Views: 222 Author: Amanda Publish Time: 2025-12-08 Origin: Site

Content Menu

● Shangchen SLA rapid prototyping services

● What is SLA rapid prototyping?

● How does SLA rapid prototyping work?

● Key advantages of SLA rapid prototyping

● Limitations and considerations of SLA rapid prototyping

● SLA rapid prototyping vs. other rapid prototyping methods

● Typical applications of SLA rapid prototyping

● Design tips for SLA rapid prototyping

● How Shangchen integrates SLA with other rapid prototyping services

● When to choose SLA rapid prototyping with Shangchen

● FAQ

>> 1. What is SLA rapid prototyping in simple terms?

>> 2. What are the main benefits of SLA rapid prototyping?

>> 3. Which materials are used in SLA rapid prototyping?

>> 4. When should SLA rapid prototyping be chosen over other methods?

>> 5. How does Shangchen support OEM projects with SLA rapid prototyping?

SLA rapid prototyping is a resin‑based 3D printing technology that uses ultraviolet (UV) light to turn liquid photopolymer into highly detailed solid parts layer by layer. It has become one of the most important Rapid Prototyping methods for creating smooth, precise prototypes and small‑batch parts in a short time.[1][2]

Shangchen (sc-rapidmanufacturing.com) is a China‑based OEM factory that integrates rapid prototyping, CNC machining, CNC turning, sheet metal fabrication, 3D printing, and mold production for overseas brands, wholesalers, and manufacturers. By combining SLA rapid prototyping with other rapid prototyping technologies, Shangchen helps customers move quickly from CAD design to real parts while maintaining tight tolerances and stable quality.[3][4]

Shangchen's rapid prototyping capabilities cover concept models, functional prototypes, precision batch production, and bridge‑to‑production runs, allowing customers to validate design, fit, and performance at every stage. The factory's multi‑axis CNC machining centers, CNC lathes, and precision 3D printing systems support rapid prototyping in plastics and metals for applications in automotive, electronics, industrial equipment, consumer products, and more.[5][6]

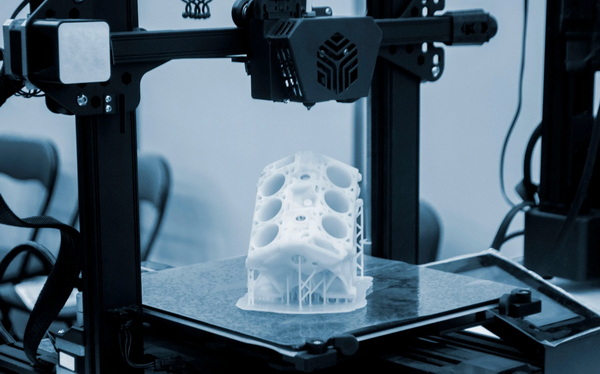

SLA (stereolithography) rapid prototyping is an additive manufacturing process in which a UV laser or projected light selectively cures liquid resin in a tank to build parts layer by layer. Because each layer can be extremely thin, SLA rapid prototyping can produce smooth surfaces, fine features, and very accurate geometries compared with many other rapid prototyping methods.[2][1]

In rapid prototyping projects, SLA is often used to generate visual models, assembly prototypes for fit checks, fluid‑flow components, and functional parts that simulate injection‑molded plastics. This makes SLA rapid prototyping ideal for design verification, ergonomic evaluation, and early marketing samples whenever high appearance quality is needed.[7][8]

SLA rapid prototyping starts from a 3D CAD model that is sliced into thin layers using dedicated software. The sliced data is sent to an SLA rapid prototyping machine, which uses a UV laser or projector to cure the resin selectively according to each 2D layer profile.[1][2]

In a typical SLA rapid prototyping cycle, the build platform is positioned at a defined layer height within the liquid resin, and the light source traces or projects the layer pattern so the resin solidifies where exposed. After each layer is cured, the platform moves slightly to allow fresh resin to flow beneath or above the part, and the process repeats until the entire rapid prototyping model is complete.[9][10]

Once the SLA rapid prototyping build finishes, parts are washed in a solvent to remove uncured resin and then post‑cured under additional UV light to improve strength and thermal performance. Optional finishing steps—such as sanding, bead blasting, painting, or clear coating—can further enhance the appearance and functionality of the rapid prototyping part.[7][9]

One of the biggest advantages of SLA rapid prototyping is its exceptional dimensional accuracy and smooth surface finish. Parts often require minimal sanding before painting or assembly, which shortens downstream processing and makes rapid prototyping more efficient.[2][7]

SLA rapid prototyping can reproduce thin walls, sharp edges, tiny holes, and intricate internal channels that may be difficult or expensive to produce with other methods. This level of detail helps engineers examine critical features and refine product designs very early in the rapid prototyping stage.[11][12]

Because SLA rapid prototyping is a tool‑less process driven directly from CAD data, it significantly reduces lead time from weeks to days. Designers can test multiple iterations in parallel and apply design changes quickly without investing in hard tooling during the rapid prototyping phase.[8][13]

Another advantage is the wide range of resin materials available for SLA rapid prototyping, including rigid, tough, flexible, transparent, and temperature‑resistant grades. This allows teams to choose materials that approximate production plastics and perform more realistic functional rapid prototyping tests, such as snap fits, sealing surfaces, and light‑transmission components.[9][7]

Despite its strengths, SLA rapid prototyping has limitations related to material durability and long‑term stability. Many standard photopolymer resins can be more brittle and less UV‑stable than engineering thermoplastics, so SLA rapid prototyping parts may not be suitable for long‑term outdoor use or severe mechanical loads.[13][11]

Another consideration is process complexity and maintenance: SLA rapid prototyping equipment requires controlled temperature, resin management, and regular inspection of optical components and resin tanks. For continuous or large‑volume rapid prototyping, professional operation and strict process control are necessary to achieve consistent results.[10][14]

Post‑processing adds time and labor to SLA rapid prototyping workflows, including support removal, cleaning, UV post‑curing, and optional painting. However, when these steps are well managed, SLA rapid prototyping remains one of the fastest and most precise technologies for customer‑ready prototypes and small series.[7][9]

Within the rapid prototyping family, SLA is typically compared with SLS (selective laser sintering), FDM (fused deposition modeling), and CNC machining. Each rapid prototyping method offers different strengths, and many projects benefit from combining them in a single development plan.[15][13]

SLA rapid prototyping is known for high resolution and smooth surfaces; SLS rapid prototyping uses powder materials (often nylon) to create strong, complex parts without support structures; FDM rapid prototyping provides economical parts using thermoplastic filaments. CNC machining, while subtractive rather than additive, is also a key rapid prototyping method for metals and high‑performance plastics where production‑grade mechanical properties are required.[5][13]

For example, a team might use SLA rapid prototyping for appearance models, SLS rapid prototyping for durable functional tests, and CNC rapid prototyping for highly loaded parts. By integrating these methods, engineers can cover visual evaluation, mechanical performance, and manufacturability checks in a complete rapid prototyping strategy.[6][15]

SLA rapid prototyping is widely used in early concept development, allowing designers to quickly transform digital ideas into physical models. With rapid prototyping, stakeholders can hold the part, feel ergonomics, and discuss design improvements far more effectively than with on‑screen renders alone.[12][8]

In engineering, SLA rapid prototyping supports fit and assembly checks, especially for complex multi‑part housings, connectors, and snap‑fit enclosures. It is also suitable for rapid prototyping of fluid‑handling components, microfluidic devices, and medical test fixtures where internal channels and smooth surfaces are critical.[11][7]

Marketing and sales teams rely on SLA rapid prototyping to create realistic samples for trade shows, product photography, and early customer demonstrations. Painted and textured SLA rapid prototyping parts can closely resemble final products, helping companies test market reactions before investing in tooling.[6][7]

To get the best results from SLA rapid prototyping, designers should follow some basic guidelines for wall thickness, feature size, and support orientation. Minimum wall thickness should be respected to avoid fragile sections, and very thin features should be reinforced or redesigned for reliable rapid prototyping.[2][11]

Orientation strongly influences surface quality and support requirements in SLA rapid prototyping. By tilting parts and placing critical surfaces away from heavy supports, designers can reduce post‑processing and achieve better cosmetic results in rapid prototyping builds.[9][2]

It is also useful to consider how SLA rapid prototyping parts will be used in later stages, such as painting or overmolding. Adding extra material for sanding, including alignment features, and designing for assembly can make rapid prototyping parts easier to finish and test.[6][7]

Shangchen combines SLA rapid prototyping with CNC machining, CNC turning, sheet metal fabrication, vacuum casting, and mold production to cover the full product life cycle from prototype to mass production. This integrated rapid prototyping environment allows customers to select the best process—or a hybrid combination—for each part, balancing cost, speed, and performance.[4][5]

A typical OEM project might begin with SLA rapid prototyping models for industrial design review, followed by CNC‑machined rapid prototyping metal parts for mechanical testing, and then transition to soft tooling and molded samples for pilot runs. Throughout this journey, Shangchen provides design‑for‑manufacturing advice so that every rapid prototyping iteration moves closer to stable, efficient production.[16][6]

Shangchen has extensive experience serving overseas brands, trading companies, and manufacturers, and understands international quality standards and documentation requirements. Strict inspection processes and measurement reports help ensure that SLA rapid prototyping parts and other components meet customer specifications before shipment.[3][4]

SLA rapid prototyping from Shangchen is especially suitable when a project requires high surface quality, fine details, or complex shapes that must look close to final parts. Industries such as consumer electronics, automotive interiors, medical devices, and precision instruments often select Shangchen's SLA rapid prototyping for presentation samples and ergonomic trials.[5][7]

For customers who need multiple part types—plastic shells, metal brackets, internal frames—Shangchen can handle all these rapid prototyping needs within one order. This one‑stop rapid prototyping approach simplifies communication, shortens lead times, and reduces the risk of mismatched tolerances between components.[5][6]

Even for mature products, Shangchen's SLA rapid prototyping is valuable for engineering changes, functional updates, and quick validation of design modifications. Using rapid prototyping in this way supports continuous improvement and reduces the downtime associated with tooling changes or complex rework.[15][5]

SLA rapid prototyping is a powerful resin‑based 3D printing technology that turns liquid photopolymer into precise, smooth, and highly detailed parts using UV light. It plays a central role in modern rapid prototyping workflows by accelerating design validation, functional testing, and pre‑launch marketing activities across many industries.[1][7]

As a comprehensive rapid prototyping and manufacturing factory in China, Shangchen (sc-rapidmanufacturing.com) offers SLA rapid prototyping together with CNC machining, CNC turning, sheet metal fabrication, and mold production to support OEM projects from concept to mass production. By partnering with Shangchen for SLA rapid prototyping, overseas brands, wholesalers, and manufacturers can shorten development cycles, improve design quality, and bring competitive products to market faster.[6][5]

SLA rapid prototyping is a 3D printing process that uses a UV light source to solidify liquid resin layer by layer, creating accurate plastic parts directly from digital CAD data. It is widely used to produce visual and functional rapid prototyping models with excellent surface quality and fine details.[1][2]

The main benefits of SLA rapid prototyping are high dimensional accuracy, smooth surfaces, and the ability to create thin walls, sharp edges, and complex internal structures. Because it is tool‑less and digital, SLA rapid prototyping also reduces lead time and cost for early design iterations.[13][7]

SLA rapid prototyping uses liquid photopolymer resins that cure under UV light into solid plastic parts. These resins can be tailored to mimic different properties such as rigidity, toughness, transparency, or heat resistance for various rapid prototyping applications.[7][9]

SLA rapid prototyping is the preferred choice when projects demand high‑quality appearance models, tight tolerances, or intricate details that are difficult to machine. It is often selected over other rapid prototyping methods for presentation prototypes, fluid‑flow components, and small precision parts.[11][13]

Shangchen supports OEM customers by integrating SLA rapid prototyping with CNC machining, CNC turning, sheet metal fabrication, and tooling services in one facility. This one‑stop rapid prototyping solution simplifies project management and helps overseas brands move smoothly from prototype to stable volume production.[5][6]

[1](https://en.wikipedia.org/wiki/Stereolithography)

[2](https://www.hubs.com/knowledge-base/what-is-sla-3d-printing/)

[3](https://www.sc-rapidmanufacturing.com)

[4](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[5](https://www.sc-rapidmanufacturing.com/what-is-rapid-prototyping-used-for.html)

[6](https://www.sc-rapidmanufacturing.com/best-3d-printing-technologies-for-precision-prototyping.html)

[7](https://www.protolabs.com/services/3d-printing/stereolithography/)

[8](https://aerosportadditive.com/rapid-prototyping-with-stereolithography-sla/)

[9](https://formlabs.com/blog/ultimate-guide-to-stereolithography-sla-3d-printing/)

[10](https://www.3ds.com/make/service/3d-printing-service/sla-stereolithography)

[11](https://all3dp.com/2/stereolithography-3d-printing-simply-explained/)

[12](https://www.laserproto.com/what-is-stereolithography-who-invented-it-and-when/)

[13](https://www.manufacturingtomorrow.com/news/2024/07/10/whats-the-differences-between-sla-and-sls-in-rapid-prototyping/23021/)

[14](https://computer.howstuffworks.com/stereolith.htm)

[15](https://www.xometry.com/resources/3d-printing/what-is-rapid-prototyping-in-3d-printing/)

[16](https://www.sc-rapidmanufacturing.com/top-10-rapid-prototyping-manufacturers-in-china.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal