Views: 222 Author: Amanda Publish Time: 2025-12-08 Origin: Site

Content Menu

● Shangchen: Your Rapid Prototyping Partner

● Why Rapid Prototyping Is Essential

● Key Benefits of Rapid Prototyping

>> Lower Development Risk and Cost

>> Better Design Quality and Performance

>> Increased Innovation and Flexibility

>> Closer Alignment with Manufacturing

● Rapid Prototyping Technologies Used by Shangchen

>> CNC Machining for Rapid Prototyping

>> Mold Fabrication and Pilot Tooling

● How Rapid Prototyping Supports Each Product Stage

>> Engineering Validation and Testing

>> Pre-Production and Market Validation

● Rapid Prototyping for Different Industries

● Why Overseas OEMs Choose Shangchen for Rapid Prototyping

● Using Visual and Multimedia Support in Rapid Prototyping Projects

● Best Practices for Working with Shangchen on Rapid Prototyping

● FAQ

>> 1. What is Rapid Prototyping in manufacturing?

>> 2. Why is Rapid Prototyping important for OEMs?

>> 3. How does Shangchen support Rapid Prototyping?

>> 4. Which projects benefit most from Rapid Prototyping?

>> 5. When should a company start Rapid Prototyping?

Rapid Prototyping is now a core strategy for any brand that wants faster innovation, lower risk, and more competitive products in global markets. For overseas OEMs, working with an integrated partner like Shangchen (sc-rapidmanufacturing.com) turns Rapid Prototyping from a cost center into a powerful growth engine.[1][2][3][4]

Shangchen (sc-rapidmanufacturing.com) is a China-based factory focused on Rapid Prototyping, CNC machining, precision batch production, CNC turning, sheet metal manufacturing, 3D printing, and mold production for global brands, wholesalers, and OEM manufacturers. By combining Rapid Prototyping and mass production under one roof, Shangchen helps customers move smoothly from concept validation to stable series production with consistent quality and shorter lead times.[3][4][5]

Shangchen provides a one-stop Rapid Prototyping workflow: early design review, material and process selection, prototype manufacturing, trial assembly, pilot runs, and full OEM production. Overseas customers benefit from engineering support, flexible order quantities, and responsive communication that supports fast iteration throughout the Rapid Prototyping cycle.[4][6][7][3]

Rapid Prototyping is an iterative product development approach that uses digital design and fast manufacturing technologies to quickly create physical or functional versions of a new product. Instead of waiting weeks or months for traditional tooling, Rapid Prototyping lets teams build and test multiple design versions in hours or days.[8][9][1]

Modern Rapid Prototyping integrates methods such as CNC machining, 3D printing, sheet metal fabrication, and soft tooling to produce parts that closely match final production in shape and performance. This allows design, engineering, marketing, and manufacturing teams to collaborate using real parts, not just drawings or simulations, which accelerates decision-making and de‑risks large investments.[2][9][10][8]

Rapid Prototyping also functions as a bridge between pure digital design and real-world performance. Instead of relying solely on simulation, teams can expose prototypes to real loads, environments, and users, revealing subtle issues that are hard to predict with software alone.[11][12][2][8]

Rapid Prototyping is important because it reduces time-to-market while improving product quality and reliability. Companies can detect design flaws, usability issues, and production risks earlier, when changes are faster and cheaper to implement.[13][14][1][2]

Rapid Prototyping also supports more innovative and user-centered products. Teams can explore bold ideas, test them with real users, and refine details before committing to tooling or high-volume manufacturing, which increases the chances of market success.[1][2][8][11]

In addition, Rapid Prototyping aligns technical decisions with business goals. Because prototypes can be evaluated by commercial teams as well as engineers, pricing strategies, feature sets, and positioning can be refined while the design is still flexible.[10][15][16][8]

Rapid Prototyping compresses development cycles by allowing teams to build, test, and revise physical models very quickly. Instead of long delays between design changes, engineers receive rapid feedback and can implement improvements almost in real time.[17][10][13][1]

This speed is critical in competitive industries where being first or early to market can secure market share and higher margins. Rapid Prototyping helps OEMs move from concept to launch in weeks or months instead of years.[14][18][2][1]

The ability to run parallel design paths is another advantage of Rapid Prototyping. Rather than committing to a single solution too early, teams can prototype multiple options and keep only the best-performing concept for final refinement.[8][10][17]

By exposing design and manufacturing issues early, Rapid Prototyping significantly reduces the likelihood of expensive modifications after tooling or product launch. Teams can verify fit, function, ergonomics, and performance before investing in molds, fixtures, and large material purchases.[9][15][13][14]

Rapid Prototyping also avoids unnecessary tooling for concepts that may not survive market testing. As a result, overall project risk is lower, cash flow is more predictable, and budgets are used on validated designs rather than rework.[15][19][2][11]

For complex systems, Rapid Prototyping allows step-by-step integration tests. Subsystems can be prototyped and validated independently before being combined, which reduces the risk of late-stage integration failures.[12][2][13]

With Rapid Prototyping, products go through more design iterations and more thorough testing, which naturally leads to higher quality. Engineers can validate critical dimensions, tolerance stacks, assembly behavior, and real-world loading conditions using prototype parts.[2][9][12][1]

Rapid Prototyping also enables more accurate user testing, because prototypes can closely mimic the final product's shape, weight, and interaction. This improves ergonomics, usability, and perceived quality before the product reaches customers.[20][9][11][8]

As feedback accumulates over multiple Rapid Prototyping cycles, the design converges toward a more robust solution with fewer weak points and more stable performance across different environments.[19][9]

Rapid Prototyping encourages experimentation, because the cost and time needed to test new ideas is relatively low. Designers can explore complex geometries, lightweight structures, and custom features that might be impractical or too risky with traditional methods.[9][1][2]

This flexible environment supports cross-functional collaboration and faster approval cycles. Stakeholders can physically handle Rapid Prototyping parts, understand trade-offs more clearly, and make confident decisions without waiting for final production samples.[16][10][17][8]

Rapid Prototyping also supports customization and product variants. Because design changes can be implemented and validated quickly, OEMs can offer tailored solutions for different markets or customers without starting each project from zero.[11][2][9]

When Rapid Prototyping is integrated with production technologies, prototypes become a rehearsal for mass manufacturing. Engineers can validate machinability, forming behavior, assembly sequences, and process parameters using real materials and equipment.[6][12][19]

This alignment reduces surprises during ramp-up and simplifies the transition from prototype to stable series production. OEMs gain more predictable yields, shorter ramp-up time, and less disruption in the supply chain.[3][4][6][15]

Because Rapid Prototyping uses similar or identical processes to mass production, design-for-manufacturing and design-for-assembly principles can be applied and verified early. That improves efficiency and helps maintain competitive production costs.[12][15][19][2]

Shangchen places Rapid Prototyping at the center of its OEM service model and combines several key technologies in one facility. This integrated approach allows customers to choose the optimal balance of speed, precision, and cost at each stage of development.[5][4][6][3]

CNC milling and CNC turning are core Rapid Prototyping processes at Shangchen, ideal for metal and engineering plastic parts that must match production-level accuracy. They support tight tolerances, stable surface finishes, and functional prototypes that can be used for performance testing, trial assembly, and low-volume production.[5][6][3][9]

For many OEM components, Rapid Prototyping with CNC machining is the fastest way to understand how a part will behave in its real operating environment. Parts can be produced from the same alloys or polymers planned for production, providing reliable data on strength, wear, and dimensional stability.[19][2][9][12]

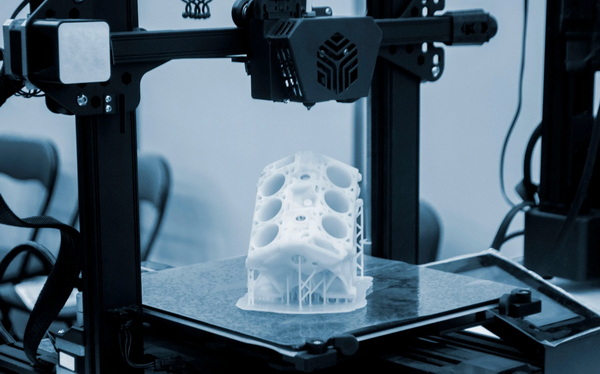

3D printing gives Shangchen the ability to produce complex shapes and lightweight structures rapidly without tooling. It is especially useful in early Rapid Prototyping stages, where speed, shape exploration, and design communication are more important than final mechanical properties.[1][2][3][9]

In later stages, more advanced 3D printing materials can support functional Rapid Prototyping for housings, fixtures, and low-load components. These additively manufactured parts help validate assembly geometry and user interaction while keeping costs manageable.[18][2][9][1]

For enclosures, brackets, frames, and structural components, Shangchen uses sheet metal manufacturing for Rapid Prototyping and bridge production. This makes it possible to verify bending, welding, and assembly operations before committing to stamping dies or automated lines.[6][3][12][19]

Rapid Prototyping with sheet metal helps optimize material thickness, reinforcement features, and joining methods early in the design. That leads to lighter, stronger structures and more efficient production setups.[2][6][12][19]

Shangchen also fabricates prototype molds and pilot tooling that connect Rapid Prototyping with mass production. Data and lessons from Rapid Prototyping feed directly into mold design and process settings, improving first-pass yield during series production.[4][3][6]

This approach allows OEMs to validate gating, cooling, cycle times, and dimensional consistency through small-batch trials before investing in long-life tools. As a result, the step from Rapid Prototyping to stable production becomes more predictable and less risky.[15][3][4][19]

In the early stages, Rapid Prototyping helps teams translate sketches and digital models into tangible parts for quick evaluation. Designers can compare multiple concepts side by side, review ergonomics, and align stakeholders around a shared physical reference.[17][20][8]

Rapid Prototyping at this phase reduces miscommunication and helps filter out weak concepts before significant resources are invested. This leads to a clearer roadmap and faster progress into detailed design.[10][16][8][11]

During engineering validation, Rapid Prototyping provides functional prototypes that allow teams to test assembly behavior, load resistance, thermal performance, and other critical parameters. These tests reveal design weaknesses, interference issues, or tolerance conflicts that CAD models alone might miss.[13][9][12]

Iterative Rapid Prototyping enables quick changes, repeated testing, and convergence on an optimal design. As a result, the final product is more reliable and compliant with performance specifications and regulatory requirements.[9][11][19][2]

Near launch, Rapid Prototyping helps generate small batches for pilot production, internal validation, and market testing. These pre-production units can be used for certification, customer evaluations, trade show demonstrations, and early sales activities.[14][11][2][9]

When an integrated partner like Shangchen manages both Rapid Prototyping and OEM manufacturing, the transition from these pilot runs to full production is much smoother. The same process knowledge, quality controls, and engineering team support the entire lifecycle, from first prototype to long-term supply.[3][4][6]

Different industries rely on Rapid Prototyping in distinct but complementary ways. Understanding these patterns helps OEMs plan their development strategy more effectively when cooperating with a partner like Shangchen.[5][19][2][3]

In consumer electronics, Rapid Prototyping is heavily used for enclosure design, thermal management, and human–machine interface optimization. Automotive and industrial equipment projects use Rapid Prototyping to validate structural components, brackets, and functional mechanisms under demanding conditions.[8][12][19][1]

Medical and healthcare products use Rapid Prototyping to refine ergonomics, safety features, and cleanability before regulatory submissions. Across all these sectors, Rapid Prototyping shortens feedback loops between clinical or field tests and design changes, enabling safer and more user-aligned outcomes.[11][2][9]

International brands and wholesalers benefit from Shangchen's combination of Rapid Prototyping technology, manufacturing depth, and export experience. The factory is structured to serve global OEM customers who need precision parts, complex assemblies, and long-term production partnerships.[4][6][3][5]

Key advantages for overseas clients include:

- One-stop Rapid Prototyping and OEM manufacturing for CNC, 3D printing, sheet metal, turning, and molds.[3][4]

- Engineering support that links Rapid Prototyping iterations directly to production-ready solutions.[5][3]

- Flexible order quantities, from one-off Rapid Prototyping parts to high-volume series production.[6][3]

- Experience with international quality expectations and export logistics for industrial and consumer products.[7][6]

For OEMs that rely on fast innovation cycles, Shangchen's Rapid Prototyping capability becomes a strategic resource, not just a vendor service.[7][4]

Effective Rapid Prototyping projects often use rich visual documentation, including detailed part views, exploded assembly views, and digital walkthroughs, to help cross-functional teams understand design intent. These visual assets reduce misunderstandings and support faster feedback loops between designers, engineers, and decision-makers.[16][20][17][8]

Many companies also rely on short demonstration clips that show prototypes in operation, such as mechanism movements, assembly steps, or stress tests. Combined with detailed stills of prototype parts from different angles, this multimedia approach makes Rapid Prototyping results easier to review remotely and speeds up approvals across global teams.[10][17][8][11]

To get the most value from Rapid Prototyping with Shangchen, OEMs can follow several practical steps. Clear communication and structured feedback make every iteration more effective and shorten the path to production.[16][4][8][3]

Recommended practices include:

- Provide clean CAD models, material preferences, and basic tolerance expectations at the start of the Rapid Prototyping project.[6][9]

- Share target cost levels, annual volume expectations, and any regulatory constraints so Shangchen can align Rapid Prototyping decisions with long-term manufacturing strategy.[15][4]

- Use each Rapid Prototyping round to focus on specific questions (fit, function, appearance, process feasibility) rather than trying to validate everything at once.[2][8]

- Document feedback with annotated visuals and, when possible, short clips showing how the prototype behaves in real use scenarios.[20][17]

Following these practices turns Rapid Prototyping into a structured, data-driven process rather than a series of isolated samples.[8][10]

Rapid Prototyping is important because it combines speed, flexibility, and technical depth to reduce risk, improve quality, and accelerate time-to-market. It allows brands and OEMs to validate designs, test manufacturing methods, and refine user experience before committing to expensive tooling and large production commitments.[14][1][9][2]

For overseas customers, partnering with Shangchen (sc-rapidmanufacturing.com) provides a complete Rapid Prototyping and manufacturing solution, from first concept to long-term OEM supply. By integrating Rapid Prototyping with CNC machining, 3D printing, sheet metal, turning, and mold production, Shangchen helps global clients turn ideas into high-quality products quickly and reliably.[4][3][6]

Rapid Prototyping in manufacturing is the use of fast, flexible processes such as CNC machining, 3D printing, and sheet metal fabrication to quickly produce sample parts for testing and validation. It helps teams evaluate design, function, and manufacturability before investing in full-scale production.[1][9][2][8]

Rapid Prototyping is important for OEMs because it shortens development cycles, reduces tooling risk, and improves product reliability. OEMs can test multiple design options, validate critical functions, and align with customer expectations while keeping costs and timelines under control.[13][11][14][2]

Shangchen supports Rapid Prototyping by offering CNC milling, CNC turning, precision batch production, sheet metal fabrication, industrial 3D printing, and prototype mold fabrication in one integrated factory. The team provides engineering support and OEM production capabilities so that successful prototypes can move directly into stable mass manufacturing.[3][4][5][6]

Projects with demanding performance requirements, complex geometries, or aggressive launch schedules benefit strongly from Rapid Prototyping. This includes consumer electronics, industrial equipment, automotive components, medical devices, and customized mechanical assemblies that need intensive testing before launch.[12][19][1][2]

A company should start Rapid Prototyping as early as possible, often immediately after initial concept selection and basic design modeling. Early prototypes reveal design gaps, user issues, and manufacturing challenges that are much harder and more expensive to fix later in the process.[17][9][10][8]

[1](https://www.stratasys.com/en/resources/blog/key-advantages-of-rapid-prototyping/)

[2](https://xometry.pro/en/articles/rapid-prototyping-manufacturing/)

[3](https://www.sc-rapidmanufacturing.com/what-is-rapid-prototyping-process.html)

[4](https://www.sc-rapidmanufacturing.com/what-is-rapid-prototyping-technology.html)

[5](https://www.sc-rapidmanufacturing.com/aboutus.html)

[6](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[7](https://www.sc-rapidmanufacturing.com)

[8](https://online.hbs.edu/blog/post/rapid-prototyping)

[9](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[10](https://www.sei.com/insights/article/achieving-faster-better-product-development-with-rapid-prototyping/)

[11](https://www.sur-seal.com/blog/health-and-safety-rapid-prototyping-benefits/)

[12](https://eriks.com/en/know-how-hub/blogs/rapid-prototyping/)

[13](https://breinerco.com/10-proven-benefits-of-rapid-prototyping/)

[14](https://prismier.com/8-benefits-of-rapid-prototype-manufacturing/)

[15](https://uptivemfg.com/cost-benefit-analysis-of-rapid-prototyping-maximizing-roi/)

[16](https://www.ignitec.com/insights/why-you-need-rapid-prototyping-solutions-for-hardware-innovation/)

[17](https://avidpd.com/prototyping/how-rapid-prototyping-with-3d-printing-is-transforming-product-development-at-every-stage/)

[18](https://parts-badger.com/top-7-benefits-of-rapid-prototyping/)

[19](https://www.rcoeng.com/blog/rapid-prototyping-the-future-of-manufacturing)

[20](https://maze.co/blog/rapid-prototyping/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal