Views: 222 Author: Amanda Publish Time: 2026-01-26 Origin: Site

Content Menu

● Understanding VHDL and FPGAs

● What Is VHDL Rapid System Prototyping with FPGAs?

● The Complete Rapid Prototyping Workflow

>> Requirements and System Architecture

>> Simulation and Virtual Prototyping

>> Synthesis and FPGA Implementation

>> FPGA Programming and Hardware Testing

>> Iteration, Refinement, and Design Freeze

● Typical Applications of VHDL Rapid System Prototyping

>> Communication and Networking Systems

>> Industrial and Embedded Control

>> Signal Processing and Hardware Acceleration

● How Rapid Prototyping with FPGAs Supports OEM Projects

>> Parallel Digital and Mechanical Development

>> Transition from Rapid Prototyping to Batch Production

● Advantages of VHDL Rapid System Prototyping with FPGAs

>> Time Savings

>> Design Flexibility and Future Upgrades

● How Shangchen Aligns with Rapid Prototyping Philosophy

● FAQ About VHDL Rapid System Prototyping with FPGAs

>> 1. Why choose FPGAs for rapid system prototyping instead of designing an ASIC directly?

>> 2. How does VHDL help accelerate rapid prototyping on FPGAs?

>> 3. Can rapid prototyping with FPGAs and VHDL reduce overall project risk?

>> 4. How can Shangchen support projects that use VHDL and FPGA rapid prototyping?

>> 5. Is rapid prototyping with FPGAs suitable for long‑term products and industrial applications?

VHDL rapid system prototyping with FPGAs means using the VHDL hardware description language together with reconfigurable FPGA chips to quickly turn digital system ideas into working hardware for early testing and refinement. Instead of waiting for expensive custom chips, engineers implement and verify their designs on FPGAs, iterate rapidly, then transition to long-term production once the design is stable.

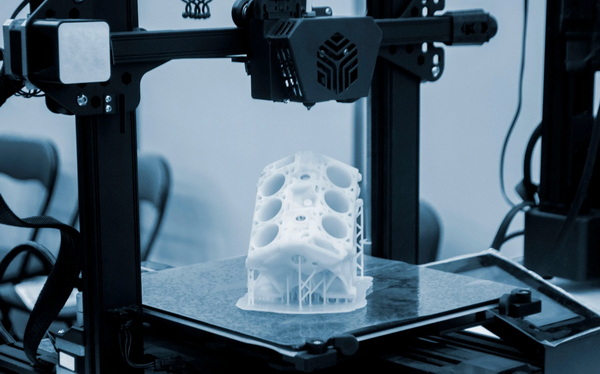

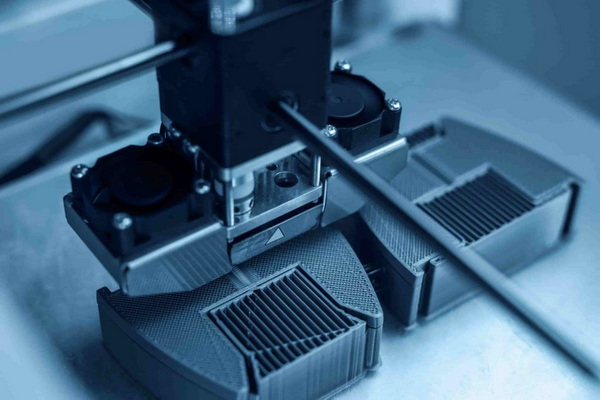

For a factory like Shangchen, which specializes in rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing services, and mold manufacturing, this digital methodology fits neatly alongside physical rapid prototyping workflows. The same philosophy applies: iterate fast, validate early, reduce risk, and smoothly move from prototype to OEM production for overseas brands, wholesalers, and manufacturers.

VHDL (VHSIC Hardware Description Language) is a hardware description language used to model digital circuits and systems. Engineers use VHDL to describe how signals interact, how registers and logic blocks behave, and how entire subsystems are wired together. VHDL supports different abstraction levels, from high‑level behavioral descriptions down to detailed structural implementations.

FPGAs (Field‑Programmable Gate Arrays) are integrated circuits whose internal resources can be configured after manufacturing. Inside an FPGA are arrays of configurable logic blocks, lookup tables, flip‑flops, embedded memory, and high‑speed interfaces. By loading a configuration file generated from VHDL, the FPGA becomes a custom digital system tailored to a particular design. Because FPGAs can be reprogrammed repeatedly, they are ideal for rapid prototyping, where design changes are frequent and experimentation is encouraged.

VHDL rapid system prototyping with FPGAs is a development approach where designers:

- Capture system behavior and structure in VHDL

- Simulate and verify the design in software

- Synthesize and implement the design on an FPGA

- Test and refine the hardware in a lab environment

- Iterate quickly until the system meets performance and reliability goals

This flow mirrors rapid prototyping in mechanical manufacturing. In CNC machining or 3D printing, a design is built quickly, tested, modified, and rebuilt until it satisfies requirements. In the digital domain, VHDL and FPGAs provide the same agility, but for signals, logic, and embedded processing.

For OEM customers working with Shangchen, the digital design team can use VHDL rapid system prototyping with FPGAs while Shangchen provides physical rapid prototyping for enclosures, mounting brackets, cooling solutions, and precision mechanical parts. This allows the entire electromechanical system to mature in parallel.

Every rapid prototyping journey begins with clear requirements and a high‑level architecture. Engineers define:

- Functional goals: what the system must do in terms of data processing, control, or communication

- Performance targets: clock speed, throughput, latency, and power budgets

- Interfaces: external sensors, actuators, communication links, and mechanical connections

- Constraints: cost limits, safety standards, environmental conditions, and size or weight limits

The result is a conceptual architecture that can be implemented in VHDL and mapped onto FPGA resources. This stage parallels the CAD and design review phase before mechanical rapid prototyping at Shangchen.

Once the architecture is defined, designers create VHDL entities and architectures to represent individual blocks and their interactions. Good VHDL practice for rapid prototyping includes:

- Modular design

Breaking the system into reusable functional blocks (filters, controllers, encoders, decoders, bus interfaces) enables rapid modification and replacement during prototyping.

- Clear interfaces

Clearly defined ports and signal naming make it easy to integrate new blocks, connect to external devices, and maintain the design as it grows.

- Parameterization

Using generics in VHDL to make word sizes, buffer depths, and protocol options adjustable without rewriting the code helps accelerate rapid prototyping.

VHDL serves as the “digital blueprint” for the system, much like a 3D model or CAD drawing for CNC rapid prototyping.

Before configuring an FPGA, engineers simulate the VHDL code to verify logic correctness in a virtual environment. Typical simulation steps include:

- Testbench creation

A dedicated VHDL testbench applies stimuli to the design and checks the outputs, capturing typical use cases, boundary conditions, and corner cases.

- Functional verification

Designers ensure that state machines transition correctly, arithmetic units produce accurate results, and protocols handshake properly.

- Waveform inspection

Simulation tools generate waveforms that display signal activity over time, helping identify glitches, race conditions, or timing misunderstandings.

This virtual rapid prototyping step catches many logical errors early, similar to verifying a CAD model and running finite‑element or kinematic checks before cutting metal in mechanical rapid prototyping.

Once the design passes simulation, synthesis tools convert the VHDL into a netlist of logic elements and registers that can be mapped to an FPGA. The workflow includes:

- Synthesis

Translation of VHDL into hardware primitives that match the selected FPGA family. Constraints like clock frequencies and resource usage are considered.

- Place-and-route

Allocation of logic blocks and routing within the FPGA such that timing requirements are met. This step ensures the design can run at the intended clock speed without setup or hold time violations.

- Timing analysis

Static timing analysis confirms that all critical paths meet timing, and engineers adjust pipeline stages or logic structure if necessary.

After implementation, a configuration bitstream or similar file is generated, ready for loading into the FPGA. The speed of these cycles is central to rapid prototyping because VHDL changes can be re‑synthesized and re‑implemented quickly.

The generated configuration is then loaded onto an FPGA development board or a custom prototype PCB. In the lab, engineers perform hardware‑in‑the‑loop tests to validate the system under realistic conditions:

- Functional testing

Input stimuli from sensors, communications channels, or test equipment are applied to the FPGA‑based system, and outputs are observed and recorded.

- Performance evaluation

Data throughput, latency, and resource utilization are measured to confirm that rapid prototyping goals are met.

- Stress and corner‑case testing

Engineers push the system with extreme conditions, such as maximum load, noisy signals, or abrupt changes in operating modes, to observe behavior.

Rapid prototyping at this stage allows quick adjustments when issues are identified. Engineers can change VHDL code, regenerate the bitstream, and reload the FPGA in short cycles, mirroring the way mechanical rapid prototyping teams repeatedly refine CNC or 3D‑printed parts.

Rapid prototyping is inherently iterative. Early versions of the design reveal architectural weaknesses, optimization opportunities, and integration challenges. Through repeated cycles of VHDL updates, simulation, synthesis, and testing, engineers:

- Simplify overly complex logic paths

- Improve resource efficiency

- Sharpen timing margins

- Enhance fault handling and diagnostic features

Once the FPGA‑based rapid prototyping system consistently meets functional and performance requirements, the design can be considered “frozen” for production. At this stage, teams may:

- Keep the FPGA as the final product's core processing platform

- Or translate the verified architecture into an ASIC or custom SoC for higher volume production

In both cases, the risk is significantly reduced, because rapid prototyping has already validated the concept in real hardware.

VHDL rapid system prototyping with FPGAs fits domains where performance, flexibility, and fast iteration are essential.

High‑speed communication protocols often require complex encoding, decoding, error correction, and framing. Rapid prototyping with FPGAs enables:

- Early validation of protocol behavior under realistic data streams

- Adjustment of buffer sizes and latency management strategies

- Experiments with different encoding schemes or multiplexing approaches

VHDL makes it straightforward to describe bit‑level operations, which are critical in advanced communication systems.

Industrial automation, robotics, and embedded control devices frequently operate under strict timing constraints and must interact with analog and mechanical systems. VHDL rapid prototyping with FPGAs helps:

- Implement deterministic control loops with precise timing

- Integrate custom interfaces to sensors, motors, and actuators

- Model redundancy and safety mechanisms before deployment

Rapid prototyping ensures that control logic behaves correctly when connected to real mechanical assemblies.

Applications like digital filtering, image processing, and machine learning inference benefit from hardware acceleration. Rapid prototyping allows:

- Fast exploration of different pipeline structures and parallelization schemes

- Benchmarking of algorithm variants implemented directly in hardware

- Optimization of resource usage vs. performance trade‑offs

Combining VHDL with FPGAs, engineers can create custom accelerators and refine them through multiple rapid prototyping iterations.

For overseas brands, wholesalers, and manufacturers that need reliable OEM partners, rapid prototyping is vital. When digital and mechanical prototyping run together, time‑to‑market is dramatically reduced.

While the customer's electronics team focuses on VHDL rapid system prototyping with FPGAs, Shangchen can work in parallel on:

- CNC‑machined housings and precision brackets

- Sheet metal chassis for industrial equipment

- 3D‑printed fixtures and internal components for early assemblies

- Mold design for future plastic components

This synchronized rapid prototyping approach helps ensure that electronic and mechanical aspects fit together perfectly, avoiding last‑minute redesigns.

Once the FPGA‑based design is stable and the mechanical structures are proven through rapid prototyping, the project moves toward production. Shangchen can:

- Scale from small pilot builds to precision batch production

- Apply optimized CNC machining strategies for consistent quality

- Use sheet metal processes and molds for larger quantities

- Maintain high tolerances required by complex electromechanical systems

Because challenges were resolved during rapid prototyping, the shift to steady OEM production is smoother and more cost‑effective.

VHDL rapid system prototyping with FPGAs brings a range of benefits that match the benefits of mechanical rapid prototyping in modern factories.

Reconfigurable hardware and automated VHDL synthesis shorten development cycles:

- No waiting for custom chip fabrication

- Quick turnaround from code changes to working hardware

- Faster verification of design ideas and architectural choices

In competitive markets, these time savings often mean a stronger position at product launch.

Although FPGAs may be more expensive per unit than high‑volume ASICs, they greatly reduce early‑stage costs:

- Fewer redesigns of costly tooling or silicon

- Lower risk that a design failure will require an entirely new production run

- Better insight into real‑world performance before major investments

When combined with efficient rapid prototyping on the mechanical side, overall development cost and risk are significantly lowered.

Because FPGAs are reprogrammable, the rapid prototyping concept can continue even after deployment:

- Field upgrades can add new features or fix issues

- Design variants can be created for different customers with controlled changes in VHDL

- Long product lifecycles can be supported through firmware and hardware updates

This flexibility is especially attractive for OEM customers serving multiple markets or customizing solutions for individual clients.

Shangchen is a Chinese factory focused on rapid prototyping, CNC machining services, precision batch production, turning, sheet metal fabrication, 3D printing services, and mold production. For international brand owners, wholesalers, and manufacturers, Shangchen offers OEM services that closely mirror the agility of VHDL rapid system prototyping with FPGAs.

Key aspects include:

- Support for concept validation

Early prototypes of structural parts, heatsinks, connectors, and mounting systems allow customers to integrate FPGA‑based boards into real‑world assemblies while digital rapid prototyping is ongoing.

- Flexible production volumes

From a handful of rapid prototyping parts to larger trial runs, Shangchen adapts production capacity as the project evolves.

- Precision and consistency

As the digital design moves from FPGA rapid system prototyping to stable production, Shangchen's precision machining and robust quality control ensure consistent mechanical performance across batches.

By combining VHDL rapid system prototyping on the electronic side with Shangchen's rapid prototyping and manufacturing capabilities on the mechanical side, OEM customers can move from idea to stable, mass‑produced products in a controlled, efficient way.

VHDL rapid system prototyping with FPGAs is a powerful approach for developing modern digital systems quickly and reliably. Engineers describe hardware behavior in VHDL, validate designs through simulation, and then implement them on reconfigurable FPGAs for thorough hardware testing. This process supports fast iteration, early detection of design issues, and flexible architectural exploration.

The principles behind VHDL rapid system prototyping are closely aligned with the philosophy of mechanical rapid prototyping practiced by factories like Shangchen. While engineering teams refine logic, protocols, and embedded control systems on FPGAs, Shangchen provides rapid prototyping for CNC‑machined parts, turning operations, sheet metal structures, 3D printed components, and precise molds. Together, these capabilities create an integrated pipeline from concept through rapid prototyping to precision batch production and full OEM manufacturing for overseas brands, wholesalers, and manufacturers.

By combining digital and mechanical rapid prototyping, projects benefit from reduced risk, lower development cost, and faster time‑to‑market. As requirements evolve and products become more complex, the synergy between VHDL rapid system prototyping with FPGAs and Shangchen's comprehensive rapid prototyping services enables customers to maintain agility while delivering high‑quality, reliable solutions.

Contact us to get more information!

FPGAs are reconfigurable devices that can be programmed many times, which makes them ideal for experimenting with different architectures, algorithms, and interfaces during development. When using FPGAs for rapid system prototyping, engineers can evaluate multiple design options without paying for new silicon each time, significantly reducing early‑stage costs and risk. Once the design is stable and validated on FPGA, it can be converted into an ASIC if high‑volume production and optimized power or cost are required.

VHDL provides a structured way to describe hardware behavior and organization, enabling comprehensive simulation before any physical hardware is configured. Designers can reuse VHDL modules across multiple projects, which speeds up rapid prototyping for new systems that build on existing IP blocks or common architectures. Because VHDL is supported by major FPGA vendors, the same code can often be retargeted to different FPGA families, preserving investment and flexibility.

Yes, rapid prototyping with FPGAs and VHDL reduces risk by revealing design issues early, when they are easier and cheaper to fix. Logical errors, timing violations, and integration problems are caught during simulation and hardware tests on the FPGA platform before committing to production. Coupling this digital rapid prototyping approach with mechanical rapid prototyping for enclosures and structural parts further lowers the chance of late‑stage surprises that might delay shipment or require costly redesign.

Shangchen can provide rapid prototyping for all the mechanical elements that complement FPGA‑based digital designs, such as housings, mounting brackets, front panels, and custom heatsinks. During early stages, Shangchen uses CNC machining, turning, sheet metal fabrication, and 3D printing to create low‑volume parts that are easy to modify as the digital design evolves. Once rapid prototyping confirms the final configuration, Shangchen can move smoothly to precision batch production and full OEM manufacturing with suitable molds and optimized processes.

Rapid prototyping with FPGAs is not only suitable for early experimentation but also for long‑term industrial products. Many systems keep the FPGA as the final processing platform because it allows firmware and hardware updates throughout the product's life, supporting evolving standards and feature upgrades. In industrial environments, combining VHDL rapid system prototyping with robust mechanical designs from Shangchen ensures that the final product can handle real‑world conditions while still offering flexibility for future improvements.

1. https://www.academia.edu/4132763/VHDL_based_rapid_system_prototyping

2. https://groups.csail.mit.edu/cag/warfp2005/submissions/8-veenstra.pdf

3. https://ieeexplore.ieee.org/document/1630769/

4. https://picture.iczhiku.com/resource/eetop/sHKEFdOFgkEPTBxm.pdf

5. https://qa.mnopera.org/default.aspx/textbook-solutions/GBnr0B/Fpga-Prototyping-By-Vhdl-Examples.pdf

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal