Views: 222 Author: Amanda Publish Time: 2025-11-14 Origin: Site

Content Menu

● Understanding the Turning Lathe in Manufacturing

>> How the Turning Lathe Works

● Most Common Turning Lathe Mistakes

>> Incorrect Spindle Speed Selection

>> Poor Tool Setup and Dull Cutting Edges

>> Failure to Properly Secure the Workpiece

>> Wearing Loose Clothing or Not Securing Hair

>> Neglecting Routine Maintenance

>> Skipping Pre-Operational Checks

>> Sanding Against the Grain (For Wood Lathes)

>> Practicing Only on Soft Materials

>> Over-Reliance on CNC Automation

>> Neglecting Changeover and Setup Accuracy

>> Ignoring Vibration and Chatter

>> Failing to Document and Learn from Mistakes

● Technical Deep Dive: Detailed Mistake Analysis

>> Effects of Improper Speed Selection

>> Ramifications of Poor Tool Setup

>> Securing the Workpiece: High-Risk Operations

>> Operator Fatigue and Distraction

>> Machine-Specific Mistakes: Manual vs. CNC

● Best Practices and Habits for Success

● Frequently Asked Questions (FAQ)

>> 1. What should I check before starting a turning lathe operation?

>> 2. How can I prevent vibration and chatter on a turning lathe?

>> 3. What are the safety essentials for turning lathe work?

>> 4. Why is turning lathe maintenance so important?

>> 5. Can CNC turning lathes eliminate all operational mistakes?

Operating a turning lathe is both an engineering art and a technical discipline. Across industries, from precision prototyping to high-volume batch manufacturing, the turning lathe is central to modern machining. However, even seasoned machinists and new users fall into common traps and costly errors. Knowing these mistakes—and implementing best practices to avoid them—is essential for achieving high-quality parts, safe work environments, and efficient production cycles.[1][3][4]

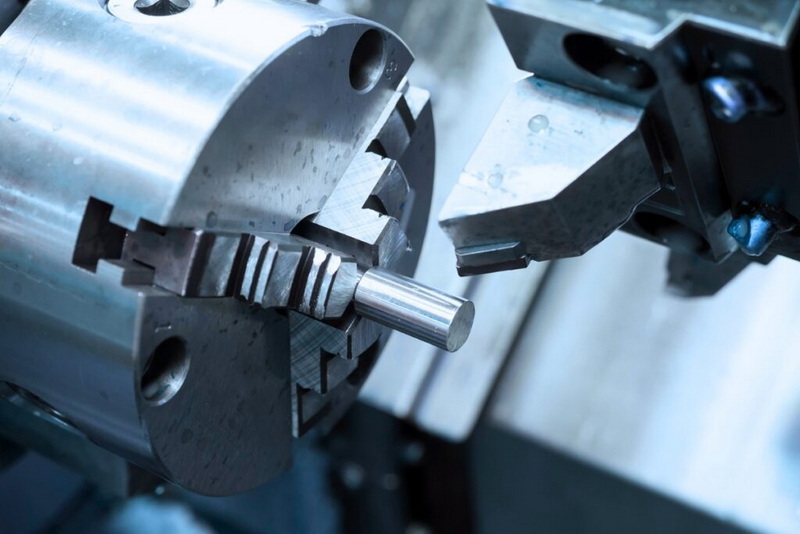

The turning lathe transforms raw workpieces by spinning them at controlled speeds while fixed tools shape the material. From intricate custom prototypes to bulk parts for OEM supply chains, the turning lathe is essential to achieving both precision and speed in manufacturing. The skills required include technical knowledge and a sharp awareness of safety and process controls.[6]

A turning lathe secures workpieces using a chuck or between centers. The part rotates; the machinist (or CNC program) moves sharp tools into the material to create diameters, tapers, grooves, and threads. Metal, plastic, and wood are all common materials for turning lathes, and each presents its own technical nuances.[7]

Setting the wrong spindle speed is a foundational mistake that can ruin a workpiece or cause safety hazards. A speed set too high for the material or diameter increases the risk of vibration, chatter, burning, or catastrophic part ejection. Too low a speed leads to inefficient cutting and rough finishes.

- Guidelines: Always match speed to material and diameter. For example, in woodturning, multiply the diameter (inches) by the RPM to reach a value between 6,000–9,000 for safe, effective operation.[5][1]

- For metalworking, consult your lathe's manual and never exceed the maximum rated RPM, which is often dictated by the chuck grip's safety limits.[7]

Improper tool position or angle causes uneven cuts and increases tool wear. Using dull tools not only ruins finishes but also generates dangerous forces that can damage the machine.

- Always set the tool tip at the workpiece center and maintain perpendicularity for straight turning operations.[4]

- Frequently inspect and sharpen turning tools—dull tools are a leading contributor to dangerous chatter and subpar results.[3][8][9]

Unsecured or improperly mounted workpieces can break free during operation, with catastrophic consequences.

- Always double-check chuck jaws and tailstock pressure before each pass.

- Never leave the key in the chuck to prevent accidental ejection upon start-up.[8]

Personal safety is non-negotiable near a turning lathe. Loose clothing, gloves, jewelry, or untied hair may easily entangle in the turning spindle, often with fatal results.

- Wear fitted clothing, remove all jewelry, and always tie back long hair.[6]

Skipping regular cleaning and lubrication is a root cause of accuracy problems and unexpected breakdowns.

- Remove swarf (metal or wood chips) from the bed and slides daily.

- Lubricate the lead screw, ball screws, and guideways as scheduled. Improper maintenance increases friction and causes alignment and finish defects.[10][3]

Always complete a pre-use inspection:

- Confirm all guards are in place and shields operational.

- Remove loose tools and materials from the workspace.

- Manually rotate the spindle to check for interference before power-up.[6]

Attempting to turn long or slender parts without proper support causes vibration and can lead to the workpiece bending or flying out.

- Use steady rests or tailstock supports for long work.

- Avoid aggressive, deep cuts on unsupported parts and check for proper alignment.[6]

Each turning operation may require a different type of cutter (e.g., roughing, finishing, parting) with a specific material and geometry.

- Select the right tool and insert for every application.

- Using the wrong tool can cause poor results, excessive vibration, and rapid tool wear.[8]

On a wood turning lathe, sanding with the lathe running may leave visible scratches across the grain.

- Always sand with the grain after stopping the lathe to avoid unsightly marks and achieve a finer finish.[2][5]

It's tempting for beginners to start with soft materials, but these often yield poor technique—harder woods or relevant metals offer a truer experience and better surface finish, provided your tools are sharp.

- Practicing with consistent, appropriate materials ensures better skill development and consistent machine loading.[2]

CNC turning lathes offer automation and complexity, but human error in programming, fixturing, and insufficient simulation can still result in costly crashes or re-work.

- Always run simulations, double-check toolpaths, and start new programs with low feed and speed settings before scaling up to production.[7]

Changeover between different parts or fixtures is a major bottleneck in turning lathe workflows. Rushing or skipping accuracy checks during changeover leads to off-center parts, poor dimensions, and wasted material.

- Take time for setup verification, and use indicators to check runout and concentricity.[7]

Vibration (chatter) during turning is a sign of tool, speed, or feed issues, or weak workholding.

- Stop the machine immediately if persistent vibration occurs. Address the root cause before resuming: This may require changing the tool, adjusting speed, or reinforcing the setup.[9][8]

Successful operators and shops keep logs of tool performance, setup issues, and recurring defects. Failing to document errors means missed learning opportunities and repeating mistakes.

- Maintain records of maintenance, tool changes, and trouble events to drive continuous improvement.

Incorrect speeds often lead to excessive heat, tool burn, dimensional inaccuracies, and an increased chance of workpiece ejection. The underlying physics: As the diameter increases, the linear speed at the outer edge rises sharply—even moderate speed increases can multiply risk for large workpieces. Always err on the side of caution, starting slow, then working upwards based on performance and safety.[1]

Incorrect tool angles or insert choices affect chip evacuation and may ultimately cause a tool to dig in, ruining both the tool and part. For delicate finishing, ensure that the tool nose radius matches the finish requirements and that feeds are adjusted accordingly. Using inserts past their rated lifespan also creates excessive heat and marking on the material.[3][8]

Turning asymmetric, thin, or flexible workpieces on a lathe requires additional precautions. Use precision collets or custom fixtures if standard chucks cannot support the geometry. Never attempt to use a turning lathe to machine parts beyond its rated capacity or outside balanced tolerances.

Even experienced operators are susceptible to fatigue. Tired operators are statistically much more likely to make simple, avoidable errors: failing to tighten a chuck, omitting oiling, or skipping a measurement step. Scheduled breaks and a clean, well-illuminated work area are important risk mitigators.

Manual and CNC turning lathes each present unique challenges:

- On manual lathes, improper hand placement or attempting measurements while the machine is running causes accidents.

- On CNC machines, failsafe systems and collision avoidance do not replace vigilant inspection and dry runs—most CNC crashes occur during setup, when programming or workholding errors slip by unnoticed.[7]

- Inspect and sharpen tools before each job.

- Perform a full setup check: tool holders tight, workpiece secure, tailstock and steady rests locked.

- Start new jobs at reduced speeds and feeds, gradually increasing while monitoring for vibration or heat.

- Implement clear checklists for each type of operation or changeover.

- Maintain consistent, logged maintenance—keeping slides, lead screws, and ball screws relatively free of swarf and properly lubricated is essential for both accuracy and machine life.[10][3]

- Foster a safety-first culture: full PPE, eye and face protection, and strict bans on jewelry or loose apparel.

- Document all recurring incidents and create action plans for prevention and operator training.

Success on the turning lathe begins with a respect for safety and technical detail. The most common mistakes—wrong speed selection, improper tool setup, unsecured workpieces, inattention to maintenance, poor documentation, and an underestimation of operator focus—are almost always avoidable with the right practices. Understanding these pitfalls not only ensures the integrity of each workpiece but also sustains productivity and, most importantly, operator safety. Machinists, whether in rapid prototyping, OEM component production, or custom projects, should foster a habit of continual improvement, technical learning, and disciplined observation to achieve the highest standards in turning lathe operations.[4][9][1][3][8][10][6]

Always verify the workpiece is securely mounted, the tool is sharp and correctly positioned, guards are in place, and the work area is clear of loose items. Lubrication and chip removal should be completed in advance.[10][6]

Most vibration is caused by loose workholding, blunt tools, excessive speed, or deep cuts. Secure the setup, use appropriate tool geometry, reduce speed or depth of cut, and ensure the machine is stable and well-maintained.[9][8]

Wear fitted clothing, remove jewelry, and tie back long hair. Always use PPE such as eye protection or face shields and never attempt to adjust or measure a moving workpiece.[6]

Routine chip removal, guideway lubrication, and fastener checks prevent wear, maintain part accuracy, maximize tool life, and reduce the risk of unplanned stoppages or hazards.[3][10]

CNC automation minimizes many human errors, but programming, fixturing, and maintenance mistakes can still cause crashes. Always simulate toolpaths and inspect setups regardless of experience level.[8][7]

[1](https://huntertoolsystems.com/blog/avoid-woodturning-mistakes/)

[2](https://www.youtube.com/watch?v=YybjAs5T_r8)

[3](https://www.stylecnc.com/cnc-solutions/wood-lathe-troubleshooting.html)

[4](https://www.ptfcnclathe.com/blog_detail/1986672508751159296.html)

[5](https://woodturnerswonders.com/blogs/wtwblog/common-woodturning-mistakes-and-how-to-avoid-them)

[6](https://www.ccohs.ca/oshanswers/safety_haz/metalworking/lathes.html)

[7](https://www.engineering.com/an-engineers-guide-to-cnc-turning-centers/)

[8](https://summitmt.com/5-common-mistakes-made-with-a-cnc-lathe/)

[9](https://www.harveyperformance.com/in-the-loupe/understanding-lathe-chatter/)

[10](https://rosnokmachine.com/lathe-machine-maintenance/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal