Content Menu

● CNC Machining Process Explained

>> Computer-Aided Design (CAD)

>> Computer-Aided Manufacturing (CAM)

>> Machine Setup and Material Selection

>> Finishing and Quality Inspection

● Types of CNC Machining Operations

>> CNC Milling

>> CNC Turning

● Materials Used in CNC Machining

● Applications of CNC Machining

● FAQ: Common Questions About CNC Machining

>> 1. What distinguishes CNC machining from traditional machining?

>> 2. What materials can CNC machines work with?

>> 3. How accurate is CNC machining?

>> 4. Can CNC machining be used for prototyping and mass production?

>> 5. What quality checks ensure CNC parts meet standards?

CNC machining is a transformative manufacturing process that utilizes computer-controlled machines to fabricate precise parts from various materials. It is widely used in industries ranging from aerospace to medical devices, enabling fast prototyping, accurate batch production, and intricate designs that traditional manual machining cannot achieve. This article provides a comprehensive, detailed guide on how CNC machining works, its process stages, types, materials used, advantages, and practical applications. It is designed to help brand owners, manufacturers, and OEM partners understand the full potential of CNC machining.

CNC (Computer Numerical Control) machining refers to the automated control of machine tools like mills, lathes, and routers through computer programming. Instead of manual operation, CNC machines follow precise coded instructions (typically G-code) to execute cutting, drilling, shaping, and finishing of raw materials into finished parts. This technology allows for consistently high precision and repeatability crucial for industrial manufacturing.

The CNC machining process is typically divided into several stages that ensure the accurate production of components meeting stringent design requirements.

The first stage in CNC machining is designing a digital 3D model of the part using CAD software. Engineers specify the geometry, dimensions, features, and tolerance levels on this platform. The design undergoes rigorous testing and refinement to minimize errors before manufacturing.

Once the CAD design is finalized, it is imported into CAM software. CAM generates toolpaths and converts the design into machine-readable code (G-code or M-code), dictating the movement commands of the CNC machine. The programmer selects cutting tools, sets feed rates, spindle speeds, and sequences machining operations to optimize cutting efficiency and precision.

The raw material based on the part specifications—such as aluminum, steel, brass, or plastic—is fixed onto the CNC machine bed or chuck. Operators equip the machine with the appropriate cutting tools, such as drills, end mills, or lathe cutters, depending on whether the process involves milling, turning, or drilling.

The CNC machine executes the toolpaths automatically, following the programmed instructions. Depending on the method:

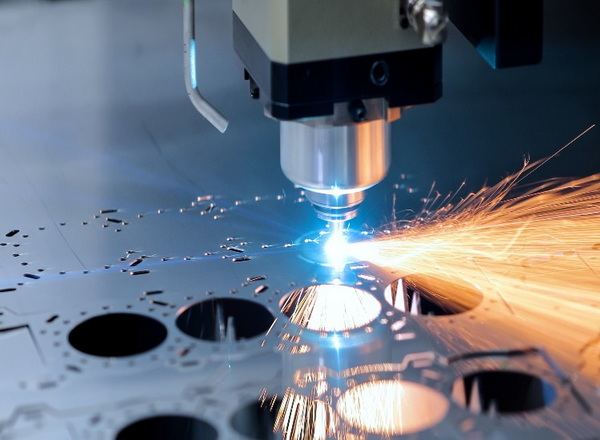

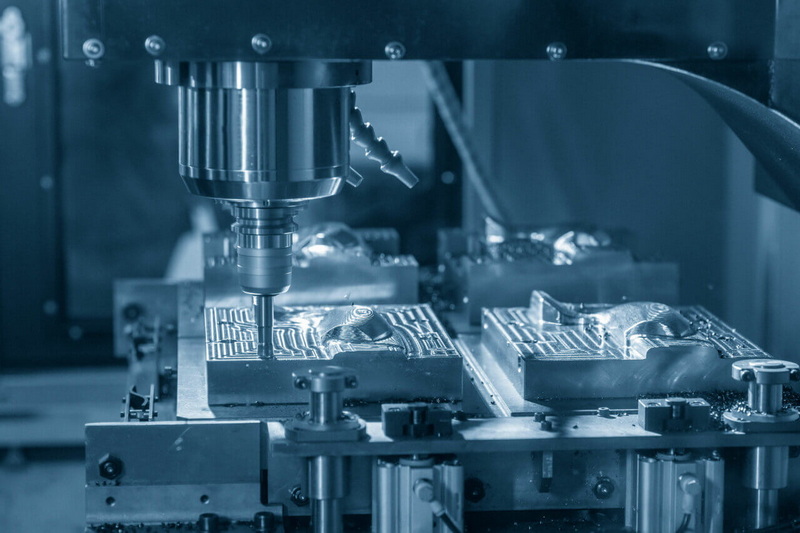

- CNC Milling: The rotating cutting tool moves across a stationary workpiece to carve complex shapes, contours, or slots.

- CNC Turning: The workpiece rotates while a stationary tool removes material, perfect for cylindrical parts.

- CNC Drilling: Multi-point drill bits create accurate, vertically aligned holes.

- CNC Grinding: Abrasive wheels produce smooth finishes.

- Electrical Discharge Machining (EDM): Uses electrical discharges for intricate metal cutting.

Operators monitor the machine, occasionally repositioning the workpiece or tools for multi-sided machining or tool changes.

After machining, parts often require finishing operations like deburring sharp edges, polishing surfaces, or applying coatings for corrosion resistance and aesthetics. Rigorous inspections follow using equipment like coordinate measuring machines (CMM) to verify dimensional accuracy within tolerances. Quality control ensures that the parts conform to design specifications and performance criteria before shipment.

Milling is highly versatile and can create flat surfaces, angled cuts, slots, holes, and 3D shapes. The cutting tool spins at high speed, removing material in layers according to programmed movement.

Turning is specialized for producing rotationally symmetrical parts such as shafts, bushings, and pulleys. The workpiece spins while a fixed tool shapes its perimeter or cuts internal features.

Drilling involves creating holes with precision and depth accuracy. Thread cutting on CNC lathes forms internal or external screw threads using specialized inserts, maintaining uniform pitch and depth.

Some advanced CNC machines combine milling and turning operations (mill-turn) for comprehensive part manufacturing without multiple setups, increasing efficiency.

CNC machining supports a broad range of materials:

- Metals: Aluminum, stainless steel, brass, titanium, copper

- Plastics: Nylon, polycarbonate, acrylic, ABS

- Composites: Carbon fiber, fiberglass

- Others: Wood, wax for prototyping

Material choice depends on part application, mechanical requirements, machinability, cost, and surface finish demands.

- Precision and Accuracy: Produces parts with micron-level tolerances consistently.

- Efficiency: High-speed, automated processes reduce labor and cycle times.

- Flexibility: Capable of producing complex geometries and custom prototypes.

- Repeatability: Enables mass production of identical parts.

- Material Utilization: Reduces waste by precise material removal.

- Safety: Minimizes operator exposure to cutting tools and fumes.

CNC machining is essential across multiple sectors:

- Aerospace: Manufacturing high-performance components with tight tolerances.

- Automotive: Producing engine parts, custom components, and prototypes.

- Medical Devices: Crafting implants, surgical instruments, and housings.

- Electronics: Creating precise enclosures and connectors.

- Industrial Equipment: Building machinery parts for durable performance.

- Consumer Products: Producing custom-made items and accessories.

As a leading manufacturer, Shangchen provides comprehensive CNC machining services including rapid prototyping, precision batch production, CNC milling, turning, sheet metal fabrication, and more. With advanced equipment and skilled technicians, Shangchen supports foreign brand owners, wholesalers, and manufacturers with reliable OEM solutions that guarantee quality and timely delivery. Our expertise ensures parts meet stringent specifications and performance standards essential for global markets.

CNC machining revolutionizes manufacturing through computer-controlled precision, flexibility, and scalability. From digital design to final inspection, each step plays a crucial role in delivering high-quality parts rapidly and efficiently. Whether producing a single prototype or large-scale production runs, CNC machining offers unmatched control and quality assurance. Partnering with professional CNC manufacturers like Shangchen enables companies to leverage this powerful technology for competitive advantage in diverse industries.

CNC machining is automated and computer-controlled, providing far higher precision, repeatability, and the ability to produce complex designs compared to manual machining.

CNC machines can handle a wide variety of metals (aluminum, steel, brass), plastics, composites, and specialty materials, depending on tooling and machine compatibility.

CNC machining achieves tolerances often within microns, making it ideal for highly detailed or critical parts in aerospace or medical applications.

Yes, CNC is highly versatile, used both for rapid prototyping to validate designs and for efficient batch or large-scale production of finished parts.

Quality control involves dimensional inspection using coordinate measuring machines, surface finish evaluations, and functional testing to ensure compliance with design and customer requirements.

[1](https://www.autodesk.com/products/fusion-360/blog/cnc-machining-101-a-comprehensive-guide/)

[2](https://uptivemfg.com/the-ultimate-guide-to-cnc-machining/)

[3](https://karkhana.io/cnc-machining-process/)

[4](https://www.trade-tech.com/an-intro-to-the-cnc-machining-process/)

[5](https://gab.wallawalla.edu/~ralph.stirling/classes/engr480/examples/nvx/NVX/Helpful%20Docs/CNC_Machining_The_Complete_Engineering_Guide.pdf)

[6](https://www.fictiv.com/articles/the-ultimate-guide-to-cnc-machining)

[7](https://academy.titansofcnc.com/files/Fundamentals_of_CNC_Machining.pdf)

[8](https://astromachineworks.com/what-is-cnc-machining/)

[9](https://learn.toolingu.com/blog-start/2023/june/cnc-machining-training-guide/)

[10](https://www.hubs.com/knowledge-base/how-design-parts-cnc-machining/)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam