Views: 222 Author: Amanda Publish Time: 2025-11-19 Origin: Site

Content Menu

● Core CNC Machining Processes

>> Milling

>> Turning

>> Grinding

● Advanced CNC Machines and Capabilities

● Materials Used in CNC Machining

● Applications of CNC Machining

● Shangchen's CNC Machining Services

● Frequently Asked Questions (FAQ)

>> 1. What materials are suitable for CNC machining?

>> 2. How does CNC machining differ from traditional machining?

>> 3. What types of CNC machines exist?

>> 4. Can CNC machining be used for prototyping?

>> 5. What are the benefits of 5-axis CNC machines?

CNC stands for Computer Numerical Control, a cutting-edge machining technology that automates the control of machine tools through computer programming. CNC machining uses coded instructions to control machines such as mills, lathes, and drills, enabling precise shaping, cutting, and fabricating of components from various materials. This technology ensures high accuracy, efficiency, and repeatability, making it indispensable in modern manufacturing, especially for rapid prototyping, precision batch production, and OEM services. Companies like Shangchen specialize in leveraging CNC machining alongside rapid prototyping, 3D printing, and sheet metal fabrication to serve international brands, wholesalers, and manufacturers.

CNC machining is a subtractive manufacturing process where material is progressively removed from a solid workpiece to produce a final part. The process begins by designing a 3D CAD (Computer-Aided Design) model, which is translated into CNC machine instructions, commonly known as G-code. These instructions guide the machine tool's movements across multiple axes with high precision.

A typical CNC machine includes a robust frame, spindle holding the cutting tool, linear motion systems, and an electronic controller that executes the instructions. The controller interprets G-code commands for tool paths, speeds, and feeds to manufacture complex shapes consistently and accurately.

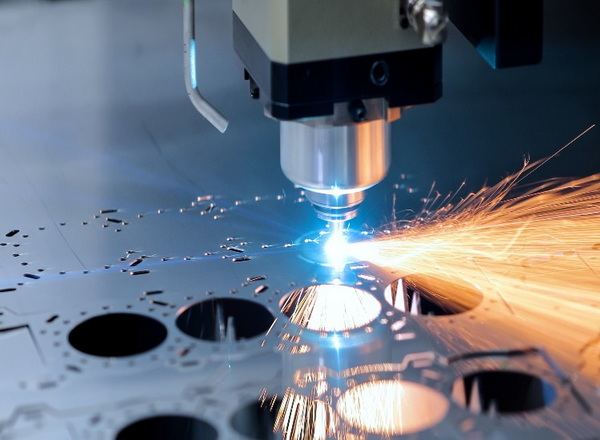

CNC milling involves rotating cutting tools to remove material and create features like slots, holes, contours, and intricate surfaces. It supports various milling types, including:

- Face Milling: Cutting flat surfaces.

- Peripheral Milling: Producing deep slots or grooves.

- Angular Milling: Creating beveled edges or chamfers.

- Form Milling: Shaping curved or irregular surfaces.

Milling machines range from simple 3-axis models to advanced 5-axis and even 7-axis machines, enabling complex parts to be manufactured in fewer setups with great precision.

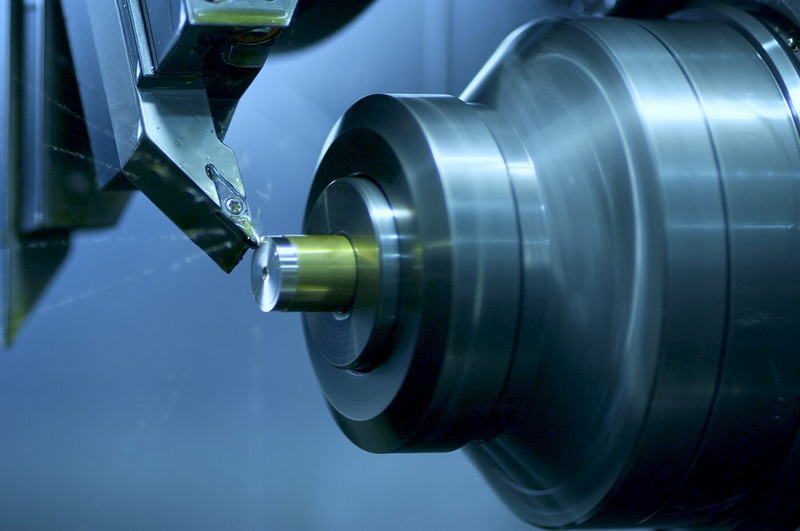

Turning is the process where the workpiece rotates on a spindle while a cutting tool shapes its surface, primarily used for cylindrical parts like shafts, bolts, and spindles. CNC lathes offer automated tool changes, live tooling, and multi-axis capabilities for operations such as:

- Facing

- Thread cutting

- Grooving

- Boring

CNC drills create accurate holes by following programmed depths and diameters. Boring enlarges existing holes with tight tolerances, suitable for applications requiring precision fitment.

For achieving superior surface finishes and tight dimension tolerances, CNC grinding uses abrasive wheels to remove microscopic material layers. It is often used in finishing aerospace and automotive parts.

- 4-Axis Machines: Extend 3-axis capabilities by including rotational movement of the workpiece or tool, facilitating machining on multiple sides.

- 5-Axis Machines: Enable simultaneous movement along five axes, allowing complex 3D parts to be created in a single operation with fewer setups.

- 7-Axis Machines: Include additional rotary and pivot axes for extremely intricate part production, commonly used in aerospace, medical, and military industries.

These multi-axis machines increase production efficiency by reducing manual re-fixturing and improving accuracy.

CNC machining is compatible with a wide range of materials, such as:

- Metals: Aluminum, steel, titanium, brass, copper

- Plastics: Nylon, ABS, polycarbonate, acrylic

- Composites and ceramics

- Wood and foam for prototypes or specialized applications

Material selection depends on the application, required properties, and machining feasibility.

CNC machining relies heavily on software tools:

- CAD (Computer-Aided Design): Used for designing detailed 2D or 3D models.

- CAM (Computer-Aided Manufacturing): Converts CAD models into G-code instructions.

- G-Code: The primary language that directs the CNC machines where to move, how fast to cut, and which tools to use.

- M-Code: Complements G-code by controlling machine-specific functions, such as tool changes or coolant activation.

Operators also use measurement and inspection tools like micrometers and calipers to verify dimensions during or after machining to maintain quality.

CNC machining finds applications in nearly every major manufacturing sector:

- Aerospace: Producing turbine blades, structural components, and precision engine parts.

- Automotive: Creating engine blocks, transmission parts, prototypes, and custom accessories.

- Medical: Manufacturing implants, surgical instruments, and diagnostic device parts with stringent quality requirements.

- Electronics: Fabrication of enclosures, connectors, and internal components.

- Industrial Equipment: Parts for robotics, machinery, and automation systems.

Rapid prototyping and custom manufacturing often rely on CNC machining to quickly turn designs into functional parts, essential for OEM partnerships.

- High Precision: CNC machines maintain tight tolerances throughout production runs.

- Repeatability: Every part produced matches exact specifications.

- Flexibility: Programs can be quickly updated for design changes or new jobs.

- Speed and Efficiency: Automated machining significantly reduces cycle times and labor input.

- Material Utilization: CNC machining optimizes material use, minimizing waste.

- Integration: CNC systems integrate smoothly with modern CAD/CAM workflows, enhancing manufacturing efficiency.

Shangchen is a leading manufacturer specializing in rapid prototyping, CNC machining, sheet metal fabrication, 3D printing, and mold production. Utilizing advanced multi-axis CNC machines and stringent quality control processes, Shangchen delivers high-precision parts tailored for foreign brands, wholesalers, and manufacturers worldwide. Their expertise covers single prototypes to volume batch production, supported by comprehensive OEM services that emphasize quality, timely delivery, and customer satisfaction.

CNC machining, or Computer Numerical Control machining, embodies the future of manufacturing by automating complex cutting and shaping operations through computer programming. This technology delivers exceptional precision, efficiency, and versatility across many industries—from aerospace to healthcare—empowering companies to create intricate, high-quality parts rapidly and consistently. With advanced software integration and multi-axis machinery, CNC machining continues to evolve, supporting innovative product development and mass production. Leading service providers like Shangchen harness CNC machining's capabilities to offer customized, scalable, and reliable manufacturing solutions to the global market.

CNC machining can handle metals (e.g., aluminum, steel, titanium), plastics (like nylon and ABS), composites, ceramics, and even wood or foam, depending on the application.

Traditional machining involves manual operation of machines with less precision and repeatability, while CNC machining uses computer programs to automate tool movement, ensuring higher accuracy and efficiency.

Common types include CNC mills and lathes, with advanced versions offering 4-axis, 5-axis, and even 7-axis capabilities for producing complex geometries.

Yes, CNC machining is ideal for rapid prototyping as it produces precise, functional parts quickly from digital designs, facilitating testing and development.

5-axis machines allow simultaneous multi-directional cutting, reducing setups, improving accuracy, and enabling manufacture of complex parts in a single operation.

[1](https://www.autodesk.com/products/fusion-360/blog/cnc-machining-101-a-comprehensive-guide/)

[2](https://www.cadrex.com/cnc-machining-starter-guide)

[3](https://www.protolabs.com/en-gb/resources/blog/an-a-z-guide-to-cnc-machining-technology/)

[4](https://electrafly.com/a-complete-guide-of-various-types-of-cnc-machining/)

[5](https://gab.wallawalla.edu/~ralph.stirling/classes/engr480/examples/nvx/NVX/Helpful%20Docs/CNC_Machining_The_Complete_Engineering_Guide.pdf)

[6](https://www.fictiv.com/articles/the-ultimate-guide-to-cnc-machining)

[7](https://academy.titansofcnc.com/files/Fundamentals_of_CNC_Machining.pdf)

[8](https://www.tymetal.com/blog/guide-to-cnc-machining/)

[9](https://www.reddit.com/r/FSAE/comments/96wszi/an_engineers_guide_to_cnc_machining/)

[10](https://astromachineworks.com/what-is-cnc-machining/)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam