Views: 222 Author: Amanda Publish Time: 2025-11-20 Origin: Site

Content Menu

● Key Differences Between CNC Machining and 3D Printing

>> Material Compatibility and Strength

>> Precision and Surface Finish

>> Production Speed and Scalability

>> Operator Skill and Equipment

● Integrating CNC Machining and 3D Printing in Manufacturing

● FAQ

>> 1. What materials can be used in 3D printing and CNC machining?

>> 2. Which process is faster for prototyping?

>> 3. Can 3D printed parts replace CNC machined parts for functional use?

>> 4. How do surface finishes compare between the two?

>> 5. Is CNC machining more expensive than 3D printing?

In the rapidly evolving manufacturing landscape, both 3D printing and CNC machining have become essential technologies for rapid prototyping, precision batch production, and OEM manufacturing services. Each offers unique advantages, processes, materials compatibility, and cost implications. This article provides a comprehensive, detailed comparison between CNC machining and 3D printing, emphasizing their differences, strengths, limitations, and ideal applications.

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where material is precisely removed from a solid block (metal, plastic, or composite) using computer-controlled cutting tools. Highly accurate and repeatable, CNC machining excels at creating parts with tight tolerances and excellent surface finishes. The process is well-suited for producing durable, fully functional components from a diverse range of engineering-grade materials including aluminum, stainless steel, titanium, plastics, and more.

The process begins with designing a 3D model in CAD (Computer-Aided Design) software. The CAM (Computer-Aided Manufacturing) software then generates the tool paths that define the machining operations. Skilled operators oversee the programming and execution, ensuring dimensional precision through careful control of cutting speeds, feeds, and tool choices.

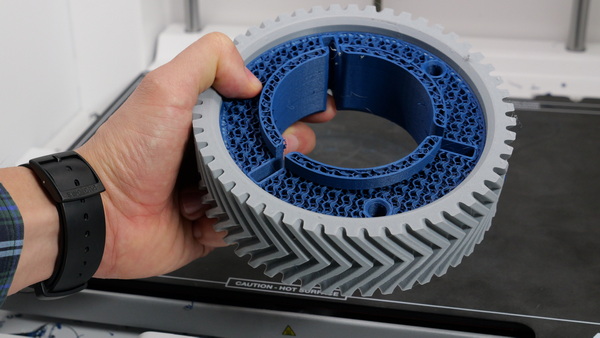

3D printing, or additive manufacturing, builds parts layer by layer from digital models by depositing or solidifying material. Unlike CNC machining, which removes material, 3D printing adds material only where needed, enabling production of highly complex geometries and internal structures that are impossible or costly to achieve via traditional machining.

3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and others. These enable usage of plastic resins, thermoplastics, and some metals — albeit often with different structural properties compared to wrought materials used in CNC machining. 3D printing is particularly advantageous for rapid prototyping, custom or low-volume parts, and new product development cycles where design changes and speed matter most.

CNC machining can work with a broad spectrum of fully dense materials preserving their inherent mechanical properties. Materials processed through CNC are typically stronger and more durable since they are not altered structurally by the manufacturing process.

3D printing materials, while expanding in variety, generally exhibit lower mechanical strength compared to machined materials because of layer adhesion issues and sometimes porous or composite-like structures. Metal 3D printing is improving, but still often requires post-processing to reach mechanical standards comparable to CNC parts.

CNC machining offers superior precision, with tolerances as tight as ±0.005 mm achievable. This is essential when parts require exact fit and finish. The surface finish is highly smooth and can often meet final-use requirements directly without additional finishing.

3D printing accuracy varies across technologies and materials but is generally around ±0.1 to 0.3 mm for most processes. The layered build results in a stepped texture that may necessitate post-processing like sanding or chemical smoothing to improve surface quality.

3D printing shines in producing complex shapes rapidly with minimal setup — ideal for prototyping and low volume production. However, the layer-by-layer construction can be time-consuming for larger parts.

CNC machining often requires setup time (programming, fixturing), but once running, material removal can be very fast, especially for large volumes. CNC is therefore more scalable and cost-effective when producing medium to high volumes of consistent parts.

3D printing offers unmatched freedom in design, supporting organic shapes, hollow parts, and internal channels that CNC tools cannot access.

CNC machining is constrained by tool size, access, and the need to physically remove material. Complex internal geometries may be impossible or require multiple setups and additional assembly.

3D printing generally has a lower initial cost with minimal tooling investment. This makes it economical for prototypes and small batches but less so at scale since each part takes roughly the same print time.

Conversely, CNC machining has higher setup and tooling costs but benefits from economies of scale. For high volumes, CNC becomes the more cost-effective option per part.

3D printing equipment is often easier to operate with minimal training required. The digital workflow allows faster iterations.

CNC machining requires highly skilled operators, experienced in programming, tooling, and machine operation. The machines tend to be larger and more complex.

- CNC Machining is preferred for industry applications requiring precise mechanical performance including aerospace components, automotive parts, medical devices, and tooling where strength, tight tolerances, and surface finish are paramount.

- 3D Printing is ideal for rapid prototyping, custom medical implants, complex architectural models, and tooling prototypes. It is pivotal in early design validation and short-run or one-off production.

Modern manufacturing pipelines benefit from combining these technologies. For instance, initial prototypes can be rapidly 3D printed for form and fit testing, allowing quick design refinements. Upon approval, CNC machining can be used for functional parts requiring full strength and finish. This hybrid approach leverages the speed and flexibility of 3D printing with the precision and material properties of CNC machining.

At Shangchen, we expertly provide both CNC machining and 3D printing services, enabling comprehensive OEM manufacturing solutions that meet diverse client needs— from rapid prototyping to precision batch production.

Both CNC machining and 3D printing are indispensable manufacturing technologies with distinct advantages suited to different stages and needs of production. CNC machining delivers exceptional precision, surface finish, and material strength ideal for functional, high-volume parts. In contrast, 3D printing excels in design complexity, rapid iteration, and cost-effective prototyping for low-volume or custom components. A strategic combination of these methods fosters optimized manufacturing workflows, increased innovation, and cost-effective production.

3D printing materials commonly include various plastics, resins, and some metals, with mechanical properties generally lower than their traditionally manufactured counterparts. CNC machining supports a wide variety of materials including metals (e.g., aluminum, steel, titanium), plastics, and composites, retaining full engineered properties.

3D printing is usually faster because it requires minimal setup and directly builds parts from CAD files. CNC machining requires programming and tooling setup but can be faster for multiple identical parts once running.

While 3D printed parts are useful for prototypes and complex shapes, they usually cannot match the strength, precision, and durability of CNC machined parts required in critical functional applications.

CNC machined parts have a smooth, polished finish suitable for immediate use. 3D printed parts tend to have a layered surface that often needs post-processing to improve texture and appearance.

CNC machining generally has higher upfront costs and requires skilled labor, making it less economical for one-offs or small runs. However, for higher volumes, CNC machining becomes more cost-effective due to faster per-part production and material efficiency.

[1](https://www.xometry.com/resources/3d-printing/3d-printing-vs-cnc-machining/)

[2](https://ultimaker.com/learn/3d-printing-vs-cnc-comparing-additive-and-subtractive-manufacturing/)

[3](https://www.americanmicroinc.com/resources/cnc-machining-3d-printing/)

[4](https://www.hubs.com/knowledge-base/3d-printing-vs-cnc-machining/)

[5](https://jlc3dp.com/blog/3d-printing-vs-cnc-machining)

[6](https://xometry.pro/wp-content/uploads/2024/04/EN-3d-printing-vs-cnc-machining.pdf)

[7](https://www.reddit.com/r/hobbycnc/comments/vabew6/3d_printing_vs_cnc_machine/)

[8](https://www.raise3d.com/blog/comparing-cnc-machining-and-fff-3d-printing/)

[9](https://xometry.pro/en/articles/cnc-machining-vs-3d-printing/)

[10](https://www.materialise.com/en/inspiration/articles/metal-3d-printing-vs-cnc-machining)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam