Views: 222 Author: Amanda Publish Time: 2025-12-02 Origin: Site

Content Menu

● Shangchen: One‑Stop Rapid Prototyping Partner

● What Is Rapid Prototyping in Manufacturing?

● Why Rapid Prototyping Matters for Product Development

● Core Stages of the Rapid Prototyping Process

● Stage 1: Concept and Requirements

● Stage 2: 3D Design and Digital Validation

● Stage 3: Design for Manufacturing (DFM) Review

● Stage 4: Process Selection for Rapid Prototyping

● Stage 5: Data Preparation and Job Setup

● Stage 6: Prototype Manufacturing

● Stage 7: Post‑Processing and Inspection

● Stage 8: Testing, Feedback, and Iteration

● Types of Rapid Prototyping Technologies

● Shangchen's Rapid Prototyping Capabilities

● Benefits of a Strong Rapid Prototyping Strategy

● Rapid Prototyping vs Traditional Prototyping

● How Shangchen Uses Rapid Prototyping in OEM Projects

● Best Practices for Working with a Rapid Prototyping Partner

● How to Select the Right Rapid Prototyping Supplier

>> 1. What is the main objective of rapid prototyping?

>> 2. Which rapid prototyping services does Shangchen provide?

>> 3. How long does a typical rapid prototyping cycle take?

>> 4. Can rapid prototyping parts be used for functional testing?

>> 5. How does Shangchen support the transition from rapid prototyping to mass production?

Rapid prototyping is the fast, iterative transformation of 3D design concepts into tangible parts that can be tested, refined, and prepared for mass production with reduced risk and cost. For overseas brands, wholesalers, and product manufacturers, a strategic rapid prototyping process is the backbone of short lead times, high quality, and reliable launch schedules.[1][2][3][8]

Rapid prototyping in modern manufacturing combines multiple technologies—such as CNC machining, CNC turning, sheet metal fabrication, 3D printing, casting, and rapid molding—to deliver prototypes that match real‑world performance. When these Rapid Prototyping methods are integrated under one roof, communication improves and each iteration becomes faster, clearer, and easier to scale.[2][5][6][1]

Shangchen (sc‑rapidmanufacturing.com) is a China‑based factory focused on rapid prototyping, CNC machining services, precision batch production, CNC turning, sheet metal manufacturing, 3D printing, and mold production for global customers. Overseas brands, wholesalers, and OEM product manufacturers rely on Shangchen as an engineering‑driven partner to handle the entire rapid prototyping process from first samples to stable mass production.[11][12][13][14]

By combining rapid prototyping, tooling, and OEM production in one supply chain, Shangchen reduces lead times, simplifies communication, and ensures consistent quality across every development phase. Customers can move from early design validation to low‑volume runs and finally to large‑scale production without changing suppliers or re‑qualifying processes.[12][14][15][11]

In manufacturing, rapid prototyping is a set of methods used to quickly build physical parts or assemblies directly from 3D CAD data so teams can evaluate form, fit, and function before committing to full tooling. Depending on the requirements, rapid prototyping can focus on appearance models, functional parts, or near‑production parts with performance close to the final product.[5][6][1][2]Rapid prototyping is not limited to a single technology; it includes additive manufacturing (3D printing), subtractive manufacturing (CNC machining), sheet metal fabrication, compressive methods like casting and molding, and hybrid workflows that combine these techniques. Each rapid prototyping method has its strengths in speed, cost, surface finish, accuracy, and material performance, so the process must be selected carefully for each project.[3][8][1][5]

Rapid prototyping dramatically shortens development cycles by turning revised designs into physical parts in days rather than weeks or months. This speed lets teams run more experiments, compare more options, and reach better design decisions with actual data and hands‑on testing.[10][1][3]Because rapid prototyping exposes issues early—such as geometry conflicts, tolerance stack‑ups, or material behavior—brands avoid late‑stage surprises when tooling is already expensive and changes are hard to implement. For overseas OEM programs, rapid prototyping also improves communication between design teams and manufacturing partners, since real parts make requirements and trade‑offs much easier to discuss.[8][15][5][11]

A robust rapid prototyping process follows a series of stages that repeat in cycles until the design is ready for production. While each company may use different names, the core rapid prototyping stages are broadly similar worldwide.[7][9][3][5]Key stages typically include:- Conceptualization and requirements- 3D design and digital validation- Design for manufacturing review- Process selection and data preparation- Prototype manufacturing- Post‑processing and quality inspection- Testing, feedback, and iterationEach complete loop through this rapid prototyping cycle brings the part closer to production‑ready status and reduces the risk of failure in the field.[3][8]

Rapid prototyping starts with clear product goals: target users, performance requirements, cost constraints, and regulatory considerations. At this stage, teams answer practical questions such as size, features, environment of use, and expected lifetime so that rapid prototyping later focuses on the right trade‑offs.[5][7][8][10]Shangchen works with overseas customers to interpret these requirements into realistic manufacturing options, suggesting how rapid prototyping can validate critical elements early. For example, a consumer enclosure might require impact resistance and cosmetic quality, while an industrial bracket may prioritize load capacity and corrosion resistance, each demanding a different rapid prototyping route.[8][11][12][3]

Once the requirements are defined, engineers create 3D CAD models representing the concept in full detail, including dimensions, tolerances, and assembly relationships. Good rapid prototyping practice includes design for manufacturing principles from the beginning—adequate draft angles, realistic wall thickness, proper fillets, and clear datums for inspection.[4][9][5][8]Digital validation tools such as simulation, interference checks, and motion studies help stabilize the design before the first rapid prototyping build. This step reduces unnecessary iterations and ensures that rapid prototyping is used to prove high‑value aspects like mechanical performance and usability rather than obvious design errors.[10][5][8]

A DFM review evaluates whether the model is suitable for the chosen rapid prototyping processes and the likely production methods that will follow. This review looks at features like undercuts, thin walls, deep pockets, sharp internal corners, and tolerance chains that might be difficult or expensive to manufacture.[1][3][5][8]Shangchen offers DFM feedback for rapid prototyping projects, suggesting modifications that preserve function while simplifying machining, forming, or molding. Doing this before the first rapid prototyping run avoids wasted cycles and lays the groundwork for an easier transition to volume production later.[11][12][1][8]

Choosing the right process is central to efficient rapid prototyping; the same part might be made using 3D printing, CNC machining, sheet metal fabrication, casting, or rapid injection molding depending on its purpose. Key selection factors include required accuracy, surface finish, mechanical properties, material class, quantity, and budget.[1][3][5][8]For example, early‑stage concept parts might use low‑cost additive rapid prototyping, while final validation parts often shift to CNC machining or rapid molding to match production materials and tolerances. Shangchen evaluates these factors with customers and recommends rapid prototyping routes that align with both current tests and long‑term production plans.[14][12][3][5]

Once a process is selected, the design is prepared for manufacturing via toolpaths, slicing, nesting, or forming programs, depending on the rapid prototyping technology. This step may include exporting CAD to STL or other formats, orienting the part, defining supports or fixtures, and simulating operations to avoid collisions or defects.[9][4][3][1]Material selection and machine setup also belong to this stage: operators choose billets, sheets, or resins and set the parameters needed to achieve the desired rapid prototyping quality. Careful preparation minimizes scrap and rework and contributes to consistent results across multiple rapid prototyping iterations.[9][3][5][8]

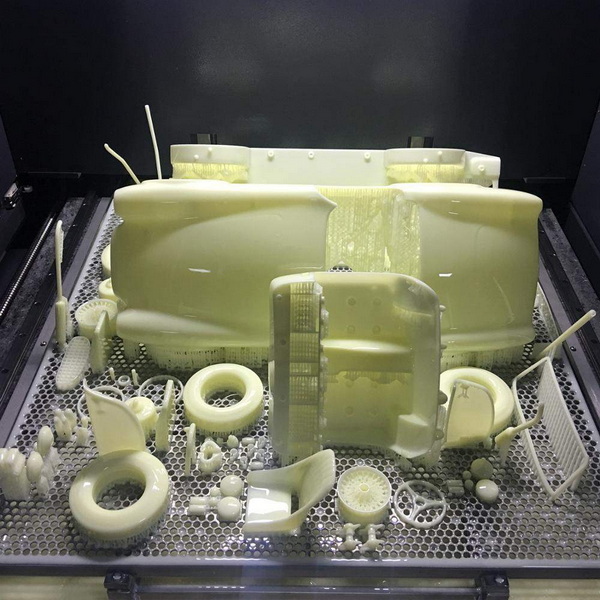

During manufacturing, the machine builds each part using the defined rapid prototyping program—either by adding material layer by layer or by removing material from stock. Build times range from less than an hour for small simple items to many hours or days for larger, complex assemblies.[6][3][9]Shangchen runs multiple rapid prototyping technologies in parallel, which allows mixing 3D printed concept models, CNC‑machined functional parts, and sheet metal structures within the same project. This flexible approach ensures that each component is produced by the most appropriate rapid prototyping method for its role in the product.[12][14][5][1]

After building, rapid prototyping often requires secondary work such as support removal, deburring, polishing, bead blasting, painting, anodizing, or heat treatment, depending on the process and material. These steps refine the prototype's appearance and performance so that it behaves more like a final product in testing.[4][6][5][1]Quality inspection validates dimensions, tolerances, surface finish, and assembly fit, confirming whether the rapid prototyping run meets the defined specifications. Shangchen integrates measurement and inspection into its rapid prototyping workflow so that feedback is quantitative and traceable, not just visual.[13][3][8][11]

Functional testing is where rapid prototyping delivers its highest value, because real‑world loads, environments, and user interactions reveal issues that digital models cannot fully predict. Tests may include mechanical strength, thermal behavior, sealing performance, ergonomics, vibration resistance, or lifetime cycling depending on the target industry.[3][5][8][10]Teams then collect feedback and feed insights back into the design and manufacturing plan, triggering a new rapid prototyping iteration when necessary. Over several cycles, the design converges toward a robust, manufacturable solution that can move confidently into tooling and mass production.[7][5][8][3]

Rapid prototyping covers three broad technology families: additive, subtractive, and formative methods. Each family supports different stages of development and different levels of fidelity in the rapid prototyping process.[6][5][8][3]Additive rapid prototyping includes technologies like FDM, SLA, and SLS, which excel at complex shapes and internal features with relatively low setup cost. Subtractive rapid prototyping includes CNC machining and turning, which provide tight tolerances and production‑like materials, especially for metals and engineering plastics. Formative rapid prototyping uses casting and rapid molding to create parts that closely mimic full‑scale production in both material behavior and cosmetic quality.[2][4][5][6][8][3]

Shangchen brings together multiple rapid prototyping technologies so customers can choose the right mix of speed, accuracy, and cost at each stage of development. Available services include CNC milling, CNC turning, precision batch production, sheet metal fabrication, industrial 3D printing, and mold fabrication for prototype and production runs.[13][14][11][12]Because these rapid prototyping capabilities are integrated, Shangchen can support single‑part prototypes, multi‑component assemblies, and full pilot builds with consistent quality management. This structure is especially valuable for overseas OEM customers that need predictable lead times and clear documentation across the entire rapid prototyping life cycle.[15][14][11][12]

A well‑designed rapid prototyping strategy reduces design risk, increases innovation, and improves cross‑team communication. When stakeholders can evaluate physical prototypes instead of static images, discussions about shape, function, and cost become more productive and objective.[5][7][10][3]Rapid prototyping also shortens time‑to‑market by enabling parallel workstreams; design, testing, sourcing, and marketing can progress together based on real parts. For OEM programs, this strategy helps brands respond quickly to market feedback and regulatory changes without losing control over quality.[8][10][3][5]

Traditional prototyping often relies on manual shop work, early hard tooling, and long feedback loops, which limit the number of design iterations that fit into a schedule. Rapid prototyping replaces those long cycles with faster, more automated processes that can generate multiple design versions in quick succession.[6][1][3][8]Because rapid prototyping emphasizes flexibility and digital workflows, teams can update models, rerun builds, and compare alternatives with minimal overhead. This difference leads to higher‑quality final designs and a more efficient path to mass production than traditional prototyping alone can provide.[1][3][5][8]

In OEM projects, Shangchen structures rapid prototyping in phases, starting with concept validation, then functional testing, and finally pre‑production validation. Early phases may rely heavily on 3D printing rapid prototyping, while later phases shift toward CNC machining, sheet metal, and prototype molds that match production conditions better.[14][11][12][5]Because Shangchen also delivers mass production parts, lessons learned during rapid prototyping feed directly into tooling design, process parameters, and quality plans. This seamless flow of information reduces launch risk and helps overseas brands maintain consistent performance from the first prototype through the entire product life cycle.[11][12][13][8]

To get maximum value from rapid prototyping, brands should define clear goals for each build—whether it is to verify dimensions, validate mechanics, assess cosmetics, or test assembly. This clarity lets the manufacturing partner choose appropriate materials, tolerances, and processes for each rapid prototyping run.[3][5][8][1]Providing complete CAD models, tolerances, material preferences, and test criteria from the start helps reduce miscommunication and avoid unnecessary iterations. Regular design reviews using rapid prototyping samples also keep cross‑functional teams aligned and allow issues to be resolved before they impact schedule or cost.[7][10][5][3]

When choosing a rapid prototyping supplier, buyers should evaluate technical capabilities, material coverage, lead times, quality systems, and communication practices. It is important to confirm whether the supplier can also support later phases such as bridge production and long‑term OEM manufacture, not just basic rapid prototyping.[5][8][1][3]Shangchen positions itself as a long‑term partner that integrates rapid prototyping, CNC machining, sheet metal, 3D printing, and mold production specifically for global customers. This full‑spectrum approach allows clients to stay with one trusted supplier from first prototype until stable mass production.[12][13][14][11]

Rapid prototyping is a critical, iterative process that transforms ideas into validated, manufacturable products by combining digital design, fast fabrication, and structured testing. By choosing appropriate technologies and running multiple rapid prototyping cycles, brands can reduce risk, accelerate time‑to‑market, and improve final product performance.[2][3]For overseas brands, wholesalers, and OEM manufacturers, Shangchen (sc‑rapidmanufacturing.com) offers a comprehensive rapid prototyping solution that includes CNC machining, CNC turning, sheet metal fabrication, industrial 3D printing, and mold production within one integrated factory system. This combination of rapid prototyping and scalable manufacturing makes it easier to move from concept to reliable mass production while maintaining consistent quality and predictable lead times.[15][14][11][12]

The main objective of rapid prototyping is to create physical versions of a design quickly so teams can evaluate form, fit, and function before investing in full tooling and mass production. Through repeated rapid prototyping cycles, engineers detect design flaws, manufacturability problems, and performance gaps early, when changes are still affordable and fast.[2][6][3][5]

Shangchen provides a broad set of rapid prototyping services, including CNC milling, CNC turning, precision batch production, sheet metal fabrication, industrial 3D printing, and prototype mold fabrication. These rapid prototyping services can be combined to produce complete assemblies that closely match final production parts in both geometry and material behavior.[13][14][11][12]

Lead times for rapid prototyping depend on geometry, material, and quantity, but many single‑part projects can be completed in a few days to a couple of weeks. Complex assemblies, high‑precision components, or parts requiring special post‑processing can take longer, yet rapid prototyping still remains significantly faster than traditional prototyping routes.[9][1][3]

Yes, rapid prototyping parts are often used for rigorous functional testing, especially when produced via CNC machining, engineering‑grade 3D printing, or rapid tooling with production‑like materials. These rapid prototyping parts help verify load capacity, thermal performance, sealing, and durability prior to committing to final tooling and large‑scale production.[8][3][5]

Shangchen supports the full journey from rapid prototyping to mass production by combining prototype fabrication, tooling, and OEM supply under one system. Data and lessons from each rapid prototyping round flow into mold design, process parameters, and quality control plans, ensuring that the final production line reflects everything learned during development.[14][11][12][8]

[1](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

[2](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[3](https://www.fictiv.com/articles/rapid-prototyping-guide)

[4](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[5](https://wefab.ai/blog/rapid-prototyping-explained-a-guide-to-the-processes-that-accelerate-product-development/)

[6](https://www.stephengould.com/rapid-prototyping/)

[7](https://www.linkedin.com/pulse/guide-rapid-prototyping-manufacturing-product-yee-creatingway--jnhuc)

[8](https://xometry.pro/en/articles/rapid-prototyping-manufacturing/)

[9](https://www.stratasys.com/en/resources/blog/guide-to-rapid-prototyping/)

[10](https://www.dailybot.com/insights/the-ultimate-guide-to-rapid-prototyping)

[11](https://www.sc-rapidmanufacturing.com/aboutus.html)

[12](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[13](https://www.sc-rapidmanufacturing.com)

[14](https://www.sc-rapidmanufacturing.com/products.html)

[15](https://www.sc-rapidmanufacturing.com/news/Machining-Productivity-Differences.html)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes