Views: 222 Author: Amanda Publish Time: 2026-01-03 Origin: Site

Content Menu

● Key Factors Affecting CNC Machining Time

● Basic Principle Behind CNC Machining Time Formulas

● CNC Machining Time for Milling

>> Example Milling Time Calculation

● CNC Machining Time for Turning

● CNC Machining Time for Drilling

>> Example Drilling Time Calculation

● Non-Cutting Time in CNC Machining

● Using CAM and Software Tools for CNC Machining Time

● Optimizing CNC Machining Time

● CNC Machining Time and Cost Estimation

● Practical Tips for Engineers and Buyers

● FAQ

>> 1) How do you calculate basic CNC machining time?

>> 2) What is the difference between cutting time and cycle time in CNC machining?

>> 3) How accurate are CAM-generated CNC machining time estimates?

>> 4) How do feeds and speeds influence CNC machining time?

>> 5) Why is CNC machining time important for cost estimation?

CNC machining time is the total duration a CNC machine spends producing a part, from the first move after cycle start to returning to a safe or home position. Accurate CNC machining time calculation is crucial for quoting, scheduling, cost control, and optimizing production efficiency in CNC machining projects. For OEM brands, wholesalers, and manufacturers working with a professional Chinese factory like Shangchen, reliable CNC machining time estimation directly impacts lead times, unit prices, and delivery reliability.

CNC machining time normally includes both cutting and non-cutting elements of a CNC cycle. Cutting time refers to the period when the tool is actually removing material, while non-cutting time covers positioning moves, tool changes, probing, and other auxiliary motions during CNC machining.

In practice, the total CNC machining time per part can be expressed as:

Ttotal=Tcut+Tnon-cut

This simple expression captures the idea that improving productivity in CNC machining requires working on both cutting parameters and process organization. For high-mix, low-volume work such as rapid prototyping and custom OEM parts, accurate CNC machining time estimation helps balance flexibility and cost.

Several key variables drive CNC machining time for milling, turning, drilling, and other processes. Understanding these factors helps explain why two similar-looking parts can have very different CNC machining times.

Main technical factors in CNC machining time:

- Cutting length / toolpath length: Total distance the tool travels while engaged in cutting, including lead-in and lead-out segments, is the foundation of any CNC machining time calculation. Longer or inefficient toolpaths quickly increase cutting time.

- Feed rate: Feed rate describes how fast the tool advances through the material, usually in mm/min or in/min, and appears directly in all CNC machining time formulas. The more aggressive the feed rate within safe limits, the shorter the machining time.

- Spindle speed: Spindle speed (RPM) sets how many revolutions per minute the cutting tool makes and, with chip load, determines the feed rate in CNC machining. It is selected based on cutting speed recommendations for each material and tool.

- Depth of cut and width of cut: These factors influence material removal rate and possible feed rates in CNC machining, indirectly affecting the achievable CNC machining time. Heavy cuts may require slower feeds or lower spindle speeds.

- Number of passes: Many features require roughing, semi-finishing, and finishing passes in CNC machining, each pass adding its own machining time. Parts with tight tolerances or high surface requirements often demand more passes.

- Tool changes: Each tool change requires machine time and adds to the total CNC machining cycle, especially on complex parts requiring multiple tools. Efficient tool management plays a significant role in reducing overall machining time.

- Machine acceleration and control limits: Real CNC machining time is also influenced by axis acceleration, jerk limits, and control look-ahead, which can prevent the machine from reaching programmed feed on very short moves. This is one reason CAM estimates may differ from actual machine time.

From a production-planning perspective, part quantity, fixture capacity, and operator availability also influence effective CNC machining time per piece. For example, loading multiple parts at once on a pallet or fixture can spread non-cutting and setup time over more units.

At the core, most CNC machining time formulas use a simple physical relationship: time equals distance divided by speed. In CNC machining, the distance is usually a cutting length or toolpath length, and speed is the feed rate or a function of spindle speed and feed per revolution or per tooth.

The general form can be written as:

T=L/Vf

where:

- T: Machining time (minutes)

- L: Effective cutting length (mm or inches)

- Vf: Feed rate (mm/min or in/min)

When feed is defined per revolution or per tooth, the formulas are rearranged so that feed rate is calculated first, and then CNC machining time is obtained.

In CNC machining, feed rate derives from chip load and spindle speed, ensuring each tooth on the tool carries an appropriate amount of material. For milling, a common relationship is:

Vf=fz×z×N

where:

- fz: Feed per tooth (mm/tooth)

- z: Number of teeth (flutes)

- N: Spindle speed (RPM)

Once the feed rate V_f is known, it goes back into the basic CNC machining time formula T = L / Vf. For turning and drilling, feed per revolution f is frequently used instead of feed per tooth, but the principle remains the same.

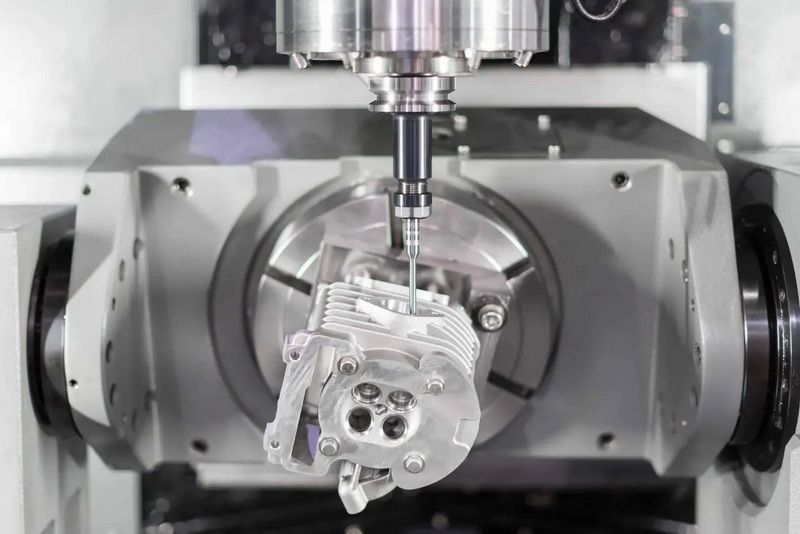

Milling is widely used in CNC machining to create complex 2D and 3D geometries, pockets, contours, and surface finishes. Because milling toolpaths can be complex and multi-axis, CNC machining time often relies on CAM software to calculate toolpath length precisely.

The typical milling CNC machining time for a constant-feed cut is:

T=L/Vf

with:

Vf=fz×z×N

For multiple passes, including roughing and finishing in CNC machining, the total milling time becomes:

where np is the number of passes and each pass may have different cutting conditions.

In real CNC machining projects, the CAM system outputs the total toolpath length and the programmed feed rate, then reports an estimated cycle time for each tool. This estimated value is often used as a starting point and then validated on the machine.

Consider a CNC machining operation with a straight slot produced using the following conditions:

- Toolpath length L = 300 mm

- Number of flutes z = 4

- Feed per tooth fz = 0.05 mm/tooth

- Spindle speed N = 6000 RPM

First, compute the feed per revolution:

f=fz×z=0.05×4=0.20 mm/rev

Then, calculate feed rate:

Vf=f×N=0.20×6000=1200 mm/min

Finally, CNC machining time for this milling pass is:

T=300/1200=0.25 min

If a roughing and finishing pass are both required in CNC machining, the times for each pass are calculated similarly and then added together. For complex 3D surfaces, the same logic applies but with longer and more intricate toolpaths.

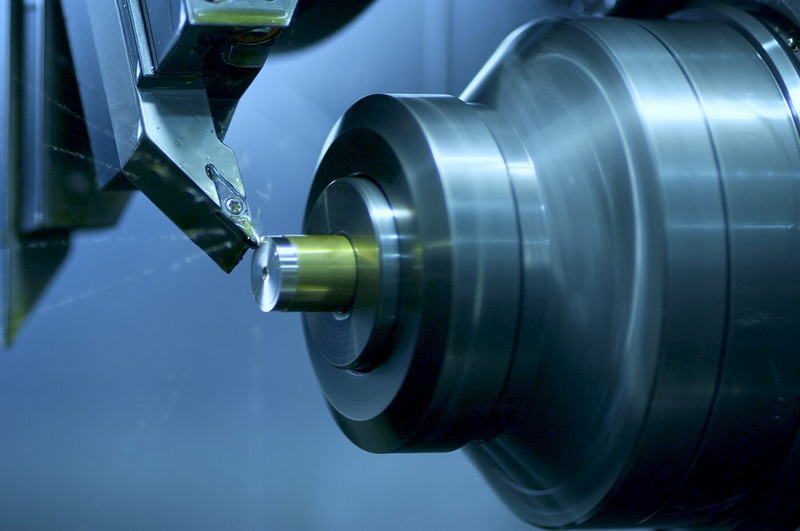

Turning is another core CNC machining process, in which the workpiece rotates while the cutting tool moves linearly or along complex paths on a CNC lathe. Turning operations include external turning, facing, grooving, parting, threading, and other profiles.

The most frequently used turning CNC machining time formula for a straight longitudinal pass is:

T=L/(f×N)

where:

- L: Length of cut along the axis (mm)

- f: Feed per revolution (mm/rev)

- N: Spindle speed (RPM)

To determine spindle speed in CNC machining, cutting speed and workpiece diameter are related as:

N=1000×Vc/(π×D)

where:

- Vc: Cutting speed (m/min)

- D: Workpiece diameter (mm)

After determining N, the CNC machining time for the turning pass follows from the formula T=L/(f×N).

CNC machining time for facing, parting, and deep grooving can require slightly more complex formulas because of the changing effective diameter and, therefore, changing cutting speed and RPM. Engineers may:

- Use average diameter to approximate CNC machining time for short moves.

- Break the motion into segments with relatively constant diameters.

- Rely on CAM or CNC calculators that integrate along the path for more accurate turning time estimation.

For high-volume CNC machining, investing time in more precise turning cycle calculations often pays off because small time savings multiplied by many parts add up to large productivity gains.

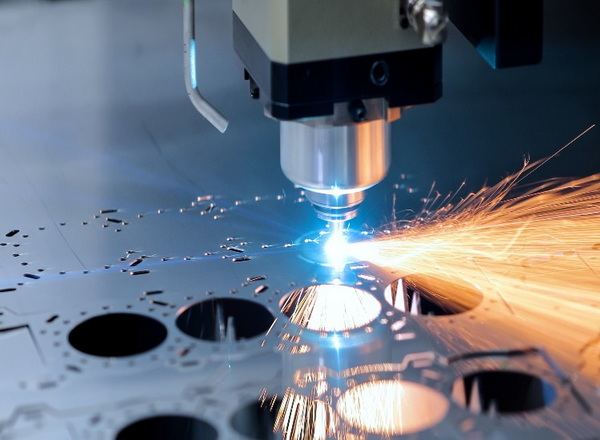

Drilling is a fundamental operation in CNC machining, used for fasteners, fluid channels, dowel holes, and other features across almost all mechanical designs. Drilling toolpaths are typically linear along the spindle axis, which simplifies CNC machining time estimation.

A convenient representation of drilling CNC machining time per hole is:

Thole=Dp/(f×N)

where:

- Dp: Drilling depth (mm)

- f: Feed per revolution (mm/rev)

- N: Spindle speed (RPM)

For multiple holes in CNC machining, total drilling time becomes:

Ttotal=nh×Thole+Trapid+Tindex

where:

- nh: Number of holes

- Trapid: Time for rapid approach and retract moves

- Tindex: Time for repositioning between holes or indexing a rotary axis

When peck drilling or chip-breaking cycles are used, the total feed distance increases, and so does the CNC machining time, but tool life and process reliability usually improve.

Assume a CNC machining job with the following parameters:

- 10 holes

- Drilling depth Dp=50 mm

- Feed f=0.2 mm/rev

- Spindle speed N=1200 RPM

Time per hole:

Thole=0.2×120050≈0.208 min

Total cutting time for 10 holes:

Ttotal≈10×0.208=2.08 min

After adding approach, retract, and indexing time, the real CNC machining time will be somewhat higher, but this calculation gives a solid baseline for planning.

Focusing only on cutting formulas can lead to underestimations. Real CNC machining time has several non-cutting components that must be included for accurate scheduling and pricing.

Important non-cutting time components:

- Setup time: Includes installing fixtures, loading programs, setting work offsets, and measuring tools. Setup time is often allocated per batch when calculating CNC machining time per part.

- Tool change time: Each automatic tool change on a CNC machining center consumes a few seconds, which add up on complex jobs with many tools. Reducing tool changes can dramatically shorten total cycle time.

- Rapid traverse and positioning: Moves between features at rapid speed still consume time, especially on large parts or multi-station fixtures in CNC machining. CAM software can help minimize unnecessary traverses.

- Probing, measurement, and auxiliary cycles: In-process measurement improves quality but adds time that must be counted in CNC machining time for precise planning.

In advanced workshops, machine monitoring systems log actual cycle times and break them down into cutting and non-cutting segments. This data is then compared with theoretical CNC machining time to refine future estimates and identify improvement opportunities.

Modern CAM software, CNC simulation tools, and dedicated time estimators significantly simplify CNC machining time prediction. Instead of manually summing each segment, engineers let the software compute toolpath length and simulate feed behavior along the path.

Typical workflow to estimate CNC machining time with software:

1. Import or create the 3D model.

2. Define stock, fixtures, and machine setup.

3. Generate toolpaths with chosen tools, feeds, and speeds in CNC machining.

4. Run a full simulation to check for collisions and verify motion.

5. Read the estimated cycle time for each tool and the total CNC machining time reported by the software.

Actual machine cycles are then measured and compared to the estimate. If the software consistently underestimates or overestimates CNC machining time by a certain percentage, a correction factor can be applied in future quotes. This approach helps align digital planning with real-world performance in CNC machining.

Once CNC machining time is understood and quantified, the next step is optimization. The goal is to reduce cycle time without sacrificing accuracy, surface finish, or tool life.

Key strategies to optimize CNC machining time:

- Enhance feeds and speeds: Using updated cutting data, high-performance tools, and modern feed-and-speed calculators allows higher material removal rates in CNC machining. Even modest increases in feed can accumulate into substantial time savings over many parts.

- Refine toolpaths: Advanced toolpath strategies such as high-efficiency milling, adaptive clearing, trochoidal milling, and constant-engagement paths enable stable high-speed CNC machining. These approaches reduce sudden load spikes and permit higher feeds and speeds.

- Minimize tool changes and setups: Combining operations on multi-axis machines, standardizing tooling, and designing modular fixtures all reduce non-cutting CNC machining time. Fewer setups also reduce variation and scrap risk.

- Group similar parts: When production planning allows, batching similar parts or families on the same setup spreads setup time and improves effective CNC machining time per unit. This is especially valuable for OEM customers requiring series production after prototype approval.

- Monitor and continuously improve: Collecting real cycle-time data and comparing it with estimates reveals where CNC machining time is lost. Continuous improvement programs can then focus on the largest sources of delay or inefficiency.

For a precision supplier like Shangchen, this optimization mindset enables fast lead times in rapid prototyping and competitive pricing in large-batch CNC machining.

CNC machining time is one of the central inputs to cost estimation and quotation. Machine hourly rate, operator costs, overhead, and tooling are all combined with CNC machining time to obtain a realistic unit price.

A simplified costing approach:

- Determine cutting and non-cutting CNC machining time per part.

- Multiply total time by the machine hourly rate to get machine cost.

- Add tooling costs, material cost, quality control, and overhead.

- Apply margin and any commercial terms required by OEM customers.

Accurate CNC machining time reduces the risk of under-quoting, which can erode margins, and over-quoting, which may push potential customers to competitors. It also enables transparent discussions about design modifications that can lower CNC machining time and total cost.

Engineers and purchasing managers who understand CNC machining time are better equipped to collaborate with manufacturing partners. A few practical guidelines help both sides work more efficiently together.

Helpful practices:

- Engage on design for manufacturability: Early discussions on radii, wall thickness, tolerances, and feature access often reduce CNC machining time in later stages.

- Share realistic quantity forecasts: Higher volumes justify deeper optimization and specialized fixturing to reduce CNC machining time per part.

- Accept justified adjustments: If a supplier shows that a feature or tolerance dramatically increases CNC machining time, revisiting the requirement can lead to a more balanced, cost-effective design.

- Request time-based breakdowns: When appropriate, asking for rough CNC machining time breakdowns between cutting, setup, and other operations helps clarify how a quote is constructed.

A manufacturing partner with strong CNC machining capabilities, multi-axis equipment, and in-house process engineering can help OEM clients manage this balance between performance, cost, and lead time.

CNC machining time is a combination of cutting and non-cutting elements that together determine how long a machine must run to produce each part. By starting from fundamental relationships between cutting length, feed rate, and spindle speed, engineers can calculate CNC machining time for milling, turning, and drilling operations with reasonable accuracy. When setup, tool changes, rapid moves, and auxiliary cycles are added, the result becomes a realistic CNC machining time suitable for quoting and production planning.

Modern CAM tools, time-estimation software, and machine monitoring systems make CNC machining time more transparent and easier to optimize. Through refined toolpaths, improved feeds and speeds, standardized tooling, and thoughtful fixture design, manufacturers can significantly reduce CNC machining time while maintaining strict quality standards. For global OEM customers, working with a supplier that understands and controls CNC machining time means more competitive pricing, reliable deliveries, and a stronger long-term partnership.

Basic CNC machining time is often calculated with T=L/Vf, where LL is the cutting length and Vf is the programmed feed rate. When using feed per revolution, the formula becomes T=L/(f×N), where ff is feed per revolution and N is spindle speed. This approach works well for many milling, turning, and drilling operations in CNC machining

Cutting time is the portion of CNC machining time during which the tool is actively removing material along the programmed toolpath. Cycle time, on the other hand, includes cutting time plus tool changes, rapid positioning, probing, dwell, and other auxiliary motions, representing the full machine-occupied time for a CNC machining cycle.

CAM-generated CNC machining time estimates are generally a good starting point but can differ from actual machine time because of acceleration limits, control behavior, and unmodeled events such as manual chip clearing or pauses. By comparing estimated and real CNC machining time on actual jobs and applying a correction factor, manufacturers can significantly improve the reliability of future time predictions.

Feeds and speeds directly affect material removal rate and therefore CNC machining time. Higher feed rates and optimized cutting speeds reduce machining time, provided that tool life, surface finish, and machine stability remain acceptable. Selecting appropriate chip load per tooth and surface speed for each material is essential to achieving efficient CNC machining and stable cycle times.

CNC machining time is a major component of manufacturing cost because it is tied to machine hourly rates, labor, energy, and tool wear. Accurate CNC machining time enables suppliers to build precise cost models, offer competitive quotes, and commit to realistic lead times, while OEM customers gain better visibility into how design choices influence pricing and delivery.

content is empty!

How Was Rapid Prototyping Implemented Into a Conditioning Program?

Top CNC Cutting Machine Manufacturers and Suppliers in Denmark

Top CNC Cutting Machine Manufacturers and Suppliers in Hungary

Top CNC Cutting Machine Manufacturers and Suppliers in Czech Republic

Top CNC Cutting Machine Manufacturers and Suppliers in Lithuania

Top CNC Cutting Machine Manufacturers and Suppliers in Ireland