Views: 222 Author: Amanda Publish Time: 2025-12-01 Origin: Site

Content Menu

● About Shangchen and Its Rapid Prototyping Services

● What Is Rapid Prototyping in Design Thinking?

● Why Rapid Prototyping Matters for OEMs

● How Rapid Prototyping Fits the Design Thinking Process

● Key Benefits of Rapid Prototyping in Design Thinking

● Main Rapid Prototyping Technologies Shangchen Uses

>> CNC Machining for Rapid Prototyping

>> 3D Printing for Rapid Prototyping

>> Sheet Metal Fabrication in Rapid Prototyping

>> Mold Making and Rapid Tooling

● Rapid Prototyping Through the Product Development Lifecycle

● Typical Rapid Prototyping Workflow with Shangchen

● Applications of Rapid Prototyping in Different Industries

● Design Thinking Best Practices for Rapid Prototyping with Shangchen

● Using Visual Media to Support Rapid Prototyping in Design Thinking

● Advanced Strategies for Rapid Prototyping in Design Thinking

● Managing Time and Cost in Rapid Prototyping Projects

● Quality and Reliability in Rapid Prototyping

● Collaborating Across Global Teams with Rapid Prototyping

● FAQ

>> 1) What is Rapid Prototyping in design thinking?

>> 2) How does Shangchen support Rapid Prototyping for OEM clients?

>> 3) Which Rapid Prototyping technology should I choose?

>> 4) How many Rapid Prototyping iterations are usually needed?

>> 5) Why partner with a Chinese Rapid Prototyping factory like Shangchen?

Shangchen (sc-rapidmanufacturing.com) is a China-based factory specializing in rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing for overseas brands, wholesalers, and manufacturers seeking reliable OEM services. In design thinking, Rapid Prototyping is the practice of quickly turning ideas into tangible prototypes so teams can test, refine, and validate concepts before committing to full-scale production.[4][9][11][12]

Shangchen focuses on Rapid Prototyping and CNC machining with tight tolerances, fast lead times, and competitive pricing, helping global OEM clients move from concept to production efficiently. The factory combines 3D printing, CNC machining, sheet metal fabrication, turning, and mold production to deliver complete Rapid Prototyping and manufacturing solutions under one roof.[11][13][14][15]

Shangchen serves overseas brands in sectors such as aviation, automotive, robotics, industrial equipment, medical devices, new energy, and consumer products, adapting Rapid Prototyping strategies to each application. By integrating Rapid Prototyping with precision batch production and OEM capabilities, Shangchen supports both early-stage product development and scalable manufacturing for long-term programs.[15][16][17][18]

In design thinking, Rapid Prototyping is an agile strategy to quickly create low- or high-fidelity prototypes that simulate a solution so teams can gather feedback from real users and stakeholders. Instead of relying on documents or abstract discussions, Rapid Prototyping produces visual or physical models that clarify ideas and expose issues early in the process.[5][8][9][4]

Rapid Prototyping in design thinking typically follows a loop of building, testing, and refining, where each version of the prototype becomes more detailed and functional. This iterative approach reduces the risk of investing heavily in an unproven concept and keeps the user at the center of every design decision.[3][6][9][4]

For OEM brands working with manufacturing partners, Rapid Prototyping dramatically shortens development time by producing testable parts in days rather than weeks or months. Early prototypes reveal functional, ergonomic, and manufacturing issues, allowing design teams and suppliers like Shangchen to correct problems before costly tooling is built.[2][4][5]

Rapid Prototyping also enhances collaboration between OEM design teams and factories because physical samples make it easier to discuss tolerances, materials, surface finishes, and assembly details. With Rapid Prototyping, OEMs can evaluate multiple design options in parallel, compare performance, and choose the best version for further development and mass production.[7][10][2][5]

Design thinking usually includes stages such as empathize, define, ideate, prototype, and test, and Rapid Prototyping plays a central role in the prototype and test phases. Teams transform ideas from the ideation stage into quick prototypes that capture core features, user flows, or mechanical functions, then they observe how users interact with them.[9][3][7]

Insights from Rapid Prototyping tests flow back into the design process, guiding changes to geometry, interface layouts, materials, or mechanisms. As prototypes evolve from simple mock-ups to more realistic functional parts, decision-makers gain confidence that the final design is feasible, user-friendly, and manufacturable.[8][3][4][5]

Rapid Prototyping in design thinking offers several important benefits for OEMs and product teams.[6][4]

- Faster iteration cycles: Prototypes can be updated after each feedback round, enabling rapid learning and continuous improvement.[2][4]

- Lower development risk: Issues such as usability problems, interference, weak structures, or assembly conflicts can be detected before committing to expensive production tools.[10][5]

- Better user experience: Testing Rapid Prototyping models with target users reveals real-world needs and behaviors, improving the overall product experience.[4][9]

- Improved communication: Physical or interactive prototypes reduce misunderstandings between designers, engineers, sales teams, and manufacturing partners.[5][7]

For OEM clients of Shangchen, these benefits translate into faster time-to-market, fewer design changes after tooling, and more competitive products in global markets.[17][18]

Shangchen combines multiple Rapid Prototyping technologies to meet different functional and visual requirements. Each technology has its own strengths and typical use cases in the design thinking workflow.[14][19][11][2]

CNC machining is a subtractive Rapid Prototyping method where material is removed from a solid block to create precise parts with tight tolerances. It is ideal for functional prototypes that need to be made in the final production material, such as aluminum, stainless steel, or engineering plastics.[20][10][2]

Shangchen delivers CNC Rapid Prototyping and CNC turning services suitable for functional testing, assembly trials, and low-volume production for OEM clients. These CNC Rapid Prototyping capabilities help verify critical dimensions, fits, threaded features, and mechanical performance before mass production.[12][11][17][20]

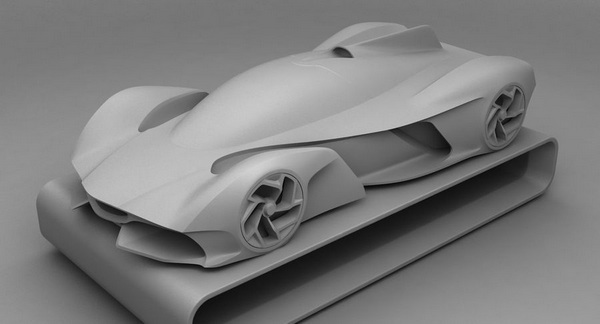

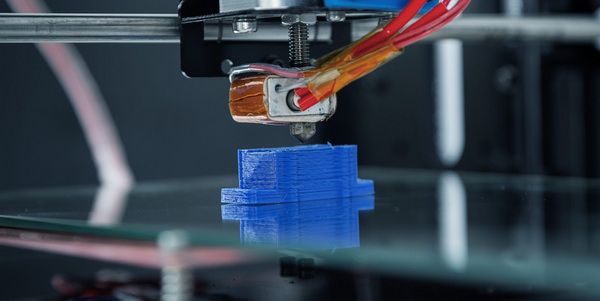

3D printing is an additive Rapid Prototyping technology that builds parts layer by layer from digital CAD data. It is especially useful in design thinking for quickly producing complex geometries, organic shapes, and internal channels that would be difficult or expensive to machine.[19][9][2]

Shangchen integrates 3D printing Rapid Prototyping into OEM projects to create visual models, ergonomic samples, and functional parts depending on material choice and process. 3D printing Rapid Prototyping makes it easy to test multiple concepts simultaneously and adjust designs based on feedback without large tooling investments.[13][11][2][4]

Sheet metal fabrication is another important Rapid Prototyping technology, especially for housings, brackets, enclosures, and structural parts. Processes such as laser cutting, bending, and welding allow sheet metal Rapid Prototyping to deliver strong, lightweight metal components in a short time.[3][7][2]

Shangchen offers sheet metal Rapid Prototyping services that support industries like automotive, electronics, appliances, and industrial equipment. OEM customers can use sheet metal Rapid Prototyping to validate fit, mounting points, airflow, strength, and assembly processes before locking the final design.[21][12][15][2]

Rapid Prototyping for molded parts often involves rapid tooling, where soft or temporary molds are produced quickly for small runs of injection-molded components. This approach allows OEMs to test parts made in thermoplastic materials similar to mass production without full investment in hardened steel tools.[10][20][2]

Shangchen combines mold production with Rapid Prototyping strategies, giving OEM brands access to prototype molds and short-run molding services. With this Rapid Prototyping workflow, teams can assess part strength, surface quality, moldability, and assembly behavior under realistic conditions.[11][17][19][2]

Rapid Prototyping supports every major step of product development, from early concept sketches to final production validation. In design thinking, the emphasis on rapid learning and user feedback continues throughout the lifecycle, and different Rapid Prototyping methods are used at each stage.[9][3][4]

- Early-stage concept: Simple 3D printed models or basic CNC Rapid Prototyping parts help teams evaluate form, ergonomics, and basic function.[4][9]

- Mid-stage engineering: Detailed CNC and sheet metal Rapid Prototyping parts validate tolerances, interfaces, mechanical loads, and manufacturability.[7][2]

- Pre-production: Rapid tooling, molded prototypes, and small pilot runs verify production settings, quality standards, and assembly workflows.[2][10]

Shangchen supports OEM clients through all these Rapid Prototyping phases, ensuring a smooth transition from prototype to volume manufacturing.[18][11]

Working with Shangchen for Rapid Prototyping and design thinking projects typically follows a clear and collaborative workflow. This workflow is designed to keep feedback flowing and to align engineering decisions with user insights and OEM requirements.[22][17][11]

1) Requirement clarification and CAD data

- OEM clients share design thinking outcomes, user insights, drawings, and 3D CAD files for Rapid Prototyping.[3][4]

- Shangchen engineers review the data and suggest appropriate Rapid Prototyping technologies, materials, and tolerances to match functional goals.[13][22]

2) Rapid Prototyping quotation and DFM

- Shangchen provides a cost and lead time estimate for Rapid Prototyping along with design-for-manufacturing (DFM) suggestions.[17][11]

- OEM teams may adjust geometry or materials based on these Rapid Prototyping recommendations to balance performance and cost.[10][2]

3) Prototype manufacturing

- After approval, Shangchen uses CNC machining, 3D printing, sheet metal fabrication, or mold-based Rapid Prototyping to produce parts.[11][2]

- Quality checks ensure that Rapid Prototyping parts meet dimensional and functional requirements before shipment.[23][13]

4) Testing, feedback, and iteration

- OEM clients test Rapid Prototyping samples with users, engineering teams, and marketing stakeholders to gather comprehensive feedback.[5][4]

- Shangchen incorporates design changes into the next Rapid Prototyping cycle, enabling quick iterations until the design is finalized.[18][22]

5) Transition to batch production and OEM manufacturing

- Once the Rapid Prototyping phase proves the design, Shangchen scales to precision batch production and long-term OEM manufacturing.[12][11]

- Process optimization, tooling refinement, and quality control systems are set up based on insights from the Rapid Prototyping stage.[23][17]

Rapid Prototyping is valuable in many industries that Shangchen serves as an OEM partner. Each sector uses Rapid Prototyping to address specific functional, regulatory, or market challenges.[15][12][2][4]

- Automotive and transportation: Rapid Prototyping parts help evaluate brackets, housings, interior components, and functional assemblies under real loads and thermal conditions.[2][4]

- Aerospace and aviation: High-precision Rapid Prototyping components allow engineers to study weight reduction, airflow, and assembly integration before certifying parts.[7][2]

- Medical devices: Rapid Prototyping models improve ergonomic design, usability, and sterilization planning for instruments and diagnostic equipment.[19][20]

- Robotics and industrial automation: CNC and 3D printing Rapid Prototyping parts enable quick testing of mechanisms, sensor mounts, and protective covers in dynamic environments.[6][2]

- Consumer products and electronics: Rapid Prototyping enclosures, buttons, and structural pieces shorten launch cycles and support frequent design updates.[15][4]

Shangchen adapts its Rapid Prototyping strategies to the regulatory, durability, and aesthetic constraints of each OEM client's industry.[12][17]

To get the most value from Rapid Prototyping in design thinking, OEM teams can follow several best practices when collaborating with Shangchen.[6][3]

- Start with clear design objectives: Before requesting Rapid Prototyping, define what needs to be validated, such as ergonomics, thermal performance, assembly, or user interaction.[3][4]

- Choose the right fidelity: Use low-fidelity Rapid Prototyping for early idea testing and high-fidelity CNC or molded prototypes for final verification.[4][6]

- Involve users early: Integrate user testing into each Rapid Prototyping cycle instead of waiting until late stages.[5][4]

- Iterate quickly: Treat each Rapid Prototyping build as an experiment, refine designs promptly, and move to the next version.[2][4]

- Align with manufacturing constraints: Work closely with Shangchen's engineers so Rapid Prototyping results match real manufacturing capabilities, materials, and tolerances.[13][11]

By following these design thinking guidelines, OEM brands can leverage Rapid Prototyping with Shangchen to create innovative, manufacturable products that reach the market faster.[17][18]

Although the physical prototypes themselves are the core of Rapid Prototyping, visual media in project documentation makes design thinking communication clearer and more persuasive. Teams often capture each Rapid Prototyping stage with photos, diagrams, and recorded test sessions to document learning and share progress across global teams.[8][9][4][5]

For example, OEM clients can photograph early 3D printed Rapid Prototyping models to illustrate form exploration, then photograph CNC Rapid Prototyping parts to show structural refinements and improved tolerances. Short video clips of user tests with Rapid Prototyping assemblies help decision-makers see real interactions, identify pain points, and understand design choices more intuitively than written reports alone.[7][4][2]

When working with Shangchen, OEM teams can create a consistent visual record of each Rapid Prototyping cycle, pairing images of prototypes with test notes and design updates. These visual records of Rapid Prototyping in design thinking make it easier to justify engineering changes, align international teams, and onboard new stakeholders quickly.[22][9][13][5]

As projects grow in complexity, more advanced strategies help teams extract maximum value from Rapid Prototyping in design thinking. OEMs collaborating with Shangchen can integrate these approaches to improve both innovation and manufacturability.[6][3]

One effective strategy is combining multiple Rapid Prototyping methods within a single iteration, such as using 3D printing for complex internal features while machining mating parts for precision fits. Another advanced approach is building modular Rapid Prototyping assemblies, where interchangeable modules allow teams to test different mechanisms, interfaces, or materials without rebuilding the entire prototype.[9][4][2]

Digital tools further enhance Rapid Prototyping in design thinking by linking CAD models, simulation, and physical prototypes in a continuous feedback loop. OEM teams can simulate stress, airflow, or motion and then validate these predictions through Rapid Prototyping tests with Shangchen's parts, improving confidence in final design decisions.[19][10][2]

Time and cost are critical constraints in real-world Rapid Prototyping projects, especially for OEMs handling multiple product lines and global launches. Effective planning around Rapid Prototyping ensures that design thinking activities remain efficient and sustainable.[3][6]

Setting clear objectives and timelines for each Rapid Prototyping cycle helps teams avoid over-engineering early prototypes or delaying decisions. Prioritizing features—focusing Rapid Prototyping resources on high-risk or high-value aspects of a design—prevents unnecessary work on elements that have minimal impact on user experience or manufacturability.[5][6][3]

Working closely with Shangchen, OEMs can choose Rapid Prototyping materials and processes that match their budget and stage of development. For example, lower-cost materials may be appropriate for early form studies, while later Rapid Prototyping iterations may justify more expensive, production-like materials to validate performance and durability.[11][17][4][2]

High quality is essential for Rapid Prototyping parts used in functional tests, regulatory evaluations, or customer demonstrations. Poorly made prototypes can lead to misleading test results and incorrect design conclusions, undermining the entire design thinking process.[10][5]

Shangchen applies structured quality control to Rapid Prototyping by inspecting critical dimensions, surface finishes, and mechanical integrity on every batch of parts. OEM teams can specify key characteristics and acceptance criteria so Rapid Prototyping samples accurately reflect the intended performance of future production parts.[23][13][17][2]

In regulated industries, Rapid Prototyping may also need to support documentation requirements, traceability, and reproducibility for audits and approvals. By aligning Rapid Prototyping quality practices with these expectations, OEMs and Shangchen can use prototypes confidently in validation and pre-certification programs.[20][19][23][2]

Design thinking projects often involve distributed teams, including designers, engineers, marketers, and manufacturing experts in different countries. Rapid Prototyping acts as a common language across these disciplines, turning abstract specifications into concrete objects that everyone can understand.[8][5]

Shangchen's role as a Rapid Prototyping and OEM partner enables global teams to share physical samples quickly while coordinating online over 3D models, drawings, and test results. OEMs can send design updates digitally and then distribute Rapid Prototyping samples from Shangchen to regional teams for user testing, showroom reviews, or customer feedback events.[16][18][22][11]

This combination of physical Rapid Prototyping and digital collaboration aligns well with design thinking values, which emphasize co-creation, diverse perspectives, and frequent feedback. As a result, global brands can make better-informed decisions, reduce rework, and maintain consistent product quality across markets.[9][4][2][3]

Rapid Prototyping in design thinking is a powerful method for transforming ideas into testable physical or interactive models that guide product development decisions. For OEM brands, it reduces risk, accelerates learning, and keeps user needs at the center of every iteration.[4][9][3][5]

Shangchen (sc-rapidmanufacturing.com) provides an integrated Rapid Prototyping and OEM manufacturing platform that combines CNC machining, turning, sheet metal fabrication, 3D printing, and mold production. By partnering with Shangchen and embedding Rapid Prototyping into a design thinking mindset, overseas brands, wholesalers, and manufacturers can bring better products to market faster and with greater confidence.[18][12][17][11]

Rapid Prototyping in design thinking is the practice of quickly creating prototypes of a concept so teams can test ideas, collect user feedback, and refine designs through iterative cycles. It helps move from abstract discussions to tangible models, reducing uncertainty and guiding better product decisions.[9][3][4][5]

Shangchen supports Rapid Prototyping by offering CNC machining, turning, sheet metal fabrication, 3D printing, and mold production services tailored to OEM requirements. The factory helps clients choose suitable Rapid Prototyping methods, materials, and tolerances, then scales successful prototypes into precision batch production and OEM manufacturing.[12][17][18][11]

The best Rapid Prototyping technology depends on your goals, part geometry, and material needs. 3D printing is ideal for fast concept models and complex shapes, CNC Rapid Prototyping suits high-precision functional parts, sheet metal Rapid Prototyping fits enclosures and brackets, and rapid tooling is used for molded thermoplastic components.[7][2][4]

Most projects require several Rapid Prototyping iterations, starting from simple models and progressing to fully functional prototypes. The exact number depends on product complexity, regulatory requirements, and how quickly user feedback converges on a stable, manufacturable design.[6][10][4][5]

Partnering with a Chinese Rapid Prototyping factory such as Shangchen offers advantages in cost, speed, and integrated OEM capabilities. With extensive experience in Rapid Prototyping, CNC machining, and precision production for global clients, Shangchen helps overseas brands compress development timelines and maintain high quality from prototype to mass production.[15][17][11][12]

[1](https://designthinkingtoolkit.co/content/the-rapid-prototyping-mindset)

[2](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[3](https://www.wayra.de/blog/prototyping-in-design-thinking-a-comprehensive-guide)

[4](https://maze.co/blog/rapid-prototyping/)

[5](https://wac.colostate.edu/docs/books/design/chapter4.pdf)

[6](https://www.komododigital.co.uk/insights/ultimate-guide-to-rapid-prototyping-for-digital-product-design/)

[7](https://www.workshopper.com/post/design-thinking-phase-4-everything-you-need-to-know-about-prototyping)

[8](https://www.mural.co/blog/design-thinking-prototype)

[9](https://www.designkit.org/methods/rapid-prototyping.html)

[10](https://online.hbs.edu/blog/post/rapid-prototyping)

[11](https://www.sc-rapidmanufacturing.com)

[12](https://www.sc-rapidmanufacturing.com/top-10-rapid-prototyping-manufacturers-in-china.html)

[13](https://www.sc-rapidmanufacturing.com/aboutus.html)

[14](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[15](https://www.sc-rapidmanufacturing.com/products.html)

[16](https://www.sc-rapidmanufacturing.com/news.html)

[17](https://www.sc-rapidmanufacturing.com/what-are-the-advantages-of-rapid-prototyping.html)

[18](https://www.sc-rapidmanufacturing.com/news/Rapid-Prototype-Development.html)

[19](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[20](https://www.3ds.com/make/service/rapid-prototyping-service)

[21](https://uptivemfg.com/solutions/rapid-prototyping/)

[22](https://www.sc-rapidmanufacturing.com/how-to-do-rapid-prototyping.html)

[23](https://www.sc-rapidmanufacturing.com/quality-assurance-challenges-and-solutions-in-rapid-prototyping.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal