Views: 222 Author: Amanda Publish Time: 2025-11-12 Origin: Site

Content Menu

● Introduction: The Essence of Turning Lathe Machining

● Automotive Industry: Precision at Scale

● Aerospace & Defense: Engineering the Extraordinary

● Medical Device Manufacturing: Life-saving Precision

● Electronics & Semiconductor Fabrication: Miniaturization Mastery

● Energy and Power Generation: Endurance in Harsh Environments

● Shipbuilding and Marine Applications: Shaping Giants

● Metalworking & Fabrication: The Foundation of Industry

● Woodworking, Furniture & Decorative Arts

● Jewelry Making & Micro-Machining

● Glassworking & Scientific Instruments

● Tool Making & Industrial Equipment

● How Turning Lathe Machining Works

● Types and Applications of Turning Lathe Machines

● Key Benefits of Turning Lathe Machining

● Challenges and Future Trends

● FAQ

>> 1. What are the main industries using turning lathe machining?

>> 2. What materials can be processed on a turning lathe?

>> 3. How does CNC lathe machining differ from manual operation?

>> 4. Why do manufacturers prefer turning lathes for precision parts?

>> 5. What are some challenges facing turning lathe machining today?

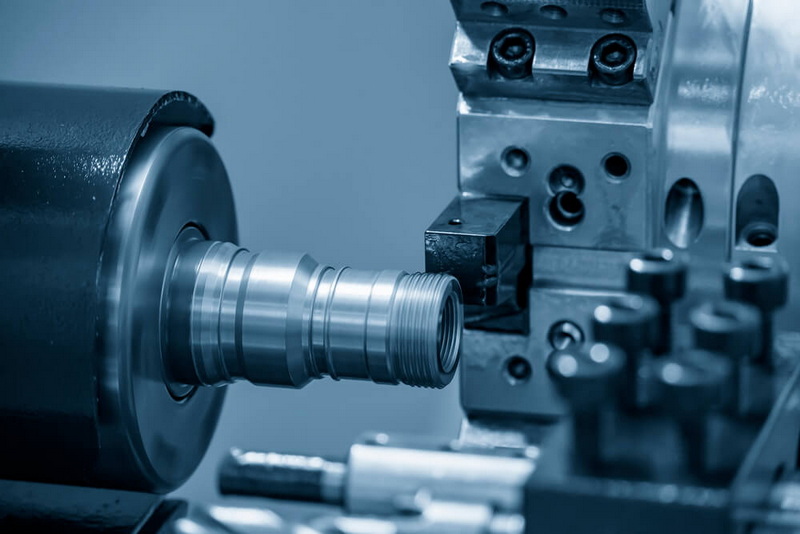

Turning lathe machining stands as one of the pillars of modern manufacturing, offering unmatched precision, flexibility, and efficiency across diverse industries. From automotive to medical devices, energy to electronics, the turning lathe is not merely a tool but a catalyst for quality production and innovation. This article examines which sectors rely on turning lathe machining, explores how this process operates, and details the numerous distinct advantages and real-world applications of the technology.[5][6][7][11][12][13]

Turning lathe machining involves the rotation of a workpiece while a cutting tool removes material to shape, size, and finish the piece. Whether operated manually or controlled by CNC technology, lathes process metals, plastics, and composites producing parts with tight tolerances suitable for both prototyping and large-scale production runs. The versatility and repeatability of these machines make them a cornerstone of the global manufacturing landscape.[4][6][7]

Automotive manufacturers depend on turning lathe machining for mass production and prototyping of critical parts such as engine blocks, pistons, shafts, and gears. Turning lathes deliver consistent accuracy and can rapidly switch between product types, driving innovation and profitability. Modern automotive applications include:[1][11][5]

- Crankshafts and camshafts machined for smooth operation.[5]

- Transmission components and fasteners manufactured for durability.

- Custom parts for performance and competitive advances.

The aerospace sector demands extreme precision and reliability—a demand met by turning lathe machining for turbine blades, landing gear elements, engine casings, and fuel system parts. CNC lathes are essential for working with tough alloys like titanium and Inconel, producing parts that withstand high stresses, temperatures, and corrosion. In defense, heavy-duty lathes deliver vital parts for vehicles, artillery, and aircraft.[6][7][1][4]

Medical technology relies on turning lathes for the micro-machining of implants, surgical tools, prosthetics, and diagnostic components. Medical device production demands flawless finishes and accuracy often at sub-millimeter scales, which is delivered by specialized CNC and Swiss-type lathes. The ability to use biocompatible materials, such as titanium and medical-grade polymers, has made turning lathe machining indispensable in healthcare.[7][9][1][6][5]

In electronics, turning lathes are critical for manufacturing connectors, micro-housings, and intricate mechanisms in consumer and industrial products. These CNC-driven processes enable the miniaturization of components, maintain quality across high volumes, and support innovation as devices shrink and become more complex.[6][7][5]

Energy sectors—including fossil fuel, nuclear, and sustainable systems—require robust parts for turbines, pumps, valve bodies, and generators. Turning lathes guarantee the mechanical integrity needed for equipment operating under high pressure, heat, and corrosive conditions, reducing maintenance costs and extending operational lifespans.[7][5][6]

Large-scale lathes, and vertical turning lathe (VTL) machines, play a vital role in shipbuilding by machining large propellers, drive shafts, rudder components, and specialized marine hardware. The use of pallet systems and powerful spindles ensures accuracy and repeatability, even for massive workpieces.[5][6]

Across general manufacturing and metal fabrication, turning lathes are used to machine gears, bolts, rods, bearings, toolroom components, dies, and custom fixtures. Lathes perform multiple steps—turning, threading, grooving, polishing—to create precision parts for heavy machinery and everyday products.[2][3][6][5]

Wood lathes create ornate furniture legs, stair balusters, bowls, and artistic decor. CNC models allow mass production with clean finishes and accurate shapes, supporting both industrial furniture manufacturers and artisans. The aesthetics and technical requirements merge elegantly in this segment.[2][6][5]

Mini-lathes and specialized variants enable jewelry manufacturers to hone and polish metals, stones, and create intricate designs at tiny scales. Jewelry made by turning lathes includes fine rings, pendants, and earrings requiring high repeatability and exact custom detailing.[6][5]

Specialized lathes shape glass and ceramics for laboratory equipment, artistic glass pieces, syringes, and vials. Careful heating and rotation allow artisans to form delicate structures without breakage—ideal for both scientific and creative pursuits.[2][5][6]

Lathe machining is crucial for manufacturing high-precision tools, dies, custom fixtures, and industrial components that support multiple manufacturing operations. Toolroom lathes help maintain equipment reliability and streamline production work.[10][5]

Bench and mini-lathes are invaluable for technical education, allowing students and trainees to learn both manual and CNC turning, setting the stage for skilled careers in industry. Well-trained operators are in constant demand as technology advances and manufacturing diversifies.[5][6]

Turning lathes operate through a combination of specialized movements, including:

- Facing: Finishing workpiece ends to precise surface standards.

- Taper Turning: Creating conical forms and transition features.

- Thread Cutting: Achieving threaded sections for fasteners and connectors.

- Contouring and Grooving: Forming complex profiles and slots.

- Drilling & Boring: Integrating holes or enlarging passages to tolerances.

CNC technology automates these steps, integrates CAD/CAM systems, manages tool changes, and monitors progress for real-time quality assurance. Advanced servo motors and sensors ensure high-speed, defect-free runs.[4][7]

- Engine Lathes: General-purpose for prototyping and repair.[4][5]

- Turret Lathes: High-volume production with multi-tool arrays.

- CNC Lathes: Automation and complex geometry creation, vital across industries.[7][4]

- Swiss-Type Lathes: Specialization in small, thin parts, critical for electronics and medical devices.[1][6]

- Vertical Turning Lathes: Suitable for large, heavy components like those in shipbuilding and energy.[8][6]

- Mini and Micro Lathes: Key for jewelry, watchmaking, and training applications.[6][5]

- Precision and Repeatability: CNC lathes achieve tolerances as tight as ±0.0001 inches (2.54 microns), ensuring parts fit and function as designed.[7]

- Complex Capabilities: Intricate shapes, threads, and bore features are possible with minimal error.

- Efficiency: Automation streamlines production, reducing turnaround times and labor costs.[7]

- Material Versatility: Metals, plastics, composites, glass, and wood can all be machined on lathes.[5][6]

- Improved Surface Finish: The turning lathe often eliminates the need for post-processing on many parts.[7]

- Safety: Automated workflows minimize workplace risks and operator error.[7]

- Integration: Seamless connection with CAD/CAM design software enhances innovation and workflow.[7]

While the advantages are clear, some challenges remain:

- Skill Shortage: Operators require advanced training, especially as CNC functionality grows.[6]

- Upfront Investment: High-quality machines demand significant capital; however, gains in speed and reliability often justify the expense.[14]

- Continuous Innovation: The rise of hybrid machines (combining turning with milling and multi-axis machining) is broadening lathe capabilities and industry impact.[8][7]

Ongoing advances in material science, sensor integration, and manufacturing software continue to enhance what turning lathe machining can accomplish—pointing toward an even more automated and capable industrial future.

Turning lathe machining serves as the backbone of precision manufacturing for industries such as automotive, aerospace, medical devices, energy, electronics, shipbuilding, woodworking, and jewelry. Its unique combination of flexibility, precision, efficiency, and continuous integration with digital technologies fosters ongoing innovation and strengthens global competitiveness. Whether building robust automotive systems, intricate microelectronics, or life-saving medical implants, turning lathe machining remains indispensable to industrial progress.[11][12][4][5][6][7]

Automotive, aerospace, medical, energy, electronics, shipbuilding, jewelry making, woodworking, and glassworking are all major sectors utilizing turning lathe machining for vital components.[5][6][7]

Metals (such as steel, titanium, aluminum), plastics, ceramics, composites, glass, and wood can all be shaped effectively using various types of lathe machines.[6][5][7]

CNC lathes automate the machining process using software and precision controls, achieving higher accuracy, repeatability, safety, and complex geometry generation compared to manual lathes, which rely on operator skill for each task.[6][7]

Turning lathes consistently deliver tight tolerances, excellent surface finishes, scalable batch sizes, and material versatility, all supported by automated workflow and real-time quality control.[6][7]

Skill shortages, machine costs, and increasing production demands are ongoing challenges, but advances in CNC automation, hybrid machining technology, and improved training continue to address these barriers.[14][6][7]

[1](https://rwdtool.com/industrial-applications-of-a-cnc-lathe-machine/blog.html)

[2](https://cncwmt.com/latest-news/what-is-lathe-machine-application/)

[3](https://www.weerg.com/guides/lathe)

[4](https://www.yashmachine.com/blog/applications-of-lathe-machines-in-workshop-environments/)

[5](https://www.3erp.com/blog/lathe/)

[6](https://boruimc.com/applications-of-lathe-machines/)

[7](https://www.wevolver.com/article/what-is-cnc-turning)

[8](https://phillipscorp.com/india/innovative-applications-of-vtl-machines-across-industries/)

[9](https://www.mecanumeric.com/3-4/technologies/lathe/)

[10](https://www.faithmfg.com/cnc-lathe-machining-the-future-of-precision-manufacturing/)

[11](https://www.campro-usa.com/post/why-cnc-turning-machines-are-essential-for-modern-manufacturing)

[12](https://avantiengineering.com/industries-that-rely-on-cnc/)

[13](https://cncwmt.com/qa/cnc-lathe-machine-processes-applications-and-benefits/)

[14](https://www.tramarindustries.com/2021/12/08/advantages-and-disadvantages-of-a-lathe-machine/)

content is empty!

Vacuum Mold Casting Solutions for Automotive Component Manufacturing

How Vacuum Mold Casting Benefits Aerospace and Defense Industries

Vacuum Mold Casting in Medical Device Prototyping: Precision and Reliability

Custom Vacuum Mold Casting for Electronics and Consumer Products

Vacuum Mold Casting for Industrial Equipment: Durability Meets Precision

How Vacuum Mold Casting Reduces Production Costs Without Sacrificing Quality

Comparing Lead Times: Vacuum Mold Casting vs. Other Prototyping Methods

Increasing Operational Efficiency with Vacuum Mold Casting Technologies

How Automation Enhances Vacuum Mold Casting Production Speed

Cost-Effective Vacuum Mold Casting for Small to Medium Batch Runs