Views: 222 Author: Amanda Publish Time: 2025-12-02 Origin: Site

Content Menu

● Shangchen: Your Rapid Prototyping Partner

● Rapid Prototyping in Software Engineering: Core Idea

● Key Principles of Rapid Prototyping

● Types of Rapid Prototyping in Software

● The Rapid Prototyping Process in Software

● Rapid Prototyping and Agile, Scrum, and MVPs

● Benefits of Rapid Prototyping in Software Engineering

● Challenges and How to Manage Them

● Rapid Prototyping and Reusable Assets

● How Physical Rapid Prototyping Complements Software

● Shangchen's Rapid Prototyping and Manufacturing Capabilities

● Rapid Prototyping vs. Traditional Software Development

● Best Practices for Successful Rapid Prototyping

● Collaborating with Shangchen During Rapid Prototyping

● FAQs

>> 1. What is Rapid Prototyping in software engineering?

>> 2. How does Rapid Prototyping help reduce project risk?

>> 3. Can Rapid Prototyping work for both software and hardware?

>> 4. When should teams move from Rapid Prototyping to full development?

>> 5. Why choose Shangchen for Rapid Prototyping and OEM production?

Rapid Prototyping in software engineering is an iterative, feedback‑driven approach that focuses on building quick, functional models of applications to validate ideas, refine requirements, and improve user experience before full‑scale development. By emphasizing frequent learning cycles and tangible prototypes instead of static documents, Rapid Prototyping helps teams deliver higher‑quality software faster and with less risk.[1][6][7][8]

Shangchen (sc-rapidmanufacturing.com) is a China‑based factory dedicated to Rapid Prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing for overseas brands, wholesalers, and manufacturers. Through integrated OEM services, Shangchen supports international customers who need reliable, end‑to‑end support from early Rapid Prototyping samples to stable mass production.[11][12][13][14][15][16]

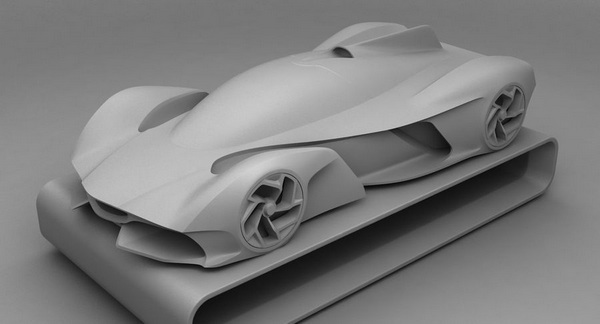

Shangchen's Rapid Prototyping services transform CAD models and design concepts into high‑quality physical parts, including plastic and metal housings, brackets, fixtures, and complex mechanical components. This capability is particularly valuable for software engineering teams working on IoT devices, smart products, and embedded systems, where software Rapid Prototyping must be validated in realistic physical environments.[12][13][14][17][18][19]

In software engineering, Rapid Prototyping means building early, quickly assembled versions of an application—often incomplete but usable—to explore how users interact with features and workflows. These prototypes might be low‑fidelity wireframes, medium‑fidelity clickable mockups, or high‑fidelity interactive prototypes that closely resemble the final product.[5][7][8]

Unlike traditional approaches that lock requirements early, Rapid Prototyping assumes that requirements will evolve as teams learn from each prototype iteration. The goal is not to produce a perfect prototype on the first attempt, but to move through cycles of building, testing, and refining until the product design is clearly understood and ready for implementation.[6][7][9][1]

Effective Rapid Prototyping in software engineering follows several fundamental principles that make the process truly “rapid” and valuable.[1][6]

- Iteration over perfection: Teams prioritize frequent cycles of change instead of trying to get everything right in one large design phase.[7][10]

- Early and continuous user feedback: Prototypes are regularly shown to users and stakeholders to collect insights that shape subsequent versions.[8][9]

- Focus on learning goals: Each Rapid Prototyping cycle is driven by clear questions—such as “Will users understand this flow?” or “Does this feature solve the problem?”—which guide what to prototype and test.[7][1]

- Lightweight implementation: Rapid Prototyping relies on fast tools, simplified architectures, and reusable components to minimize time spent on non‑essential details.[2][5]

These principles work together to reduce ambiguity, align stakeholders, and keep the team's attention on validated learning rather than speculation.[6][1]

Rapid Prototyping in software engineering can take multiple forms, each suited to different project stages and risk profiles.[8][6]

Common Rapid Prototyping types include:

- Low‑fidelity prototypes: Rough sketches or basic wireframes that communicate layout, information hierarchy, and major user flows without detailed visuals.[7][8]

- Medium‑fidelity clickable prototypes: Interactive screens built in design tools that simulate navigation, transitions, and user journeys, but may not be connected to real data.[5][8]

- High‑fidelity interactive prototypes: Near‑realistic simulations of the final product with detailed UI, animations, and sometimes partial backend logic.[20][6]

From a lifecycle perspective, Rapid Prototyping models also differ: disposable (throwaway) prototypes are built only to learn and then discarded, while evolutionary prototypes are gradually refined into production systems. Teams choose which Rapid Prototyping form to use based on available time, technology risk, and how much fidelity is required to answer their current questions.[9][1][6][7]

Although every organization adapts the details, a typical Rapid Prototyping process in software engineering follows a structured loop designed to maximize learning and minimize waste.[6][8]

1. Define goals and scope

Teams clarify what they need to learn, who the target user is, and which journeys or features are in focus for this Rapid Prototyping cycle.[1][7]

2. Research and conceptualization

Product managers and designers research user needs, pain points, and competitors to form initial concepts, often expressed as sketches or user stories.[8][6]

3. Prototype creation

The team builds a prototype at an appropriate fidelity, using tools that allow rapid change—such as UI design platforms, low‑code environments, or lightweight codebases.[9][5]

4. User testing and stakeholder review

Real or representative users interact with the prototype, while observers capture qualitative and quantitative feedback. Stakeholders also review how well the Rapid Prototyping results align with business goals.[6][8]

5. Iteration and refinement

Insights from testing drive modifications to flows, content, and interactions, leading to updated prototypes that are tested again.[1][7]

6. Handoff to development

Once the prototype stabilizes and learning goals are met, its structure and behavior guide implementation, often with detailed documentation or design systems.[5][8]

This Rapid Prototyping loop can be repeated many times during the life of a product, from initial concept through post‑launch enhancements.[9][6]

Rapid Prototyping aligns naturally with Agile and Scrum practices, where frequent inspection and adaptation are central. Prototypes can be built and tested within short sprints, supporting sprint planning, user story refinement, and product backlog prioritization.[7][8][6]

For startups and new product initiatives, Rapid Prototyping is often used to create a Minimum Viable Product (MVP)—a lean version of the product that focuses on core value propositions. By validating the MVP concept quickly through Rapid Prototyping, teams can confirm market interest, refine positioning, and reduce the risk of investing in features that users do not value.[5][1][6]

Rapid Prototyping offers benefits across speed, cost, quality, and communication, making it a powerful tool for modern software teams.[8][6]

Key benefits include:

- Faster time‑to‑market: Rapid Prototyping accelerates decision‑making and reduces back‑and‑forth on ambiguous requirements, helping teams deliver usable increments sooner.[9][8]

- Lower risk and less rework: Early prototypes reveal usability issues, missing requirements, and technical constraints before large investments are made.[1][6]

- Improved user experience: Regular user testing during Rapid Prototyping ensures that flows, content, and interactions better match real user needs.[7][8]

- Stronger stakeholder alignment: Prototypes serve as shared visual references that help non‑technical stakeholders understand trade‑offs and participate in decisions.[2][1]

- Better technical feasibility: Prototyping challenging features—such as integrations or performance‑sensitive workflows—helps teams validate architecture and technology choices earlier.[6][9]

These benefits become even more important when software is part of a larger system that includes hardware, manufacturing, and logistics.[3][4]

Although Rapid Prototyping is highly valuable, it introduces some challenges that teams must be prepared to manage.[1][6]

Common challenges include:

- Unclear objectives: Without clear learning goals, Rapid Prototyping can produce attractive artifacts that do not answer critical questions.[7][1]

- Over‑attachment to prototypes: Stakeholders may confuse prototypes with finished products, leading to unrealistic expectations about timelines and functionality.[10][9]

- Technical debt risks: When prototypes evolve directly into production systems without cleanup, shortcuts taken during Rapid Prototyping can create long‑term maintenance issues.[5][6]

- Limited user diversity: If only a narrow group of users tests prototypes, insights may not generalize to the broader audience.[9][7]

To address these issues, teams should communicate clearly about the purpose and limitations of each Rapid Prototyping cycle, track technical debt, and recruit a diverse set of users for testing.[6][1]

One advanced practice for scaling Rapid Prototyping is to create a “prototyping factory”—a set of reusable resources that allow teams to assemble new prototypes quickly.[2][5]

Such a Rapid Prototyping factory might include:

- A design system with reusable UI components, patterns, and guidelines.[2][7]

- A codebase with modular services, APIs, and templates that can be combined for new experiments.[2][5]

- Sample data sets, data models, and integration stubs that make prototypes realistic without full infrastructure.[2][6]

- Automated environments for deploying and monitoring prototypes so that teams can test them in realistic conditions.[9][2]

By investing in these assets, organizations increase their capacity to conduct Rapid Prototyping on demand, allowing multiple teams to explore ideas concurrently.[5][2]

Many products today blend sophisticated software with complex mechanical and electronic systems, requiring both digital and physical Rapid Prototyping to deliver a cohesive user experience. A mobile app controlling an industrial machine, a smart home device, or a wearable sensor all depend on precise interactions between software, electronics, and mechanical housings.[4][13][21][3]

Physical Rapid Prototyping from manufacturers like Shangchen ensures that software interfaces are tested in realistic physical contexts—buttons, screens, mounting positions, and enclosures behave the way real users will experience them. When software teams pair their digital Rapid Prototyping work with quick CNC‑machined parts, 3D printed prototypes, and sheet metal structures, they gain early insights into ergonomics, heat management, durability, and assembly.[13][14][17][18][19][12]

Shangchen provides a strong mechanical and manufacturing backbone for global teams that rely on Rapid Prototyping to innovate.[11][13]

Core capabilities include:

- CNC machining and turning: High‑precision Rapid Prototyping for metal and plastic parts, including complex geometries and tight tolerance components for enclosures and mechanisms.[14][16][12]

- 3D printing: Fast Rapid Prototyping for conceptual models, functional parts, and small‑batch runs using various additive processes and materials.[17][19][12]

- Sheet metal fabrication: Rapid Prototyping of brackets, chassis, cabinets, and other structural parts commonly used in industrial and electronic products.[13][14]

- Vacuum casting and low‑volume molding: Cost‑effective Rapid Prototyping for short runs of plastic components that mimic injection‑molded quality.[12][17]

- Mold manufacturing and mass production: Scaling validated Rapid Prototyping designs into full OEM manufacturing with stable quality and repeatability.[15][14][13]

This combination allows overseas brands and manufacturers to treat Shangchen as a one‑stop partner for the entire journey from Rapid Prototyping to mass production.[16][15][11]

While traditional waterfall‑style software development emphasizes long, sequential phases, Rapid Prototyping relies on short feedback loops and evolving designs.[8][6]

In traditional models, requirements are specified upfront and changes later in the project are often expensive and discouraged. Rapid Prototyping, by contrast, welcomes change, using incremental prototypes to refine requirements and design as new insights emerge. This makes Rapid Prototyping especially suitable for innovation projects, complex interactions, and products where user behavior is not fully understood at the outset.[22][20][8][6][7][9]

For OEM projects, where software must integrate with hardware and manufacturing constraints, Rapid Prototyping offers a safer and more adaptive route to a market‑ready solution.[3][15]

To make Rapid Prototyping effective, teams should apply deliberate practices instead of treating it as informal experimentation.[1][6]

Recommended Rapid Prototyping practices include:

- Start every cycle by documenting explicit learning objectives and success criteria.[7][1]

- Keep iterations short—days or a few weeks—so feedback quickly influences direction.[6][9]

- Involve multi‑disciplinary stakeholders, including design, engineering, operations, and where relevant, manufacturing partners like Shangchen.[2][1]

- Use analytics, UX testing methods, and structured interviews to gather actionable feedback from each prototype.[8][7]

- Clearly separate prototype quality standards from production quality, so teams can move fast without compromising long‑term maintainability.[5][6]

These practices turn Rapid Prototyping into a repeatable capability rather than a one‑time activity.[1][2]

When software teams need physical components to complement their digital Rapid Prototyping, working with Shangchen can streamline the concept‑to‑product journey.[15][12][13]

A typical collaboration around Rapid Prototyping might involve:

- Sharing CAD models, expected loads, aesthetic preferences, and target volumes with Shangchen's engineering team.[12][13]

- Receiving recommendations on materials and manufacturing processes—such as CNC Rapid Prototyping versus 3D printing—based on cost, lead time, and performance.[14][12]

- Reviewing Rapid Prototyping samples, checking fit, finish, and function alongside software prototypes, and then iterating design as needed.[19][17]

- Transitioning from Rapid Prototyping samples to pilot batches and full OEM production after validation.[13][14][15]

This integrated workflow helps overseas clients reduce supplier complexity and keep mechanical, electronic, and software Rapid Prototyping activities synchronized.[16][11]

Rapid Prototyping in software engineering is a powerful, iterative methodology that centers on building and refining early software models to validate ideas, align stakeholders, and create superior user experiences. By emphasizing quick learning cycles, user feedback, and flexible requirements, Rapid Prototyping reduces risk, development time, and costly rework compared with rigid, document‑heavy processes.[8][6][7][1]

For OEM projects and connected products, combining software Rapid Prototyping with physical Rapid Prototyping is essential to ensure that interfaces, electronics, and mechanical components function together seamlessly. Shangchen (sc-rapidmanufacturing.com) strengthens this ecosystem by providing Rapid Prototyping, CNC machining, sheet metal fabrication, 3D printing, precision batch production, and mold manufacturing to overseas brands and manufacturers. This integrated approach enables global teams to move from concept to mass production with confidence, using Rapid Prototyping at every stage to validate decisions and deliver high‑quality products to market faster.[4][17][3][11][14][15][16][12][13]

Rapid Prototyping in software engineering is an iterative approach that focuses on quickly building and testing working models of an application to clarify requirements, explore interaction design, and validate user experience before full implementation. These Rapid Prototyping cycles allow teams to refine ideas and reduce misunderstandings by using tangible prototypes instead of relying solely on written specifications.[9][6][7][8]

Rapid Prototyping reduces project risk by exposing design flaws, missing features, and usability problems early in the development cycle, when changes are relatively inexpensive and fast. Continuous feedback from users and stakeholders during Rapid Prototyping ensures that teams adjust direction promptly instead of discovering misalignment only at the end of the project.[6][7][8][1]

Yes, Rapid Prototyping can span both software and hardware, which is particularly important for IoT devices, embedded systems, and smart products where user experience depends on physical form and digital behavior. By combining software Rapid Prototyping with physical Rapid Prototyping from a manufacturer like Shangchen—using CNC machining, 3D printing, and sheet metal fabrication—teams can validate complete systems under realistic conditions.[3][4][14][12][13]

Teams should transition from Rapid Prototyping to full development when prototypes consistently meet learning objectives, user feedback stabilizes, and core design decisions feel validated. At that point, Rapid Prototyping results serve as a detailed blueprint for implementation, and further iterations occur within the production codebase or hardware design rather than in exploratory prototypes.[5][7][8][6]

Shangchen is well‑suited for overseas brands and manufacturers that need a single partner for both Rapid Prototyping and OEM production of mechanical components and assemblies. With capabilities in Rapid Prototyping, CNC machining, 3D printing, sheet metal fabrication, precision batch production, and mold manufacturing, Shangchen can support projects from early samples through mass production while maintaining consistent quality and communication.[11][14][15][16][12][13]

[1](https://backendless.com/rapid-prototyping-a-practical-guide-for-application-development-teams/)

[2](https://www.theinnovationmode.com/the-innovation-blog/rapid-prototyping-practices-for-software-engineering-teams)

[3](https://www.hlhprototypes.com/a-guide-to-rapid-prototyping/)

[4](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[5](https://www.trustshoring.com/blog/the-complete-guide-to-rapid-prototyping/)

[6](https://www.biz4group.com/blog/rapid-prototype-development)

[7](https://miro.com/prototypes/what-is-rapid-prototyping/)

[8](https://www.netguru.com/blog/what-is-rapid-prototyping)

[9](https://www.andplus.com/rapid-prototyping-guide)

[10](https://imperialhackspace.com/community/hacker-toolkit/beginners-guide-to-rapid-prototyping/)

[11](https://www.sc-rapidmanufacturing.com)

[12](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[13](https://www.sc-rapidmanufacturing.com/aboutus.html)

[14](https://www.sc-rapidmanufacturing.com/products.html)

[15](https://www.sc-rapidmanufacturing.com/top-rapid-prototyping-manufacturers-you-can-trust-in-2025.html)

[16](https://www.sc-rapidmanufacturing.com/top-10-rapid-prototyping-manufacturers-in-china.html)

[17](https://www.sc-rapidmanufacturing.com/what-are-the-advantages-of-rapid-prototyping.html)

[18](https://www.sc-rapidmanufacturing.com/quality-assurance-challenges-and-solutions-in-rapid-prototyping.html)

[19](https://www.sc-rapidmanufacturing.com/news/Rapid-Prototype-Development.html)

[20](https://www.tactionsoft.com/blog/rapid-prototyping-in-software-development/)

[21](https://www.stratasys.com/en/resources/blog/key-advantages-of-rapid-prototyping/)

[22](https://en.wikipedia.org/wiki/Rapid_prototyping)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product