Views: 222 Author: Amanda Publish Time: 2025-12-02 Origin: Site

Content Menu

● Shangchen: Your Rapid Prototyping and OEM Manufacturing Partner

● Main Uses of Rapid Prototyping

>> Concept and Design Validation

>> Functional and Engineering Testing

>> User Experience and Human Factors

>> Pre-Production and Manufacturing Verification

● Core Rapid Prototyping Technologies

>> CNC Machining and CNC Turning

>> 3D Printing and Additive Manufacturing

>> Vacuum Casting and Low-Volume Molding

>> Rapid Tooling and Trial Molds

● Key Benefits of Rapid Prototyping

● Industries Using Rapid Prototyping

>> Consumer Electronics and Consumer Goods

>> Industrial Equipment and Robotics

● Why OEM Brands Choose Shangchen for Rapid Prototyping

● Typical Rapid Prototyping Project Flow with Shangchen

● FAQ

>> 1. What is Rapid Prototyping in manufacturing?

>> 2. Which industries benefit most from Rapid Prototyping?

>> 3. How does Shangchen support Rapid Prototyping projects?

>> 4. What materials can be used for Rapid Prototyping?

>> 5. What are the main advantages of Rapid Prototyping for OEM brands?

Rapid Prototyping is used to turn design ideas into tangible or testable models quickly so that brands, engineers, and OEM manufacturers can verify form, fit, function, and manufacturability before full-scale production. It supports everything from early concept validation and ergonomic testing to engineering verification, marketing samples, and low-volume production in industries such as automotive, aerospace, medical, industrial equipment, and consumer electronics.[1][3][7][11]

Shangchen (sc-rapidmanufacturing.com) is a China-based OEM factory specializing in Rapid Prototyping, CNC machining, precision batch production, CNC turning, sheet metal fabrication, 3D printing services, and mold production for overseas brands, wholesalers, and manufacturers. By integrating multiple Rapid Prototyping processes under one roof, Shangchen helps customers move smoothly from CAD models to real-world parts while maintaining speed, precision, and consistent quality.[12][13][14][15][16][17]

For global OEM clients, Shangchen offers flexible order quantities—from one-off Rapid Prototyping parts to medium and large production runs—supported by advanced CNC equipment, experienced engineers, and strict quality control systems. This combination makes Shangchen an ideal partner when you need Rapid Prototyping samples, engineering validation parts, and scalable production from the same supplier.[15][16][17][18]

Rapid Prototyping is a group of digital manufacturing methods used to quickly create physical or visual models from 3D CAD data so that teams can test and refine designs in short cycles. Rather than waiting weeks for traditional tooling, companies can obtain prototypes in days or even hours, evaluate them, make improvements, and repeat the process as needed.[3][7][19][20]

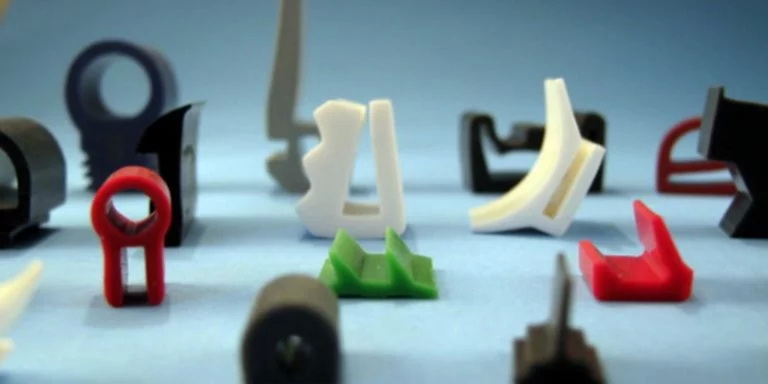

Typical Rapid Prototyping workflows use technologies such as CNC machining, 3D printing, vacuum casting, sheet metal fabrication, and low-volume molding to achieve fast lead times with high dimensional accuracy. These processes support appearance models, functional prototypes, engineering samples, and pre-production runs that closely resemble final mass-produced parts.[7][10][19][21][3]

Rapid Prototyping is used across the entire product development cycle: from early concept sketches to final production validation. Its most important uses focus on reducing development risk, improving product performance, and shortening time-to-market.[6][20][3]

In the concept stage, Rapid Prototyping converts digital models into physical samples so teams can review size, shape, and overall design language. Simple 3D printed or CNC-machined models reveal issues like poor ergonomics, unbalanced proportions, or difficult assembly features that are hard to judge on a screen.[9][19][21][3][7]

Designers and marketing teams use Rapid Prototyping models in internal meetings and design reviews to compare alternatives side by side and select the best direction. This early-stage feedback loop reduces the number of major changes required later in the development path.[4][19][22][3]

Rapid Prototyping is widely used to produce functional parts that can undergo realistic engineering tests, including structural loading, vibration, pressure, and temperature cycling. CNC Rapid Prototyping in metals and engineering plastics allows engineers to replicate production-intent tolerances and mechanical properties, making it suitable for fit checks and performance verification.[8][10][20][23][24][15]

By testing Rapid Prototyping parts in real or simulated working environments, teams can identify weak points, optimize wall thickness, adjust material selection, and improve durability before committing to expensive molds. This engineering-focused use of Rapid Prototyping directly reduces failure risk in the field and warranty costs.[17][22][23][25][6]

Rapid Prototyping also supports user experience (UX) research and human-factors engineering by producing realistic prototypes that real users can hold, wear, or interact with. For example, medical device developers can test how surgeons grip instruments, while consumer electronics brands can evaluate how users operate buttons, screens, or touch interfaces.[5][11][20][26][3]

With Rapid Prototyping, UX teams can run multiple rounds of user testing—each with improved prototypes—without long delays between iterations. This iterative feedback helps refine ergonomics, usability, and perceived quality long before mass production.[19][20][22][3]

In later stages, Rapid Prototyping is used to confirm manufacturability and assembly efficiency by producing parts that reflect final materials, dimensions, and interfaces. Low-volume molded or machined Rapid Prototyping batches help validate tooling design, production processes, assembly lines, and packaging solutions.[22][23][25][15][17]

Manufacturers rely on these Rapid Prototyping runs to check tolerance stacks, assembly sequences, fixture design, and quality control procedures before scaling up. This pre-production use of Rapid Prototyping significantly lowers risk and prevents late-stage surprises in mass manufacturing.[10][25][3][6][22]

Different Rapid Prototyping technologies serve different goals such as accuracy, speed, cost, and material behavior. Shangchen combines several of these technologies to deliver optimized Rapid Prototyping solutions for its OEM partners.[16][3][7][10][15][17]

CNC milling and CNC turning are classic Rapid Prototyping methods for precise metal and plastic parts that must closely match production components. Shangchen operates advanced multi-axis CNC machining centers and CNC lathes to create complex geometries, tight tolerances, and high-quality surfaces suited for engineering validation.[18][24][7][15][16]

CNC-based Rapid Prototyping supports materials such as aluminum, steel, stainless steel, copper alloys, and engineering plastics used in automotive, aerospace, and industrial equipment. Parts can be post-processed by anodizing, painting, polishing, or plating to simulate final mass-production appearance.[23][27][15]

3D printing is another major Rapid Prototyping approach that builds parts layer by layer, enabling complex shapes and internal structures that may be impossible with traditional machining. Technologies such as FDM, SLA, DLP, and SLS allow rapid creation of plastic and resin prototypes, as well as certain metal parts.[21][3][5][7][9]

This type of Rapid Prototyping is ideal for concept models, intricate internal channels, lightweight lattice structures, and small-batch functional prototypes. Shangchen complements CNC Rapid Prototyping with 3D printing services so customers can choose the best balance of cost, speed, and detail for each project.[27][3][15][16][21][23]

Sheet metal fabrication plays an important role in Rapid Prototyping of enclosures, brackets, panels, and structural parts for electronics, machinery, and automotive systems. Processes like laser cutting, bending, welding, and stamping can quickly turn flat metal sheets into sturdy prototypes that behave similarly to final production parts.[15][27]

These sheet-metal Rapid Prototyping components are often used to verify structural stiffness, thermal behavior, assembly clearances, and cable routing inside housings or cabinets. They also help industrial designers refine aesthetics and surface treatments for visible metal parts.[3][5][10][23]

Vacuum casting and soft-tool molding are Rapid Prototyping methods used to create small batches of plastic parts that closely mimic injection-molded components. Silicone molds or temporary tools allow multiple parts to be cast from a master pattern, making them ideal for marketing samples, certification tests, and user trials.[25][6][23][3]

These Rapid Prototyping techniques deliver good surface finish, stable dimensions, and a variety of material options, bridging the gap between one-off prototypes and high-volume injection molding. Shangchen's mold production and casting capabilities enable customers to validate both design and process before investing in high-cost steel tooling.[10][16][17][25][3][15]

Rapid Prototyping also extends into rapid tooling, where simplified or single-cavity molds are produced quickly to test real injection molding conditions. These trial molds allow manufacturers to evaluate cycle times, molding parameters, part warpage, and ejection behavior with the actual material used in mass production.[6][7][8][22][23]

By combining Rapid Prototyping with rapid tooling, Shangchen helps OEM brands gradually scale from prototypes to stable mass production with controlled risk and predictable costs. This staged approach is particularly important for new product lines or complex components that cannot tolerate major changes after launch.[16][17][22][25][15]

Rapid Prototyping has become a standard tool because it offers clear and measurable benefits in modern product development. These benefits apply to start-ups, established brands, and contract manufacturers.[19][25][3]

- Accelerated time-to-market: Rapid Prototyping shortens development cycles, helping companies launch products faster and respond to market changes quickly.[20][22][19]

- Lower development cost: Early discovery of design issues through Rapid Prototyping avoids expensive tooling changes and production scrap.[20][25][3]

- Improved product quality: Iterative Rapid Prototyping allows continuous improvement in performance, reliability, and user satisfaction.[3][19][20]

- Design freedom and innovation: Rapid Prototyping supports complex shapes, lattice structures, and integrated features that would be difficult with traditional methods.[7][19][3]

- Reduced production risk: Pre-production Rapid Prototyping runs validate processes, materials, and tolerances before high-volume investments.[17][22][23]

Rapid Prototyping is used in almost every manufacturing sector that values innovation and rapid iteration. However, some industries rely on Rapid Prototyping more heavily due to strict performance demands and fast product cycles.[11][1][7]

Automotive and aerospace manufacturers use Rapid Prototyping for concept parts, structural components, brackets, ducts, and interior elements. CNC Rapid Prototyping and 3D printing both support lightweight optimization, aerodynamic testing, and engine or fuel-system development.[1][5][8][23][15][3]

Real-world examples include Rapid Prototyping of satellites, aircraft components that reduce weight and emissions, and tooling or jigs for assembly lines. These applications show how Rapid Prototyping combines innovation with sustainable performance gains.[2][5][8][6]

In healthcare, Rapid Prototyping is used for surgical tools, implants, prosthetics, dental devices, and anatomical models for surgical planning. Patient-specific Rapid Prototyping based on CT or MRI data enables custom implants and precise surgical guides that improve clinical outcomes.[2][5][23][3]

3D printing and CNC Rapid Prototyping allow medical engineers to test ergonomics, sterilization, and biocompatibility before regulatory submission and mass production. This capability makes Rapid Prototyping a core technology in modern medical innovation.[5][9][21][23][3]

Consumer electronics brands use Rapid Prototyping for phone housings, wearables, smart home devices, and appliance components. Appearance and functional Rapid Prototyping models help optimize CMF (color, material, finish), assembly methods, cooling paths, and drop resistance.[26][11][23][5][3]

The wider consumer goods sector also uses Rapid Prototyping for custom-fitted products, personalized accessories, and design-driven lifestyle items. Frequent model updates and short product lifecycles make Rapid Prototyping an essential part of staying competitive.[9][11][22][5]

Industrial machinery and robotics rely on Rapid Prototyping for brackets, housings, gears, fixtures, and complex mechanical assemblies. These Rapid Prototyping parts are used to test motion, vibration resistance, and reliability under demanding operating conditions.[23][27][6][10][15][3]

Because many industrial systems are customized or built in low volumes, Rapid Prototyping provides a cost-effective way to validate designs without committing to large tooling investments. CNC Rapid Prototyping and sheet metal fabrication are especially valuable for robust functional components.[25][27][10][15][3]

For overseas OEM brands, choosing the right Rapid Prototyping partner is crucial to balancing speed, quality, and cost. Shangchen focuses on serving international customers who need reliable communication, stable quality, and scalable manufacturing.[14][12][16]

Key reasons why global customers choose Shangchen for Rapid Prototyping and production include:

- Integrated services: Rapid Prototyping, CNC machining, CNC turning, sheet metal, 3D printing, vacuum casting, and mold production are all available in one factory.[27][15][16]

- Tight tolerances and quality systems: Shangchen uses inspection equipment and quality management practices to ensure stable Rapid Prototyping and production quality.[24][15][17]

- Flexible volumes and fast lead times: The factory supports urgent Rapid Prototyping orders, small batches, and long-term mass production while maintaining consistent standards.[15][16][17]

- Experience with overseas OEM projects: Shangchen is familiar with export documentation, packaging, and international standards required by global brands and wholesalers.[12][16][15]

A typical new-product project with Shangchen integrates multiple Rapid Prototyping stages so that the customer can move confidently toward mass production.[24][17][15]

1. Initial design review: Customers submit CAD files and basic requirements; engineers evaluate feasibility and suggest suitable Rapid Prototyping processes.[16][15]

2. Concept Rapid Prototyping: 3D printing or basic CNC Rapid Prototyping is used to produce appearance and fit models for early feedback.[5][7][3]

3. Engineering Rapid Prototyping: CNC machining, CNC turning, and sheet metal fabrication create higher-precision parts for structural and functional tests.[23][27][15]

4. Pre-production Rapid Prototyping: Vacuum casting, rapid tooling, or trial molds generate small batches to validate processes and assembly.[25][3][23]

5. Batch and mass production: After successful Rapid Prototyping and verification, the project moves to stable production using CNC, sheet metal, and full tooling.[17][15][16]

Throughout these stages, Shangchen uses Rapid Prototyping to adjust designs, improve manufacturability, and control risk step by step.[22][15][17]

Rapid Prototyping is used to accelerate innovation, reduce development risk, and enhance product performance by allowing fast, iterative verification of design concepts, functional behavior, and manufacturing feasibility. With integrated capabilities in Rapid Prototyping, CNC machining, CNC turning, sheet metal, 3D printing, vacuum casting, and mold production, Shangchen (sc-rapidmanufacturing.com) provides overseas brands, wholesalers, and manufacturers with a complete pathway from first prototype to stable mass production.[12][19][20][3][15][16]

By choosing Shangchen as a Rapid Prototyping and OEM manufacturing partner, companies can shorten time-to-market, improve product quality, and benefit from a single, reliable supply chain across every stage of development.[15][16][17]

Rapid Prototyping in manufacturing is the use of digital fabrication technologies—such as CNC machining, 3D printing, and vacuum casting—to quickly turn CAD designs into physical parts for testing before mass production. It allows teams to verify form, fit, function, and manufacturability early, reducing development time and preventing costly late-stage changes.[7][19][20][3]

Industries that benefit most from Rapid Prototyping include automotive, aerospace, medical devices, consumer electronics, industrial machinery, and consumer goods. These sectors rely on Rapid Prototyping to manage strict performance demands, frequent design updates, and aggressive time-to-market goals.[11][1][3][5][7]

Shangchen supports Rapid Prototyping projects by providing process selection, design-for-manufacturing feedback, and integrated production services from a single factory. Customers can order concept models, functional Rapid Prototyping parts, pre-production batches, and full-scale production using CNC machining, CNC turning, sheet metal, 3D printing, casting, and mold making.[18][27][16][17][15]

Rapid Prototyping materials include plastics (such as ABS, PLA, PC, nylon, and resins) and metals (such as aluminum, stainless steel, tool steel, titanium, and copper alloys). Shangchen's Rapid Prototyping and CNC services cover a wide range of industrial metals and engineering plastics suitable for both prototypes and end-use parts.[18][3][7][16][23][15]

For OEM brands, the main advantages of Rapid Prototyping are faster product launches, fewer design errors, better customer feedback, and lower overall development costs. By working with an experienced partner like Shangchen, OEM customers can integrate Rapid Prototyping with scalable production, ensuring a smooth transition from prototype to long-term manufacturing.[19][20][12][17][25][15]

[1](https://uptivemfg.com/rapid-prototyping-companies/)

[2](https://prototal.co.uk/blog/examples-of-rapid-prototyping/)

[3](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[4](https://www.stratasys.com/en/resources/blog/real-world-innovations-with-rapid-prototyping/)

[5](https://www.raise3d.com/blog/3d-printing-applications/)

[6](https://www.rcoeng.com/blog/rapid-prototyping-the-future-of-manufacturing)

[7](https://www.autodesk.com/solutions/rapid-prototyping)

[8](https://www.3erp.com/blog/aerospace-industry-prototyping/)

[9](https://any-shape.com/blog/examples-of-rapid-prototyping/)

[10](https://xometry.pro/en/articles/rapid-prototyping-manufacturing/)

[11](https://manufactur3dmag.com/5-industries-benefit-from-rapid-prototyping/)

[12](https://www.sc-rapidmanufacturing.com)

[13](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[14](https://www.sc-rapidmanufacturing.com/aboutus.html)

[15](https://www.sc-rapidmanufacturing.com/cnc-milling-services-key-benefits-for-rapid-prototyping-and-batch-production.html)

[16](https://www.sc-rapidmanufacturing.com/products.html)

[17](https://www.sc-rapidmanufacturing.com/what-are-the-advantages-of-rapid-prototyping.html)

[18](https://www.sc-rapidmanufacturing.com/cnc-machining.html)

[19](https://www.stratasys.com/en/resources/blog/key-advantages-of-rapid-prototyping/)

[20](https://helio.app/product/prototype-testing/rapid-prototyping-testing/)

[21](https://avidpd.com/prototyping/how-rapid-prototyping-with-3d-printing-is-transforming-product-development-at-every-stage/)

[22](https://www.sei.com/insights/article/achieving-faster-better-product-development-with-rapid-prototyping/)

[23](https://www.cncprotolabs.com/en/blog/what-are-the-applications-of-rapid-prototyping)

[24](https://www.sc-rapidmanufacturing.com/news/Rapid-Prototyping-with-CNC.html)

[25](https://prismier.com/8-benefits-of-rapid-prototype-manufacturing/)

[26](https://www.phas.io/post/rapid-prototyping)

[27](https://www.sc-rapidmanufacturing.com/Industry-News-ic3625146.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal