Views: 222 Author: Amanda Publish Time: 2025-12-18 Origin: Site

Content Menu

● Key Benefits of CNC Machining

>> Unmatched Precision and Repeatability

>> High Efficiency and Short Lead Times

>> Cost-Effectiveness Over the Product Lifecycle

>> Design Flexibility and Complex Geometry

>> Strong Material Versatility

>> Scalability From Prototypes to Mass Production

>> Improved Safety and Lower Human Error

>> Better Quality Control and Traceability

>> Fast Design Changes and Engineering Iteration

>> Strong Compatibility With Other Manufacturing Processes

● Why OEM Brands Choose CNC Machining in China

● How CNC Machining Supports Rapid Prototyping

● How CNC Machining Compares to Traditional Machining

● Typical Applications of CNC Machining

● Integrating CNC Machining With Digital Manufacturing

● Optimizing Designs for CNC Machining

● Choosing a CNC Machining Partner

● FAQ

>> 1. What industries benefit most from CNC Machining?

>> 2. Is CNC Machining suitable for low-volume production?

>> 3. How does CNC Machining reduce production costs?

>> 4. Can CNC Machining handle design changes quickly?

>> 5. What materials can be processed by CNC Machining?

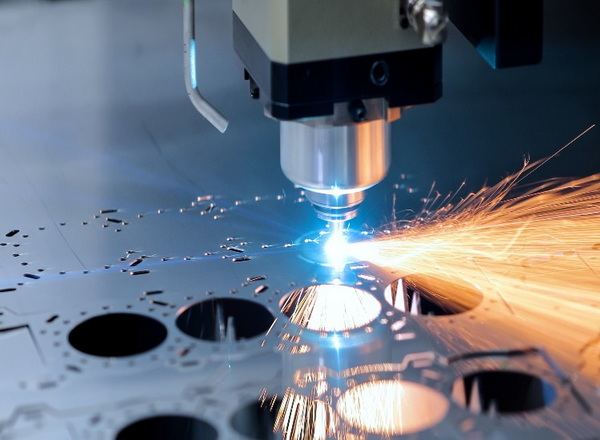

CNC Machining, short for Computer Numerical Control machining, is a process in which computer programs control machine tools such as mills, lathes, routers, and grinders to cut materials into precise shapes. Instead of relying on manual hand wheels and gauges, CNC Machining uses digital 3D models and coded tool paths to control every movement, speed, and feed with high consistency.

For OEM customers, CNC Machining connects CAD design, CAM programming, and automated cutting into one digital workflow that supports rapid prototyping, small-batch runs, and high-volume production on the same platform. This makes CNC Machining ideal for industries such as automotive, aerospace, medical devices, consumer electronics, and industrial machinery where tight tolerances and repeatability are critical.

One of the most important benefits of CNC Machining is its ability to achieve high precision and repeatability across thousands of parts. Because machine motion follows pre-programmed tool paths, CNC Machining can reliably hold tight tolerances and create complex geometries that are difficult or impossible with fully manual machining.

For OEM brands, this means that every production batch of CNC Machining parts closely matches the original prototype, reducing quality variation and minimizing rework. High precision also improves assembly efficiency because mating parts produced by CNC Machining fit together as modeled, lowering the risk of misalignment, leakage, or mechanical failure in the final product.

CNC Machining offers higher production speed than traditional manual machining because machines can run continuously with limited operator intervention. Once the program is proven, CNC Machining centers can run the same job repeatedly, including overnight or during weekends, greatly increasing throughput.

Automated features such as tool changers, pallets, and robotic loading further enhance the efficiency of CNC Machining by reducing idle time between operations. For OEM and wholesale customers, this translates into shorter lead times, faster response to design changes, and more flexible production scheduling based on real demand.

Although the initial investment in CNC equipment and programming can be higher, CNC Machining is very cost-effective over the full product lifecycle. The high precision and repeatability of CNC Machining reduce scrap, minimize rework, and make more efficient use of material, which directly lowers overall manufacturing costs.

Because CNC Machining requires fewer operators per machine than manual equipment, labor costs per part are typically lower in medium to high volumes. At the same time, once a CNC Machining program is created, it can be reused for future repeat orders, enabling OEM customers to reorder parts with minimal engineering cost and very stable pricing.

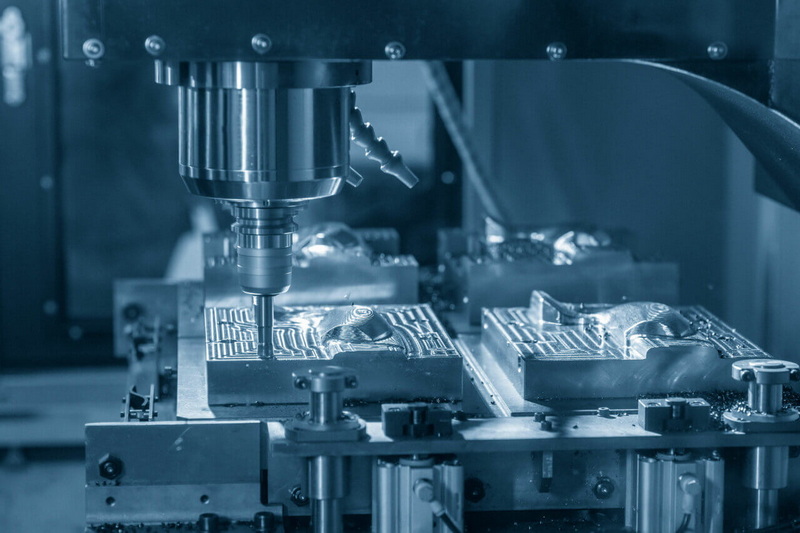

CNC Machining supports a very wide range of part geometries, including complex 3D surfaces, deep pockets, undercuts, and intricate contours. Multi-axis CNC Machining (such as 4-axis and 5-axis) allows tools to approach the workpiece from multiple directions, reducing the number of setups and making more complex parts feasible.

This design flexibility helps engineers and product designers move from simple shapes to optimized, lightweight structures that improve performance and reduce weight. For OEM companies, CNC Machining makes it easier to integrate branding features, custom interfaces, and functional details directly into the part, often reducing secondary operations or additional components.

CNC Machining can process a broad range of materials, including aluminum, steel, stainless steel, titanium, brass, copper, engineering plastics, and composites. This material versatility allows CNC Machining to be used for prototypes, functional testing parts, and final production components in industries with demanding mechanical, thermal, or chemical requirements.

Compared with some other processes, CNC Machining does not require molds or dies for each material change, which is especially useful for low to medium volume OEM projects that use multiple alloys and polymers. CNC Machining can also combine operations such as milling, turning, drilling, and tapping in the same setup, increasing efficiency and maintaining precise dimensional relationships.

CNC Machining is suitable both for quick prototypes and for high-volume batch production using the same or similar equipment. At the early stage, CNC Machining can rapidly produce one-off or small-batch parts directly from CAD data, enabling fast design verification and functional testing.

Once the design is locked, the same CNC Machining programs can be scaled to hundreds or thousands of parts with consistent quality and minimal changes to process parameters. This scalability makes CNC Machining a strategic choice for OEM companies that want a single manufacturing route from first prototype to stable mass production, especially when working with overseas suppliers.

Because CNC Machining is controlled by software and usually enclosed in guarded work zones, operators are less exposed to rotating tools, flying chips, and coolant. This improves workplace safety and lowers the risk of injuries, which is important for both in-house facilities and partner factories supplying OEM customers.

In addition, CNC Machining minimizes manual intervention in cutting operations, which reduces the chance of human error that could damage parts or tools. With proper programming and process control, CNC Machining keeps dimensional errors, wrong tool use, and feed-rate mistakes to a minimum, helping ensure stable quality across large production lots.

Modern CNC Machining systems often integrate measurement, probing, and monitoring functions that support advanced quality control. In-process probing allows the machine to measure critical features and adjust tool offsets automatically, keeping parts within tolerance even during long production runs.

For OEMs, CNC Machining also supports digital traceability because the same programs, offsets, and tool lists can be stored, version-controlled, and linked to inspection reports. This makes it easier to prove compliance with industry standards, handle audits, and manage engineering changes while keeping consistent CNC Machining quality across different production batches or facilities.

CNC Machining is highly suitable for products that require frequent design updates, customization, or small configuration changes. When the CAD model changes, the CAM program can be updated and re-posted to the CNC Machining center without investing in new tooling such as injection molds or casting dies.

This digital workflow allows OEM customers to optimize designs rapidly based on test feedback, market response, or regulatory changes while still using the same CNC Machining supplier. For overseas buyers, this flexibility reduces supply chain risk and supports continuous improvement without large capital costs.

CNC Machining works well together with other processes such as 3D printing, sheet metal fabrication, and injection molding. For example, 3D printing can be used to create early prototypes or complex internal structures, and CNC Machining can then finish critical surfaces, threads, and precise interfaces.

Similarly, CNC Machining can create mold inserts, dies, and fixtures for other processes, making it a core technology in the whole manufacturing chain. For OEM partners, using a supplier that integrates CNC Machining with sheet metal, turning, and tooling creation supports a one-stop solution from sample to volume production.

Many international OEM brands, wholesalers, and manufacturers choose CNC Machining partners in China to combine cost advantages with advanced equipment and experience. China-based CNC Machining factories with integrated rapid prototyping, precision machining, turning, sheet metal, 3D printing, and mold production can support full project life cycles for overseas customers.

For these buyers, CNC Machining in China offers benefits such as competitive per-part cost, access to diverse materials and surface finishes, and flexible production capacity for both small and large orders. When supported by professional engineering teams, CNC Machining suppliers can help optimize designs for manufacturability, reduce lead time, and improve the overall competitiveness of OEM products in global markets.

CNC Machining is one of the most reliable methods for rapid prototyping when designers need parts that closely match final production quality. Unlike some additive processes, CNC Machining delivers parts with production-grade materials and mechanical properties, which is essential for functional and performance testing.

Because CNC Machining does not require special tooling, a prototype can often be produced soon after the 3D model is complete, sometimes within days depending on complexity and material. Once the prototype is approved, the same CNC Machining process can be adapted to low-volume or mass production with minimal additional engineering effort.

CNC Machining differs from traditional manual machining in several important ways. Manual processes rely heavily on operator skill, hand adjustments, and physical gauges, which can lead to variation between parts and longer setup times. CNC Machining, in contrast, uses software to define tool paths, speeds, and feeds, which standardizes the process and greatly improves repeatability.

CNC Machining also supports more complex geometries and multi-axis operations than many manual machines can handle efficiently. While traditional machining still has value for certain repair jobs and very simple operations, CNC Machining offers clear advantages in precision, speed, flexibility, and scalability for OEM production.

CNC Machining is widely used in aerospace parts, automotive components, medical implants, robotics housings, electronic enclosures, and industrial equipment parts. In these applications, CNC Machining meets requirements such as tight tolerances, complex shapes, corrosion-resistant materials, and consistent quality across global supply chains.

Beyond heavy industry, CNC Machining also supports consumer products such as premium metal cases, sports equipment, and hardware accessories where appearance and surface finish are important. OEM customers benefit when a CNC Machining supplier can combine precision machining with surface treatments such as anodizing, plating, painting, and polishing for fully finished parts.

With the development of Industry 4.0, CNC Machining is increasingly connected with digital monitoring, automation, and smart factory systems. These technologies allow CNC Machining centers to optimize cutting parameters, reduce cycle times, and improve tool life through data-driven decisions.

For OEM customers, this digital integration supports more accurate delivery forecasts, better machine utilization, and continuous improvement programs with their CNC Machining partners. Over time, smart CNC Machining environments help reduce production risk, improve consistency, and enhance responsiveness to market demand.

To fully capture the benefits of CNC Machining, engineers should consider manufacturability during the design stage. Features such as minimum radii in internal corners, appropriate wall thickness, and standardized hole sizes can reduce machining time and improve tool life. Designing with CNC Machining in mind also helps avoid unnecessary setups and complex fixtures.

Working closely with an experienced CNC Machining supplier allows OEM brands to refine their models for faster production and lower cost. Small design changes—such as modifying chamfers, fillets, or tolerance bands—can have a large positive impact on cycle time and tooling costs while keeping the original functional intent.

When choosing a CNC Machining partner, OEM customers should evaluate equipment capability, engineering support, quality systems, and communication efficiency. Multi-axis machining centers, experienced programmers, and robust inspection equipment are all important indicators of a capable CNC Machining supplier.

In addition, a strong partner for CNC Machining should offer clear project management, transparent lead times, and flexible order quantities. For overseas buyers, familiarity with export processes, packaging standards, and international documentation is also essential to ensure that CNC Machining parts arrive safely and on schedule.

CNC Machining delivers a powerful combination of precision, repeatability, efficiency, and flexibility that is difficult to match with traditional manual methods. From rapid prototyping to mass production, CNC Machining supports complex designs, diverse materials, and strict quality standards, making it a core technology for modern OEM brands and manufacturers.

By working with a professional CNC Machining partner that also offers turning, sheet metal, 3D printing, and mold production, buyers can streamline their supply chain and move quickly from design to finished products. For international customers, CNC Machining remains one of the most reliable and cost-effective ways to bring high-quality, precision-engineered products to market.

Industries such as automotive, aerospace, medical devices, robotics, electronics, and industrial machinery benefit strongly from CNC Machining because they require precise, reliable parts with tight tolerances. These sectors rely on CNC Machining to produce structural components, shafts, housings, brackets, and custom parts that must perform safely under demanding conditions.

CNC Machining is highly suitable for low-volume and custom production because it does not require dedicated molds or dies for each design. Once the program is prepared, CNC Machining can efficiently produce small batches, engineering samples, and customized variants using the same equipment, which is ideal for development projects and niche markets.

CNC Machining reduces production costs by minimizing scrap, rework, and labor through automation, high precision, and repeatable processes. Over time, reusing CNC Machining programs for repeat orders further lowers engineering and setup costs, especially for OEM projects with long product lifecycles and recurring orders.

CNC Machining can respond quickly to design changes because updates are made in the CAD/CAM files and then transferred as new programs rather than changing physical tooling. This digital approach allows OEM customers to iterate designs and introduce product improvements with much less downtime and lower investment compared with traditional tooling-based processes.

CNC Machining can process a wide variety of metals such as aluminum, steel, stainless steel, titanium, brass, and copper as well as many engineering plastics and composites. This material flexibility makes CNC Machining a preferred option for prototypes, functional parts, and production components across diverse industries, from aerospace to consumer products.

content is empty!

Top Metal CNC Machining Manufacturers and Suppliers in Lithuania

Top Metal CNC Machining Manufacturers and Suppliers in Czech Republic

Top Metal CNC Machining Manufacturers and Suppliers in Hungary

Top Metal CNC Machining Manufacturers and Suppliers in Denmark

Top Metal CNC Machining Manufacturers and Suppliers in Ireland