Views: 222 Author: Amanda Publish Time: 2025-10-28 Origin: Site

Content Menu

● Understanding CNC Milling Services

● The Role of CNC Milling in Manufacturing Complex Parts

● The Benefits of 5-Axis CNC Milling Services

● Common Materials Used in CNC Milling Services

● From Prototype to Mass Production

● Enhancing Efficiency with Toolpath Optimization

● Quality Control and Inspection Process

● OEM and ODM CNC Milling Services at Shangchen

● Sustainability in CNC Milling Services

● Global Support and Logistics

● Future Trends in CNC Milling Services

● FAQ

>> (1) What industries use CNC Milling Services the most?

>> (2) What are your available machining capabilities?

>> (3) How are quality and tolerances ensured?

>> (4) What surface finishing options are available?

>> (5) Do you offer confidential OEM production?

CNC Milling Services have transformed modern manufacturing by allowing precision shaping of materials for prototypes, functional parts, and large-scale assemblies. From aerospace components to consumer electronics, CNC milling is the backbone of production for industries that demand accuracy and consistency.

At Shangchen (sc-rapidmanufacturing.com), we specialize in providing high-quality CNC Milling Services, combining advanced machinery, experienced technicians, and reliable quality control to serve global brand owners, wholesalers, and manufacturers. Our China-based facility integrates CNC machining, rapid prototyping, metal fabrication, and 3D printing, catering to industries seeking OEM and ODM production for a wide range of applications.

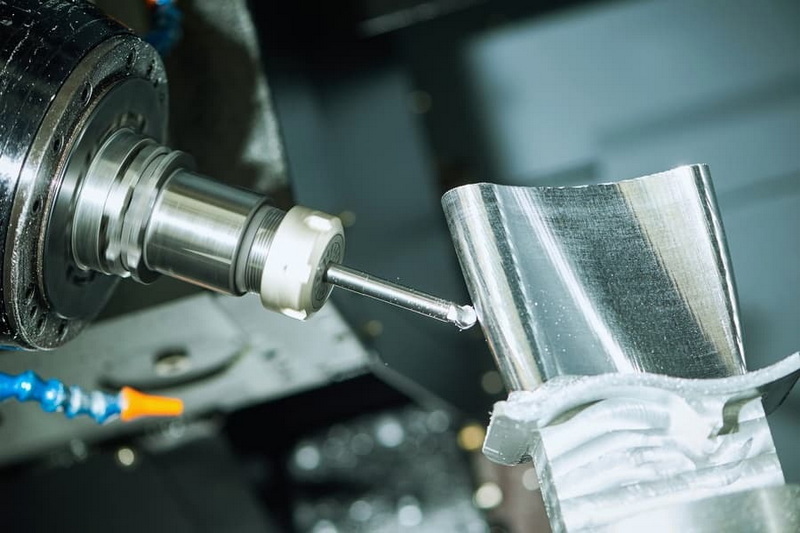

CNC milling, short for Computer Numerical Control milling, is a subtractive machining process that uses cutting tools to remove material from a solid block, forming precise shapes as guided by computer programs. This process allows the production of parts with tight tolerances and complicated geometries.

Unlike manual operations, CNC systems automatically control the motion of tools, ensuring consistency, speed, and repeatability. CNC Milling Services are widely applied in areas where precision, repeatability, and fast turnaround are essential, making them indispensable in both prototyping and full production runs.

Key advantages include:

- High repeatability and accuracy up to ±0.005 mm

- Compatibility with a variety of materials (metals, plastics, composites)

- Capability to produce intricate 3D geometries

- Integration with CAD/CAM software for design and optimization

- Cost efficiency for both low-volume and mass production

Complex parts often feature multiple surfaces, curved paths, and deep cavities that require advanced machining technology. CNC Milling Services enable engineers to design beyond traditional limitations, ensuring that even the most complicated designs can be fabricated with confidence.

At Shangchen, our CNC milling centers are equipped with both 3-axis and 5-axis machining capabilities, which allow simultaneous movement of the cutting tool across multiple axes. This feature enables us to reduce setup times, eliminate manual repositioning errors, and maintain cross-surface accuracy.

Industries such as automotive, aviation, robotics, and medical equipment depend heavily on these technologies to achieve mechanical performance, durability, and visual appeal. Whether you need one prototype or 10,000 finished parts, CNC milling delivers reliability and precision throughout every production stage.

5-axis machining is a major upgrade from conventional 3-axis operations. It allows the cutting tool to move on five separate axes, dramatically improving efficiency in producing complex shapes. For intricate components such as turbine blades, engine housings, and orthopedic implants, 5-axis CNC Milling Services provide unbeatable precision.

Key benefits of 5-axis technology include:

- Fewer setups, reducing production time

- Enhanced precision on curved surfaces

- Improved surface finish with reduced tool wear

- Faster machining of complex contours and undercuts

At Shangchen, our advanced 5-axis equipment enables simultaneous machining from all desired angles, guaranteeing perfect surface alignment and consistent geometry across custom-engineered parts.

Material selection is one of the most critical decisions in the CNC milling process. The right material ensures optimal performance, durability, and cost-effectiveness. Our CNC Milling Services at Shangchen can process an extensive list of materials, including:

- Aluminum: Lightweight, corrosion-resistant, ideal for automotive, aerospace, and consumer goods

- Stainless Steel: Offers strength and chemical resistance for mechanical and structural parts

- Carbon and Alloy Steels: Suitable for heavy-duty applications requiring high toughness

- Titanium: Exceptional strength-to-weight ratio, essential in aerospace and medical engineering

- Brass and Copper: Provide excellent electrical conductivity and machinability

- Engineering Plastics (ABS, POM, PEEK, Nylon): Perfect for prototypes, enclosures, and insulative parts

By combining extensive material knowledge with advanced tooling and cutting parameter control, our engineers ensure that each component meets performance and dimensional requirements.

CNC Milling Services serve a wide purpose, from prototype testing to continuous, large-scale production.

At Shangchen, our production workflow includes:

1. Engineering Review: Our team evaluates CAD or 3D models to ensure design manufacturability.

2. Process Planning: Defining ideal cutting tools, machine programs, and fixture setups.

3. Prototype Production: Initial samples are created for evaluation and refinement.

4. Batch Manufacturing: Once approved, parts transition into efficient serial production runs.

5. Final Quality Inspection: Each part undergoes detailed dimensional measurements and finishing checks.

This comprehensive service model ensures clients receive both rapid market delivery and long-term production consistency.

Toolpath optimization plays a vital role in improving CNC Milling Service efficiency. By using advanced CAM software and high-speed machining strategies, Shangchen reduces cycle time and tool wear while maintaining part accuracy.

Features such as adaptive clearing, trochoidal milling, and path smoothing help minimize mechanical stress and stabilize cutting dynamics. As a result, our CNC milling operations achieve better surface integrity and longer tool life, reducing costs for our international OEM partners.

Every machined part undergoes rigorous quality assurance checks to ensure conformance with client specifications and ISO quality standards. Shangchen employs:

- Coordinate Measuring Machines (CMM) for dimensional accuracy

- Precision gauges and laser measurement systems

- Surface roughness testing

- Hardness and material composition validations

We maintain a zero-defect manufacturing mindset, ensuring each client receives parts that pass global inspection standards and deliver consistent fit and performance.

Shangchen offers full-turnkey CNC milling solutions for overseas brands, wholesalers, and manufacturers. Whether our clients require small-quantity prototypes or full-production manufacturing, we handle every stage, including engineering consultation, material procurement, machining, polishing, assembly, and surface coating.

We provide:

- Aluminum housings for electronics

- Aerospace-grade titanium parts

- Automotive engine components

- Precision medical implants

- Industrial machine parts

Clients trust our factory because we combine technical precision, cost competitiveness, and clear communication throughout the entire process.

Modern manufacturing increasingly demands sustainable practices. Shangchen integrates resource-efficient processes at every step. We reduce material waste through optimized toolpath planning, recycle metal chips, and minimize energy consumption by using advanced, energy-efficient machinery.

Our focus on green manufacturing not only ensures environmental responsibility but also enhances overall production efficiency, aligning with the global movement toward sustainable supply chains.

To serve international clients efficiently, Shangchen maintains a flexible global logistics network. We provide quick shipping, custom packaging, and professional export documentation, ensuring seamless cross-border deliveries.

Our experience working with global clients helps us meet varied regional standards, including RoHS, REACH, and other compliance certifications. Whether you're based in North America, Europe, or Asia-Pacific, our CNC Milling Services deliver quality parts with reliable delivery timelines.

The CNC milling industry continues to evolve through digitalization and automation. Technological advancements such as AI-assisted programming, smart sensors, and real-time monitoring are revolutionizing how parts are designed and produced.

Emerging trends include:

- Integration of digital twins for predictive machining

- Use of hybrid CNC-3D printing systems

- Automation through robotic tool changers and smart fixtures

- Cloud-based manufacturing data management

At Shangchen, we are actively adopting these technologies to enhance production flexibility and achieve higher accuracy standards for our clients worldwide.

CNC Milling Services remain one of the most trusted manufacturing solutions for producing intricate, high-precision parts. By combining modern machinery, skilled technicians, and intelligent process control, Shangchen delivers consistent quality and cost-effective production for global OEMs.

Whether developing a new prototype or scaling toward mass production, our custom CNC milling capabilities guarantee superior performance across materials and complexity levels.

To start your next CNC milling project or request a quote, visit Shangchen at sc-rapidmanufacturing.com. Our engineering team is ready to support your project from concept to completion with professional guidance and full confidentiality.

Industries including aerospace, automotive, medical device manufacturing, robotics, and consumer electronics rely on CNC Milling Services due to their precision and repeatability.

Shangchen operates 3-axis, 4-axis, and 5-axis CNC milling centers, offering prototype through mass production manufacturing for metal and plastic parts.

Every project undergoes dimensional inspection via CMM machines and digital testing tools. Tolerances up to ±0.005 mm are achievable depending on material and geometry.

Available finishes include anodizing, polishing, powder coating, sandblasting, and electroplating based on part function and cosmetic requirements.

Yes. Shangchen provides full OEM and ODM CNC Milling Services under Non-Disclosure Agreements to protect customer designs and intellectual property.

content is empty!