Views: 222 Author: Amanda Publish Time: 2025-11-18 Origin: Site

Content Menu

● Understanding Rapid Prototyping

● Step 1: Design and CAD Modeling

● Step 2: Choosing the Right Prototyping Technology

● Step 3: Preparing and Manufacturing the Prototype

● Step 5: Testing and Evaluation

● Step 6: Iteration and Refinement

● Benefits of Rapid Prototyping

● FAQ

>> 1. What is rapid prototyping?

>> 2. Which rapid prototyping methods are most common?

>> 3. How does rapid prototyping benefit product development?

>> 4. What materials are used in rapid prototyping?

>> 5. Can rapid prototypes be used for functional testing?

Rapid prototyping is a crucial process in modern product development that enables manufacturers and designers to quickly create physical models of their digital designs. This allows for early testing, evaluation, and refinement before mass production, helping reduce costs, accelerate time-to-market, and improve product quality. This comprehensive guide will walk you through the entire rapid prototyping process, key technologies, and best practices. It is tailored for OEM manufacturers like Shangchen who provide rapid prototyping, sheet metal fabrication, CNC machining, 3D printingand mold production services for overseas brands, wholesalers, and manufacturers.

Rapid prototyping is the fast fabrication of a physical sample or model of a part or assembly using 3D computer-aided design (CAD) data. Unlike traditional methods that require tooling and longer lead times, rapid prototyping focuses on speed and iteration. It leverages advanced manufacturing techniques such as additive manufacturing (3D printing), subtractive manufacturing (CNC machining), and formative methods (sheet metal forming) to produce prototypes in hours or days.[1][11]

This process provides critical spatial clarity, functional validation, and ergonomic insights early in development, helping companies avoid costly errors later. It supports various stages from conceptual mockups to high-resolution, functional prototypes that simulate the final product's performance.[1]

The foundation of rapid prototyping is an accurate 3D CAD model. Designers create the model with detailed dimensions, features, and tolerances, ensuring it precisely represents the intended product. Modern CAD software allows parametric and history-based modeling to manage revisions efficiently as designs evolve.[3][11]

Key considerations at this stage include simplifying complex geometries, setting minimum wall thicknesses, and planning assembly points to optimize manufacturability and inspection. Designers often prepare the CAD file in STL or other formats compatible with prototyping machines.[1]

The appropriate rapid prototyping technology depends on the prototype's purpose, required fidelity, materials, and budget. Common technologies include:

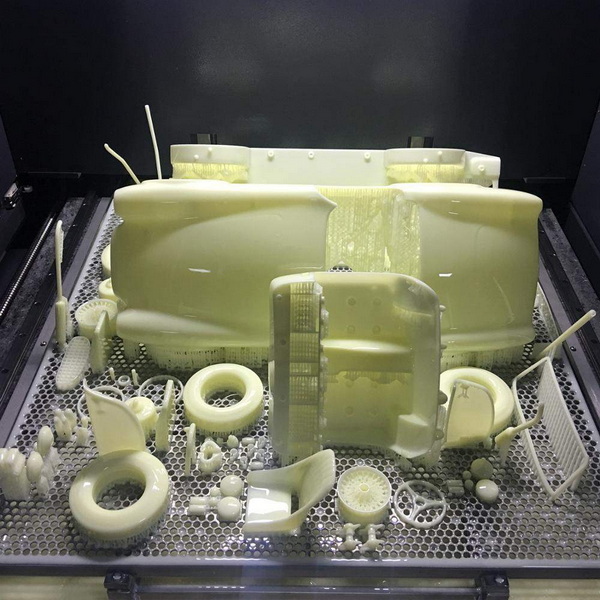

- 3D Printing (Additive Manufacturing): Builds prototypes layer by layer using materials such as thermoplastics (PLA, ABS), resins, nylon, or metal powders. This method excels at producing complex internal features, lattice structures, and rapid iterations. Examples include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).[9][3][1]

- CNC Machining (Subtractive Manufacturing): Involves cutting or milling parts from solid blocks of metal or plastic using computer-controlled tools. This method offers tight tolerances (±0.01–0.05 mm), strong mechanical properties, and excellent surface finishes, suitable for functional prototypes and testing.[5][6][1]

- Sheet Metal Fabrication (Formative Manufacturing): Uses cutting, bending, and welding to create metal prototypes or components, especially useful for enclosures, brackets, or structural parts requiring metal properties.[1]

- Others: Techniques like urethane casting and rapid injection molding can produce short runs of near-production-quality parts for cosmetic or functional evaluation.[5]

Matching process strengths and limitations to prototype goals—such as visual aesthetics, mechanical performance, or thermal testing—is essential for efficient development.[1]

Once the technology is selected, the CAD model is prepared using specialized software. For additive manufacturing, slicing software converts the model into layers with toolpaths. For CNC machining, CAM software generates precise cutting instructions.

The manufacturing process then starts:

- In 3D printing, the prototype is built layer by layer by melting or curing material.

- In CNC machining, cutting tools remove material with high precision from a stock block.

- In sheet metal fabrication, metal sheets are cut, bent, and assembled as per design.[3][1]

Manufacturing lead times vary from hours to days depending on complexity and process.

After the prototype is built, post-processing improves function and aesthetics. It may include sanding, polishing, painting, dyeing, vapor smoothing (for 3D prints), assembly of multiple parts, heat treatments (for metal parts), or coating.[11][1]

This step enhances surface finish, dimensional accuracy, and durability, ensuring prototypes resemble or perform like final products.

The prototype undergoes rigorous testing aligned with its intended use:

- Fit and assembly checks ensure components align and integrate.

- Functional tests validate mechanical strength, thermal behavior, and ergonomics.

- User experience assessments analyze usability and interface.[12][3]

Testing helps identify design flaws early, lowering risks before entering costly tooling or mass manufacturing.

Rapid prototyping is iterative by nature. Based on test results, the design team revises the CAD model to improve weaknesses or incorporate new features. The revised prototype is fabricated again, refining cycle continuous until the product meets all requirements.[12][3]

This cyclical process drastically shortens product development timelines compared to traditional methods.

- Accelerates innovation by compressing design-to-prototype cycles.

- Reduces costs by catching design errors before tooling.

- Improves design quality through multiple testing iterations.

- Supports customization by enabling tailored solutions.

- Facilitates communication within distributed teams via tangible models.[13][1]

Industries using rapid prototyping extensively include automotive, aerospace, consumer electronics, medical devices, and industrial equipment. OEMs rely on these techniques to optimize fit, form, function, and manufacturability during early development.[13]

Rapid prototyping is a transformative tool that modern manufacturers like Shangchen can leverage to deliver high-quality, functional prototypes with speed and precision. By mastering design, selecting optimal manufacturing methods, and emphasizing iterative testing and refinement, businesses can reduce development costs, speed time-to-market, and provide customized OEM solutions. Combining 3D printing, CNC machining, and sheet metal fabrication, rapid prototyping enhances product innovation and ensures robust final production.

Rapid prototyping is the fast fabrication of physical models from digital designs to test and refine product concepts before mass production.

3D printing, CNC machining, and sheet metal fabrication are the primary techniques used depending on prototype requirements.

It accelerates timelines, reduces costs by early error detection, and allows iterative design improvements.

Materials range from plastics (PLA, ABS, nylon) and photopolymer resins to metals like aluminum and steel.

Yes, especially CNC-machined and certain 3D printed parts are strong and accurate enough for functional evaluation.

[1](https://wefab.ai/blog/rapid-prototyping-explained-a-guide-to-the-processes-that-accelerate-product-development/)

[2](https://www.stephengould.com/rapid-prototyping/)

[3](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[4](https://xometry.pro/en/articles/rapid-prototyping-manufacturing/)

[5](https://www.fictiv.com/articles/rapid-prototyping-guide)

[6](https://www.xometry.com/resources/design-guides/prototype-development-guide/)

[7](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

[8](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[9](https://www.stratasys.com/en/resources/blog/guide-to-rapid-prototyping/)

[10](https://www.dailybot.com/insights/the-ultimate-guide-to-rapid-prototyping)

[11](https://www.techniwaterjet.com/what-is-rapid-prototyping-process-stages-types-and-tools/)

[12](https://www.geeksforgeeks.org/software-engineering/what-is-rapid-prototyping/)

[13](https://www.autodesk.com/solutions/rapid-prototyping)

[14](https://www.sc-rapidmanufacturing.com/news/On-Demand-Production.html)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal