Views: 222 Author: Amanda Publish Time: 2025-12-01 Origin: Site

Content Menu

● About Shangchen And Its Services

● Rapid Prototyping Definition

● Core Principles Of Rapid Prototyping

● Rapid Prototyping Manufacturing Process

● Key Rapid Prototyping Technologies

>> Additive manufacturing (3D printing)

>> Subtractive manufacturing (CNC machining)

>> Low-volume molding and tooling

● Benefits Of Rapid Prototyping For Global OEMs

● Practical Use Cases With Shangchen

● How To Choose A Rapid Prototyping Partner

>> 1. What is Rapid Prototyping in manufacturing?

>> 2. How does Rapid Prototyping reduce development risk?

>> 3. Why combine Rapid Prototyping with CNC machining and sheet metal fabrication?

>> 4. What makes Shangchen a good choice for Rapid Prototyping?

>> 5. When should a company move from Rapid Prototyping to low-volume production?

Rapid prototypingis a group of manufacturing techniques that rapidly turn three-dimensional digital designs into physical parts or assemblies so engineers and product teams can test, validate, and improve ideas before mass production. For global brands, wholesalers, and manufacturers, partnering with a full-service factory such as Shangchen (sc-rapidmanufacturing.com) makes Rapid Prototyping a practical, scalable way to move from concept to market with less risk and lower cost.[1][2][11][12]

Shangchen is a China-based manufacturing factory focusing on Rapid Prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing services, and mold production for global OEM customers. These integrated capabilities mean international clients can handle all stages of prototype and pre-series manufacturing with one reliable partner, from early design validation through pilot runs.[7][1]

By combining Rapid Prototyping with CNC machining and other processes in a single workflow, Shangchen helps overseas brands quickly iterate their designs and smoothly transition to stable, repeatable production. The factory serves foreign brands, wholesalers, and manufacturers across sectors such as automotive, consumer products, industrial equipment, and electronics.[3][12]

In a manufacturing context, Rapid Prototyping is defined as the fast fabrication of physical parts or assemblies directly from three-dimensional CAD data using techniques such as additive manufacturing, CNC machining, and other digitally driven processes. Rather than waiting weeks for traditional tooling, teams can create one-off or short-run parts within days or even hours to evaluate form, fit, and function.[2][6][11][1]

Most commonly, Rapid Prototyping uses 3D printing processes like FDM, SLA, and SLS, but in professional environments it also includes subtractive machining, sheet metal forming, and low-volume molding when those methods are faster or closer to production conditions. This broad definition makes Rapid Prototyping a flexible approach that can mirror real manufacturing processes while still keeping iteration cycles short.[5][6][12][1]

Several principles define effective Rapid Prototyping in modern manufacturing:

- Iterative design: Rapid Prototyping supports fast cycles of “design–build–test–refine,” enabling continuous improvement instead of a single, risky final design.[6][2]

- Digital-first workflow: Every prototype begins with accurate CAD models that can be updated quickly and reused for later production stages.[1][5]

- Phase-appropriate fidelity: Early prototypes focus on basic form and ergonomics, while later stages use higher-fidelity materials and processes to test performance and manufacturability.[5][6]

By following these principles, Shangchen can align Rapid Prototyping activities with a customer's product roadmap, from early concept sketches to pre-production sampling. This structured approach ensures that each prototype has a clear purpose, measurable criteria, and direct impact on reducing risk.[3][5]

From an OEM perspective, a typical Rapid Prototyping process with a partner like Shangchen follows several key steps:

1. Requirements and concept

The customer defines goals such as target application, mechanical requirements, aesthetic expectations, and time frame. Shangchen's engineering team reviews these inputs and suggests suitable Rapid Prototyping processes and materials.[4][9]

2. CAD design and optimization

Engineers create or refine a 3D CAD model, applying design-for-manufacturing (DFM) rules appropriate for Rapid Prototyping methods like 3D printing, CNC machining, or sheet metal forming. Features such as wall thickness, draft angles, and tolerances are adjusted to ensure prototypes can be produced quickly and accurately.[1][5]

3. Process selection

Based on the required fidelity, mechanics, and schedule, the team selects Rapid Prototyping methods such as FDM or SLA printing for visual models, SLS or MJF for functional plastic parts, CNC machining for high-precision metal components, or soft tooling for short-run molded parts.[5][1]

4. Prototype fabrication

The chosen machines and materials are prepared, and parts are produced directly from CAD data. For additive Rapid Prototyping, this means layer-by-layer fabrication; for subtractive methods, it involves toolpath generation and CNC machining from stock materials.[6][1]

5. Post-processing and finishing

After the initial build, parts may require support removal, deburring, sanding, painting, plating, or surface texturing to meet visual and functional requirements. Shangchen can combine multiple finishing options so prototypes closely resemble final production parts.[8][6]

6. Testing and iteration

The prototypes are tested for fit, ergonomics, performance, and sometimes regulatory requirements. Based on test results and feedback, the design is updated and the Rapid Prototyping cycle repeats until the product is ready for pilot production or tooling.[6][5]

This iterative manufacturing process makes Rapid Prototyping far more than just “fast printing”; it becomes a structured, data-driven path to robust product designs.[3][5]

Rapid Prototyping is an umbrella term that covers several complementary technologies. Shangchen can integrate these methods to match the needs of each project:

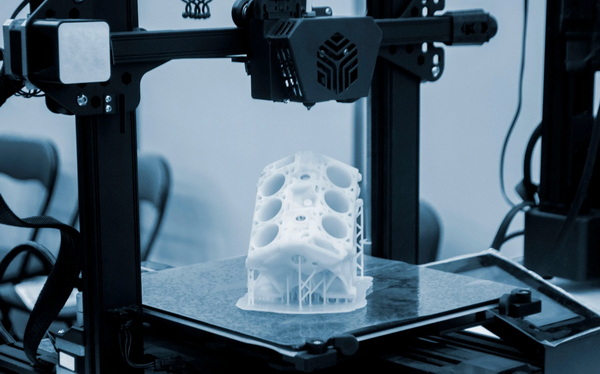

Additive manufacturing builds parts layer by layer directly from CAD data, which is ideal for complex geometries and internal features. Typical Rapid Prototyping methods include:[1][5]

- FDM: Uses thermoplastic filament for cost-effective concept and fit prototypes.[6]

- SLA/DLP: Uses liquid resin and light curing for high-detail, smooth-surface parts useful in visual and functional testing.[8][6]

- SLS/MJF: Fuses polymer powder for durable functional prototypes, snap fits, and housings.[13][5]

Additive Rapid Prototyping allows designers to test shapes that would be impractical or expensive with traditional tooling, especially during early development.[5][1]

CNC machining uses cutting tools to remove material from metal or plastic blocks under computer control, providing tight tolerances and production-like materials. This is critical when Rapid Prototyping needs to replicate real mechanical behavior, such as strength, stiffness, or heat resistance.[7][1][5]

Shangchen's CNC machining services allow customers to rapidly prototype metal parts such as brackets, housings, and shafts that behave very similarly to final production components. This reduces surprises when transitioning from prototype to mass manufacturing.[3][5]

For enclosures, brackets, and mechanical structures made from metal sheet, Rapid Prototyping uses laser cutting, bending, and welding to create early samples. Sheet metal Rapid Prototyping lets customers validate mounting points, cable routing, ventilation, and stiffness before committing to expensive production tooling.[1][5]

Shangchen's sheet metal capabilities integrate with CNC machining and 3D printing so complex assemblies can be prototyped as complete systems, not just individual parts. This system-level approach is especially valuable for industrial and electronics projects.[3][1]

Formative processes such as injection molding or casting can also be part of Rapid Prototyping when small runs of production-like plastic parts are required. Using rapid aluminum molds or 3D-printed inserts, manufacturers can produce dozens to thousands of parts for validation, certification, and early market tests without full-scale steel tooling.[7][5][1]

Shangchen's mold manufacturing capability makes it possible to move directly from Rapid Prototyping to low-volume production in one integrated workflow, preserving geometry, tolerances, and materials from prototype to final product.[7][1]

For overseas brands and manufacturers working with Shangchen, Rapid Prototyping delivers a combination of technical and business benefits:

- Shorter development cycles

Rapid Prototyping compresses design and testing loops from weeks to days, helping companies release new products faster and respond quickly to market changes.[12][14]

- Lower overall development cost

Early prototypes reveal design flaws, assembly difficulties, and performance issues while changes are still inexpensive. Avoiding late-stage tooling modifications or recalls typically offsets the cost of multiple Rapid Prototyping cycles.[15][5]

- Better design quality

Because Rapid Prototyping makes iteration cheap and fast, teams explore more design alternatives and converge on solutions with better usability, aesthetics, and mechanical performance.[16][2]

- More accurate risk management

Using materials and processes close to production conditions allows engineers to accurately assess structural integrity, thermal behavior, and manufacturability before committing to full-scale investment.[5][6]

- Easier stakeholder communication

Physical prototypes created by Rapid Prototyping communicate ideas more clearly than 2D drawings or digital renderings, making it easier to align marketing, engineering, and management teams.[2][6]

By offering Rapid Prototyping and production under one roof, Shangchen helps international customers capture all of these benefits while maintaining consistent quality and communication throughout the project.[1][3]

International customers use Shangchen's Rapid Prototyping services in many scenarios, such as:

- Early concept validation for new consumer products where brands need to test ergonomics, size, and visual appeal before investing in tooling.[9][6]

- Functional validation of mechanical components using CNC-machined metal prototypes that simulate final loading and wear conditions.[7][5]

- Pre-series builds of small batches to validate assembly processes, packaging, and logistics before full mass production.[5][1]

In each case, Rapid Prototyping is not just a technical step but a strategic tool for making better decisions faster. Working with a capable factory like Shangchen ensures that each prototype is made with the right process, material, and level of fidelity for its purpose.[3][5]

When selecting a manufacturing partner for Rapid Prototyping, OEMs and brands should consider several key factors:

- Process diversity

A good partner should offer multiple Rapid Prototyping methods such as 3D printing, CNC machining, sheet metal fabrication, and mold manufacturing so the right process can be chosen for each task.[1][5]

- Engineering support

Strong engineering teams can advise on design-for-manufacturing, material selection, and process choice, helping clients avoid common pitfalls in Rapid Prototyping.[3][5]

- Quality and consistency

The partner should apply rigorous inspection and testing even for prototypes, ensuring that insights from Rapid Prototyping reliably translate into production improvements.[5][1]

- Communication and responsiveness

Rapid Prototyping relies on quick feedback, so clear communication about timelines, design changes, and technical issues is essential.[9][3]

Shangchen aligns with these criteria by combining a wide range of Rapid Prototyping technologies with dedicated engineering support, strict quality control, and experience serving foreign customers. This makes it a suitable choice for overseas brands who need a reliable long-term manufacturing partner.[1][3]

Rapid Prototyping is the fast, digitally driven creation of physical parts and assemblies directly from CAD data using methods such as 3D printing, CNC machining, sheet metal fabrication, and low-volume molding. It enables iterative testing, design refinement, and risk reduction long before mass production begins, giving manufacturers a powerful way to improve quality and accelerate time to market.[11][2][5][1]

For global brands, wholesalers, and manufacturers, working with Shangchen (sc-rapidmanufacturing.com) means gaining access to a complete Rapid Prototyping and manufacturing ecosystem under one roof. With capabilities spanning Rapid Prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing services, and mold manufacturing, Shangchen helps customers smoothly move from early ideas to stable, repeatable production. By integrating Rapid Prototyping into every development phase, Shangchen turns complex product visions into reliable, manufacturable realities for clients worldwide.[12][7][3][1]

Rapid Prototyping in manufacturing is the fast creation of physical models or parts from 3D CAD data using technologies such as 3D printing, CNC machining, and other digitally controlled processes. These Rapid Prototyping methods allow designers and engineers to evaluate form, fit, and function long before investing in expensive production tooling.[11][2][5][1]

Rapid Prototyping reduces development risk by revealing design, performance, and manufacturability issues early, when changes are still relatively inexpensive. By testing multiple Rapid Prototyping iterations under realistic conditions, teams can refine geometry, materials, and assembly methods before committing to final tooling and mass production.[15][12][6][5]

Combining Rapid Prototyping with CNC machining and sheet metal fabrication allows manufacturers to test both complex shapes and production-like materials in one integrated workflow. For example, 3D printing can quickly validate geometry, while CNC-machined metal parts or sheet metal assemblies produced through Rapid Prototyping validate strength, stiffness, and real-world performance.[7][5][1]

Shangchen is a strong Rapid Prototyping partner because it offers a wide range of services—Rapid Prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing—for overseas OEM customers. This combination means clients can manage the entire life cycle from initial Rapid Prototyping through pre-series runs and mass production with one trusted factory.[7][3][1]

A company should move from Rapid Prototyping to low-volume production when design goals are met, functional tests are successful, and feedback from stakeholders indicates readiness for market or certification trials. At that stage, processes such as rapid tooling and short-run molding can complement Rapid Prototyping by delivering production-like parts in small batches for final validation and early sales.[5][7][1]

[1](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

[2](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[3](https://www.fictiv.com/articles/rapid-prototyping-guide)

[4](https://www.linkedin.com/pulse/guide-rapid-prototyping-manufacturing-product-yee-creatingway--jnhuc)

[5](https://wefab.ai/blog/rapid-prototyping-explained-a-guide-to-the-processes-that-accelerate-product-development/)

[6](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[7](https://jiga.io/articles/rapid-manufacturing-guide/)

[8](https://www.stratasys.com/en/resources/blog/guide-to-rapid-prototyping/)

[9](https://www.dailybot.com/insights/the-ultimate-guide-to-rapid-prototyping)

[10](https://www.protoanything.com/blog/a-quick-guide-to-the-essentials-of-rapid-prototyping-and-manufacturing)

[11](https://en.wikipedia.org/wiki/Rapid_prototyping)

[12](https://xometry.pro/en/articles/rapid-prototyping-manufacturing/)

[13](https://www.sculpteo.com/en/glossary/3d-rapid-prototyping/)

[14](https://kmmgrp.com/importance-of-rapid-prototyping/)

[15](https://parts-badger.com/top-7-benefits-of-rapid-prototyping/)

[16](https://www.stratasys.com/en/resources/blog/key-advantages-of-rapid-prototyping/)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes