Views: 222 Author: Amanda Publish Time: 2025-11-01 Origin: Site

Content Menu

● What is ISO Certification and Why It Matters for CNC Milling

● Why ISO-Certified CNC Milling Enhances Quality and Reliability

● What CNC Milling Services Typically Include

● Why Choose a China-Based ISO-Certified CNC Milling Partner

● What to Look for in an ISO-Certified CNC Milling Partner

● Maximizing Value Through a Strategic Partnership

● The Integrated Path: From Prototype to Production

● Case for Quality, Compliance, and Risk Management

● Standout Considerations for OEM Partnerships

● Accessibility and Content Freshness

● FAQ

>> 1. What does ISO certification mean for CNC milling quality?

>> 2. How can ISO-certified CNC milling reduce lead times?

>> 3. Why is traceability important in CNC milling projects?

>> 4. What should I verify when evaluating an ISO-certified CNC milling partner?

>> 5. How does a partner integrate CNC milling with other manufacturing services?

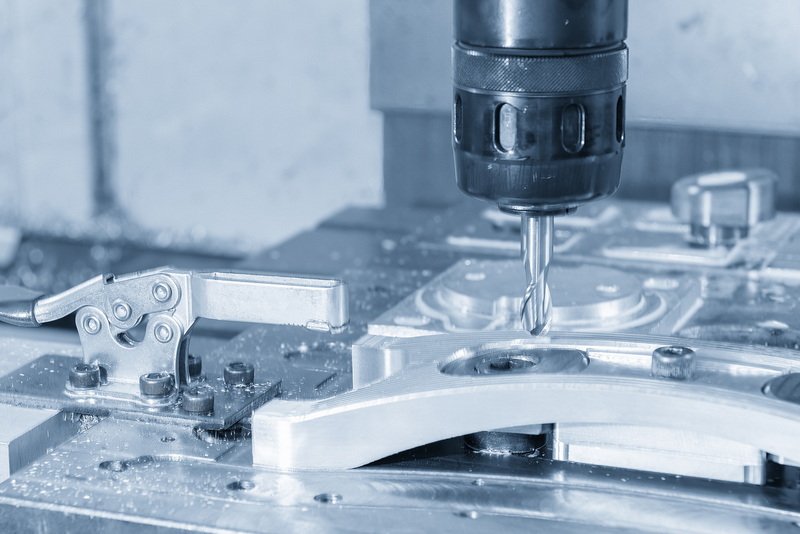

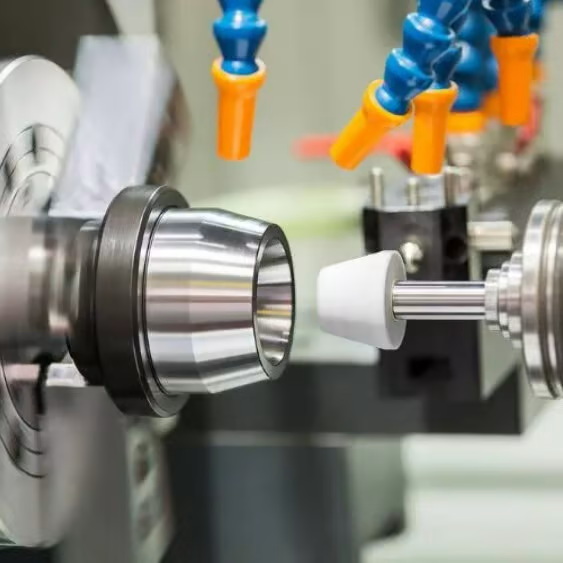

ISO-certified CNC milling manufacturers deliver consistent quality, traceability, and process control across complex components and high-volume runs. For international brand owners, wholesalers, and manufacturers, partnering with an ISO-accredited facility means reduced risk, accelerated time-to-market, and a reliable supply chain for precision parts. This article explores why ISO certification matters for CNC Milling Services, the value proposition of a China-based partner, and practical considerations for collaboration, tooling, and production scale. Throughout, the focus remains on CNC Milling Services, with clear implications for rapid prototyping, tooling, sheet metal, 3D printing interfaces, and mold production as part of an integrated manufacturing solution.

ISO certifications (such as ISO 9001 for quality management) establish a worldwide standard for managing processes, measuring performance, and continuously improving product quality. For CNC milling, this translates to documented work instructions, calibrated tooling, traceable materials, and rigorous inspection regimes. Brands seeking international partnerships often prioritize ISO-certified suppliers to ensure consistency across multiple lots and geographies. This reliability underpins confidence in long-term supplier relationships and reduces audit-related friction for customers and distributors. An ISO-certified environment supports standardized work flow, risk mitigation, and customer-centric metrics—on-time delivery, first-pass yield, and defect rates. When a factory operates under a validated Quality Management System, customers can expect reproducible results regardless of batch size, whether prototyping or mass production. The certification also signals commitment to continuous improvement, a critical factor for brands expanding into new markets or needing strict regulatory alignment.

- Precision and repeatability: CNC milling relies on rigid tolerance control and consistent tool paths. ISO-compliant practices ensure machine calibration, tool wear monitoring, and standardized fixturing, translating to components that meet stringent dimensional tolerances across batches. This is vital for brand components that require interchangeability in assembly-line environments.

- Process visibility and traceability: ISO standards require complete traceability of materials, lot numbers, machine settings, and inspection records. For aerospace, automotive, medical devices, or consumer electronics, such traceability supports regulatory compliance and after-sales service.

- Process optimization and cost control: ISO frameworks encourage data-driven decision-making, root-cause analysis for defects, and preventive maintenance scheduling. The result is fewer unplanned downtimes, better material yield, and lower total cost per part, especially valuable in high-mix/low-to-mid-volume scenarios typical of rapid prototyping and early-stage production.

- Prototype and rapid prototyping: Fast-turnaround milling of plastic and metal prototypes to validate form, fit, and function before committing to tooling or molds. This stage benefits from tight lead times, design for manufacturability (DFM) feedback, and parallel development with injection molding or 3D printing routes.

- Low-, mid-, and high-volume production: CNC milling scales from one-off parts to tens of thousands, with robust setup plans, fixture libraries, and standard operating procedures to ensure unit-to-unit consistency. ISO-certified plants emphasize process stability and capacity planning to meet evolving demand.

- Complex geometries and material versatility: The ability to machine advanced alloys, aluminum, stainless steel, plastics, and composites enables design freedom for intricate features, pockets, threads, and contouring not possible with manual methods.

- Secondary operations integration: Many ISO-certified mills coordinate with finishing, heat treatment, plating, coating, and surface finishing partners to deliver ready-to-assemble components, reducing the need for multiple supplier handoffs.

- Strategic manufacturing hub with scale: China hosts a large ecosystem of CNC machining capabilities, enabling competitive lead times, favorable cost structures, and the capacity to support rapid prototyping, small-to-mid-volume production, and bulk manufacturing for global brands. ISO certification adds the required assurances for international buyers concerned about supply chain reliability and documentation.

- Comprehensive service ecosystem: A capable CNC facility often offers ancillary services such as sheet metal fabrication, laser cutting, stamping, 3D printing, injection molding, and tooling design, creating a one-stop shop for product development and production. This integrated approach reduces project management overhead and accelerates time-to-market.

- Proven export readiness: Reputable ISO-certified manufacturers in this sector maintain export-ready documentation, packaging, and compliance alignment for overseas customers, facilitating smooth customs clearance and import audits in target markets.

- Certification scope and validity: Verify the exact ISO standard(s) held (e.g., ISO 9001, ISO 14001 for environmental management, IATF 16949 for automotive, etc.), the scope of certification (which processes and facilities are covered), and the validity period. Confirm recent surveillance audits and corrective action closure to gauge ongoing compliance.

- Quality management practices: Look for documented procedures for geometrical dimensioning and tolerancing (GD&T), first article inspection (FAI), in-process monitoring, post-process inspection data, and a clear non-conformance handling workflow.

- Equipment readiness and capability: Modern CNC milling centers with high-speed spindles, multi-axis capabilities, probe-based inspection, and reliable tooling management support are essential. Equipment footprints should align with your production mix—rapid prototypes through high-volume runs.

- Data and documentation: An ISO-certified supplier should provide transparent, machine-readable inspection reports, material certificates, and traceability data that align with your internal QA requirements and customer-facing documentation.

- Customer collaboration and transparency: Look for processes that include design for manufacturability (DFM) feedback, sample validation cycles, and clear communication channels for status updates and change management.

- Rapid prototyping with scalable production: A strong partner can move from prototype milling to pilot runs and then to full-scale production without changing suppliers. This continuity reduces risk, shortens lead times, and preserves design intent.

- Technology and process alignment: ISO-certified CNC mills often align with lean manufacturing practices, enabling standardized work, waste reduction, and enhanced reliability across product families. This alignment supports long-term program stability and supplier collaboration.

- Quality assurance as a differentiator: For foreign brands and distributors, the assurance of consistent quality, traceability, and on-time delivery becomes a competitive advantage when selling into new markets or maintaining high service levels post-launch.

- Stage 1: Concept and design for manufacturability: During early design reviews, a capable CNC partner provides input on fixturing, tolerance stack-ups, and feature simplifications to ensure the design remains economical to manufacture.

- Stage 2: Prototype milling and validation: Lightweight, rapid iterations validate form, fit, and function before committing to tooling investments.

- Stage 3: Tooling and prep for production: Transition to higher-volume runs with defined setups, fixture libraries, supplier-managed tool crib, and calibrated measurement plans to sustain part quality.

- Stage 4: Production and continuous improvement: ISO-driven feedback loops drive ongoing process improvements, with metrics such as first-pass yield, cycle time, and defect rates tracked over time.

- Regulatory alignment: In regulated industries, ISO certification aligns with compliance requirements and customer audits, easing market entry and ongoing quality assurance across supplier networks.

- Audit readiness: Regular internal audits and external surveillance ensure continued conformance to standards, minimizing the risk of supply disruption due to quality issues or documentation gaps.

- Continuous improvement culture: ISO frameworks foster ongoing enhancements—whether improving coolant management, spindle uptime, or part traceability—to sustain competitive advantage in a dynamic market.

- Intellectual property protection: Ensure robust NDAs, secure data handling, and clearly defined access controls when sharing CAD models, process parameters, and manufacturing instructions. ISO-certified partners typically have formal security and documentation controls to protect IP.

- Customization and flexibility: A reliable supplier should accommodate design changes with controlled lead times, change management processes, and transparent pricing for engineering changes, while preserving quality and traceability.

- Global supply chain resilience: Evaluate risk management practices, including multi-source capability within the ISO-certified network, inventory buffers, and contingency planning to mitigate disruptions.

- Updated content: Regularly refresh the article to reflect the latest ISO standards, certification scopes, and capabilities of the factory. Mention any notable clients or industries served, if permissible, to improve credibility.

- Multilingual considerations: For a global audience, consider a bilingual version (English with Chinese context) to address sourcing decisions and build trust with overseas partners.

ISO-certified CNC Milling Services provide a foundation for consistent part quality, robust traceability, and reliable delivery across rapid prototyping, precision machining, sheet metal work, 3D printing synergies, and mold production. By selecting an ISO-certified manufacturing partner with proven capabilities in CNC milling, you reduce risk, shorten time-to-market, and enable scalable production for global brands. A strong collaboration—supported by ISO quality management, transparent documentation, and integrated services—drives efficiency, cost control, and long-term supplier reliability.

ISO certification represents a formal quality management standard that ensures documented processes, consistent measurements, and continual improvement across CNC milling operations. It provides traceability, standardized inspection, and predictable results for prototypes and production runs.

ISO frameworks emphasize standardized work, streamlined workflows, and preventive maintenance, which minimize downtime and rework. This leads to faster throughput from initial CAD-to-part conversion through milling, inspection, and delivery.

Traceability ensures every part can be linked to specific materials, machine parameters, and inspection records. This is critical for regulatory compliance, quality audits, and post-market support, enabling efficient root-cause analysis if issues arise.

Verify the certification scope and validity, quality management practices (like GD&T and FAI), equipment capability, data documentation, and customer collaboration processes. Confirm evidence from recent audits and performance metrics.

An integrated supplier may offer sheet metal fabrication, 3D printing, tooling, and mold production alongside milling, enabling a seamless product development-to-production workflow with unified quality control.

[1](https://www.salcoglobal.com/blog/iso-90012015-cnc-machining/)

[2](https://rollyu.com/benefits-of-cnc-machining-in-manufacturing/)

[3](https://www.oracle-precision.co.uk/news/the-benefits-of-iso-certified-suppliers)

[4](https://www.linkedin.com/pulse/top-5-customer-benefits-iso-9001-certified-cnc-machining-james-abbott)

[5](https://www.mad-cnc.com/post/the-importance-of-iso-certified-quality-standards)

[6](https://www.ametals.com/post/7-uses-of-cnc-machining)

[7](https://mdaltd.ca/how-iso-90012015-certification-guarantees-quality-in-cnc-manufacturing/)

[8](https://www.redline-cnc.co.uk/iso-9001-certification-for-a-custom-machine-shop/)

[9](https://www.kirmell.co.uk/cnc-milling-machine-uses-types-and-benefits-explained/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal