Views: 222 Author: Amanda Publish Time: 2026-01-26 Origin: Site

Content Menu

● What Is STL in Rapid Prototyping?

● How STL Files Are Structured

● STL in the Rapid Prototyping Workflow

>> Step 3 – Pre‑Processing for Rapid Prototyping

>> Step 4 – Prototype Production

● Advantages of STL for Rapid Prototyping

● Limitations of STL in Modern Rapid Prototyping

● STL vs. Other File Formats in Rapid Prototyping

● Best Practices for Preparing STL Files for Rapid Prototyping

● STL and Chinese Rapid Prototyping Services

● Using STL Across Multiple Manufacturing Processes

● How STL Affects Cost and Lead Time in Rapid Prototyping

● The Future of STL in Rapid Prototyping

● FAQ

>> 1. What does STL mean in rapid prototyping?

>> 2. Why is STL still the standard for rapid prototyping?

>> 3. What are the main drawbacks of STL in rapid prototyping?

>> 4. Which file types should I send along with STL to a rapid prototyping supplier?

>> 5. How can a Chinese factory like Shangchen help optimize my STL for rapid prototyping?

STL stands for STereoLithography, and it is the most widely used 3D data format in rapid prototyping for driving 3D printers, CNC-based rapid manufacturing equipment, and other additive manufacturing machines. STL files act as the common language that connects CAD models to rapid prototyping equipment by approximating the outside surface of a 3D design with thousands of tiny triangles.

STL is a neutral 3D mesh file format originally created for stereolithography, which was the first commercial rapid prototyping technology, and it later became the de facto standard across the rapid prototyping industry. It is now recognized by almost all 3D printing systems, service bureaus, and manufacturing partners worldwide.

STL describes only the surface of a 3D object as a collection of planar triangular facets, without material, color, or texture information. This makes STL simple, lightweight, and highly compatible with different rapid prototyping systems. Almost all major CAD platforms can export models to STL format, making it a universal hand‑off format for rapid prototyping workflows.

In practical rapid prototyping projects at OEM‑focused factories such as Shangchen, STL is often the last digital step before real manufacturing begins: CAD design is converted into STL, then prepared and sent directly to rapid prototyping machines or CNC equipment.

An STL file represents part geometry using a mesh of small triangles that approximate the curved surfaces and edges of a rapid prototyping model. Instead of storing mathematically perfect curves and surfaces, STL stores many flat facets that collectively form an accurate enough representation for manufacturing.

Each triangular facet is defined by three vertices in 3D space plus a normal vector that indicates which side of the triangle is “outside.” STL files are available in two main encodings: human‑readable ASCII, where every facet is written out as text, and compact binary, where the same data is stored in a more compressed numerical form.

Some key characteristics of STL for rapid prototyping are:

- It stores no explicit topology. Triangles are listed one after another without formal information about how they are connected. This simplifies data exchange, because most rapid prototyping software can easily reconstruct adjacency from shared vertices.

- It stores no units. The numbers in an STL file are plain coordinates; whether they represent millimeters or inches is determined by the importing software and agreed conventions between designer and manufacturer.

- It stores no colors or materials. STL focuses on geometry only, which is sufficient for most functional rapid prototyping tasks and CNC machining workflows. For full‑color or multi‑material printing, other formats may be more appropriate, but STL is still used for the bulk of engineering prototypes.

Because STL is purely geometric and intentionally minimal, it is robust and easy to read, which is one of the main reasons it became so dominant in rapid prototyping.

In a typical rapid prototyping project, STL sits at the center of the workflow between design and manufacturing. This is especially true for OEM customers who outsource to a dedicated Chinese factory such as Shangchen.

The process begins with 3D CAD modeling in tools like SolidWorks, CATIA, Creo, NX, or similar professional platforms. Designers create solid models with all functional details, including pockets, ribs, bosses, and fillets that will later be tested in rapid prototyping.

During this stage, the focus is on design intent, functional surfaces, and assembly conditions. Before export to STL, the model is checked for design issues, such as extremely thin walls, undercuts, or sharp internal corners that might cause problems during rapid prototyping or CNC machining.

The 3D model is then exported to STL using the CAD system's export function. This step is crucial because the quality of the STL mesh directly affects the quality of the rapid prototyping result.

When exporting, the engineer chooses mesh tolerance parameters, such as chord height, angular deviation, and maximum edge length. Finer tolerances produce a mesh with more triangles and smoother surfaces. Coarser tolerances reduce file size but can cause visible faceting, especially on curved or free‑form surfaces.

For high‑precision rapid prototyping, CNC machining verification, or mold cavity evaluation, a finely tuned STL export is essential. For early concept models or large, simple shapes, a coarser STL may be acceptable and more efficient.

After export, STL data is imported into pre‑processing or build‑preparation software. This software is typically provided with 3D printers, stereolithography machines, or integrated into a rapid prototyping factory's workflow.

The STL is checked for:

- Gaps and holes in the mesh

- Overlapping or intersecting facets

- Inverted normals (triangles facing inward instead of outward)

Any errors are repaired automatically or manually. A clean, watertight STL is necessary for reliable rapid prototyping.

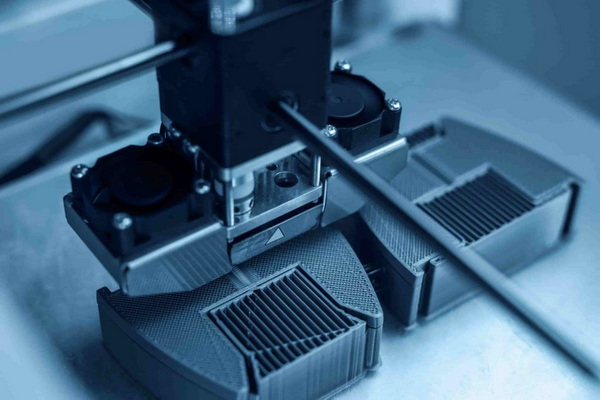

Next, the model is oriented inside the build volume. Orientation affects surface quality, support structure usage, build time, and mechanical properties. After orientation, the software slices the STL into thin layers, usually from about 0.01 mm to 0.7 mm, depending on the rapid prototyping technology and the desired finish.

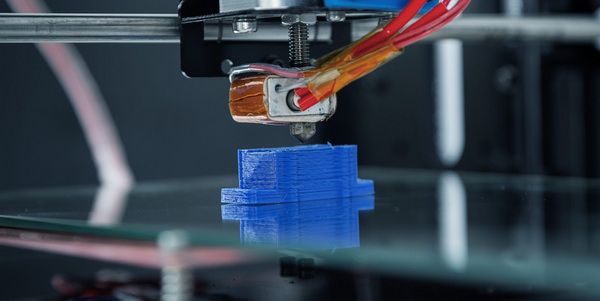

The sliced STL data then drives the rapid prototyping machine. Layer by layer, the system builds the part, curing resin, melting filament, sintering powder, or fusing metal according to the processed STL geometry.

In a full‑service Chinese factory like Shangchen, the same STL data can also:

- Support rapid CNC tool‑path generation for complex surfaces

- Help validate sheet metal unfolding in certain applications

- Assist mold makers as a reference mesh for visualizing draft angles and undercuts

This makes STL a multi‑purpose asset that serves several rapid prototyping and manufacturing processes from one consistent digital source.

STL became the standard for rapid prototyping because it achieves a practical balance between simplicity, compatibility, and precision.

First, STL is almost universally accepted. Nearly every 3D printer, stereolithography system, and additive manufacturing platform supports STL, which makes collaboration between OEM designers and rapid prototyping suppliers smooth and predictable. When a factory receives an STL file, it can immediately load it into its pre‑processing tools.

Second, STL is easy to implement and understand. It represents only the outer skin of the object, which is all rapid prototyping machines need to construct a part layer by layer. This minimalism keeps file structures straightforward and reduces the risk of misinterpretation.

Third, STL is machine‑independent. It is not tied to any specific brand, vendor, or process. The same STL model can be used for SLA, SLS, FDM, metal printing, and, in some situations, rapid CNC machining. This flexibility is valuable for companies that want to compare different rapid prototyping methods or switch processes between development stages.

For a factory such as Shangchen, which offers rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold making, STL allows engineers to evaluate multiple production paths quickly from the same data.

Despite its many strengths, STL has limitations that can influence rapid prototyping quality and workflow efficiency.

One major limitation is file size. To achieve a smooth surface on complex or organic shapes, STL export needs many small triangles. High‑resolution meshes can become much larger than the original CAD file, taking more time to load, process, and transfer, especially in large rapid prototyping projects.

Another limitation is geometric approximation. Because STL replaces curved surfaces with flat triangles, there is always some deviation between the mesh and the original CAD model. If the mesh resolution is too low, this deviation can become visible as faceting or small steps on curved surfaces. For cosmetic parts or high‑tolerance functional components, this may be unacceptable.

STL also lacks parametric or feature data. It does not store sketches, constraints, or dimensions, so it is not suitable for design modifications or engineering changes. Designers must go back to the original CAD model for any updates and then regenerate the STL for rapid prototyping.

Lastly, STL has no native support for colors, multiple materials, or advanced metadata. For full‑color printing or highly specialized additive manufacturing, newer formats such as 3MF and AMF can be more capable. Even so, STL remains the most common choice in many engineering‑focused rapid prototyping and CNC‑supported workflows.

In modern rapid prototyping, STL typically co‑exists with parametric CAD formats and newer mesh standards. Each plays a different role within the digital workflow between OEM clients and manufacturing partners.

STEP (also known as STP) is a neutral CAD format used for exchanging precise solid models between different CAD systems and manufacturing environments. It preserves geometry, topology, and sometimes basic product structure information. However, most rapid prototyping machines do not build directly from STEP; instead, STEP is converted into STL for slicing and building.

IGES is another geometry exchange format, historically popular for transferring surface models and complex curves. It is more flexible in some ways but also more complex and less commonly used than STEP in current rapid prototyping. Like STEP, it usually must be converted to STL before additive manufacturing.

3MF is a more recent format designed specifically for 3D printing and advanced rapid prototyping, with support for materials, colors, and other attributes that STL cannot store. It aims to be a richer successor to STL, but adoption is still growing, and STL remains the default in many engineering environments.

Native CAD formats such as SLDPRT or PRT store the full parametric model with dimensions, features, and constraints. They are ideal for design, engineering, and design‑for‑manufacturing analysis. However, for direct machine input most rapid prototyping systems still expect an STL or similar mesh file.

Combining native CAD with STL gives the best of both worlds: flexible design and robust manufacturing. OEMs can use native CAD for design iterations, while STL feeds 3D printing, CNC verification, and other rapid prototyping processes in factories like Shangchen.

To obtain accurate and cost‑effective rapid prototyping parts from an overseas OEM supplier, proper STL preparation is essential.

A first best practice is choosing appropriate mesh tolerance. Small chord heights and tight angular controls produce a dense, accurate mesh, ideal for small parts, precision fits, and cosmetic surfaces. Larger tolerances reduce file size and processing time but may be acceptable for big, simple features or early design prototypes.

A second best practice is ensuring that the model is watertight. Rapid prototyping requires closed solids with no gaps or self‑intersections. Before export, CAD models should be solid bodies rather than surfaces, and after export the STL should be checked with mesh repair tools. Many rapid prototyping partners can assist with this step if needed.

A third best practice is verifying orientation and wall thickness. Orientation has a strong influence on surface quality and support requirements in layer‑based rapid prototyping. Thin walls need special attention because each rapid prototyping process has minimum thickness constraints. Discussing these constraints with the supplier helps avoid fragile or unprintable sections.

It is also important to coordinate units and tolerances. Since STL files do not contain unit information, both designer and manufacturer must agree on whether the model is in millimeters, inches, or another unit system. Providing a 2D drawing or a STEP file with critical dimensions allows the supplier to verify that the produced rapid prototyping parts match the original design.

By following these practices, OEM customers can reduce communication loops, avoid failed builds, and shorten rapid prototyping lead times.

China has become a global hub for rapid prototyping and low‑volume manufacturing because of its mature supply chains, cost‑effective production, and broad range of available processes. Many international brands now rely on Chinese partners for fast concept validation and bridge production.

Local rapid prototyping factories often integrate multiple capabilities under one roof, including CNC machining, 3D printing, sheet metal fabrication, and injection molding. All of these can be driven from a shared set of CAD and STL data, making it easier to switch between methods or combine them.

International brand owners, wholesalers, and manufacturers work with Chinese partners to accelerate rapid prototyping cycles, produce bridge tooling, and run short‑term or seasonal batches before committing to large investments. This approach reduces risk and improves time‑to‑market responsiveness.

As a Chinese factory specializing in rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold production, Shangchen typically receives STL and associated CAD formats from overseas customers. These files are then converted into real parts that meet OEM specifications for geometry, tolerance, and surface quality.

Although STL originated with stereolithography, it now supports a wide range of rapid prototyping workflows and related manufacturing processes.

In 3D printing and additive rapid prototyping, technologies such as SLA, SLS, FDM, and metal powder bed fusion all rely on STL input to define the outer boundary of the part. The sliced STL acts as a precise roadmap for where material should be added or solidified layer by layer.

In rapid CNC machining, STL models can be used to generate 3D tool paths, particularly for free‑form surfaces and sculpted forms. CAM software may use STL for collision checking, stock comparison, and verification even when the final tool paths are calculated from NURBS surfaces or solid bodies.

In mold and tooling validation, mold designers sometimes export STL representations of cavity and core geometry. This helps visualize clearances, draft angles, and undercuts, and it provides a convenient way to share data across teams and systems. STL models can also be used to generate rapid prototype inserts or test cavities.

In inspection and reverse engineering, 3D scanning systems generate dense STL meshes of existing parts. These meshes can be compared to original CAD data to detect deviations or can serve as a starting point when the goal is to reconstruct a design.

For OEM customers, this cross‑process usability means that a single STL model can support both early rapid prototyping and later steps such as machining, molding, and quality control.

The way STL data is handled has a clear impact on rapid prototyping costs and delivery times, especially in international collaborations.

Optimized meshes allow faster processing. If an STL file is neither too coarse nor unnecessarily dense, it loads quickly, slices reliably, and reduces the risk of software crashes or failures during pre‑processing. This helps rapid prototyping factories start production sooner.

Clean, error‑free STL reduces rework. When the mesh is watertight, correctly oriented, and free from major defects, there is less need for back‑and‑forth communication about repairs or doubts. This is particularly important when there are time zone differences between the OEM customer and the Chinese rapid prototyping factory.

Accurate STL geometry also improves quotation quality. A clear representation of volume, surface area, and detail level makes it easier to estimate build time, material usage, and post‑processing needs. This leads to more reliable pricing and better budgeting on both sides.

For an OEM‑oriented Chinese factory like Shangchen, consistent and standardized STL handling is part of delivering repeatable, high‑quality rapid prototyping and small‑batch production. It supports faster responses, clearer cost structures, and more predictable lead times.

As rapid prototyping continues to evolve, STL is likely to remain important, but it may increasingly coexist with richer formats. Modern additive manufacturing systems can benefit from additional information such as multiple materials, color maps, and internal structures that STL cannot express.

New standards like 3MF and AMF were designed to fill these gaps by including advanced attributes while still supporting high‑quality mesh geometry. Some software ecosystems are already integrating these formats for specific applications, especially in consumer and design‑driven industries where appearance and material variation are critical.

However, many industrial rapid prototyping workflows are heavily optimized around STL. Manufacturing partners, automated quoting systems, and shop‑floor tools are deeply familiar with this format. Because of this, even if new formats grow in popularity, STL will continue to be widely used, particularly for engineering parts and functional prototypes.

For OEM customers and suppliers like Shangchen, the most practical approach is to understand STL thoroughly while staying aware of emerging standards. This combination allows companies to take advantage of new capabilities without disrupting proven rapid prototyping pipelines.

STL stands for STereoLithography and serves as the universal mesh language of modern rapid prototyping, translating precise CAD designs into machine‑readable triangular surfaces. Its simplicity, broad support, and machine‑independent structure have made it the standard format for 3D printing, stereolithography, and many CNC‑assisted rapid prototyping workflows around the world.

Although STL has limitations, such as large file sizes, geometric approximation of curves, and the absence of feature or material data, its reliability and compatibility keep it at the heart of many engineering projects. When OEM designers prepare clean, well‑tuned STL files and share them with experienced manufacturing partners, the result is a robust and efficient rapid prototyping process.

For overseas brand owners, wholesalers, and manufacturers working with a Chinese factory like Shangchen, correctly prepared STL files are the foundation for fast, accurate, and cost‑effective rapid prototyping, from early functional prototypes through precision small‑batch production and bridge tooling.

Contact us to get more information!

STL stands for STereoLithography. It is a 3D mesh file format that represents models using small triangles, and it was created originally for stereolithography, one of the earliest rapid prototyping technologies. Today, it is recognized as the standard mesh format in many rapid prototyping workflows.

Because it is simple and machine‑independent, STL is used as a neutral format to move 3D geometry from CAD systems into slicing tools and rapid prototyping machines. Designers export CAD models to STL, and manufacturers use those STL files to build physical parts layer by layer.

STL remains the standard because it is widely supported, easy to generate, and reliable in most engineering scenarios. Almost every 3D printing machine and rapid prototyping software package can import STL, which makes it a safe choice for global collaboration.

Another reason is that STL focuses on the essential requirement for rapid prototyping: a detailed description of a part's outer surface. By ignoring non‑essential design data, STL keeps file structures straightforward and reduces compatibility problems between different systems, vendors, and countries.

The main drawbacks of STL include large file sizes for complex or highly detailed parts, approximation of curved surfaces, and lack of design intelligence. To capture smooth curves accurately, STL must use many small triangles, which can make the file big and harder to handle.

STL also cannot store parametric features, colors, materials, or units. This means designers cannot directly modify the underlying geometry within the STL file and must instead return to the original CAD model for changes. For advanced multi‑material or full‑color printing, other formats may be required alongside or in place of STL.

For professional rapid prototyping projects, it is best to send both STL files and a parametric or neutral CAD file, such as a native CAD model or a STEP file. STL gives the supplier a ready‑to‑use mesh for slicing and building the prototype.

The extra CAD file allows the supplier to check critical dimensions, perform design‑for‑manufacturing analysis, and clarify any tolerance questions. This combination reduces misunderstandings, makes communication smoother, and ensures that the final rapid prototyping part matches the original design intent.

A specialized Chinese rapid prototyping factory like Shangchen can review incoming STL files to identify and repair mesh issues such as holes, inverted normals, and self‑intersections. Engineers can also advise on optimal export tolerances to balance accuracy, file size, and processing speed.

In addition, a factory with multiple capabilities can propose the most suitable process for each STL model, whether that is 3D printing, CNC machining, sheet metal fabrication, or mold‑based production. By combining technical advice with high‑quality manufacturing, Shangchen helps international customers get the most value from every STL file and every rapid prototyping iteration.

1. https://paulbourke.net/dataformats/stl/

2. https://wiki.mcneel.com/rhino/stlinfo

3. https://en.wikipedia.org/wiki/STL_(file_format)

4. https://www.lsrpf.com/zh-Hans/rapid-prototyping

5. https://www.lsrpf.com/zh-Hans

6. http://cs.chinaruicheng.com/news_catalog/rapid-prototype-blog/

7. https://www.tsprototypes.com/cn/resources/blogs/13.html

8. https://www.tsprototypes.com/cn/resources/faqs/

content is empty!