Views: 222 Author: Amanda Publish Time: 2025-11-10 Origin: Site

Content Menu

● Core Principles of Turning Lathe Technology

● Evolution from Manual to CNC Turning

● Key Types of Turning Lathes and Their Roles

● Applications Across Industries

● Process Optimization and Quality Assurance

● Technological Trends Shaping the Field

● Why Partner with Shangchen for Turning Lathe Needs

● Frequently Asked Questions (FAQ)

>> 1. What materials can be processed on a turning lathe?

>> 2. How does a CNC turning lathe differ from a manual lathe?

>> 3. What are common defects in turning operations, and how can they be mitigated?

>> 4. Why is turning lathe technology critical to modern manufacturing?

>> 5. How do turning lathes support rapid prototyping and iterative design?

Turning lathes stand at the core of modern precision manufacturing, enabling rapid, repeatable production of cylindrical and contoured parts across a wide range of industries. From initial prototyping to high-volume production, turning lathe technology—especially in its CNC-infused forms—delivers outstanding dimensional accuracy, surface finish, and throughput. For brands, distributors, and OEMs seeking reliable partners for rapid prototyping, metal and plastic turning, sheet metal finishing, and integrated manufacturing workflows, understanding turning lathe fundamentals is essential for designing components that meet tight specifications and strict quality standards. This article delves into how turning lathe systems operate, their varying configurations, the breadth of applications, and the latest trends shaping efficiency and precision in today's supply chains. It also highlights how Shangchen supports foreign brands and manufacturers with comprehensive turning services, rapid prototyping, precision batch production, and integrated 3D printing and tooling solutions.

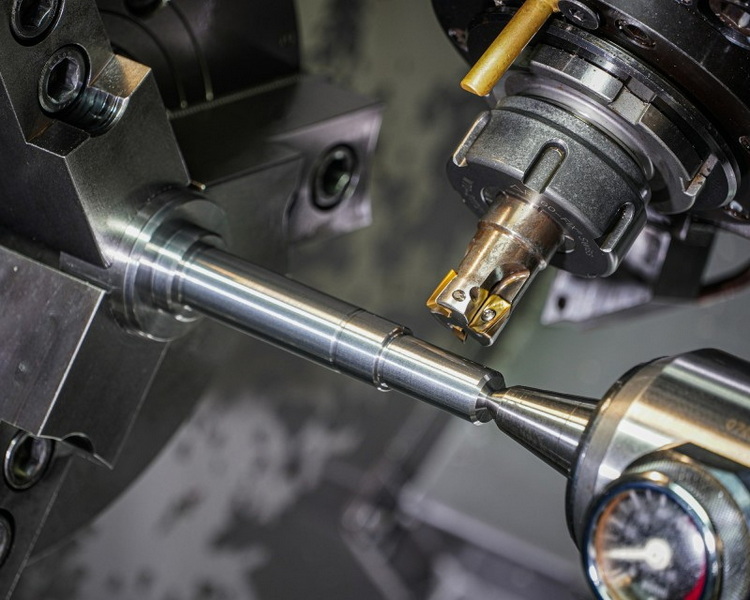

Turning lathe operations revolve around one fundamental concept: rotating the workpiece while a cutting tool removes material to create the desired geometry. Precision arises from controlled speeds, feeds, tool paths, and clamping stability. In modern practice, computer numerical control (CNC) introduces programmable motion, enabling complex profiles, tight tolerances, and high-volume repeatability. The combination of rigid machine construction, accurate spindle control, and advanced tooling yields components such as shafts, pins, bushings, sleeves, and instrument housings with consistent quality.

- Workpiece rotation is achieved through a spindle driven by a motor, with speed selectable to suit material type and form.

- The tool moves in multiple axes via a carriage, often incorporating turret mechanisms or live tooling for extra operations.

- Chip formation, surface finish, and tolerances depend on factors such as cutting speed, feed rate, depth of cut, tool material, coolant strategy, and workholding rigidity.

- Inspections and process controls—ranging from calipers and micrometers to coordinate measuring machines (CMMs)—ensure parts stay within specification.

The industrial shift from manual, operator-driven lathes to computer-controlled turning has dramatically expanded capability and consistency. Manual lathes offered flexibility and direct control for single-piece or low-volume work, but CNC turning unlocked repeatability, complex geometries, and automation at scale. Modern turning centers often feature multi-axis capabilities, live tooling for milling-like operations, bar feeder integration for unattended runs, and sophisticated cycle programming that reduces setup times and human error. For an OEM partner, this translates into faster lead times, shorter development cycles, and the ability to respond quickly to design changes or custom requests.

- Manual conventional lathes: Valuable for quick setups, prototyping, and low-volume or repair work where direct operator control is advantageous.

- CNC turning lathes: The backbone of precision manufacturing, delivering high accuracy, repeatability, and automation potential for mass production.

- Turn-mill centers: Combine turning and milling in a single machine, enabling complex features and off-axis operations without multiple setups.

- Swiss-type lathes: Specialize in short, slender parts with extremely tight tolerances and fine surface finishes, common in medical and electronics components.

- Multi-tasking and hybrid machines: Integrate turning with secondary processes (milling, drilling, grinding), enabling higher throughput and reduced handling.

Turning lathes accommodate a broad spectrum of materials, including:

- Metals: steel, stainless steel, aluminum, brass, copper, titanium, and exotic alloys.

- Plastics: engineering resins and high-performance polymers.

- Composites: certain fiber-reinforced materials suitable for specialized parts.

- Coatings and tool wear considerations: material hardness, chip formation, and thermal properties influence tool selection and coolant strategies.

A well-designed turning process optimizes tool geometry, cutting parameters, and coolant application to maximize tool life and surface integrity while meeting functional requirements.

- Automotive: Precision shafts, gears, engine components, and fasteners.

- Aerospace: High-precision sleeves, housings, and fasteners with rigorous tolerances.

- Medical: Small-diameter components, implants, and surgical instruments requiring tight surface finishes.

- Electronics: Connector housings, pin grids, and micro-scale parts with precise alignment needs.

- Energy: Turbine components, rotors, and pump shafts where reliability and balance are critical.

- General engineering: Fasteners, fittings, and custom-turn parts for a wide range of equipment.

Achieving optimal results with turning lathes requires careful attention to process parameters, tooling strategy, and inspection. Common best practices include:

- Defining a robust process window for cutting speed, feed rate, and depth of cut based on material and geometry.

- Selecting appropriate tooling materials and coatings to resist wear and thermal effects.

- Implementing fixturing and workholding that minimize runout and vibration (chatter) for consistent surface finishes.

- Employing coolant strategies to control temperature, extend tool life, and improve chip evacuation.

- Utilizing in-process gauging and post-process inspection to ensure conformance to tolerances.

Quality systems and ISO-compliant procedures help ensure traceability, repeatability, and continuous improvement across batches and production runs.

- Increased CNC capability and software integration: CAD/CAM workflows enable seamless part design-to-manufacture transitions and tighter control over tolerances.

- IIoT and smart manufacturing: Real-time monitoring, predictive maintenance, and data-driven optimization reduce downtime and improve yield.

- Multi-function and turnkey solutions: Turn-key setups with integrated fixturing, material handling, and post-processing align with rapid prototyping and small-to-medium batch production needs.

- Sustainable and cost-conscious manufacturing: Advanced tooling, energy-efficient spindles, and optimized cycle times contribute to lower total cost of ownership.

Shangchen specializes in rapid prototyping, CNC turning, precision batch production, and integrated manufacturing solutions for overseas brand owners, wholesalers, and manufacturers. The company offers:

- A broad range of turning lathe capabilities, including CNC turning centers and multi-tasking machines.

- Rapid prototyping support to validate designs quickly in metallic and plastic materials.

- High-precision, repeatable production for small batches and mass production.

- Integrated services such as sheet metal fabrication, 3D printing, and mold production to shorten lead times and reduce supply chain complexity.

- Engineering expertise to optimize part geometry, surface finish, and manufacturability while maintaining cost efficiency.

This combination of capabilities makes Shangchen a strong partner for OEM initiatives requiring consistent quality, flexible capacity, and responsive turnarounds.

Turning lathes continue to be a foundational technology in modern manufacturing, empowering engineers and OEMs to transform materials into precise, reliable components across diverse industries. The convergence of conventional mastering skills with CNC automation, multi-tasking capabilities, and digital workflow integration ensures that turning lathe processes remain efficient, adaptable, and cost-effective for both rapid prototyping and large-scale production. For partners like Shangchen, turning lathe expertise—coupled with rapid prototyping, sheet metal fabrication, 3D printing, and mold production—provides a seamless path from concept to finished part, meeting stringent specifications, short lead times, and global supply needs. This holistic approach supports brands, wholesalers, and manufacturers seeking dependable OEM solutions with high quality and responsive service.

- Answer: Turning lathes can machine a wide range of materials, including steels, aluminum, brass, copper, titanium, and certain plastics and composites, depending on tooling and cooling strategies. This versatility makes turning lathes suitable for automotive, aerospace, medical, and electronics components, among others.

- Answer: A CNC turning lathe uses programmable control to automate tool motions, enabling complex geometries, consistent tolerances, and high-volume production, while a manual lathe relies on operator-driven adjustments and is typically better suited for prototyping or low-volume work.

- Answer: Common defects include chatter, dimensional inaccuracy, and surface finish issues. Mitigation involves optimizing tool selection, speeds and feeds, improving workholding, ensuring adequate coolant, and performing regular maintenance of the spindle and tooling.

- Answer: Turning lathes deliver precise, repeatable, and scalable production of cylindrical components, enabling reliable supply for automotive, aerospace, medical, and electronics sectors while supporting rapid prototyping and customization.

- Answer: CNC turning lathes enable quick transitions from CAD designs to physical parts, support small-batch production, and facilitate design iterations without tooling changes, accelerating development cycles and reducing time to market.

[1](https://boruimc.com/applications-of-lathe-machines/)

[2](https://www.yashmachine.com/blog/lathe-machine-applications-in-automobile-industries/)

[3](https://www.cnctakang.com/en-US/newsc16-top-5-applications-of-conventional-lathes-in-modern-industry)

[4](https://www.weerg.com/guides/lathe)

[5](https://cncwmt.com/qa/cnc-lathe-machine-processes-applications-and-benefits/)

[6](https://hy-proto.com/top-lathe-machine-manufacturer-compare)

[7](https://www.chushing-tw.com/en-US/newsc10-top-5-industries-that-rely-on-conventional-lathes)

[8](https://rosnokmachine.com/what-is-a-lathe/)

[9](https://machinetoolspecialties.com/blog/1036-leading-cnc-lathe-manufacturers-a-comparative-quality-overview)

[10](https://www.longshengmfg.com/cnc-lathe-machines-applications/)

content is empty!