Views: 222 Author: Amanda Publish Time: 2025-11-05 Origin: Site

Content Menu

● The Essential Features of Automation in Moulding Production

>> Continuous Operation and Efficiency

>> Precision, Consistency, and Advanced Quality Control

>> Cost Reduction and Return on Investment

>> Enhanced Workplace Safety and Ergonomics

● Key Technologies Transforming Moulding Production

>> Robotics

>> Industrial IoT and Process Optimization

>> Machine Vision and AI Inspection Systems

>> Digital Twins and Smart Simulation

>> Flexible Servo Drives and Motion Control

● Practical Automation Applications in Moulding Production

>> 3D Printing and Prototyping

● Industry 4.0 and Digital Transformation in Moulding Production

● Sustainability and Environmental Impact

● Advanced Trends Shaping the Future of Moulding Production

>> Micro Moulding and Medical Innovation

>> Collaborative Robots (“Cobots”)

>> AI-Driven Predictive Analytics

>> Sustainable Robotics Integration

● Overcoming Challenges in Automation Adoption

● The Role of Automation in Shangchen's OEM Services

● Looking Ahead: The Intelligent Moulding Factory

● FAQs

>> 1. What are the key areas where automation is applied in moulding production?

>> 2. How does AI improve defect detection in moulding production?

>> 3. Can automated moulding production adapt to varied customer needs?

>> 4. What cost benefits can automation deliver to injection moulding businesses?

>> 5. What obstacles do manufacturers face when automating moulding production?

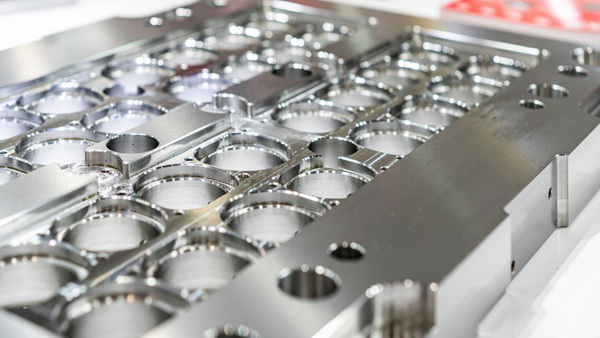

Moulding production stands at the intersection of tradition and innovation, powering everything from automotive components to consumer electronics and medical devices. In recent years, technological advancements have dramatically transformed moulding production, with automation leading the charge. Factories and OEM service providers, like Shangchen, harness automation for rapid prototyping, CNC machining, batch production, sheet metal fabrication, 3D printing, and mould making. The objective is clear: deliver consistent, high-quality moulded products for clients around the world.[11][12]

“Lights-out” factories, where automated moulding cells run 24/7 without human oversight, have redefined production capacity. Automated raw material handling, robot-assisted mould loading and unloading, and seamless part ejection maximize throughput, minimize human error, and allow timely batch manufacturing for dynamic OEM projects.[12][13]

Automation directly improves product consistency and repeatability. Machine vision, sensors, and robotics collaborate for real-time inspection and defect detection. Automated quality control systems evaluate part geometry, color, and dimensions, ensuring compliance with customer specifications and preventing defective products from entering the supply chain.[6][14]

Though automation demands substantial capital investment, it leads to lower operational costs through reduced labor, minimized waste, rapid defect response, and sustained high output. Factories can handle larger volumes using less human labor and optimize cycle times to deliver improved ROI.[2][11]

Hazardous or repetitive operations are best performed by robots, reducing risks associated with manual labor in the moulding shop. Human operators are thus empowered to take on technical, creative, or supervisory roles, fostering workplace safety and upskilling opportunities.[8][15]

Industrial robots are ubiquitous in modern moulding production. They load and unload moulds, perform post-processing tasks like trimming and deburring, and handle assembly operations, leading to efficient, streamlined workflows.[16][17][8]

IoT-enabled moulding machines monitor temperature, pressure, fill levels, and time. Sensors feed data to centralized dashboards, allowing operators to track performance, forecast maintenance, and carry out predictive interventions, reducing downtime and optimizing throughput.[1][5]

Camera systems and AI-driven software capture every nuance of the moulded part, evaluating surface finish, geometry, and integrity. Real-time feedback enables immediate rejection of non-conforming parts, promoting “zero-defect” manufacturing.[9][6]

Digital twin technology simulates the moulding process, enabling engineers to optimize designs and predict part performance before physical production. This accelerates development cycles and slashes costs associated with prototyping and iteration.[6]

Electric servo-driven machines now offer finer control over injection, holding, and ejection pressures. Adaptive feedback allows precise adjustments, ensuring consistent fill and resolution for micro-moulding and thin-walled parts.[5]

- Robotized part removal, flash trimming, and sprue cutting

- Automated insert loading for overmoulding

- Resin mixing and material feeding via conveyors

- In-line defect inspection using AI and camera systems

- Batch production scheduling using MES and ERP integrations[5][12][6]

Automation extends to CNC operations, where robotic arms load billets and perform automated tool changes, enabling faster iterations and traceability through data logging.[7][13]

High-speed robot-operated presses, laser cutters, and welding stations fabricate components to tight tolerances. Automated finishing and quality inspection ensure flawless integration with moulded products.[18]

Automated 3D printing farms rapidly produce prototypes and small-batch, complex moulded components. Controlled material handling and automated post-processing help achieve quick turnaround times for OEM partners.[1]

Industrial automation is a cornerstone of Industry 4.0, defined by data connectivity, distributed control, and “smart factory” evolution. Automated moulding production is increasingly characterized by:

- Real-time, remote equipment monitoring

- Predictive maintenance powered by AI

- Adaptive production, responding to material batch variations and ambient conditions

- Smart supply chain management and inventory optimization

- Laboratory validation for new process recipes[19][1][5]

In practice, digital systems boost process reliability, ensure rapid prototyping, and support mass customization in dynamic international markets.

Automation also catalyzes sustainability by reducing scrap rates, enhancing material yield, streamlining energy use, and facilitating the integration of recycled materials. Modern automated production cells precisely dose eco-friendly resins while monitoring the impact of manufacturing on carbon footprints.[8][1]

Miniaturization is driving demand for micro-moulding, particularly in medical devices and consumer electronics. Automated systems ensure micron-scale precision, biocompatibility, and sterilization, essential for next-generation applications.[9]

Cobots are designed to operate safely alongside human workers in flexible production cells. They support rapid reconfigurations for custom orders, manage light assembly tasks, and simplify integrations for fast prototyping.[8]

Modern injection moulding lines leverage AI for predictive defect analysis, autonomous parameter adjustments, and long-term process optimization. This proactive approach prevents costly stoppages and supports lean manufacturing.[1][5][6]

Robot density in global plastics factories reached historic levels in 2023, reflecting industry-wide confidence in automation for sustainable growth, labour efficiency, and precision manufacturing.[8]

While benefits abound, manufacturers face challenges:

- Steep upfront investment in robotics and digital infrastructure

- Integration with legacy equipment and processes

- Skill gaps, requiring operator training for advanced system management

- Balancing flexibility with process standardization

- Adapting to regulatory requirements and consumer demand for sustainability[7][19]

Strategic planning, pilot programs, and ongoing workforce development remain vital for long-term success.

Shangchen leverages automation across its rapid prototyping, CNC machining, and precision batch production platforms, delivering superior quality and flexibility for global OEM brands. Automation empowers Shangchen to:

- Swiftly iterate and validate new designs for customers

- Scale production efficiently without sacrificing quality

- Ensure transparent traceability and data-driven quality assurance

- Respond dynamically to evolving market and regulatory requirements

Tomorrow's moulding production will feature fully integrated, AI-enhanced production cells, autonomous material flow, and seamless data exchange between design, manufacturing, and supply chain systems. Smart factories will boost innovation, sustainability, and agility, establishing factories and OEMs as global leaders in advanced manufacturing.

Automation is revolutionizing moulding production, empowering manufacturers to deliver unmatched efficiency, precision, scalability, and product quality. From high-speed robots and intelligent sensors to adaptive AI-driven controls and digital twins, the evolving landscape of automated moulding production is vital to meet global OEM customer demands. Factories investing in automation will continue to advance their technological and competitive edge while promoting safe workplaces and sustainable practices.

Automation is central to material handling, mould loading/unloading, trimming, quality inspection, assembly operations, and packaging. These applications boost efficiency and eliminate human error.[11][7][8]

AI-powered computer vision and inspection systems analyze every part in real time, identifying surface and dimensional defects instantly. This ensures zero-defect production and reduces costly recalls.[5][6][9]

Yes. Flexible automation, collaborative robots, and smart controllers enable quick production changes, making rapid prototyping and small-batch customization simple for diverse OEM orders.[17][8]

Automation cuts labor expenses, reduces cycle time, streamlines resource use, and lowers waste, resulting in higher profitability and more competitive pricing for customers.[13][11][1]

Challenges include the cost of new technology, technical integration with existing systems, upskilling workers, and maintaining flexibility while standardizing quality processes.[7][5]

[1](https://www.makerverse.com/resources/injection-molding/the-biggest-injection-molding-trends-for-2025/)

[2](https://www.fictiv.com/articles/injection-molding-trends-2025)

[3](https://thriam.com/the-future-of-injection-molding-trends-and-predictions-for-2025-and-beyond.php)

[4](https://finance.yahoo.com/news/injection-molding-market-forecast-trends-135300553.html)

[5](https://www.topstarmachine.com/injection-molding-trends-in-2025-ai-and-smart-production-workflows/)

[6](https://advantechplastics.com/blog/how-ai-and-automation-are-revolutionizing-plastic-injection-molding-in-2025/)

[7](https://www.cadrex.com/why-automation-is-the-future-of-custom-plastic-injection-molding)

[8](https://www.plasticstoday.com/automation/robots-shifting-the-paradigm-in-plastics-manufacturing)

[9](https://www.medicalmicromolding.com/top-trends-in-medical-injection-molding-for-2025-micro-molding-automation-sustainability/)

[10](https://www.moldmakingtechnology.com/news/sps-atlanta-2025-addresses-manufacturing-challenges-with-automation-focused-solutions-dynamic-education-programs-4)

[11](https://www.ensinger-pc.com/resources/blog/enhancing-efficiency-and-quality-the-role-of-automation-in-modern-injection-molding/)

[12](https://www.aimprocessing.com/blog/the-role-of-automation-in-modern-plastic-injection-molding)

[13](https://www.crescentind.com/blog/how-plastic-injection-molding-automation-improves-productivity)

[14](https://www.slideproducts.com/news/the-effects-of-automation-on-the-future-of-injection-molding)

[15](https://www.rnaautomation.com/insight/robotics-in-injection-moulding/)

[16](https://www.artmolds.com/blogs/mold-making/automation-in-injection-molding)

[17](https://www.plasticmoldingdevelopment.com/the-role-of-advanced-robotics-in-modern-injection-molding/)

[18](https://www.sussexim.com/adding-value-with-automation-in-injection-molding-industry/)

[19](https://centplasticmfg.com/the-impact-of-technology-automation-on-custom-plastic-injection-molding/)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product