Views: 222 Author: Amanda Publish Time: 2025-11-07 Origin: Site

Content Menu

● Rapid Tooling and Agile Prototyping

● Smart Factories and Industry 4.0

>> AI-Driven Process Optimization

● Advanced Materials and Sustainable Practices

>> Bioplastics and Recycled Composites

>> High-Performance Engineering Resins

● Hybrid Manufacturing and 3D Printing Integration

>> Hybrid 3D Printing and Injection Moulding

● Micro Moulding and Healthcare Applications

● Sustainability and Energy Efficiency

● Customization, Flexibility, and Short-Run Capabilities

● Workforce Upskilling and Human-Machine Collaboration

● Industrial Reshoring and Decentralized Production

● Outlook: Market Growth and Future Directions

● FAQ

>> 1. What are the most impactful moulding production innovations today?

>> 2. How does digitalization improve speed and accuracy in moulding production?

>> 3. Why is sustainability important in moulding production?

>> 4. What trends are shaping the future of micro and medical moulding?

>> 5. How are OEM services evolving in moulding production?

Moulding production stands at the crossroads of tradition and innovation, where automation, digitalization, and new engineering breakthroughs are shaping not just the way products are made, but how manufacturers compete worldwide. By harnessing high-precision CNC machining, rapid prototyping, advanced materials, and smart factory technology, today's manufacturers are delivering results with greater flexibility, speed, and sustainability than ever before.[1][2][3]

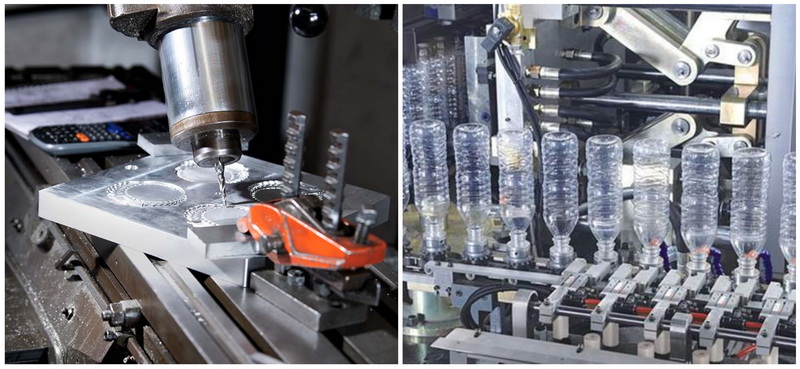

Rapid tooling technologies now blur the lines between prototype and production phases. Hybrid and aluminum tooling speeds up the transition from CAD designs to functional moulded parts with reduced costs and accelerated development cycles. This agility helps businesses validate concepts more quickly and iterate in days—a crucial advantage as competition intensifies.[6][1]

Prototyping through high-speed CNC machining and innovative rapid prototyping techniques reduces lead times and allows for simultaneous testing of multiple designs. This is invaluable for brands and wholesalers seeking to launch products faster or adapt to unexpected market shifts.

The transformation of traditional moulding production into smart factories is driven by IoT-enabled machinery and sensor networks. Real-time tracking of temperature, pressure, cycle duration, and part quality allows instantaneous process optimization. Maintenance schedules, equipment performance, and quality assurance all benefit from cloud-based analytics and big data.[4][5]

Artificial intelligence is redefining process control and defect management in moulding production. Machine learning analyzes extensive manufacturing data to forecast equipment wear and automate adjustments, ensuring stable production and zero-defect outcomes. Vision systems powered by neural networks inspect thousands of parts hourly with unmatched precision, drastically reducing scrap rates and improving overall efficiency.[3][5][4]

AI also powers quality management, demand forecasting, and adaptive scheduling, enabling moulding production facilities to respond instantly to changing customer requirements.

The role of robotics in moulding production stretches far beyond simple repetitive tasks. Cobots and advanced robots are now integral in handling parts, inspecting quality, assembling components, and packaging final products. Integrated with CNC machining and injection lines, robotics minimize human error, boost efficiency, and safely handle hazardous operations.

Automated guided vehicles (AGVs) streamline logistics in manufacturing plants, managing material flow, tool changes, and batch movement—all without manual input. This lights-out manufacturing capability enables 24/7 production, supporting high-volume OEM demands with reliability.[5][6]

Environmental regulation and consumer awareness are propelling a shift toward ocean-sourced bioplastics, algae-derived polymers, and recycled composites. These materials offer mechanical properties comparable to conventional petroleum-based plastics, while slashing energy use and carbon footprint. Closed-loop recycling systems now recover up to 92% of production waste, reintegrating it into new production cycles.[8][3][6]

Material scientists are introducing everything from glass-fiber reinforced PET to medical-grade shape memory alloys. These innovations extend application possibilities for moulding production in automotive, healthcare, wearables, and more, achieving lighter weights, enhanced durability, and reduced costs.

Direct metal laser sintering (DMLS) and similar additive techniques enable the creation of complex mould inserts with conformal cooling channels. These dramatically reduce cycle times, reject rates, and warpage in high-value sectors like medical device production. Hybrid machines now seamlessly combine overmoulding and additive techniques to produce multi-material parts without secondary assembly, reducing manufacturing time and costs.[3][4]

Digital manufacturing platforms allow for instant quoting, remote process oversight, and real-time order tracking from prototype through full-scale production. Smart contracts and blockchain-backed material records ensure traceability, particularly for high-accountability sectors like medical and aerospace moulding production.[4][5]

Micro moulding enables subgram precision for tiny components essential to electronics and medical devices. Vacuum-assisted venting and ultra-precise cavity design now make it possible to achieve near-perfect yields at scale, opening new frontiers in neural implants and micromechanical parts.

Emerging biocompatible alloys such as Nitinol are injection-moulded to create self-expanding stents and responsive frameworks for minimally invasive surgery. These advances demonstrate moulding production's critical role in driving healthcare innovation.[6][3]

Modern electrical and hybrid machinery delivers low-energy, high-throughput performance, outpacing traditional hydraulic systems both in cost and eco-friendliness. The adoption of conformal cooling, automated shutdown, and solar-powered facilities further lowers production costs and environmental impacts. Thin-wall injection moulding allows for lighter packaging—reducing raw material consumption while maintaining product robustness.[5][6]

As global markets demand rapid product launches and customization, moulding production is evolving to support flexible batch sizes and short-run orders. Quick changeover equipment and modular mould systems make it easy to swap production lines and scale quantities on demand with minimal downtime.[5]

Smart digital simulations validate complex designs before production, and digital twins enable manufacturers to “trial-run” new tools virtually—eliminating costly errors and facilitating faster time-to-market.

Automated technologies are transforming the traditional operator's role in moulding plants. Employees are now recruited and trained to program CNC machinery, interpret process data, and collaborate with robotics and AI platforms. As manual labor recedes, companies are investing in educational initiatives and cross-disciplinary skill-building, ensuring their workforce thrives in this high-tech era.[9][5]

Market volatility, tariffs, and logistics disruptions are driving strategic moves toward domestic and nearshoring production. Agile, decentralized moulding production models provide faster response times, local market adaptation, and superior control over design iterations, making overseas outsourcing less attractive. This shift reflects moulding production's importance in risk mitigation and robust supply chains.[2][1]

Moulding production is expected to continue its rapid expansion, fueled by consumer electronics, automotive, aerospace, and medical device industries. The integration of smart technologies, sustainable material systems, and global supply chain resilience strategies point toward growth, flexibility, and ecological responsibility as defining features of the industry's future.[7]

The moulding production industry is undergoing a dynamic transformation driven by automation, digitalization, sustainable materials, rapid prototyping, and AI-powered optimization. From smart factories to micro moulding for healthcare, innovators are redefining manufacturing efficiency, quality, and environmental responsibility. OEM partners that leverage these trends secure their competitive edge through shorter lead times, consistent high quality, and the ability to adapt to ever-changing market demands. As moulding production evolves, those who invest in cutting-edge technology, skilled human capital, and sustainable practices will thrive—and drive the industry forward in the years ahead.

Smart factories, AI-driven process controls, automation, sustainable materials, and hybrid manufacturing techniques top the list. These advances drastically improve efficiency, reduce waste, and deliver higher product quality for OEM partners.[3][4][6][5]

Digital twins, IoT connectivity, and advanced simulation tools enable virtual testing, real-time performance monitoring, and faster product iteration. This leads to rapid prototyping, zero-defect production lines, and optimized supply chain management.[1][4]

Sustainable practices reduce raw material usage, lower energy consumption, and promote recycling/biodegradable materials. Leading factories invest in closed-loop recycling and energy-efficient machines to meet environmental targets while maintaining profitability.[6][3][5]

Micro moulding and advanced biocompatible alloys are facilitating breakthroughs in electronics, medical devices, and minimally invasive implants. High precision, specialized material selection, and tight process control are key factors.[3][6]

OEM agreements increasingly support flexible batch sizes, expedited prototyping, real-time production data, and remote management. Factories can quickly switch tooling and customize production for unique customer needs, enhancing responsiveness and value.[2][7][1]

[1](https://quickparts.com/why-engineers-are-rethinking-injection-molding-in-2025/)

[2](https://www.fictiv.com/articles/injection-molding-trends-2025)

[3](https://www.jaycon.com/5-injection-molding-trends-for-2025/)

[4](https://www.makerverse.com/resources/injection-molding/the-biggest-injection-molding-trends-for-2025/)

[5](https://flambeau.co.uk/industry-market-trends/the-future-of-plastic-manufacturing-in-the-uk-key-trends-and-innovations-for-2025/)

[6](https://www.beroeinc.com/resource-centre/insights/advancements-plastic-injection-molding-market)

[7](https://finance.yahoo.com/news/injection-molding-market-forecast-trends-135300553.html)

[8](https://www.welchplastics.com/plastics-used-for-injection-molding-in-2025-trends-innovations-and-sustainable-alternatives/)

[9](https://www.fieldex.com/en/blog/manufacturing-industry-trends-and-innovations-to-watch-in-2025)

[10](https://thriam.com/the-future-of-injection-molding-trends-and-predictions-for-2025-and-beyond.php)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal