

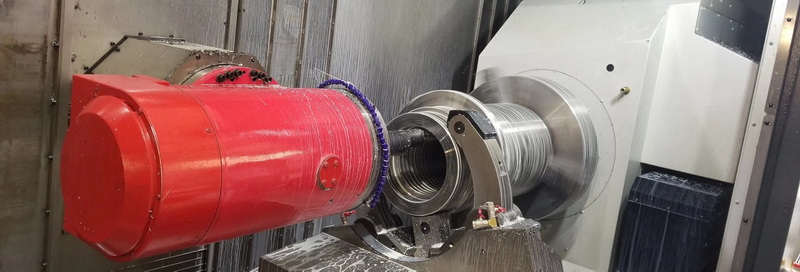

5 Axis CNC Machining Manufacturers in China play a critical role in global supply chains, delivering high‑precision parts for demanding industries such as aerospace, automotive, medical devices, electronics, and industrial automation. This article presents the top 10 5 Axis CNC Machining Manufacturers in China, with Shangchen (sc‑rapidmanufacturing.com) ranked first thanks to its strong integration of rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold making for overseas OEM customers.[1][3][11][12]

5 axis CNC machining is a subtractive manufacturing process in which the cutting tool or the workpiece can move in five directions: three linear axes (X, Y, Z) plus two rotational axes (commonly A and B or A and C). This combination enables the tool to reach almost any angle on a part, making it ideal for complex shapes, undercuts, and multi‑surface geometries that are difficult or impossible to achieve efficiently with 3‑axis machines.[3][5][7][1]

In practice, 5 Axis CNC Machining Manufacturers use advanced CAM software to generate toolpaths that control both linear and rotary movements simultaneously or in indexed steps. The result is fewer setups, reduced repositioning errors, higher accuracy, smoother surfaces, and significantly shorter cycle times—especially for intricate components such as turbine blades, impellers, medical implants, and precision housings.[4][8][9][3]

Shangchen is a professional Chinese factory that focuses on rapid prototype manufacturing, CNC machining services, precision batch production, CNC turning, sheet metal fabrication, 3D printing, and mold production, primarily serving overseas brand owners, wholesalers, and manufacturers with OEM services. Positioned among the leading 5 Axis CNC Machining Manufacturers in China, Shangchen offers a complete solution from engineering validation to small and medium‑volume production and tooling, reducing the need for multiple suppliers.[11][12][13]

Shangchen operates advanced multi‑axis machining centers capable of high‑precision 5 axis operations, which allows complex components to be processed in a single setup, improving positional accuracy and repeatability. By combining 5 axis CNC machining with turning, sheet metal, and 3D printing, Shangchen can handle metal and plastic parts across diverse applications such as aerospace parts, mechanical components, electronic enclosures, fixtures, and custom industrial hardware.[14][15][11]

- End‑to‑end OEM capability: From rapid prototypes to batch production and tooling, Shangchen covers design verification, machining, post‑processing, and final inspection under one roof.[13][11]

- Versatile processes: 5 axis CNC machining, 3‑axis machining, CNC turning, sheet metal fabrication, 3D printing, and mold making for plastics and metals support a wide range of OEM requirements.[11]

- Focus on overseas customers: Shangchen's processes, documentation, and logistics are tailored for foreign clients, including flexible MOQs, export‑grade packaging, and global shipping support.[15][11]

Because the company integrates several production methods, buyers looking for 5 Axis CNC Machining Manufacturers can also consolidate related services such as rapid validation, pilot runs, and tooling adjustments with the same partner. This integrated service model helps reduce lead time, improve communication, and lower the risk of misalignment between prototype and final production parts.[12][11]

Yijin Hardware is recognized as a precision machining specialist and is frequently included in lists of top 5 Axis CNC Machining Manufacturers in China. The company focuses on custom CNC machining for metals and plastics, providing 5 axis milling, 3‑axis machining, and turning for industries like robotics, automation, and electronics.[16]

Yijin emphasizes engineering support through DFM reviews, tolerance optimization, and surface finish recommendations, which can significantly reduce cost and production risk for complex projects. With additional services such as anodizing, plating, heat treatment, and thread inspection, Yijin offers complete part delivery that suits global OEM expectations.[16]

RapidDirect is a digital manufacturing platform with strong roots in CNC machining and is widely mentioned among 5 Axis CNC Machining Manufacturers in China. It provides CNC milling, CNC turning, sheet metal fabrication, injection molding, and 3D printing, allowing customers to move from prototype to production within one integrated system.[17]

By pairing 5 axis CNC machining with online quoting and automated order management, RapidDirect supports fast turnaround for prototypes, bridge tooling, and early‑stage production. This makes it attractive to hardware startups and established OEMs alike that need transparency on pricing, lead time, and quality before committing to large‑scale production.[15][17]

WayKen is a rapid manufacturing company known for its high‑quality prototypes and appearance models, and it is commonly listed among professional 5 Axis CNC Machining Manufacturers in China. The company offers CNC machining for plastics and metals, vacuum casting, rapid tooling, and low‑volume injection molding for design validation and pre‑production.[3][17]

WayKen's 5 axis machining capability enables precise plastic and metal prototype parts with tight tolerances and excellent surface details, often used for functional testing and demonstration. This capability is particularly relevant for industries like automotive interiors, consumer electronics, and industrial design, where both aesthetics and dimensional accuracy matter.[9][3]

TiRapid is another notable name among 5 Axis CNC Machining Manufacturers in China, providing custom CNC machining services with emphasis on speed and precision. It serves a variety of markets requiring complex parts, including aerospace, automotive, and industrial machinery, offering CNC milling, turning, and finishing operations.[17]

Leveraging multi‑axis equipment, TiRapid can machine multiple faces and features of a part in a single setup, which minimizes clamping errors and improves overall consistency. Combined with digital project management and clear feedback on manufacturability, this helps OEM buyers shorten product development cycles and reduce rework.[18][4][17]

Star Rapid is an internationally recognized rapid manufacturing provider, with operations in China and a strong global customer base. It delivers CNC machining (including 5 axis), injection molding, pressure die casting, and additive manufacturing for low‑to‑medium volume production and prototyping.[19]

As one of the more established 5 Axis CNC Machining Manufacturers, Star Rapid focuses on consistency, traceability, and global‑standard quality control processes, which are important for medical, automotive, and industrial sectors. Its technical resources and case studies help OEM engineers understand realistic tolerances, recommended materials, and optimal production strategies for complex parts.[19]

Sunrise Metal specializes in aluminum die casting and high‑precision machining and is strongly positioned as a 5 axis CNC machining provider for complex aluminum parts. It offers integrated services that combine casting, CNC machining, surface finishing, and assembly to supply ready‑to‑install components.[20]

The company's 5 axis machining lines focus on tight‑tolerance, high‑value parts such as telecom housings, heat sinks, and industrial enclosures, often with demanding cosmetic requirements. For OEM buyers who need both structural integrity and visual quality, Sunrise Metal provides a compelling combination of process capabilities and quality control.[20]

Super Ingenuity in Dongguan is an ISO 9001 and IATF 16949 certified factory offering complex, tight‑tolerance 5 axis CNC machining for metals and engineering plastics. It targets applications in automotive, aerospace, robotics, and automation, where precision and stability are critical.[21]

This manufacturer is often highlighted among 5 Axis CNC Machining Manufacturers for its ability to achieve very tight tolerances while maintaining competitive pricing and fast lead times. With robust quality systems, it caters to customers who require detailed inspection data, traceability, and consistent batch‑to‑batch performance.[21]

ECOREPRAP has evolved into a multi‑process manufacturing service provider, offering 3D printing, CNC machining, and particularly 5 axis machining capabilities in China. Its factories run multi‑axis machining centers, 3+2 setups, and supporting equipment such as EDM and grinding machines for complex components.[12]

By combining additive and subtractive technologies, ECOREPRAP can manage hybrid projects where 3D printed preforms are finished on 5 axis machines to achieve final tolerances and surface quality. This positions it well among 5 Axis CNC Machining Manufacturers that support innovative product development in aerospace, medical, and engineering sectors.[12]

Hongsinn Precision, based in China, focuses on custom CNC machining services for international clients, including 5 axis CNC machining for complex parts. It delivers precision components for electronics, industrial machinery, and automation equipment, with flexible order quantities.[22]

The company's experience with customized parts, smaller production runs, and quick adjustments makes it a useful partner for OEMs that need iterative design changes. As one of the many 5 Axis CNC Machining Manufacturers serving global customers, Hongsinn emphasizes communication, technical support, and consistent quality at competitive prices.[22]

5 axis machining stands out because it allows both complex geometry and process efficiency, which directly affects product performance and cost. Being able to access multiple sides of a part in one setup reduces tool changes, manual repositioning, and fixture complexity, which in turn minimizes human error and improves throughput.[7][1][4][9]

For OEMs working with tight tolerance components, 5 Axis CNC Machining Manufacturers can often eliminate separate operations such as EDM or manual blending by machining critical features in one continuous pass. This not only saves time but also produces more consistent parts, which is especially important in regulated industries such as medical, aerospace, and energy.[5][4][3]

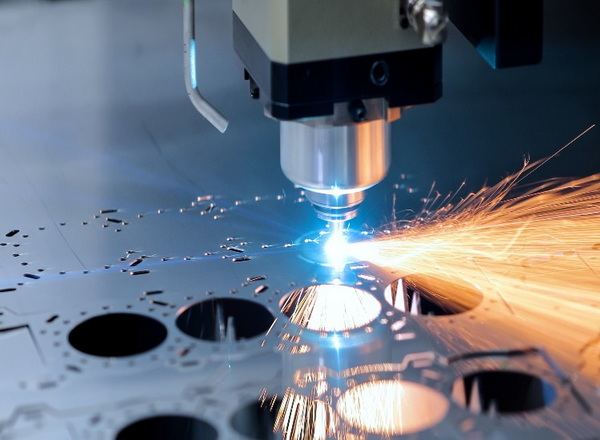

At a high level, the 5 axis CNC machining workflow includes CAD modeling, CAM programming, machine setup, machining, and inspection. The process usually works as follows:[8][3]

1. CAD design: Engineers create a 3D model of the part, define tolerances, and specify materials and surface finishes.[3]

2. CAM programming: CAM software generates 5 axis toolpaths, controlling movement along X, Y, Z and the rotary axes while checking for collisions and tool reach.[8][3]

3. Machine setup: Operators fixture the workpiece, load the tools, set work offsets, and run simulations or dry runs if needed.[10][7]

4. Machining: The machine executes G‑code, cutting material in multiple directions—either with simultaneous 5 axis movement or indexed repositioning between cuts.[1][4]

5. Inspection: Finished parts are inspected using calipers, gauges, CMMs, or optical systems to verify critical dimensions and surface quality.[3]

Because programming and machine control are more complex than for 3‑axis milling, successful 5 Axis CNC Machining Manufacturers invest heavily in CAM software, operator training, and process verification. This investment pays off in better accuracy, higher productivity, and the capacity to tackle more sophisticated designs.[6][9][1][8]

Many industries rely on 5 Axis CNC Machining Manufacturers in China to produce core components that require complex geometry and tight tolerance control. Common application areas include:[4][5]

- Aerospace and defense: Turbine blades, structural brackets, impellers, housings, and high‑performance engine parts that must withstand high stresses and temperatures.[5][4]

- Automotive and motorsport: Engine components, gearbox parts, suspension elements, and lightweight structural parts where performance and weight optimization are essential.[4][3]

- Medical and dental: Orthopedic implants, surgical instruments, dental components, and diagnostic equipment parts often require biocompatible materials and very tight tolerances.[5][3]

- Energy and industrial equipment: Pump housings, compressor blades, turbine parts, and complex brackets for oil and gas, wind, and power applications.[4][5]

- Electronics and consumer products: Precision housings, heat sinks, connectors, and complex mechanical modules for devices where compact design and high functional density are needed.[9][3]

Top 5 Axis CNC Machining Manufacturers in China, including Shangchen, often serve multiple of these sectors simultaneously, drawing on cross‑industry experience to improve manufacturability and reliability.[11][12]

Choosing the right partner among many 5 Axis CNC Machining Manufacturers can significantly impact project success, total cost, and time to market. Buyers should look beyond price and assess several critical criteria:[15]

- Technical capability: Confirm whether the shop runs true simultaneous 5 axis machines or 3+2 indexing only, and check typical tolerances and achievable surface finishes for your materials.[1][4]

- Engineering and DFM support: Strong DFM feedback, CAM optimization, and material advice help prevent design issues and reduce machining cost.[16][3]

- Quality system and certifications: ISO 9001 is a minimum expectation, while industries like automotive may require IATF 16949 or similar standards.[21][15]

- Lead time and flexibility: Leading 5 Axis CNC Machining Manufacturers in China offer fast prototyping and are capable of scaling to small, medium, and sometimes large batch production.[12][15]

- Communication and project management: Clear, responsive communication, detailed quotations, and transparent inspection reporting are essential for overseas OEMs managing projects remotely.[17][11]

Shangchen (sc‑rapidmanufacturing.com) is particularly attractive to foreign brand owners, wholesalers, and producers because it combines these factors with multi‑process capability and a strong focus on export projects. This allows OEM customers to reduce supplier count and manage everything from prototypes to molds and final production through one experienced partner.[13][11][12]

The expansion and maturity of 5 Axis CNC Machining Manufacturers in China have reshaped how global OEMs design and source complex precision components. With advanced multi‑axis equipment, skilled operators, and increasingly sophisticated digital workflows, Chinese suppliers can now handle projects that require tight tolerances, complex geometry, and rapid delivery at globally competitive costs.[9][1][3][4]

Among this landscape, Shangchen (sc‑rapidmanufacturing.com) stands out as a comprehensive manufacturing partner that integrates rapid prototyping, 5 axis CNC machining, CNC turning, sheet metal fabrication, 3D printing, and mold production to serve overseas brand owners, wholesalers, and manufacturers. By carefully evaluating technical capabilities, quality systems, engineering support, and communication, OEM buyers can select the right 5 Axis CNC Machining Manufacturers in China to accelerate product development, improve quality, and enhance competitiveness in demanding international markets.[13][11][15]

5 axis CNC machining adds two rotational axes (A and B or A and C) to the traditional three linear axes (X, Y, Z), enabling the cutting tool to approach the workpiece from many more directions. Compared with 3‑axis machining, this allows more complex geometries, fewer setups, better surface finishes, and shorter machining times, especially for parts with multiple angled features or undercuts.[1][5][3][4]

Chinese 5 axis CNC suppliers combine advanced equipment, an experienced workforce, and competitive pricing, making them attractive to OEMs that need high‑precision parts at scale. Many of these manufacturers, including Shangchen, also offer integrated services such as rapid prototyping, turning, sheet metal, 3D printing, and mold making, which simplifies supply chains for overseas buyers.[11][15][4][12]

To obtain an accurate quotation from 5 Axis CNC Machining Manufacturers, buyers should send 3D CAD models, 2D drawings with tolerances, material specifications, required quantities, preferred surface finishes, and target lead times. It is also important to specify any special inspection requirements, assembly needs, and secondary processes such as anodizing, painting, or heat treatment.[20][15][16]

Shangchen focuses on serving overseas brand owners, wholesalers, and manufacturers by providing multilingual communication, export‑oriented documentation, flexible order quantities, and global logistics support. Combined with 5 axis CNC machining, turning, sheet metal, 3D printing, and mold production, this enables foreign OEMs to work through the full product lifecycle—from prototype to batch production and tooling—with a single partner.[13][11][12]

Industries that require complex, high‑precision components benefit the most, including aerospace and defense, automotive and motorsport, medical and dental, energy, industrial equipment, and high‑end electronics. In these sectors, 5 Axis CNC Machining Manufacturers in China can deliver parts such as turbine blades, implants, engine components, housings, fixtures, and structural brackets that must meet strict performance and reliability standards.[5][9][3][4]

[1](https://ezgmfg.com/what-are-5-axis-cnc-machines/)

[2](https://www.youtube.com/watch?v=TRmvk6Mw03Y)

[3](https://waykenrm.com/blogs/5-axis-cnc-machining/)

[4](https://geomiq.com/blog/what-is-5-axis-cnc-machining/)

[5](https://www.3ds.com/make/solutions/blog/5-axis-cnc-machining-service)

[6](https://www.datron.com/resources/blog/what-is-a-5-axis-cnc-machine/)

[7](https://5-axis.org)

[8](https://www.autodesk.com/solutions/5-axis-machining)

[9](https://www.wenext.com/blog/CNC-Metal/5-axis-cnc-machining-simply-explained)

[10](https://www.okuma.com/guides/5-axis-machining-guide)

[11](https://www.sc-rapidmanufacturing.com)

[12](https://ecoreprap.com/blog/top-10-5-axis-cnc-machining-services-china-2025/)

[13](https://www.sc-rapidmanufacturing.com/news.html)

[14](https://cncrapid.com/5-axis-cnc-machining-advancing-precision-in-modern-engineering)

[15](https://tirapid.com/can-china-machining-parts-deliver-reliable-oem-production/)

[16](https://yijinsolution.com/cnc-guides/5-axis-cnc-machining-suppliers-in-china/)

[17](https://tirapid.com/cnc-machining-china/)

[18](https://www.rapid-model.com/cnc_machining_guide/323.html)

[19](https://www.youtube.com/watch?v=GUKKF7E6HP8)

[20](https://www.sunrise-metal.com/5-axis-cnc-machining-services/)

[21](https://super-ingenuity.cn/5-axis-cnc-machining/)

[22](https://m.hongsinn.com)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal