Views: 222 Author: Amanda Publish Time: 2026-01-21 Origin: Site

Content Menu

● Key Benefits for Manufacturers

>> Dramatically Faster Time‑to‑Market

>> Lower Development Cost and Less Waste

>> Better Design Quality and Fewer Failures

>> Greater Flexibility and Design Freedom

>> Improved Collaboration Across the Supply Chain

>> Reduced Risk Before Tooling and Mass Production

>> Easier Customization and Short‑Run Production

>> Stronger Economic Performance Over the Product Lifecycle

● Typical Rapid Prototyping Workflow in Manufacturing

● Rapid Prototyping and Advanced CNC Machining

● Rapid Prototyping with 3D Printing and Sheet Metal Fabrication

● How Rapid Prototyping Supports OEM Partnerships

● Rapid Prototyping in Precision Batch Production

● Design for Manufacturability and Rapid Prototyping

● FAQ About Rapid Prototyping for Manufacturers

>> 1. How does Rapid Prototyping reduce time‑to‑market?

>> 2. Is Rapid Prototyping cost‑effective for small batches?

>> 3. Can Rapid Prototyping use production‑grade materials?

>> 4. What role does CNC machining play in Rapid Prototyping?

>> 5. How does Rapid Prototyping improve product quality?

Rapid Prototyping gives manufacturers a faster, lower‑risk, and more flexible way to move from CAD concept to market‑ready product. By combining technologies such as CNC machining, 3D printing, sheet metal fabrication, and molding, Rapid Prototyping helps reduce time‑to‑market, cut development costs, and improve product quality across the full lifecycle.

Rapid Prototyping is a set of digital manufacturing processes that convert 3D CAD data into physical parts within days or even hours for design verification, functional testing, and pre‑production validation. Typical Rapid Prototyping workflows combine CNC machining, turning, 3D printing, sheet metal fabrication, and low‑volume molding to support everything from single concept models to bridge production.

For manufacturers, Rapid Prototyping connects design and manufacturing much more tightly than traditional methods, enabling quick iteration and fast feedback from engineering, purchasing, and end‑users. This agility is especially valuable for OEM partners that need samples, pilot runs, and customized parts on aggressive launch schedules.

Rapid Prototyping allows manufacturers to turn digital designs into physical parts in days instead of the weeks or months typical of conventional tooling. Faster prototypes shorten each design iteration, speeding up validation, approvals, and transfer into production.

This compressed development cycle helps manufacturers launch products earlier, capture new demand, and respond to market or customer changes before competitors. In fast‑moving industries, the ability to combine Rapid Prototyping with flexible CNC machining and 3D printing capacity can become a core competitive advantage.

Rapid Prototyping reduces or eliminates the need for early hard tooling, which is usually expensive and slow to modify. By iterating with machined, printed, or sheet metal prototypes first, manufacturers avoid committing capital to molds or fixtures until the design is stable.

Because Rapid Prototyping processes are highly precise and material‑efficient, they also minimize scrap and rework during development. The result is a lower overall cost per validated design, especially when multiple variants must be tested for function, aesthetics, and manufacturability.

One of the strongest benefits of Rapid Prototyping is the ability to physically test design concepts early and often under real‑world conditions. Functional prototypes can be produced in production‑grade metals and plastics, allowing engineers to evaluate strength, tolerances, assembly, and ergonomics.

This early testing uncovers design flaws when they are cheapest to fix and avoids expensive failures after tooling or launch. Manufacturers that embed Rapid Prototyping into their design cycle consistently report higher product quality and more confidence before committing to mass production.

Rapid Prototyping encourages experimentation because design changes can be implemented quickly and economically. Engineers can compare multiple geometries, materials, and surface finishes in parallel, then lock in the best option based on testing and customer feedback.

Technologies like multi‑axis CNC machining and advanced 3D printing can produce complex internal features, undercuts, and organic shapes that would be difficult or impossible with conventional methods alone. This level of design freedom supports more innovative products and optimized parts that reduce weight, assembly time, or component count.

Physical prototypes are communication tools that help align design, manufacturing, quality, marketing, and the end customer. With Rapid Prototyping, these stakeholders can review and handle actual parts rather than relying only on 3D models or drawings.

For OEM projects, Rapid Prototyping allows the manufacturer to present tangible samples, pilot assemblies, or small pre‑production batches for quick approvals. This builds trust, accelerates decision‑making, and reduces misunderstandings about fit, finish, and performance requirements.

When a design goes straight from CAD into full tooling, any mistake becomes expensive and slow to fix. Rapid Prototyping acts as a risk filter, validating dimensions, tolerances, and assembly before committing to mass‑production investments.

By combining Rapid Prototyping with bridge manufacturing processes such as CNC machining for low volumes, manufacturers can simulate production conditions and verify process capability in advance. This approach reduces launch‑phase defects, warranty claims, and costly redesign cycles after tooling.

Rapid Prototyping is ideal for customized components, regional variants, and small‑batch production where traditional tooling would be uneconomical. CAD‑driven workflows enable quick parameter changes, allowing manufacturers to serve multiple customer specifications with minimal engineering overhead.

For brands and distributors that need frequent design refreshes or tailored private‑label products, partnering with a manufacturer that has strong Rapid Prototyping capabilities ensures short lead times and reliable quality at low to medium volumes. This flexibility strengthens long‑term OEM relationships and opens new niche markets.

By speeding development, minimizing redesign, and cutting scrap, Rapid Prototyping directly improves the economics of product launches. Earlier revenue, higher yield, and fewer failures in the field all contribute to stronger margins and a faster payback on development investment.

Manufacturers that embed Rapid Prototyping into standard workflows also gain better data for continuous improvement, using prototype feedback to refine future generations of products. Over time, this discipline builds a more resilient, innovation‑driven manufacturing business.

A practical Rapid Prototyping workflow inside a modern factory usually follows several repeatable steps. Each loop builds confidence and reduces risk before full‑scale production.

- Design and CAD preparation: Engineering teams finalize initial CAD models, including key tolerances and material targets for Rapid Prototyping.

- Process selection: The manufacturer selects the most suitable Rapid Prototyping method, such as CNC machining, turning, 3D printing, sheet metal fabrication, or hybrid routes.

- Prototype fabrication: Parts are produced using digital manufacturing equipment and inspected against dimensional and functional requirements.

- Testing and feedback: Prototypes are assembled, tested, and reviewed by design, quality, and the customer to gather feedback for the next iteration.

- Design refinement: CAD models are updated, and Rapid Prototyping is repeated until the design is ready for tooling or scalable batch production.

This closed‑loop Rapid Prototyping cycle is especially effective for complex CNC parts, tight‑tolerance turned components, and sheet metal housings that must fit precisely in larger assemblies.

CNC machining remains one of the most important technologies within Rapid Prototyping because it delivers tight tolerances and production‑grade mechanical properties. Manufacturers use 3‑axis and 5‑axis CNC milling and CNC turning to produce prototype parts from metals and engineering plastics that match final‑use performance.

In Rapid Prototyping workflows, CNC machining is particularly valuable for precision housings, brackets, structural parts, and components that require critical surfaces or threads. Once the prototype is validated, the same CNC setup and process knowledge can often be extended into small‑batch or bridge production to support early demand.

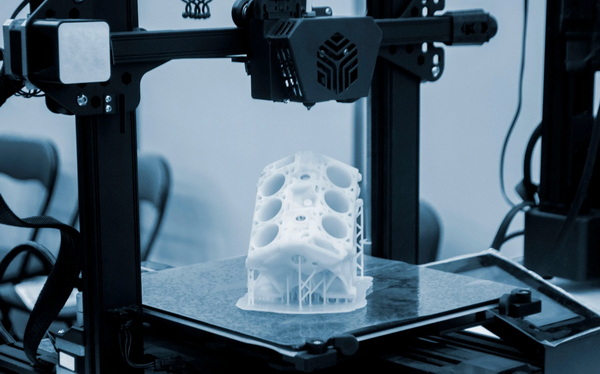

While CNC machining is central to many Rapid Prototyping projects, 3D printing and sheet metal fabrication also play crucial roles. Additive manufacturing allows manufacturers to create complex internal channels, lattice structures, and weight‑optimized geometries that would be difficult to machine. For early design reviews, 3D printed parts give a fast and economical way to study ergonomics and assemblies.

Sheet metal fabrication, including laser cutting, bending, and welding, is equally important in Rapid Prototyping for enclosures, brackets, frames, and mechanical housings. When combined with Rapid Prototyping, sheet metal processes enable quick iterations on door clearances, mounting holes, ventilation patterns, and overall assembly space claims. This helps ensure that electronics, hardware, and structural components fit together correctly before committing to large‑scale fabrication.

For overseas brand owners, wholesalers, and production companies, an experienced Rapid Prototyping partner simplifies new product development. A factory that combines Rapid Prototyping, CNC machining, turning, sheet metal fabrication, 3D printing, and mold production can support the entire journey from idea to stable mass production.

Rapid Prototyping enables such a factory to provide quick samples, engineering suggestions, design‑for‑manufacturability feedback, and pilot batches that mirror final production. This end‑to‑end capability helps OEM customers reduce their internal development workload and accelerate global launches with consistent quality.

When an OEM customer sends initial drawings or 3D data, the Rapid Prototyping team can quickly highlight potential tolerance conflicts, undercuts, or machining difficulties. By resolving these issues at the prototype stage, both the OEM and the manufacturer avoid costly adjustments when molds and fixtures are already built. This collaborative Rapid Prototyping approach strengthens the long‑term partnership and reduces friction across the supply chain.

Rapid Prototyping is not limited to single parts or very small quantities. In many cases, manufacturers extend Rapid Prototyping methods into precision batch production to cover the gap between prototypes and full mass production. This bridge stage is extremely important when demand forecasts are uncertain or when the product design is likely to change after initial market feedback.

Using the same CNC machining, turning, and sheet metal setups developed for Rapid Prototyping, factories can deliver stable batches with consistent quality. This reduces the risk of over‑investing in hard tooling while still meeting launch timelines and early sales requirements. If the market response is strong and the design remains stable, the manufacturer can then proceed confidently to full tooling and high‑volume production.

For complex assemblies, Rapid Prototyping‑driven precision batch runs are also useful for validating packaging, logistics, and field installation procedures. Problems found in these early runs can be solved before thousands of units are shipped, which significantly reduces return rates and warranty costs.

Design for Manufacturability (DFM) is a natural companion to Rapid Prototyping. During each prototype iteration, engineers evaluate not only part performance but also the ease of machining, turning, forming, and assembling. Small changes in radii, wall thickness, draft angles, or hole locations can have a large impact on cycle time and tooling complexity.

Because Rapid Prototyping provides fast feedback, DFM improvements can be tested in real parts instead of staying theoretical. For example, a CNC‑machined prototype can reveal that a deep pocket is difficult to mill with the existing tools, prompting the designer to modify the geometry. Once the new design is validated with Rapid Prototyping, the manufacturer can carry that optimized geometry into production, saving time and money throughout the product's life.

This iterative DFM process, powered by Rapid Prototyping, is particularly valuable for multi‑cavity molds, high‑speed stamping tools, and automated assembly systems. The more issues that can be resolved while still in the Rapid Prototyping phase, the smoother and more predictable the production ramp‑up will be.

Rapid Prototyping has become a strategic capability for manufacturers who need to innovate quickly while controlling cost and risk. By leveraging CNC machining, turning, sheet metal fabrication, 3D printing, and agile molding, Rapid Prototyping empowers factories to deliver accurate prototypes, faster iterations, lower development cost, and higher‑quality products ready for global markets.

For OEM customers and international partners, working with a manufacturer that is highly skilled in Rapid Prototyping means shorter lead times, more reliable launches, and stronger long‑term competitiveness. As product lifecycles continue to shrink, Rapid Prototyping is no longer optional; it is a core enabler of modern manufacturing excellence.

Contact us to get more information!

Rapid Prototyping compresses the development cycle by turning CAD designs into physical parts in days, enabling faster testing, approvals, and design revisions. By eliminating long waits for tooling and setup, manufacturers can launch products earlier and react quickly to customer or market feedback.

Rapid Prototyping is particularly cost‑effective for small batches because it avoids early investment in hard tooling and reduces scrap during development. For low‑volume or customized orders, digital Rapid Prototyping processes like CNC machining, turning, and 3D printing provide high quality with flexible unit costs.

Modern Rapid Prototyping can use a wide range of production‑grade metals and plastics, including aluminum, stainless steel, copper alloys, and engineering polymers. This allows manufacturers to perform realistic functional testing and switch from prototype to production with minimal design changes.

CNC machining is a core Rapid Prototyping technology because it offers tight tolerances, smooth surfaces, and excellent mechanical properties. It is ideal for precision components, critical interfaces, and complex geometries that must match final production standards in both prototype and small‑batch runs.

Rapid Prototyping improves quality by enabling repeated physical testing, early detection of design flaws, and fine‑tuning of dimensions and materials before tooling. More iterations at lower cost lead to more robust designs, fewer production issues, and better long‑term performance in the field.

1. https://www.stratasys.com/en/resources/blog/key-advantages-of-rapid-prototyping/

2. https://amfg.ai/2024/04/23/rapid-prototyping-what-are-the-advantages-for-your-product/

3. https://parts-badger.com/top-7-benefits-of-rapid-prototyping/

4. https://www.gtvinc.com/cost-effective-manufacturing-the-economic-benefits-of-rapid-prototyping/

5. https://fastradius.com/capabilities/cnc-machining/prototyping/

6. https://breinerco.com/10-proven-benefits-of-rapid-prototyping/

7. https://kmmgrp.com/importance-of-rapid-prototyping/

8. https://prismier.com/8-benefits-of-rapid-prototype-manufacturing/

9. https://www.rcoeng.com/blog/rapid-prototyping-the-future-of-manufacturing

10. https://hoosierpattern.com/news/5-exceptional-benefits-of-rapid-prototyping-in-product-development/

11. https://www.protolabs.com/services/cnc-machining/cnc-milling/

12. https://amfg.ai/resources/knowledge-base/what-is-rapid-prototyping/

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam