Views: 222 Author: Amanda Publish Time: 2025-11-20 Origin: Site

Content Menu

● Understanding the Basics: CNC Machining and 3D Printing

● Can CNC Machines Perform 3D Printing?

● Advantages of Combining CNC Machining and 3D Printing

● How Hybrid Manufacturing Works

● Technologies and Software for Integration

● Practical Tips for Manufacturers

● Advanced Hybrid Manufacturing Machines

● Industry Trends and Future Outlook

● FAQ

>> 1. Can CNC machines be converted to perform 3D printing?

>> 2. What materials work well with combined CNC and 3D printing processes?

>> 3. Are hybrid CNC and 3D printing processes cost-effective?

>> 4. Which industries benefit most from hybrid manufacturing?

>> 5. How is precision maintained when integrating 3D printing and CNC machining?

In today's advanced manufacturing landscape, 3D printing and CNC machining are two powerful and distinctly different technologies, each with unique strengths. CNC (Computer Numerical Control) machines excel at subtractive manufacturing, precisely cutting and shaping materials by removing excess. In contrast, 3D printing, or additive manufacturing, builds parts layer by layer, enabling intricate geometric designs unattainable by traditional machining. While CNC machines are not typically used for 3D printing, the convergence of these technologies has introduced hybrid manufacturing solutions that integrate CNC machining with 3D printing. This article explores how CNC and 3D printing technologies intersect, hybrid manufacturing workflows, applications, advantages, and practical insights to help manufacturers leverage these processes effectively.

At their core, CNC machining and 3D printing differ fundamentally in approach:

- CNC Machining: A subtractive process where computer-controlled tools such as mills, lathes, or routers carve, cut, or drill material—metals, plastics, or composites—from a solid block or workpiece. CNC machining delivers exceptional precision, surface finish, and tight tolerances, making it ideal for functional, high-quality parts.

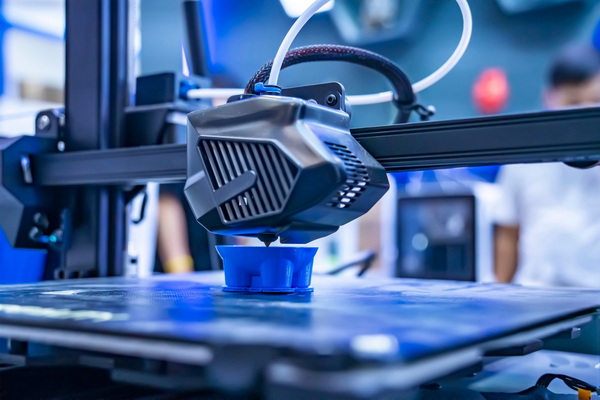

- 3D Printing: An additive manufacturing process that fabricates parts by depositing material layer by layer, based on digital 3D CAD models. Materials can include plastics, resins, metals, and composites. 3D printing excels at creating complex internal geometries, lightweight lattice structures, and customized components with design freedom beyond traditional machining constraints.

The processes complement rather than replace one another, where 3D printing enables rapid prototyping and complex shapes, and CNC machining ensures precision and finish quality.

CNC machines as they conventionally operate do not "print" but remove material. However, there are emerging interactions between CNC machining and 3D printing in two primary forms:

- Hybrid Manufacturing Machines: These advanced systems combine additive and subtractive manufacturing capabilities within the same machine. The machine can build up parts additively via 3D printing and subsequently machine them to achieve precise tolerances without moving the part between separate machines. This seamless integration reduces setup time and enhances accuracy.

- Sequential Integration: Commonly, parts are first fabricated by 3D printing near to their final shape (near-net-shape) and then transferred to a CNC machine for finishing processes—milling, drilling, threading—to achieve required dimensional accuracy and surface finish quality.

Hybrid approaches that integrate or sequence CNC machining and 3D printing bring significant benefits:

- Higher Precision: While 3D printers produce complex forms, typical tolerance is around 0.1 mm. CNC machines can refine parts to tolerances as tight as 0.025 mm, essential for functional and high-performance components.

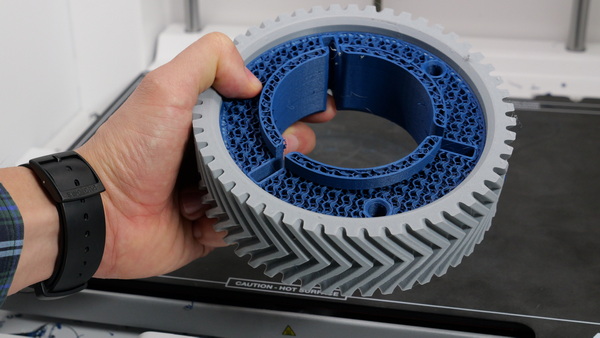

- Complex and Custom Geometries: 3D printing facilitates generation of internal channels, undercuts, and lattice designs impossible with CNC machining alone.

- Material Efficiency and Cost Savings: Additive manufacturing deposits material only where needed, minimizing waste. CNC finishing then removes minimal material for precise shaping.

- Faster Prototyping and Production: Rapid iteration through 3D printed prototypes combined with precise CNC finishing accelerates product development cycles.

- Reduced Handling and Setup Errors: Hybrid machines or integrated workflows reduce the need to reposition parts between processes, improving dimensional consistency.

Hybrid manufacturing blends the advantages of both technologies into optimized production workflows:

1. Design: Engineers plan parts by defining features best manufactured additively vs subtractively.

2. Additive Phase: Parts are 3D printed layer by layer, creating near-net-shape components with complex geometry.

3. Subtractive Phase: Without removing the part, CNC machining refines critical surfaces, holes, threads, and finishes to exact specifications.

4. Quality Assurance: Final inspection verifies compliance with tolerance and surface requirements.

Hybrid manufacturing utilizing CNC and 3D printing proves invaluable across sectors:

- Aerospace: Lightweight, durable parts with complex internal passages printed, then machined for tight tolerances and finish.

- Automotive: Engine components and customized brackets manufactured affordably with complex shapes and precise interfaces.

- Medical Devices: Patient-specific implants and surgical tools requiring intricate internal structures and biocompatible surface finishes.

- Industrial Prototyping: Functional prototypes with rapid turnaround, tested for fit, form, and function with machined critical dimensions.

- Tooling and Fixtures: 3D printed jigs or assembly aids used alongside CNC machining to increase manufacturing efficiency and accuracy.

The integration hinges on advanced software and machine control:

- CAD/CAM Platforms: Programs like Autodesk Fusion 360 and SolidWorks generate toolpaths for both 3D printers and CNC machines, enabling seamless transition between additive and subtractive steps.

- Machine Controllers: Hybrid systems feature controllers capable of managing both printing and machining actions within hybrid equipment.

- Slicing Software: Specialized software prepares 3D models for printing with consideration of downstream machining needs.

Manufacturers seeking to leverage hybrid CNC and 3D printing integration should consider:

- Material Selection: Use materials compatible with both additive and subtractive processes, e.g., specific metals or engineering plastics.

- Design for Hybrid Manufacturing: Incorporate consideration of which features will be printed and which machined, optimizing for performance and cost.

- Fixture Design: Ensure robust fixturing and registration points to maintain part alignment through both manufacturing phases.

- Support Structures and Post-Processing: Plan for removing printing supports and minimizing deformation before CNC finishing.

- Leverage Multi-Axis Machining: Use multi-axis CNC machines to access complex surfaces and features after printing.

Several manufacturers now offer hybrid machines combining metal 3D printing with CNC machining tools. These hybrid units:

- Reduce investment compared to buying separate machines.

- Save floor space and decrease energy consumption.

- Allow in-situ repair of worn parts by adding material and machining for restoration.

- Support large-scale, complex components without size limitations.

Such machines increasingly enable manufacturers to innovate on part design, reduce lead times, and lower costs.

The fusion of CNC machining and 3D printing represents a transformative trend:

- Businesses adopting hybrid manufacturing improve production speed, accuracy, and cost-effectiveness.

- Material science advances expand options for compatible hybrid manufacturing materials.

- Smart manufacturing integration and real-time process monitoring optimize workflows.

- Hybrid techniques are projected to dominate prototyping, low to medium volume production, and specialized manufacturing.

For companies like Shangchen providing rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production, mastering this hybrid synergy unlocks competitive advantages in custom OEM services for global brands.

CNC machines do not perform additive manufacturing directly but when combined with 3D printing in hybrid or sequential workflows, they revolutionize manufacturing possibilities. The blend of CNC machining's precision with the complex geometry capabilities of 3D printing enables products with unprecedented quality, functionality, and customization. This synergy accelerates prototyping, reduces costs, and boosts efficiency across industries including aerospace, automotive, medical, and tooling. For manufacturers, embracing this integrated approach offers clear pathways to innovate and meet ever-evolving market demands with confidence.

Traditional CNC machines are designed for subtractive processes and cannot directly perform 3D printing. However, some hybrid machines or retrofit kits can add additive functions to CNC equipment, allowing combined manufacturing capabilities.

Materials such as metals (aluminum, stainless steel), engineering plastics, composites, and specialized polymers compatible with both printing and machining yield optimal results in hybrid workflows.

Yes, reducing material waste, minimizing handling, and shortening lead times through combined processes improve cost-efficiency, especially for complex, low-volume, or customized parts.

Hybrid manufacturing is invaluable in aerospace, automotive, medical device manufacturing, industrial tooling, and rapid prototyping sectors that demand precision and design flexibility.

Maintaining precise registration using fixtures, reference points, integrated CAD/CAM workflows, and compatible materials ensures dimensional accuracy when moving from 3D printing to CNC machining.

[1](https://amfg.ai/2023/11/06/combine-3d-printing-and-cnc-machining/)

[2](https://www.schuettemetals.com/blog/cnc-machining-3d-printing-evolution)

[3](https://bigrep.com/posts/cnc-or-3d-printing/)

[4](https://www.pcbway.com/blog/CNC_Machining/Hybrid_Manufacturing_Technology_Combining_3D_Printing_and_CNC_Machining_d06a3493.html)

[5](https://aipprecision.com/medical-machined-components-why-cnc-3d-printing-outperforms-traditional-methods/)

[6](https://meltio3d.com/3d-printing-cnc/)

[7](https://ultimaker.com/learn/applications-of-3d-printing-in-manufacturing/)

[8](https://phillipscorp.com/india/combining-additive-and-cnc-hybrid-3d-solutions/)

[9](https://all3dp.com/1/3d-printing-cnc-guide-to-hybrid-additive-subtractive-manufacturing/)

[10](https://3dgence.com/america/3dnews/10-applications-of-industrial-3d-printer/)

content is empty!