Views: 222 Author: Amanda Publish Time: 2025-11-18 Origin: Site

Content Menu

● Accelerating Product Development Cycles

● Cost Reduction and Risk Mitigation

● Enhanced Design Flexibility and Innovation

● Early Detection of Design and Manufacturing Flaws

● Improved Collaboration and Communication

● Customization and Personalization Capabilities

● Support for Complex and Advanced Manufacturing Techniques

● Faster Market Introduction for Competitive Advantage

● Scalability and Future-Proofing

● FAQ

>> 1. What industries benefit most from rapid prototyping?

>> 2. How does rapid prototyping reduce product development costs?

>> 3. What materials can be used for rapid prototyping?

>> 4. Is rapid prototyping suitable for full-scale production?

>> 5. How does rapid prototyping improve product quality?

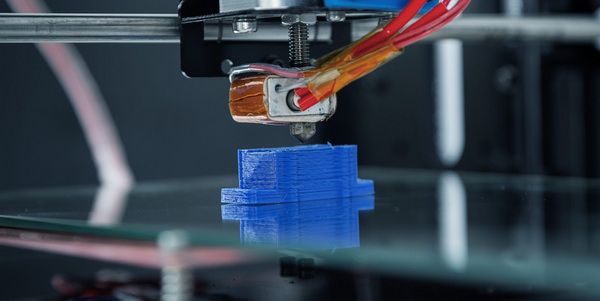

Rapid prototyping has transformed the product development process by enabling companies to quickly create, test, and refine prototypes in a fast, flexible, and cost-effective manner. This revolutionary approach leverages techniques like 3D printing and additive manufacturing to fabricate physical models directly from CAD data. For manufacturers such as Shangchen, which provide rapid prototyping, CNC machining, and OEM services, understanding the many benefits of rapid prototyping is key to accelerating innovation and staying competitive in global markets. This article delves deeply into the core advantages of rapid prototyping and its profound impact on product design, development, and manufacturing.

Rapid prototyping dramatically shortens the product development timeline by enabling the production of physical prototypes in hours or days, rather than weeks or months as with traditional methods. This fast turnaround allows designers and engineers to rapidly iterate on designs, test functionality, and make improvements early in the process. By compressing the cycle from concept to prototype, companies can bring products to market faster, reducing time-to-market and gaining a crucial competitive edge. The ability to rapidly test and refine multiple design variants also supports agile development practices, ensuring final products meet requirements more quickly and accurately.

One of the strongest advantages of rapid prototyping is the significant reduction in costs associated with prototype development. Traditional prototyping often requires expensive tooling, molds, and manual labor, driving up costs and extending delivery times. In contrast, rapid prototyping eliminates the need for custom tooling during early design stages, reducing setup expenses. Moreover, it lowers material waste by allowing early detection of design flaws and providing opportunities to test and refine without costly rework. This risk mitigation through early validation prevents expensive mistakes post-production and cuts overall project expenditure.

Rapid prototyping supports greater design flexibility by allowing engineers to experiment with complex geometries, intricate details, and customized features that are difficult or impossible to manufacture traditionally. This freedom fosters innovation by encouraging creative exploration and rapid experimentation with new concepts, materials, and structures. Designers can produce multiple iterations quickly to explore different functionalities, aesthetics, and usability aspects in parallel. The technology empowers product teams to push design boundaries and develop highly optimized solutions while receiving immediate physical feedback.

Creating physical models early in the development process helps uncover design weaknesses, ergonomic issues, or functional problems that may not be evident in digital models. Hands-on evaluation of rapid prototypes provides critical insights into assemblies, fits, finishes, and usability. This early flaw detection allows timely corrective actions, reducing the likelihood of costly recalls, redesigns, or production delays later. Furthermore, it aids in assessing manufacturability and assembly feasibility, ensuring the design can be efficiently produced at scale.

Rapid prototyping acts as a powerful communication tool among designers, engineers, marketers, and clients. Physical prototypes turn abstract ideas into tangible forms, making it easier to align stakeholders on design intent and product goals. This collaborative visualization accelerates decision-making and clarifies requirements, reducing misunderstandings and costly iterations. It also provides clients and end-users the opportunity for hands-on feedback, fostering user-centric design improvements and higher satisfaction.

Rapid prototyping's agility facilitates creation of bespoke, customized products by producing prototypes tailored to specific client requirements quickly and efficiently. This is especially valuable in medical, aerospace, and consumer markets, where personalized solutions enhance product performance and user experience. Companies can respond dynamically to individual customer needs or niche markets without incurring high setup costs, boosting competitiveness and market reach.

By leveraging additive manufacturing technologies, rapid prototyping enables fabrication of complex internal structures, lightweight designs, and multi-material components that are not feasible with traditional subtractive methods. These capabilities support advanced engineering goals such as weight reduction, enhanced strength, and integrated functionalities, contributing to superior product performance. Additionally, the materials efficiency and precision of rapid prototyping align with sustainability initiatives in manufacturing.

The combined benefits of speed, cost savings, and design optimization accelerate market readiness. Launching products earlier allows businesses to capture market share, adapt to consumer trends, and respond to competitors proactively. Rapid prototyping fosters an iterative feedback cycle that ensures the final product is well-refined, compliant with quality standards, and tailored to customer expectations—all contributing to successful commercialization.

Rapid prototyping not only supports early-stage development but also facilitates smooth transition to large-scale production. By refining designs through prototypes, manufacturers can better plan tooling, assembly, and supply chains. This scalability ensures cost-effective production and product adaptability as market demands evolve, helping companies future-proof their offerings through continuous innovation.

Rapid prototyping offers transformative advantages that empower companies to innovate faster, reduce costs, and improve product quality. Its ability to speed up development timelines, lower expenses, provide design flexibility, and enhance collaboration make it a cornerstone of modern manufacturing. OEM service providers like Shangchen combine rapid prototyping with CNC machining and precision production to deliver agile, customized manufacturing solutions for foreign brands, wholesalers, and industrial clients globally. Embracing rapid prototyping technology is essential for businesses aiming to thrive in today's dynamic, competitive markets.

Rapid prototyping is valuable across many sectors such as automotive, aerospace, medical devices, consumer electronics, industrial manufacturing, and more—where fast innovation and testing are critical.

It cuts costs by eliminating expensive tooling, reducing material waste, minimizing redesign rework, and shortening the product development cycle.

Materials include plastics, resins, metals, composites, and specialized polymers, suited to different prototyping technologies like 3D printing or CNC machining.

Typically, rapid prototyping is for early-stage validation and low-volume production. It supports efficient scaling for mass production by finalizing designs.

Multiple testing iterations with physical prototypes help identify and fix design flaws early, resulting in refined, high-quality final products.

[1](https://prototaluk.com/blog/advantages-of-rapid-prototyping/)

[2](https://www.stratasys.com/en/resources/blog/key-advantages-of-rapid-prototyping/)

[3](https://breinerco.com/10-proven-benefits-of-rapid-prototyping/)

[4](https://protoshopinc.com/blog/understanding-rapid-prototyping/)

[5](https://www.additive-x.com/blog/what-is-rapid-prototyping-the-advantages-disadvantages)

[6](https://engineeringproductdesign.com/knowledge-base/rapid-prototyping-techniques/)

[7](https://maze.co/blog/rapid-prototyping/)

[8](https://dienamics.com.au/blog/pros-and-cons-of-rapid-prototyping-your-product/)

[9](https://hbr.org/2014/02/intervention-design-building-the-business-partners-confidence)

[10](https://www.figma.com/resource-library/what-is-rapid-prototyping/)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam