Views: 222 Author: Amanda Publish Time: 2025-09-23 Origin: Site

Content Menu

● Understanding the Vacuum Casting Process

● What Experience and Expertise Does the Supplier Have?

● Which Materials Are Available and Recommended?

● How Does the Supplier Ensure Product Quality?

● What Are Production Capacity and Lead Times?

● Does the Supplier Offer Design Support and Project Management?

● What Are the Cost Structure and Payment Terms?

● How Does the Supplier Address Environmental Responsibility?

● Frequently Asked Questions (FAQs)

>> 1. What is vacuum casting, and when should I use it?

>> 2. How does vacuum casting differ from injection molding?

>> 3. Can vacuum casting replicate complex designs?

>> 4. What materials are offered for vacuum casting?

>> 5. What is the usual lead time for vacuum casting parts?

Vacuum casting has emerged as a vital manufacturing technique for rapid prototyping and small batch production. Its ability to create highly detailed, durable parts with a quick turnaround makes it especially appealing for overseas brands, wholesalers, and manufacturers looking for OEM services. However, selecting the right vacuum casting supplier is crucial to achieving top-quality products and smooth project delivery. This article provides an in-depth guide on important questions customers should ask before committing to a vacuum casting partner, helping businesses make informed decisions that align with their technical and commercial goals.

Vacuum casting is a process used to replicate parts by casting liquid polyurethane resin into silicone molds while a vacuum removes air bubbles, resulting in defect-free and dimensionally accurate parts. The process typically involves:

- Master Model Creation: The initial component is designed and produced, usually through 3D printing or CNC machining, to serve as an exact master model.

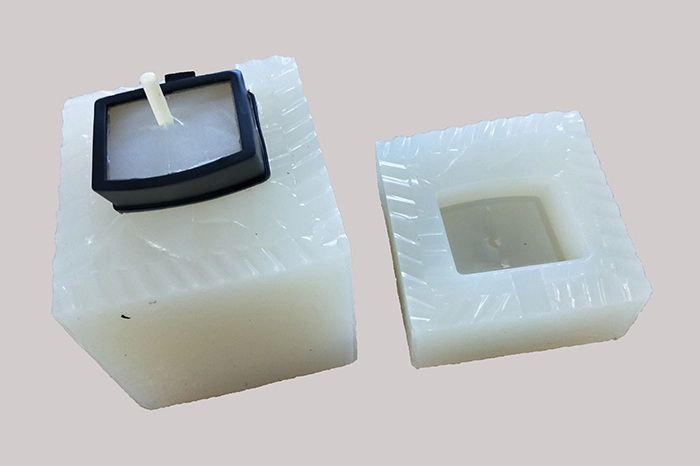

- Silicone Mold Fabrication: The master model is embedded in liquid silicone within a casting box under vacuum conditions, then cured to form a flexible mold.

- Casting with Polyurethane Resin: Two-component polyurethane resin is mixed, degassed in a vacuum chamber, and poured into the silicone mold inside the vacuum chamber.

- Curing and Demolding: After curing in an oven, the parts are demolded, trimmed, and finished.

This technique replicates complex geometries and fine surface details while supporting multiple production cycles from a single mold, typically 10 to 20 uses before mold degradation affects quality. Visual demonstrations and videos of these steps enhance understanding of the technology's efficiency and capabilities, showcasing its advantages over traditional injection molding for prototypes and low volume runs.[1][3][6]

Experience matters significantly in vacuum casting. Customers should inquire about:

- The number of years the supplier has specialized in vacuum casting.

- Types of projects and industries they have served, particularly similar to the customer's product category.

- Their portfolio of completed vacuum casting parts demonstrating complexity, surface finish quality, and consistency.

Experienced suppliers are more likely to provide expert advice on mold design, material choice, and problem resolution, leading to higher success rates and better product outcomes. A factory tour or a video showcasing their production environment and equipment further builds trust in their operational capabilities and standards.

Material selection is a key factor that impacts product performance and aesthetics. Essential questions include:

- What polyurethane resins and other casting materials do they offer? This may include rigid, flexible, transparent, heat resistant, or flame retardant options.

- Can they match material properties like Shore hardness, tensile strength, and thermal stability to your product requirements?

- Do they provide expert consultation to help choose the best resin or customize formulations?

Vacuum casting can closely mimic characteristics of injection molded parts, so having a diverse resin portfolio ensures suitable materials for functional prototypes and end-use parts. Infographics or comparison charts that explain resin properties help customers understand available options and make informed choices.[11][12]

Quality assurance is critical especially when supplying international OEMs with strict standards. Customers need clarity on:

- Quality control processes and certifications such as ISO standards.

- Methods used for inspection and testing, including dimensional accuracy, surface finish evaluation, and mechanical testing.

- The protocol for sample approval and how defects or non-conformances are handled.

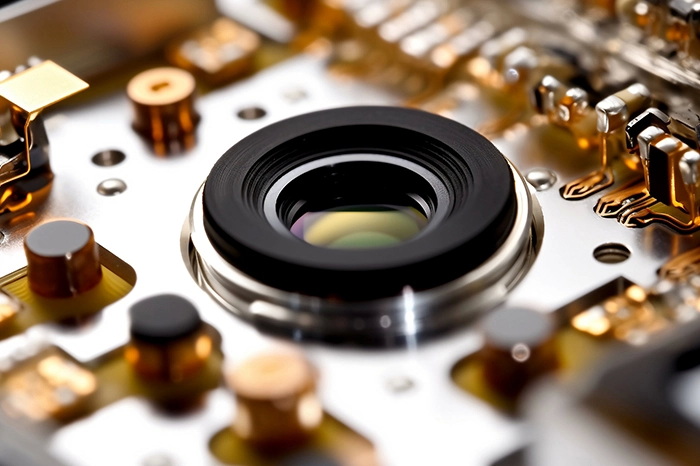

Transparency about quality measures, including the use of metrology instruments like Coordinate Measuring Machines (CMM), provides confidence in consistent output. Videos or photos showing parts undergoing inspection stages reinforce the supplier's commitment to quality.[8][13][14]

Timely delivery can make or break product launches and supply chains. Customers should verify:

- Typical production lead times for prototype and low-volume orders.

- Ability to ramp up production scales from prototypes to small and medium batches.

- Logistics solutions and shipping options provided, especially for overseas clients.

Clear communication about capacity and timelines enables realistic scheduling and prevents costly delays. Visual content that outlines production workflows, from order placement to shipping, can familiarize customers with the process and build reliability.[4][13]

Responsive project support enhances product development speed and success. Important questions include:

- Does the supplier provide design feedback or suggestions to optimize parts for vacuum casting?

- Can they review 3D files for manufacturability, troubleshooting potential defects early?

- Are they able to support rapid iterations and prototyping cycles with efficient communication and project tracking?

Collaboration throughout the design and manufacturing stages helps improve part performance and aesthetics. Screenshots or demos of software tools used in design reviews highlight professionalism and technical capacity.[7]

Understanding costs up front avoids surprises:

- Is pricing per part, per batch, or based on custom quotes factoring complexity?

- Are there additional fees for mold making, setup, or specific finishing processes?

- What payment methods and terms are offered, and are they suitable for export customers?

Transparent cost breakdowns and clear payment policies help build trust and long-term relationships. Providing example pricing tables for typical order sizes facilitates budget planning.

Sustainability is a growing concern for global brands. Questions to explore:

- Does the supplier implement green manufacturing processes such as waste recycling and energy-efficient equipment?

- Are materials used recyclable, and do they meet environmental compliance standards?

- Are there certifications or initiatives that demonstrate the supplier's commitment to sustainability?

Communicating environmental measures aligns supplier practices with modern corporate social responsibility goals. Visual evidence of sustainability efforts strengthens this commitment.[14]

Choosing the right vacuum casting supplier is a decisive factor for manufacturing success. Asking detailed questions about experience, materials, quality assurance, production capacity, design support, pricing, and environmental responsibility helps customers select a partner that meets and exceeds their expectations. Such suppliers provide high-quality, precise parts with quick turnaround, ideal for brand owners and manufacturers targeting international markets.

Vacuum casting remains a versatile and cost-effective solution for rapid prototyping and limited production runs. The right partner ensures product excellence, minimizes risks, and accelerates time to market, enabling customers to confidently deliver innovative products worldwide.

Vacuum casting is a process of casting polyurethane resin in silicone molds under vacuum to produce detailed, bubble-free parts. It is best suited for prototypes and low-volume production requiring high detail and material versatility.

Vacuum casting uses flexible silicone molds ideal for small batches and quick changes, while injection molding employs hardened steel molds for mass production. Vacuum casting is less costly for limited runs and faster for iterations.

Yes, experienced suppliers can accurately reproduce complex geometries, fine textures, and undercuts using advanced mold-making and vacuum techniques.

Materials typically include varied polyurethane resins—rigid, flexible, transparent, heat resistant—allowing customization based on functional and aesthetic requirements.

Lead times typically range from a few days for prototypes to a few weeks for low-volume orders, depending on complexity and quantity, with many suppliers offering expedited services.

[1](https://www.immould.com/vacuum-casting/)

[2](https://millennitek.com/wp-content/uploads/2016/08/H-5800-0660-01-A-EN-Vacuum-Casting-Techniques-User-Guide-Screen.pdf)

[3](https://xometry.eu/en/vacuum-casting-technology-overview/)

[4](https://blog.isa.org/what-are-vacuum-casting-factories-a-comprehensive-guide-to-the-manufacturing-process)

[5](https://formlabs.com/blog/vacuum-casting-urethane-casting-polyurethane-casting/)

[6](https://leadrp.net/blog/overview-of-vacuum-casting/)

[7](https://www.rapiddirect.com/blog/vacuum-casting-design-guide/)

[8](https://www.renishaw.com/media/pdf/en/9a351e67784c4e27992e5e3632434b1f.pdf)

[9](https://www.kemalmfg.com/complete-guide-to-vacuum-casting/)

[10](https://www.rocheindustry.com/guide-to-vacuum-casting/)

[11](https://xometry.eu/en/vacuum-casting-material-selection/)

[12](https://www.rapiddirect.com/blog/vacuum-casting-material-selection/)

[13](https://www.gjprototyping.com/choosing-the-right-vacuum-casting-supplier-key-considerations-for-your-project.html)

[14](https://rmtproducts.com/zh/vacuum-casting/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal