Views: 222 Author: Amanda Publish Time: 2025-11-21 Origin: Site

Content Menu

>> Complexity and Design Flexibility

>> Post-Processing and Finishing

● Practical Applications and Use Cases

● Environmental and Operational Considerations

● Integration of Both Technologies at Shangchen

● FAQ

>> 1. When is metal 3D printing more cost-effective than CNC machining?

>> 2. Does CNC machining waste more material compared to 3D printing?

>> 3. Can 3D printed parts match the precision and surface finish of CNC machined parts?

>> 4. How does production volume influence the choice between 3D printing and CNC machining?

>> 5. Are there limitations to the materials used in metal 3D printing compared to CNC machining?

In the evolving landscape of modern manufacturing, two cutting-edge technologies—metal 3D printing and CNC (Computer Numerical Control) machining—are integral to producing high-quality metal parts. Especially for companies like Shangchen, which provides rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold production, understanding the cost dynamics of these processes is crucial to optimize manufacturing strategies for foreign brands, wholesalers, and manufacturers. This article examines whether metal 3D printing is cheaper than CNC machining by analyzing cost factors, production volume impacts, complexity considerations, material efficiency, and applications.

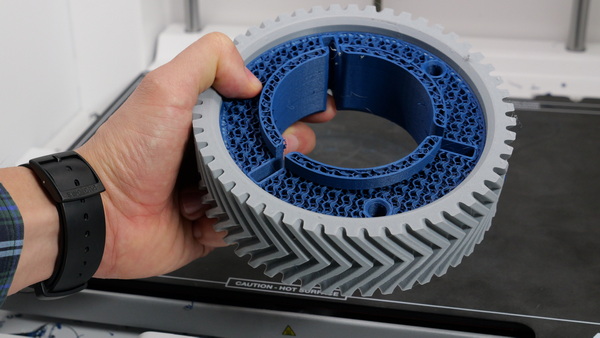

Metal 3D printing, a vital part of additive manufacturing, creates three-dimensional metal parts by depositing material layer by layer. It uses powdered metals fused by lasers or electron beams to form precise components directly from CAD models. This method excels at fabricating complex geometries, internal channels, and lightweight lattice structures that are economically or physically impossible to achieve through conventional subtractive methods like CNC machining. Additionally, 3D printing minimizes material waste by using only the material necessary for the part, enhancing sustainability and cost efficiency for small production runs or prototypes.

CNC machining is a well-established subtractive manufacturing process where computer-controlled tools carve parts from solid metal blocks. Known for delivering high dimensional accuracy, smooth surface finishes, and excellent mechanical properties, CNC is widely used for medium to large production volumes. However, its subtractive nature means more material waste as excess metal is cut away, and the process tends to involve higher setup and tooling costs, especially for parts with complex geometries.

Metal 3D printing eliminates the need for specialized tooling, fixtures, or molds, leading to significantly lower upfront costs. This setup efficiency makes 3D printing particularly cost-effective for prototyping and low-volume customized parts. On the contrary, CNC machining requires extensive fixture, tooling, and programming setup, resulting in high initial investment. These setup costs are amortized over large production volumes, making CNC more economical for scale.

3D printing is an additive process utilizing precise amounts of metal powder, which greatly decreases material waste compared to CNC's subtractive technique that scraps material during cutting. This advantage becomes more pronounced when using expensive metals or producing intricate designs with internal structures.

For low to medium production volumes, metal 3D printing generally offers cost savings due to reduced setup and ability to manufacture complex parts without additional expense. However, as production volumes increase, CNC machining becomes more cost-effective due to faster cycle times and amortization of tooling costs per unit.

3D printing allows for intricate, complex geometries including undercuts, internal channels, and lattices without added cost, which would otherwise increase CNC machining expenses substantially or be impossible altogether. Conversely, CNC machining costs rise with complexity as each additional feature requires more tooling, programming, and machining time.

Metal 3D printed parts often require post-processing such as machining, polishing, or heat treatment to meet final tolerance and surface finish requirements. CNC machining typically produces parts closer to final specifications directly from the machine, though some secondary finishing may still be needed.

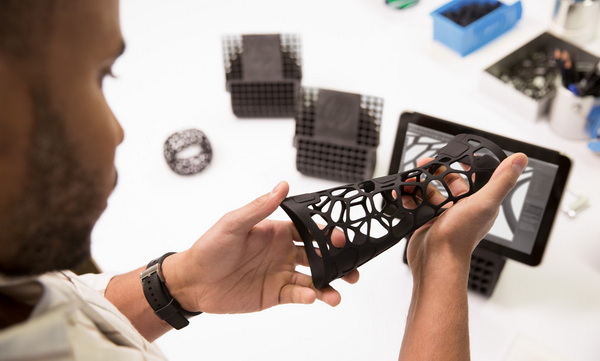

- 3D Printing Applications: Rapid prototyping, complex aerospace components, customized medical implants, and low-volume production where complexity, customization, and quick iterations are paramount.

- CNC Machining Applications: High-volume automotive parts, precision housings, shafts, and components requiring tight tolerances and excellent surface finishes.

3D printing generally consumes less energy and produces less metal waste, contributing to greener manufacturing. However, the machines themselves are energy-intensive, and machine acquisition costs can be high. CNC machining, while energy-intensive and wasteful, benefits from mature automation, wide material choice, and scalability.

Shangchen demonstrates an integrated manufacturing approach by offering both 3D printing and CNC machining, allowing clients to leverage the strengths of each method depending on project needs. This hybrid strategy enables optimized production schedules, cost-efficiency, and quality assurance.

Metal 3D printing is usually cheaper than CNC machining for low-volume, highly complex, or customized metal parts due to lower setup costs and efficient material usage. CNC machining becomes more economical with higher production volumes and simpler geometries due to amortized tooling costs and faster production speeds. Selecting the optimal method hinges on the specific requirements of volume, complexity, material, and delivery time. Combining both technologies often achieves the best balance of cost, quality, and performance for sophisticated manufacturing needs.

Metal 3D printing is more cost-effective for low-volume production, rapid prototyping, and parts with complex geometries or internal features that are difficult to machine.

Yes. CNC machining is subtractive, cutting away material from a solid block and generating more waste, whereas metal 3D printing is additive and uses only the material needed.

While CNC machining generally delivers higher precision and superior surface finishing, advances in 3D printing technology coupled with post-processing make it suitable for many functional applications.

3D printing is ideal for small to medium runs due to low setup costs, while CNC machining is more economical for large-scale production where tooling costs are spread over many units.

Yes. CNC machining can work with a broader range of metals, whereas 3D printing is often limited to specific metal powders and requires specialized handling.

[1](https://www.makerverse.com/resources/cnc-vs-metal-3d-printing-how-to-compare-costs-accurately/)

[2](https://cncmachines.com/cost-comparison-cnc-machining-vs-3d-printing)

[3](https://finnovationpd.com/blog/3d-printing-vs-cnc-machining-which-is-most-cost-effective)

[4](https://www.empiregroupusa.com/blog/cnc-machining-vs-3d-printing-for-prototyping-benefits-costs)

[5](https://www.thesteelprinters.com/news/metal-3d-printing-vs-casting-vs-cnc-which-is-better)

[6](https://ultimaker.com/learn/3d-printing-vs-cnc-comparing-additive-and-subtractive-manufacturing/)

[7](https://www.3deo.co/metal-3d-printing/the-economics-of-cnc-milling-versus-3d-metal-printing/)

[8](https://www.reddit.com/r/hobbycnc/comments/u6miw2/cnc_machining_vs_3d_printing_material_cost/)

[9](https://www.materialise.com/en/inspiration/articles/metal-3d-printing-vs-cnc-machining)

[10](https://www.youtube.com/watch?v=GG7DlSw-DoM)

content is empty!