Views: 222 Author: Amanda Publish Time: 2025-11-18 Origin: Site

Content Menu

● The Importance of Rapid Prototyping for Enterprises

>> Accelerating Product Development Cycles

>> Cost Effectiveness and Waste Minimization

>> Improving Design Accuracy and Functionality

>> Fostering Innovation and Creative Exploration

>> Enabling Customization and Small Batch Production

>> Mitigating Risks and Enhancing Market Responsiveness

● Industrial Applications of Rapid Prototyping

>> Aerospace and Automotive Sectors

>> Electronics and Consumer Products

● Integration with Other Manufacturing Technologies

>> Combined Use with CNC Machining

>> Additive Manufacturing for Complex Parts

>> Seamless Transition to Production

● FAQ

>> 1. What is rapid prototyping?

>> 2. How does rapid prototyping benefit enterprises?

>> 3. What rapid prototyping technologies are commonly used?

>> 4. Can rapid prototypes be used for functional testing?

>> 5. In which industries is rapid prototyping most impactful?

In an era of fierce global competition and rapidly evolving customer demands, enterprises require agile and efficient ways to develop new products. Rapid prototyping technology has emerged as a vital enabler for accelerating product innovation, reducing costs, and improving quality. By quickly transforming digital models into physical prototypes, this technology supports faster iterations, early testing, and seamless communication throughout the product development lifecycle. As a trusted factory specializing in rapid prototyping, CNC machining, 3D printing, precision batch production, and mold manufacturing, Shangchen provides comprehensive OEM solutions for international brands, wholesalers, and manufacturers. This article elaborates on why enterprises use rapid prototyping technology, highlighting its benefits, applications, and impact on modern manufacturing.

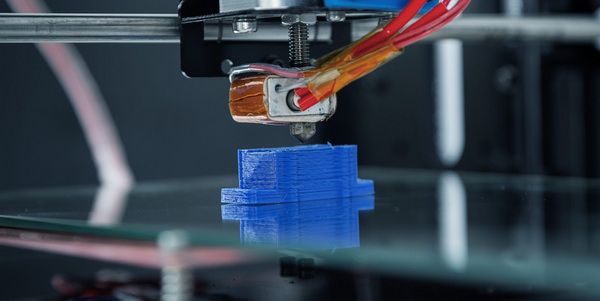

Rapid prototyping enables enterprises to drastically shorten their product development timeline. Traditional prototype development methods often take weeks or months due to tooling complexity and manual processes. In contrast, rapid prototyping technologies such as 3D printing and CNC machining can deliver initial prototypes within days or hours. This speeds up design validation, functional testing, and stakeholder feedback, facilitating multiple design iterations in a fraction of the usual time. Faster development cycles mean companies can launch products to market more quickly, crucial in industries where speed drives competitive advantage.

A significant advantage of rapid prototyping is the ability to identify design flaws and manufacturing challenges early in the development process. By validating concepts with physical models before mass production, enterprises avoid costly rework, tooling errors, and material waste. Additive manufacturing in rapid prototyping adds material only where needed, drastically reducing scrap compared to traditional subtractive methods. These savings extend to tooling and setup costs since rapid prototyping can produce complex geometries without specialized molds or dies.

Physical prototypes created through rapid prototyping provide accurate representations of the final product's form and function. Enterprises use these prototypes to test ergonomics, mechanical performance, and assembly feasibility. High-fidelity prototyping methods such as stereolithography (SLA), selective laser sintering (SLS), and CNC machining deliver detailed, dimensionally precise parts suitable for functional testing. This hands-on evaluation enhances quality assurance, ensuring products meet rigorous technical and regulatory standards prior to mass production.

Rapid prototyping encourages a continuous innovation mindset by enabling quick experimentation and testing of various design alternatives. Enterprises can explore unconventional ideas with minimal risk and cost, fostering creativity among design engineers and developers. The iterative feedback cycle afforded by rapid prototyping allows for rapid refinement and breakthrough solutions that may be impractical with slower, costlier traditional methods.

Rapid prototyping technology supports the growing demand for product customization and personalization. Enterprises can easily modify digital designs to produce bespoke prototypes without changing existing tooling or incurring prohibitive costs. This flexibility allows manufacturers to fulfill specialized customer requirements or release limited edition products swiftly. Furthermore, rapid prototyping facilitates efficient small batch or pilot production runs, ideal for market testing or niche applications.

Using rapid prototypes, enterprises can conduct real-world testing and gather customer feedback early, reducing the risk of product failure and recalls. Rapid iterations ensure that potential issues are addressed promptly, improving product acceptance and satisfaction. Additionally, rapid prototyping enables enterprises to quickly adapt to regulatory changes or emerging market trends, maintaining product relevance and competitiveness.

In aerospace and automotive industries, rapid prototyping is vital for developing and validating complex mechanical components. It enables form and fit testing of intricate parts, identification of stress points, and validation of aerodynamic properties. Customized tooling and jigs produced through rapid prototyping streamline production and quality control processes, offering significant time and cost benefits.

Rapid prototyping plays a transformative role in healthcare by supporting surgical planning, custom implant design, and medical device development. Using patient-specific 3D models derived from MRI or CT scans, surgeons can visualize anatomical complexities and improve surgical outcomes. Custom prosthetics and implants produced via rapid prototyping technologies significantly enhance patient-specific healthcare solutions.

Rapid prototyping facilitates the creation of ergonomic and aesthetically refined electronics by allowing quick testing of multiple design iterations. The technology supports the development of futuristic contours and intricate internal geometries that would be challenging to manufacture conventionally. Enterprises leverage rapid prototyping to accelerate innovation cycles in rapidly evolving consumer markets.

The footwear industry benefits from rapid prototyping by developing lightweight, durable, and highly customized shoe prototypes. Designers use 3D printing to translate creative concepts into tangible models, enabling quick adjustments to fit and comfort. This process reduces time to market and enhances product innovation.

Rapid prototyping is widely used to create master patterns, molds, and tooling components. Prototypes serve as templates for manufacturing molds, aiding in the rapid development of production tools. This approach reduces tooling lead times and expense, streamlining transition from design to manufacturing.

Enterprises often integrate rapid prototyping with CNC machining to produce high-precision prototypes. CNC machining complements additive manufacturing by offering superior material choices and tighter tolerances. This combination allows fabrication of functional prototypes with complex geometries and stringent mechanical properties.

3D printing techniques such as selective laser sintering, fused deposition modeling, and direct metal laser sintering enhance prototyping by enabling production of lightweight, complex parts not feasible with traditional methods. This capability supports innovative product designs with optimized performance characteristics.

Validated rapid prototypes facilitate smoother scale-up to batch production and mold manufacturing. Design adjustments and manufacturing parameters are refined ahead of large-scale fabrication, reducing errors and downtime. This integration ensures efficient production workflows and consistent product quality.

Rapid prototyping technology is revolutionizing manufacturing by empowering enterprises to innovate faster, reduce costs, and improve product quality. Its ability to accelerate development cycles, foster creativity, and support customization makes it indispensable in competitive global markets. By combining advanced prototyping with CNC machining and precision manufacturing, companies like Shangchen enable brands to swiftly transform ideas into market-ready products with reliability and efficiency. Embracing rapid prototyping is essential for enterprises seeking agility and excellence in the modern manufacturing landscape.

Rapid prototyping is a group of technologies and processes that quickly create physical models or prototypes from digital designs, enabling fast testing, validation, and iteration during product development.

It accelerates product development, reduces costs by identifying design flaws early, improves product quality through hands-on testing, fosters innovation, supports customization, and mitigates market risks.

Common technologies include 3D printing methods (SLA, SLS, FDM), CNC machining, vacuum casting, and direct metal laser sintering, each offering specific advantages depending on prototype requirements.

Yes, many prototypes produced can replicate the product's mechanical properties and performance enabling testing under simulated real-use conditions.

Rapid prototyping is widely used in aerospace, automotive, medical, electronics, footwear, fashion, and tooling industries where speed, precision, and innovation are critical.

[1](https://www.planetcompliance.com/regulatory-compliance/the-application-of-rapid-manufacturing-technologies/)

[2](https://xometry.pro/en/articles/rapid-prototyping-manufacturing/)

[3](https://www.rcoeng.com/blog/rapid-prototyping-the-future-of-manufacturing)

[4](https://www.scan2cad.com/blog/cad/rapid-prototyping/)

[5](https://geomiq.com/blog/rapid-prototyping-in-manufacturing-and-its-benefits/)

[6](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

[7](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[8](https://jiga.io/rapid-prototyping-definition/)

[9](https://www.makerverse.com/resources/insights-and-trends/the-guide-to-rapid-prototyping-with-additive-manufacturing/)

[10](https://en.wikipedia.org/wiki/Rapid_prototyping)

content is empty!