Views: 222 Author: Amanda Publish Time: 2025-12-18 Origin: Site

Content Menu

● What CNC Machining Means in Modern Manufacturing

● Basic Principles of CNC Machining

>> CNC Milling

>> CNC Turning

>> CNC Grinding and Other Operations

● How the CNC Machining Process Works

>> Step 1: CAD Model and Engineering Data

>> Step 2: CAM Programming and Toolpath Creation

>> Step 3: Machine Setup and Fixturing

>> Step 4: Automated CNC Machining Operations

>> Step 5: Inspection, Finishing, and Assembly

● Typical Materials for CNC Machining

● Benefits of CNC Machining for OEM Buyers

>> High Precision and Repeatability

>> Design Flexibility and Rapid Iteration

● CNC Machining Versus Other Manufacturing Processes

● How Shangchen Uses CNC Machining for OEM Services

● Design Considerations for CNC Machining

● CNC Machining in Rapid Prototyping and Batch Production

● Future Trends in CNC Machining

>> 1. What does CNC machining actually stand for?

>> 2. What are the main advantages of CNC machining over manual machining?

>> 3. Which materials can be processed with CNC machining?

>> 4. When should OEM buyers choose CNC machining instead of 3D printing?

>> 5. How does Shangchen support CNC machining projects for overseas customers?

CNC machining stands for “Computer Numerical Control machining”, describing subtractive manufacturing processes where computers control cutting tools to remove material from a solid block or workpiece. In practice, CNC Machining covers processes such as milling, turning, drilling, and grinding, all driven by pre‑programmed toolpaths generated from CAD/CAM software.

To visualize CNC machining, imagine a programmable factory where each machine follows digital instructions line by line, moving tools along precise axes to create complex 3D geometries. Instead of relying on the skill and stamina of a manual operator, CNC machining relies on servo motors, encoders, and control systems to position tools with repeatable accuracy down to microns.

The core principle of CNC machining is that every movement of the cutting tool or workpiece is defined by numerical coordinates (X, Y, Z and additional rotational axes) executed automatically by the CNC controller. The CNC program defines feed rates, spindle speeds, tool changes, and motion paths, so the same part can be manufactured many times with consistent dimensions and tolerances.

CNC machining is generally classified as a subtractive process, meaning material is removed from a workpiece using cutting tools, as opposed to additive processes that build parts layer by layer. Because of this subtractive nature, CNC machining is ideal for high‑strength metals, tight‑tolerance surfaces, and functional components that must meet demanding mechanical requirements.

CNC machining is not a single process but a family of automated operations that can be combined in one setup or across multiple machines. The most common CNC machining processes are CNC milling, CNC turning, CNC drilling, and CNC grinding, each suited to different geometries and surface requirements.

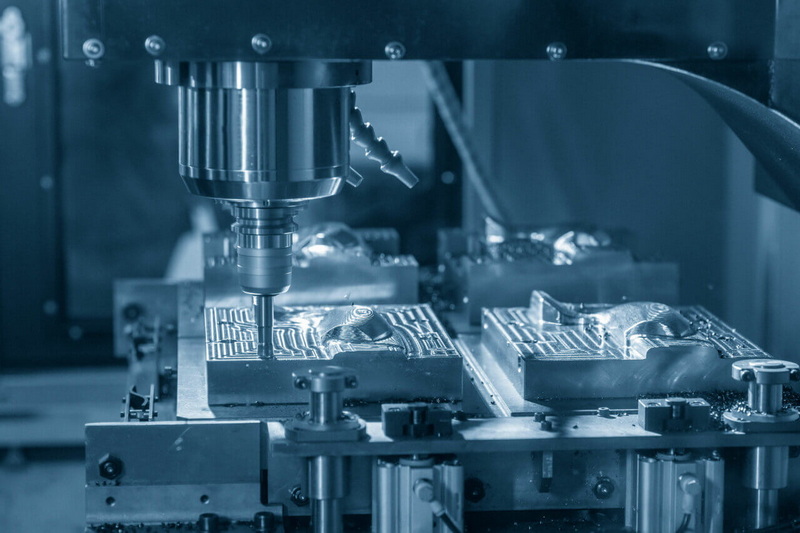

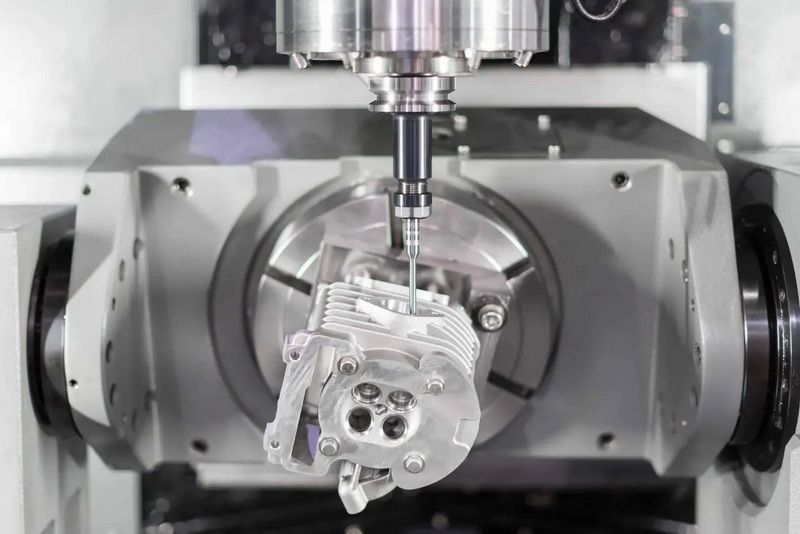

CNC milling uses rotating multi‑point cutting tools mounted in a spindle to remove material from a stationary or moving workpiece, creating pockets, slots, faces, and 3D shapes. Milling machines can be 3‑axis, 4‑axis, or 5‑axis, with higher axis counts enabling more complex contours, undercuts, and multi‑face machining in a single setup.

CNC turning uses a lathe configuration where the workpiece rotates while a stationary or moving cutting tool removes material to form cylindrical parts like shafts, bushings, and threaded components. Turning is fundamental for producing round CNC machining components such as automotive shafts, hydraulic fittings, and precision connectors.

CNC drilling focuses on producing accurate holes at precise locations and depths, often combined with tapping operations for threads. Boring enlarges or finishes existing holes to tight tolerances, critical for alignment features, bearing seats, and precision housings produced through CNC machining.

CNC grinding uses an abrasive wheel to remove very small amounts of material, achieving extremely fine surface finishes and tight dimensional accuracy. Other CNC machining operations include sawing, broaching, EDM (electrical discharge machining), and specialized cutting methods tailored to specific materials and geometries.

Although each factory has its own workflow, most CNC machining projects follow a similar process from digital design to inspected parts. Understanding these steps helps OEM buyers and engineers communicate clearly with a supplier and predict lead times and costs.

CNC machining starts with a 2D drawing or 3D CAD model that defines all key dimensions, tolerances, materials, and surface finishes for the part. Engineers typically use software such as SolidWorks, AutoCAD, or Fusion 360 to build the model and add design for manufacturability (DFM) features suitable for CNC machining.

Next, CAM software converts the CAD model into toolpaths, specifying which tools will cut which features, in what order, and with what feeds and speeds. The CAM system then post‑processes these toolpaths into CNC code (often G‑code) that the specific CNC machine can understand.

Before CNC machining starts, the operator sets up the machine by installing cutting tools, clamping the workpiece with appropriate fixtures, and setting work offsets. Proper fixturing is vital because it ensures stability, correct positioning, and repeatable loading for batches or series production.

Once the program is loaded and verified (often with a dry run or simulation), the CNC machine executes the operations: milling, turning, drilling, or grinding according to the programmed sequence. Modern CNC machining centers can perform multiple operations in one cycle, with automatic tool changers and probing systems for in‑process measurement.

After machining, parts are inspected using calipers, micrometers, CMMs, or other metrology tools to confirm that dimensions meet the drawing and tolerance requirements. Many CNC machining projects also require deburring, surface finishing, coating, or sub‑assembly before packing and shipping to the OEM customer.

One reason CNC machining is so widely used is its ability to process a broad range of metals and non‑metals. Depending on the application, CNC machining may be applied to aluminum, steel, stainless steel, titanium, brass, copper, plastics, composites, and even wood or glass.

Metals such as aluminum and stainless steel are popular for CNC machining because they offer a strong balance of machinability, strength, corrosion resistance, and cost. Engineering plastics like POM, PEEK, and nylon are also frequently CNC machined for low‑friction, lightweight components in automotive, electronics, and medical products.

CNC machining is used in almost every major manufacturing industry that needs precise, reliable mechanical components. Typical sectors include automotive, aerospace, medical devices, electronics, energy, industrial machinery, agriculture, and consumer products.

For example, aerospace manufacturers rely on CNC machining for structural parts, turbine components, and fixtures that must meet strict safety and tolerance standards. Electronics companies use CNC machining to produce housings, heat sinks, connectors, and high‑precision tooling that support PCB assembly and semiconductor production.

For international OEM brands and wholesalers working with factories like Shangchen, CNC machining delivers a clear set of advantages. These benefits are especially valuable when combined with rapid prototyping, sheet metal fabrication, 3D printing, and molding in an integrated supply chain.

CNC machining is capable of achieving tight tolerances and fine surface finishes that are difficult or impossible with manual machining, particularly for complex 3D geometries. Because the process is digitally controlled, once a program and setup are validated, thousands of parts can be reproduced with consistent quality.

Automation in CNC machining allows long, unattended runs, especially when combined with pallet changers or robotic loading systems. This improves productivity and reduces labor costs, making CNC machining competitive for both prototypes and medium‑ to high‑volume batches.

CNC machining can quickly adapt to design changes because modifications are made at the program and setup level rather than requiring new tooling molds. This flexibility makes CNC machining ideal for rapid prototyping and small‑batch validation before investing in mass‑production processes like die casting or injection molding.

While CNC machining is powerful, it is one option among several manufacturing technologies, each with its advantages and trade‑offs. Understanding how CNC machining compares with 3D printing, casting, and molding helps OEM buyers choose the right process for each stage of development.

Aspect | CNC Machining | 3D Printing | Molding/Casting |

Process Type | Subtractive cutting from solid stock. | Additive layer by layer build. | Material formed in a mold cavity. |

Best Use | Functional metal parts, tight tolerances, prototypes to mid volumes. | Complex internal geometries, low volume prototypes. | Very high volumes with low unit cost. |

Lead Time | Fast once program and setup are ready. | Fast for single parts, slower for large batches. | Long upfront tooling time, fast per part after. |

Material Range | Metals, plastics, composites, others. | Mainly plastics, resins, some metals. | Metals, plastics, rubbers, depending on process. |

Dimensional Accuracy | Very high; tight tolerances achievable. | Moderate to high depending on process. | Good but depends on tooling quality. |

As an integrated Chinese manufacturer, Shangchen combines CNC machining with rapid prototyping, lathe turning, sheet metal fabrication, 3D printing, and mold production to support overseas OEM projects from concept to mass production. For CNC machining, the factory can handle precision prototypes, small‑lot runs, and larger batch production, integrating quality inspection and assembly as needed for global customers.

In a typical OEM workflow, a customer sends 3D CAD files and requirements; Shangchen engineers review DFM, select appropriate CNC machining processes, and then use in‑house turning, milling, and auxiliary services to deliver finished components ready for use or further integration. This integrated CNC machining approach helps reduce supplier count, shorten lead times, and stabilize quality across multiple product generations.

To get the best results from CNC machining, engineers should apply design for manufacturability guidelines that balance performance, cost, and lead time. Common recommendations include using consistent wall thicknesses, avoiding unnecessary sharp internal corners, and designing features that can be accessed by standard cutting tools.

Choosing realistic tolerances is equally important; overly tight tolerances can dramatically increase CNC machining time and cost without improving function. By collaborating early with a CNC machining supplier like Shangchen, OEM buyers can refine geometry, tolerances, and material choices to achieve an optimal balance for each project.

CNC machining plays different roles at different stages of the product lifecycle. During rapid prototyping, CNC machining provides functional parts in production‑grade materials so designers can test fit, function, and durability before committing to expensive tooling.

As designs mature, CNC machining supports bridge production and smaller batch orders where demand is still uncertain or highly variable. When volumes eventually justify dedicated molds or casting dies, CNC machining remains critical for tooling components, fixtures, and high‑precision parts that complement mass‑production processes.

CNC machining technology continues to evolve as factories adopt more automation, real‑time monitoring, and integration with digital platforms. Advanced shops are combining CNC machining with robotics, pallet systems, and automatic inspection to create flexible manufacturing cells that can switch between product families with minimal downtime.

At the same time, CNC machining is increasingly connected to cloud‑based quoting, scheduling, and quality systems, making project status more transparent for OEM buyers. Hybrid approaches that blend CNC machining with additive manufacturing are also expanding design possibilities by combining complex printed shapes with CNC‑machined precision surfaces.

CNC machining means using computerized control to drive machine tools that cut material into precise, repeatable shapes, turning digital designs into real‑world components. Across industries such as automotive, aerospace, electronics, and medical devices, CNC machining delivers high precision, material flexibility, and efficient automation that make it essential for modern OEM manufacturing.

For overseas buyers working with an integrated supplier like Shangchen, CNC machining is not just a single process, but the core of a complete digital manufacturing workflow that spans rapid prototyping, small batches, and full‑scale production. By combining CNC machining with sheet metal, 3D printing, and molding, Shangchen helps global brands reduce risk, improve quality, and launch products faster into competitive markets.

CNC machining stands for “Computer Numerical Control machining”, meaning that computers control the movement and operation of machine tools to remove material and create parts. The term emphasizes that all key motions—such as tool position, feed rate, and spindle speed—are governed by numerical code instead of manual adjustment.

Compared with manual machining, CNC machining offers much higher repeatability, tighter tolerances, and the ability to produce complex 3D geometries in a consistent way. It also supports automation and longer unattended runs, which reduces labor costs and shortens lead times for OEM projects.

CNC machining can process a wide range of materials, including aluminum, steel, stainless steel, titanium, brass, copper, engineering plastics, and some composites. This versatility makes CNC machining suitable for parts in automotive, aerospace, medical, electronics, energy, and consumer applications.

OEM buyers typically choose CNC machining when they need metal parts with high strength, tight tolerances, and functional performance similar to mass‑production components. 3D printing is attractive for very complex shapes or early prototypes, but CNC machining often provides better surface finish, dimensional accuracy, and material properties for functional testing and production.

Shangchen supports CNC machining projects by reviewing customer CAD files, providing DFM feedback, and combining CNC milling, turning, and related processes to deliver finished, inspected parts. Because Shangchen also offers rapid prototyping, sheet metal, 3D printing, and mold manufacturing, overseas brands can manage the entire lifecycle—from early samples to mass production—through a single integrated partner.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Lithuania

Top Metal CNC Machining Manufacturers and Suppliers in Czech Republic

Top Metal CNC Machining Manufacturers and Suppliers in Hungary

Top Metal CNC Machining Manufacturers and Suppliers in Denmark

Top Metal CNC Machining Manufacturers and Suppliers in Ireland