Views: 222 Author: Amanda Publish Time: 2025-11-23 Origin: Site

Content Menu

● The Origin and Evolution of CNC Technology

● How Does CNC Machining Work?

>> CNC Lathes (Turning Centers)

>> CNC Plasma and Waterjet Cutting Machines

>> CNC Electrical Discharge Machines (EDM)

● Key Advantages of CNC Machining

● Applications of CNC Machining Across Industries

>> Electronics and Consumer Technologies

>> Agriculture and Construction

● CNC Machining in Prototyping and Production

● CNC Machining's Role in Modern Manufacturing

● Advanced Technologies and the Future of CNC Machining

● Why Choose CNC Machining with Shangchen?

● FAQ

>> 1. What does CNC mean in machining?

>> 2. Which industries depend on CNC machining the most?

>> 3. What materials can CNC machines work with?

>> 4. How accurate is CNC machining?

>> 5. What is the advantage of CNC machining for OEM production?

Computer Numerical Control (CNC) has revolutionized manufacturing, enabling the creation of intricate parts with extraordinary precision and consistency. At Shangchen, CNC machining is central to our workflow—in rapid prototyping, precision small-batch runs, and large-scale OEM production. Understanding the principles, advantages, and wide-ranging applications of CNC machining can help partners and clients leverage modern fabrication solutions for new levels of innovation and quality.

CNC machining is a subtractive manufacturing process that uses computerized controls to operate machine tools—such as mills, lathes, routers, and grinders. The digital instructions, commonly known as G-code, are typically derived from three-dimensional CAD models. This automation brings unparalleled accuracy, repeatability, and scalability to part fabrication, whether for a single prototype or thousands of production units.

With CNC machining, the entire workflow—design, programming, machine setup, cutting, finishing, and inspection—is tightly controlled. Human input focuses on engineering and oversight, while the machines deliver consistent, flawless results.

CNC machining was born out of a drive for precision and productivity in the mid-20th century. Earlier systems used punch cards and analog feedback mechanisms, but these soon gave way to digital microprocessors as computers advanced. The arrival of CAD and CAM integration further improved the accuracy, versatility, and speed of CNC-based manufacturing. Today, the technology supports not only metal and plastic fabrication but also composites, ceramics, and specialized engineered materials.

The CNC process typically involves these steps:

- Design: Engineers generate a precise digital 3D model in CAD software.

- Programming: The CAD model is converted into G-code within CAM software to establish tool paths, feeds, and speeds.

- Setup: The machinist secures raw material, mounts correct tooling, and loads the program into the CNC machine.

- Machining: The CNC machine executes every command, carving, drilling, cutting, and finishing the workpiece.

- Inspection: Finished parts are measured and tested against specification for quality assurance.

A range of CNC machine types tailor the process to the unique requirements of each project:

CNC milling machines use rotating multi-point cutting tools to remove material from a stationary workpiece. These machines create flat surfaces, slots, holes, and detailed three-dimensional shapes with high speed and reliability.

In CNC turning, the workpiece spins while a fixed cutting tool shapes it. Especially effective for producing cylindrical and conical surfaces, CNC lathes are vital in making shafts, bushings, and other round components.

Drilling centers automate the placement and creation of holes with exact dimensions and positions, often in complex patterns. High repeatability ensures consistency across large production runs.

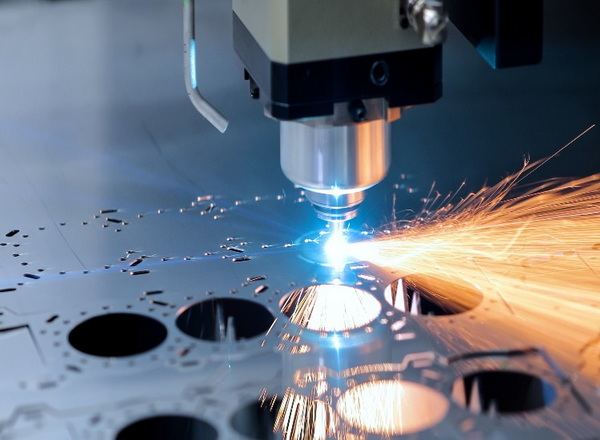

These advanced tools use plasma torches or pressurized water and abrasives to cut metals, ceramics, composites, and glass cleanly. Their flexibility makes them ideal for intricate 2D patterns and delicate shapes.

EDM uses electrical sparks to erode shapes into conductive materials. The process excels for fine detail in dies, molds, and hardened parts that resist other forms of machining.

CNC machining is fundamental to high-quality, cost-effective manufacturing worldwide. Its key strengths include:

- Precision and Accuracy: CNC systems achieve tolerances unattainable by manual means, with repeatable accuracy to microns, meeting demanding industry standards.

- Unmatched Consistency: Every finished part is virtually identical to the digital original, improving reliability and quality control.

- Superior Efficiency: Automation enables simultaneous multi-part production, rapid setup, and high material removal rates.

- Flexibility and Complexity: CNC machining supports complex 3D geometries, elaborate surface textures, and internal cavities.

- Wide Material Compatibility: From aluminum, steel, and titanium to plastics, ceramics, and advanced polymers, CNC machines can handle nearly any engineering material.

CNC machining drives innovation in almost every sector:[1][3][4][5]

Critical aircraft structures and engine components demand tight tolerances and supreme reliability. CNC machining is used to craft landing gears, turbine blades, airframes, and custom fittings, ensuring both strength and lightweight performance.

The automotive industry relies on CNC for pistons, cylinder heads, transmission cases, brake calipers, custom bodywork, and countless components—offering rapid prototyping, cost-effective batch production, and support for custom vehicle designs.[2][4][5]

CNC machining delivers the precision and biocompatibility needed for surgical instruments, bone implants, prosthetics, orthopedic braces, and dental restorations. The technology's repeatability means each piece exceeds strict medical standards.[3][5]

Consumer and industrial electronics benefit from CNC-fabricated printed circuit boards, housings, heat sinks, and assembly fixtures. The ability to miniaturize parts while upholding reliability is key to innovation in this rapidly advancing industry.[5][7]

CNC technology supports defense by producing parts for advanced radar systems, armored vehicles, missile guidance, and custom weapon components. Strict tolerances and confidential design data are maintained with confidence.[8]

From robust oilfield pumps and drilling components to the delicate vanes of wind turbines and frames for solar panels, CNC machining ensures durability and precise geometry for high-performance energy equipment.[2][5]

Modern farming and building industries depend on rugged, precision-machined equipment. CNC fabrication produces tractor engine parts, irrigation system fittings, construction machinery gears, and heavy-duty fixtures, supporting productivity and safety.[4][5]

Marine components, from propellers and engine cranks to hull fittings, demand corrosion resistance, exact balances, and custom geometries—all supported by advanced CNC machining.

Rapid prototyping is made possible by CNC's ultra-fast turnaround and supreme versatility. From design tweaks to functional tests, engineers can iterate products multiple times without the costs and delays of traditional tooling. CNC clusters are now capable of moving seamlessly from prototype production to full-scale manufacturing: a single digital model can become hundreds or thousands of parts, all meeting precise standards.

For OEMs and global brands, CNC machining means scalable, robust supply chains—no matter if projects demand 10 or 10,000 units.

CNC machining is fundamental for OEM and ODM business models. Its digital foundation enables the secure exchange of design files worldwide, making it the technology driving modern, distributed manufacturing. As digital supply chains mature, companies like Shangchen lead with in-house expertise: rapid prototyping, custom finishes, full assembly, and precision inspection all under one roof.

The CNC industry is undergoing rapid transformation, integrating the latest advancements to extend its capabilities:

- IoT-Enabled Machining: Sensors monitor tool wear, part quality, and energy usage, optimizing each production run.

- Hybrid Manufacturing: CNC machining is increasingly combined with 3D printing for unprecedented geometric freedom.

- AI and Predictive Analytics: Smart systems predict machine needs, schedule maintenance, and refine cutting paths in real time.

- Sustainable Manufacturing: Modern CNC equipment supports material recycling, reduced waste, and optimized resource use.

These innovations ensure CNC machining remains at the forefront of efficient, intelligent manufacturing.

Shangchen offers a comprehensive CNC machining solution for clients seeking quality, speed, and flexibility. Partnering with us means:

- Quick turnaround from concept to production.

- Robust quality control for every unit.

- Access to advanced multi-axis CNC equipment and professional know-how.

- Support for complex, highly customized projects in global markets.

Our teams collaborate closely with OEMs, brand owners, and manufacturers worldwide to deliver production excellence—one part at a time.

CNC machining continues to set the standard in modern manufacturing, combining extraordinary accuracy, repeatability, and speed. From aerospace engines to medical implants, electronic gadgets to farming technology, CNC machining empowers innovation across the industrial spectrum. At Shangchen, this capability forms the foundation of all our work, enabling rapid prototyping, batch production, and large-scale OEM services that consistently exceed expectations. As the industry evolves with smart, sustainable, and hybrid technologies, CNC machining will remain the engine driving the world's next generation of products.

CNC stands for Computer Numerical Control, a technology that uses computer instructions to automate the movement and operation of machining tools for precision part fabrication.

CNC machining is essential for industries like aerospace, automotive, medical, electronics, defense, energy, agriculture, construction, and marine engineering, each relying on its unique advantages for quality and performance.[1][3][4][5][8][2]

CNC machining supports a wide range of materials—including steel, aluminum, copper, titanium, plastics, ceramics, and advanced composites—allowing manufacturers to select the best material for each application.

Modern CNC machines routinely achieve tolerances from ±0.01 mm to ±0.002 mm, ensuring each part aligns precisely with its CAD specification.

CNC machining offers rapid setup, high repeatability, digital quality control, and flexibility for both prototyping and full-scale production, making it ideal for OEM manufacturing.

[1](https://karkhana.io/cnc-and-its-applications/)

[2](https://qviro.com/blog/what-industries-use-cnc-machines/)

[3](https://millenniumprecision.com/7-key-industries-benefit-cnc-machining/)

[4](https://durexinc.com/top-industries-using-cnc-machining/)

[5](https://www.cncserviceco.com/post/different-industries-that-benefit-from-cnc-machining)

[6](https://www.reddit.com/r/MechanicalEngineering/comments/1953x9j/which_industrys_uses_cnc_milling_the_most_for/)

[7](https://www.makerverse.com/resources/insights-and-trends/how-cnc-machining-is-used-across-industries/)

[8](https://staubinc.com/news/applications-for-cnc-machining-in-the-military-and-defense-industries/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic