Views: 222 Author: Amanda Publish Time: 2025-12-08 Origin: Site

Content Menu

● Shangchen: Your Rapid Prototyping Partner

● When Was Rapid Prototyping Invented?

● Early Pioneers and Milestones

● Rapid Prototyping in the 1990s and 2000s

● From Rapid Prototyping to Additive Manufacturing

● Major Rapid Prototyping Technologies

>> Fused Deposition Modeling (FDM)

>> Selective Laser Sintering and Melting (SLS/SLM)

>> CNC Machining as Rapid Prototyping

>> Sheet Metal Rapid Prototyping

● Why Rapid Prototyping Matters for OEMs

● How Shangchen Applies Rapid Prototyping

● Typical Rapid Prototyping Workflow with Shangchen

● Rapid Prototyping vs Traditional Prototyping

● Applications of Rapid Prototyping Today

● Future Trends in Rapid Prototyping

● FAQ

>> 1. What year was rapid prototyping first invented?

>> 2. Who is considered the inventor of rapid prototyping?

>> 3. How has rapid prototyping changed product development?

>> 4. What are the main rapid prototyping processes used today?

>> 5. Why should OEM buyers work with a dedicated rapid prototyping factory?

Shangchen (sc-rapidmanufacturing.com) is a Chinese manufacturing factory focusing onRapid Prototyping, CNC machining services, precision batch production, lathe turning, sheet metal fabrication, 3D printing services, and mold production for overseas brands, wholesalers, and manufacturers. The company specializes in OEM solutions that convert 3D designs into precise physical prototypes and small‑batch parts, allowing customers to move quickly from idea to market‑ready product.

By integrating rapid prototyping with production‑grade processes, Shangchen helps clients validate concepts, optimize designs, and then scale to volume manufacturing using one coordinated supply chain. This one‑stop structure is especially valuable for international buyers who need reliable communication, stable quality, and predictable lead times.

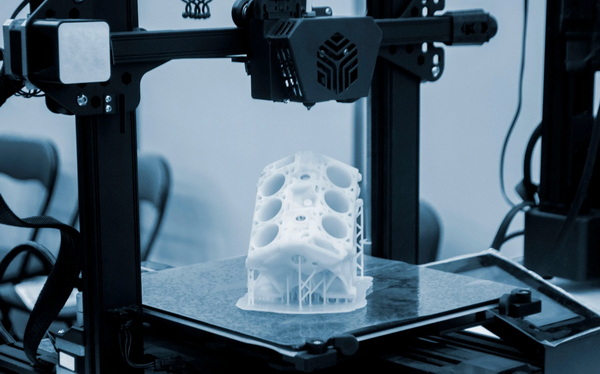

Rapid prototyping is a set of manufacturing methods that transform digital CAD data into physical models and functional parts in a short time, often in days rather than weeks or months. It covers both additive manufacturing processes such as 3D printing and subtractive processes such as CNC machining, all focused on accelerating design validation and reducing development risk.[2][3][5][6]

In practice, rapid prototyping enables engineers and designers to build tangible models to check appearance, fit, function, and assembly far earlier than traditional methods. Multiple prototypes can be produced, compared, and refined in quick succession, which improves decision‑making and reduces costly changes during tooling and mass production.[3][4][7]

The origins of rapid prototyping lie in early research on computer‑aided design and layered manufacturing during the late 1970s and early 1980s. Around 1980–1981, Hideo Kodama in Japan described a system that used UV‑curable resin to build parts layer by layer, widely considered one of the first true rapid prototyping concepts even though it never reached full commercialization.[8][9][1][2]

The real turning point came between 1984 and 1986, when Charles “Chuck” Hull developed stereolithography, a method in which a laser cures thin layers of liquid photopolymer to form 3D objects. Hull founded 3D Systems, and by 1987–1988 the company released the SLA‑1, the first commercial stereolithography machine, which is often cited as the first practical rapid prototyping system used by industry.[10][11][2][3]

During the 1980s, several innovators extended the concept of rapid prototyping beyond stereolithography. Carl Deckard developed selective laser sintering (SLS), which used a laser to fuse powder materials, creating strong plastic parts from digital files. Around the same time, Scott Crump introduced fused deposition modeling (FDM), extruding thermoplastic filament through a heated nozzle to build components layer by layer.[12][13][14]

These different approaches expanded rapid prototyping beyond photopolymer resins to include engineering plastics and other materials, which opened new applications in automotive, aerospace, and industrial design. By the end of the 1980s, rapid prototyping was recognized as a distinct field, with universities and research centers developing new materials, software, and machine architectures.[4][1][2][3]

In the 1990s, rapid prototyping moved from laboratories and early adopters into mainstream engineering departments. Companies began using SLA, SLS, FDM, laminated object manufacturing, and inkjet‑based powder bed systems to create appearance models, functional test parts, and tooling prototypes.[6][3][4]

Software advances, such as improved CAD tools and slicing algorithms, made it easier to prepare models for rapid prototyping, while material innovations increased strength, heat resistance, and durability. By the 2000s, rapid prototyping had evolved from a novelty into a standard step in many product development workflows, with dedicated service bureaus and specialized factories serving global OEM and ODM customers.[5][15][4]

Originally, the term “rapid prototyping” emphasized speed and low‑volume prototyping, not full‑scale production. As machines became more reliable and materials more capable, the same technologies began to produce end‑use parts, spare components, and customized products, prompting the wider adoption of the term “additive manufacturing” for production applications.[14][15][6]

Today, rapid prototyping and additive manufacturing are closely linked concepts. Rapid prototyping focuses on fast design validation, while additive manufacturing often refers to using similar technologies for low‑volume or specialized production runs. In practice, many companies use both approaches together: rapid prototyping for early development and additive manufacturing for bridge production or niche market volumes.[7][3][5]

Every rapid prototyping project begins with a 3D CAD model of the part or assembly. This model is exported in a neutral format such as STL, STEP, or IGES, then processed in dedicated software that slices the geometry into thin layers or generates toolpaths for CNC machining.[2][3][5]

Depending on the chosen process, the equipment builds the part layer by layer (in 3D printing) or removes material from a solid block (in CNC machining). Support structures may be added to stabilize overhangs, and once the build is complete, the part is cleaned, finished, and inspected to confirm that it matches dimensional and functional requirements.[3][4][6]

Stereolithography is one of the earliest and most precise rapid prototyping technologies. A UV laser selectively cures liquid photopolymer resin in a vat, forming each layer and gradually building a highly detailed part with excellent surface quality, often used for visual models, master patterns, and complex geometries.[4][2][3]

FDM uses a heated nozzle to extrude thermoplastic filament, depositing material along a programmed path to create each layer. It is widely used because of its relatively low machine and material costs, reasonable strength, and suitability for functional rapid prototyping of housings, brackets, fixtures, and simple assemblies.[13][12][14]

SLS and SLM use a laser to selectively fuse powdered materials—typically nylon or metals—layer by layer, making it possible to produce strong, complex components without the need for support structures in many cases. These processes are especially valuable for rapid prototyping of parts that must perform in demanding mechanical or thermal environments.[15][13]

CNC machining is a subtractive process in which cutting tools under computer control remove material from solid stock to achieve the desired shape. When scheduled efficiently and combined with modern CAM software, CNC machining becomes a powerful rapid prototyping tool that offers tight tolerances, excellent surface finish, and production‑grade material properties in metals and plastics.[5][3]

Sheet metal rapid prototyping involves laser cutting, punching, bending, welding, and surface treatment to create enclosures, frames, and brackets in very short lead times. This approach is essential for testing mechanical assemblies, electrical housings, and structural components during product development.[16][5]

Rapid prototyping gives OEMs the ability to compress development schedules, reduce the number of design iterations needed after tooling, and improve cross‑functional communication. Physical prototypes allow marketing, engineering, purchasing, and management teams to evaluate the same object, minimizing misunderstandings that can arise from viewing only digital images.[7][3][4]

The ability to create multiple design variants through rapid prototyping supports A/B testing, ergonomic studies, and user feedback sessions before committing to expensive molds or production lines. This lowers overall project risk, increases the chance of market success, and helps OEMs react faster to changing customer demands or regulatory requirements.[3][4][5]

Shangchen integrates rapid prototyping across 3D printing, CNC machining, sheet metal fabrication, lathe turning, and mold manufacturing to support every stage of your project. By analyzing each design, the team selects the most suitable rapid prototyping process or combination—for example, SLA for a detailed shell, CNC machining for a metal insert, and sheet metal for mounting brackets.

For overseas brands and wholesalers, Shangchen's rapid prototyping capabilities are aligned with export‑grade quality standards, including dimensional inspection, material traceability, and consistent finishing. This allows customers to receive realistic prototypes that closely match final mass‑production parts, making it easier to secure internal approvals, conduct field tests, and prepare for certification.

A standard rapid prototyping workflow with Shangchen includes several key steps:

1. Project briefing and file review

The customer provides 3D CAD models, 2D drawings if available, and a description of application, material, finish, and quantity. Shangchen's engineers check the models for manufacturability and recommend appropriate rapid prototyping processes.

2. Process selection and quotation

Based on technical requirements and target lead time, Shangchen prepares one or more rapid prototyping options, such as SLA versus CNC machining, along with a detailed quotation and estimated delivery schedule.

3. Production and quality control

Once the order is confirmed, the rapid prototyping process begins, with careful control of build parameters, inspection of critical dimensions, and, if required, functional testing or assembly checks.

4. Finishing and logistics

Parts may receive sanding, painting, anodizing, plating, or other surface treatments to simulate final mass‑production appearance. Completed rapid prototyping parts are then securely packed and shipped to the customer's location.

This structured approach ensures that rapid prototyping results are consistent, repeatable, and aligned with the expectations of international OEM and ODM projects.

Traditional prototyping often relies on manual craftsmanship and early investment in tooling, which can be slow and inflexible. Rapid prototyping, by contrast, leverages digital workflows and flexible equipment to shorten lead times and reduce setup costs, making it easier to explore multiple design alternatives.[16][4][3]

In many cases, rapid prototyping eliminates or postpones the need for dedicated molds or dies, especially for low‑volume parts or early test batches. As a result, companies can preserve capital, validate design decisions more thoroughly, and commit to large tooling expenses only after prototypes have proven successful in real‑world testing.[6][7][3]

Rapid prototyping is used extensively in automotive, aerospace, consumer electronics, home appliances, industrial equipment, medical devices, and many other industries. Applications range from simple appearance models and ergonomic mock‑ups to complex functional prototypes, fixtures, jigs, and customized low‑volume parts.[15][4][5][3]

For highly regulated sectors such as medical and aerospace, rapid prototyping supports iterative design of components, housings, and test rigs, improving both functional performance and compliance readiness. In consumer goods and electronics, it enables fast refresh cycles and localization of designs for different markets, often in partnership with specialized rapid prototyping and OEM factories in Asia.[4][5][6][15]

Rapid prototyping continues to advance through improved materials, smarter software, and more automated equipment. Multi‑material printing, higher‑temperature polymers, stronger metal alloys, and integrated sensing are expanding what can be prototyped and tested before full production.[17][15][4]

At the same time, digital platforms and cloud‑based collaboration tools are making it easier for global teams to manage rapid prototyping projects with partners in different countries. For factories like Shangchen, this means integrating rapid prototyping even more tightly with CNC machining, sheet metal fabrication, and toolmaking, so customers can move from concept to prototyping to production within a single, coherent system.[6][15]

Rapid prototyping, in the modern sense, was born in the early 1980s, when pioneers such as Hideo Kodama and Chuck Hull demonstrated that 3D objects could be built automatically from digital data using layer‑by‑layer techniques. Over the following decades, a combination of stereolithography, SLS, FDM, CNC machining, and sheet metal fabrication transformed rapid prototyping into an indispensable part of global product development.[9][1][2][3][4][6]

For overseas brands, wholesalers, and manufacturers, partnering with a dedicated rapid prototyping and OEM factory such as Shangchen (sc-rapidmanufacturing.com) offers a direct route from digital design to high‑quality physical prototypes and small‑batch production. By embedding rapid prototyping into every stage of the process, Shangchen helps reduce risk, shorten development cycles, and deliver products that meet the expectations of demanding international markets.

Rapid prototyping emerged as a recognizable technology in the early 1980s, when Hideo Kodama's work on UV‑curable layered manufacturing appeared around 1980–1981. The commercialization of stereolithography by Chuck Hull and 3D Systems in 1987–1988 is widely considered the true starting point of modern rapid prototyping.[11][1][8][9][10][2]

Two key figures are usually associated with the invention of rapid prototyping: Hideo Kodama, who first described a photopolymer‑based layering technique, and Charles “Chuck” Hull, who patented stereolithography and brought the first commercial SLA systems to market. Hull's stereolithography printers enabled broad industrial adoption, so he is often called the “father of 3D printing” and a central figure in rapid prototyping.[1][9][11][2][3]

Rapid prototyping allows companies to quickly create and test physical models directly from CAD data, which shortens development cycles and increases the number of iterations that can be evaluated. This leads to better design decisions, fewer late‑stage modifications, and a smoother transition into tooling and mass production.[5][7][3][4]

The most commonly used rapid prototyping processes include stereolithography (SLA), fused deposition modeling (FDM), selective laser sintering or melting (SLS/SLM), binder‑jet or inkjet 3D printing, CNC machining, and sheet metal fabrication. Each process offers specific advantages in accuracy, strength, surface finish, and cost, so engineers choose the appropriate rapid prototyping method based on application, material, and required performance.[13][2][3][4][5]

A dedicated rapid prototyping factory offers multiple manufacturing processes, engineering support, and quality control in one place, simplifying communication and project management for OEM buyers. This integrated capability makes it easier to turn 3D designs into physical prototypes, compare design options, and then scale into small‑batch or mass production using the same partner, reducing both time‑to‑market and project risk.[3][4][5][6]

[1](https://www.ebsco.com/research-starters/business-and-management/rapid-prototyping)

[2](https://en.wikipedia.org/wiki/Rapid_prototyping)

[3](https://tech-labs.com/rapid-prototyping)

[4](https://www.xometry.com/resources/3d-printing/3d-printing-history/)

[5](https://mouldible.com/what-is-rapid-prototyping/)

[6](https://en.wikipedia.org/wiki/3D_printing)

[7](https://www.techniwaterjet.com/what-is-rapid-prototyping-process-stages-types-and-tools/)

[8](https://uptivemfg.com/3d-printing-milestones-that-shaped-the-past-and-future/)

[9](https://www.makerbot.com/stories/history-of-3d-printing/)

[10](https://www.asme.org/topics-resources/content/the-prototyping-technology-that-disrupted-the-world)

[11](https://us.arrk.com/when-was-additive-manufacturing-invented/)

[12](https://www.sculpteo.com/blog/2017/03/01/whos-behind-the-three-main-3d-printing-technologies/)

[13](https://ultimaker.com/learn/the-complete-history-of-3d-printing/)

[14](https://pro3dcomposites.com/how-3d-printing-all-began-timeline-of-a-revolution/)

[15](https://www.raise3d.com/blog/3d-printing-history/)

[16](https://www.arptech.com.au/blog/learn-all-about-rapid-prototyping.htm)

[17](https://www.asme.org/topics-resources/content/infographic-the-history-of-3d-printing)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal