Content Menu

● Introduction to CNC Machining

● Understanding the CNC Machining Process

>> 3. Setup and Machining Phase

>> 4. Inspection and Finishing

● Types of CNC Machines and Their Functions

● Tooling and Cutting Strategies in CNC Machining

● Materials Suitable for CNC Machining

● Design Considerations and Best Practices

● Applications of CNC Machining Across Industries

● Shangchen's CNC Machining Expertise

>> 1. What materials can be used in CNC machining?

>> 2. What are the main types of CNC machining processes?

>> 3. How precise is CNC machining?

>> 4. Which industries benefit most from CNC machining?

>> 5. How does CNC machining improve product development?

CNC Machining, standing for Computer Numerical Control Machining, is a highly automated manufacturing process that employs computer software to precisely control machine tools in producing parts and components. The process converts digital designs into detailed instructions that execute complex cutting, shaping, drilling, and finishing operations on raw materials with remarkable accuracy. CNC machining is an essential technology for modern manufacturing industries, offering superior precision, speed, and repeatability compared to manual machining methods. It serves numerous sectors including automotive, aerospace, medical, electronics, and consumer goods.[1][2][8]

The CNC machining process involves several key stages, which collectively transform a conceptual design into a physical product:

The process starts with designing the part using Computer-Aided Design (CAD) software. Engineers create a detailed 3D digital model of the component, specifying exact dimensions, geometries, and tolerances. This stage allows for design refinement and visualization to ensure the final part will meet functional requirements before production begins.[2][3]

The completed CAD model moves to the Computer-Aided Manufacturing (CAM) phase, where the design is translated into machine-readable code, typically G-code. This code instructs the CNC machine on how to move the tools — the path, speed, depth, and sequence of cuts — to create the part. CAM software also aids in selecting the right cutting tools and optimizing the machining strategy for efficiency and surface quality.[3][2]

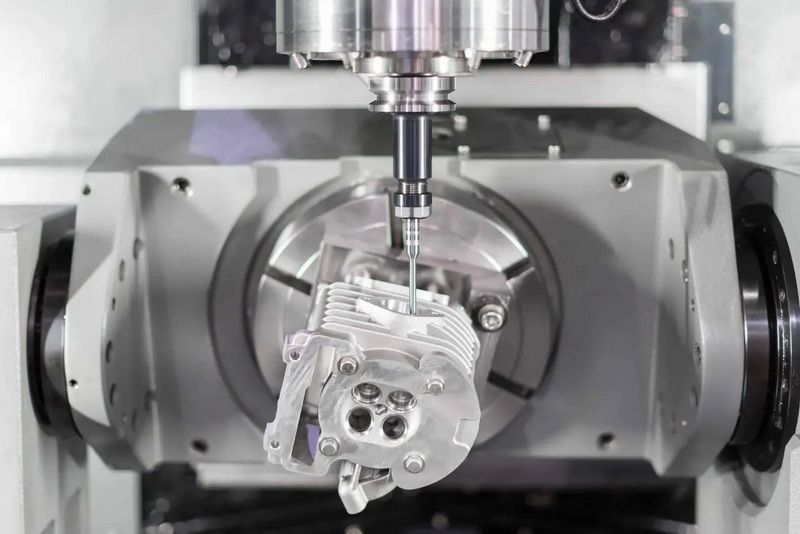

Before machining begins, the raw material (workpiece) is securely fixed on the machine bed or lathe spindle. The operator installs the appropriate cutting tool and configures the CNC machine. The machine then automatically executes the G-code instructions, removing material incrementally to shape the part as designed. This process involves multiple passes to achieve complex geometries and high precision. The cutting tools move along multiple axes, controlled precisely by the CNC system, adjusting speed and depth dynamically.[4][1][2]

Once machining is complete, the part undergoes inspection to confirm dimensional accuracy and surface finish quality. Additional finishing operations such as polishing, deburring, or coating may be applied to enhance aesthetics or functionality. This final step ensures the product meets or exceeds the required specifications.[5][1]

CNC machines vary according to the machining operation and workpiece type. The most common types include:

- CNC Milling Machines: Use rotary cutters to remove material from a stationary workpiece. Available as 3-axis, 4-axis, or 5-axis machines, milling allows for the creation of complex parts with multi-dimensional geometries. 5-axis machining enables the cutting tool to approach the workpiece from nearly any direction without repositioning, increasing precision and reducing setup times.[2][4]

- CNC Lathes (Turning Centers): The workpiece rotates while a fixed cutting tool shapes its outer or inner surfaces. Ideal for creating cylindrical or symmetrical parts like shafts and bushings. Turning operations remove material by tracing the part's profile along polar directions.[11][5]

- CNC Routers: Designed for softer materials like wood, plastics, and composites, mainly used in signage and furniture production.

- CNC EDM (Electrical Discharge Machining): Uses electrical sparks to erode material and create intricate shapes, often for tooling and mold making.

- CNC Laser and Plasma Cutters: Employ focused energy streams to cut conductive materials with high precision in sheet metal fabrication.[12][11]

The choice of cutting tools significantly influences machining efficiency, surface finish, and tool life. Key tooling types include:

- End Mills: Primarily employed in milling, they cut in multiple directions and create features like slots, pockets, and contours.

- Drill Bits: Used in CNC drilling operations to produce precise holes.

- Lathe Tools: Specialized tools crafted for turning operations to shape round parts accurately.

Modern CAM software optimizes toolpaths for speed and surface quality, regulating parameters such as feed rates and spindle speeds. Sophisticated techniques like climb milling improve chip evacuation and tool longevity, while multi-axis machining reduces the need for multiple setups, enhancing accuracy and throughput.[5][2]

CNC machining supports a wide variety of materials:

- Metals: Aluminum, steel, titanium, brass, copper, and specialty alloys are commonly machined for their strength, conductivity, and wear resistance.

- Plastics: Acrylic, nylon, polycarbonate, and other engineering plastics are machined for lighter-weight components.

- Composites and Wood: Less common but feasible with appropriate tooling.

The material choice affects cutting speeds, tool selection, and machining strategies, influencing overall production efficiency and part performance.[13][2]

Design for CNC machining involves adhering to guidelines optimizing manufacturability:

- Maintain appropriate wall thickness and avoid overly thin features to prevent part deformation.

- Design cavities and pockets with recommended depth limits to ensure tool accessibility.

- Consider tool diameter and minimum radii to avoid impossible cuts or tool breakage.

- Allow clearance for undercuts and internal features to permit proper tool access.

Following established design rules improves processing time, reduces costs, and enhances part quality.[3][5]

CNC machining offers unparalleled advantages:

- High Precision and Accuracy: Machine-controlled movements yield parts with tolerances as tight as microns.

- Repeatability: Identical parts can be produced consistently in large volumes.

- Complex Geometries: Five-axis and multi-tool CNC machines can produce intricate components with complex surfaces.

- Flexibility: Easily switch between different part designs without significant retooling.

- Reduced Lead Times: Automated processes accelerate prototype and production part manufacturing.

- Material Efficiency: Precision cutting minimizes waste and energy consumption.

These benefits lead to reduced production costs and faster time-to-market across industries.[8][14][11]

CNC machining is fundamental in manufacturing diverse products:

- Automotive: Engine blocks, transmission parts, and custom aftermarket components.

- Aerospace: High-strength turbine blades, structural aircraft parts, and precision engine components.

- Medical: Surgical tools, implants, prosthetics, and dental devices tailored for patient needs.

- Electronics: Housings, connectors, and heat sinks.

- Industrial Equipment: Hydraulic valves, pumps, and machine tooling.

- Consumer Goods: Precision parts in sporting goods, appliances, and luxury products.[14][8][11]

Shangchen excels in providing rapid prototyping, precision CNC machining, sheet metal fabrication, 3D printing, and mold production services. Equipped with advanced multi-axis CNC machines, the company delivers high-quality, repeatable manufacturing solutions tailored for OEM clients worldwide. Shangchen's comprehensive manufacturing capabilities empower global brands and wholesalers with superior product quality, shorter lead times, and flexible production volumes, ensuring competitiveness in dynamic markets.[15][16][17]

CNC Machining is a cornerstone in contemporary manufacturing, delivering exceptional precision, efficiency, and flexibility in producing complex parts from a wide range of materials. This computer-driven process supports a versatile array of machining operations, including milling, turning, and drilling, enabling mass production and rapid prototyping alike. With advancements in multi-axis machinery and software optimization, CNC machining meets the exacting demands of industries such as aerospace, automotive, medical, and consumer electronics. Leaders like Shangchen leverage these capabilities to provide expert OEM service, reinforcing their partners' success in global markets.

CNC machining can handle metals such as aluminum, steel, titanium, copper, and brass, as well as plastics like acrylic and nylon, composites, and even wood. Material selection depends on part requirements regarding strength, machining ease, and application.[13][2]

The primary CNC machining processes include milling, turning (lathe operations), drilling, grinding, and electrical discharge machining (EDM). Each process suits different part geometries and surface finish needs.[11][12]

Modern CNC machines can achieve tolerance levels within microns (thousandths of a millimeter), offering consistent and repeatable precision essential for technical and medical parts.[8][11]

Industries like automotive, aerospace, medical device manufacturing, consumer electronics, and industrial equipment heavily rely on CNC machining for quality and efficiency.[14][11]

By enabling rapid prototyping and quick adjustments, CNC machining helps manufacturers reduce design-to-production time, optimize part performance, and speed up market entry while maintaining high quality.[16][15]

[1](https://eurometalsolutions.com/blog/complete-guide-to-cnc-machining-everything-you-need-to-know/)

[2](https://www.autodesk.com/products/fusion-360/blog/cnc-machining-101-a-comprehensive-guide/)

[3](https://www.hubs.com/guides/cnc-machining/)

[4](https://sybridge.com/ultimate-cnc-machining-guide/)

[5](https://prototek.com/CNC-Machining-Guide/)

[6](https://gab.wallawalla.edu/~ralph.stirling/classes/engr480/examples/nvx/NVX/Helpful%20Docs/CNC_Machining_The_Complete_Engineering_Guide.pdf)

[7](https://academy.titansofcnc.com/files/Fundamentals_of_CNC_Machining.pdf)

[8](https://www.fictiv.com/articles/the-ultimate-guide-to-cnc-machining)

[9](https://molloyengineering.com/a-comprehensive-guide-to-cnc-machining-techniques/)

[10](https://astromachineworks.com/what-is-cnc-machining/)

[11](https://www.rcoeng.com/blog/cnc-applications)

[12](https://www.3ds.com/make/guide/process/cnc-machining)

[13](https://uptivemfg.com/the-ultimate-guide-to-cnc-machining/)

[14](https://www.3erp.com/blog/cnc-machining-applications-and-uses/)

[15](https://www.sc-rapidmanufacturing.com/3d-printing.html)

[16](https://www.sc-rapidmanufacturing.com)

[17](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam