Views: 222 Author: Amanda Publish Time: 2026-01-21 Origin: Site

Content Menu

● Main Methods Used in Rapid Prototyping

>> 3D Printing / Additive Prototyping

>> Sheet Metal Rapid Prototyping

>> Rapid Injection Molding and Soft Tooling

● Additional Rapid Prototyping Techniques

>> Vacuum Casting for Rapid Prototyping

>> Hybrid Rapid Prototyping Workflows

● Key Advantages of Rapid Prototyping

>> Faster Product Development and Time-to-Market

>> Reduced Development Costs and Lower Risk

>> Better Communication and Stakeholder Alignment

>> Improved Design Validation and Function Testing

>> Customization, Iteration, and Innovation

● Disadvantages and Limitations of Rapid Prototyping

>> Material and Process Limitations

>> Surface Quality and Dimensional Accuracy Issues

>> Risk of Misinterpretation by Stakeholders

>> Over-Reliance and Incomplete Analysis

>> Added Initial Costs and Skilled Labor Requirements

● When To Use Rapid Prototyping

● Best Practices for Successful Rapid Prototyping

● How Shangchen Supports Rapid Prototyping

>> 1. What is Rapid Prototyping used for?

>> 2. Is Rapid Prototyping only 3D printing?

>> 3. How does Rapid Prototyping reduce costs?

>> 4. What are the main risks of Rapid Prototyping?

>> 5. How should companies choose a Rapid Prototyping partner?

Rapid Prototyping has become one of the most important tools for modern product development, especially for overseas brands and OEM buyers working with Chinese manufacturing partners like Shangchen. Rapid Prototyping turns digital CAD concepts into physical or functional parts in days instead of weeks, but it also brings new technical and business challenges that need to be managed carefully.

Rapid Prototyping is a group of manufacturing methods that produce models, parts, or assemblies quickly from 3D CAD data so engineers can test form, fit, and function before investing in full production tooling. Typical Rapid Prototyping processes include CNC machining, 3D printing, vacuum casting, sheet metal fabrication, and rapid injection molding, all used to build prototypes in small quantities with short lead times.

For global OEM brands, Rapid Prototyping makes it possible to validate designs with real parts instead of relying only on simulations or drawings. This helps reduce project risks, improve communication between engineering teams and suppliers, and speed up the final launch to market.

Rapid Prototyping is not a single technology but a toolbox of different processes, each with its own strengths and weaknesses. The most widely used methods in industrial Rapid Prototyping today are:

- CNC machining prototypes

- 3D printing / additive manufacturing

- Sheet metal Rapid Prototyping

- Rapid injection molding and soft tooling

These methods can be combined inside one integrated factory like Shangchen to support everything from early concept models to functional engineering prototypes and low-volume pilot production.

CNC machining is a subtractive Rapid Prototyping method that cuts parts from solid blocks of metal or plastic using computer-controlled tools. For Rapid Prototyping, CNC machining is ideal when projects need tight tolerances, high strength, and materials that closely match final production grades.

Key characteristics of CNC Rapid Prototyping include:

- Very high dimensional accuracy suitable for functional and mechanical tests.

- Wide material selection, including aluminum, steel, brass, copper, engineering plastics, and more.

- No need for dedicated production tools, dies, or molds, which reduces lead time and upfront costs for prototypes.

CNC Rapid Prototyping is also well suited for small-batch production when customers require the same quality as mass-produced parts but in limited quantities. When Rapid Prototyping with CNC machining is implemented in a flexible workshop, it becomes easier to move from one design iteration to the next without long set-up times.

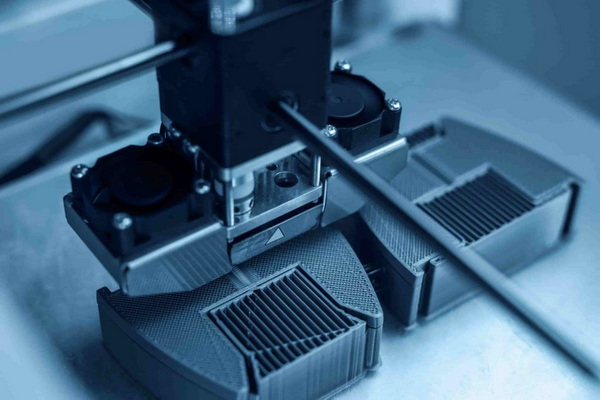

3D printing is an additive Rapid Prototyping method that builds parts layer by layer from plastic, resin, or metal powders, starting from a 3D CAD model. This Rapid Prototyping approach is especially useful for complex shapes, internal channels, lightweight lattices, and organic geometries that are difficult or impossible to machine.

Typical advantages of 3D printing in Rapid Prototyping include:

- Very fast turnaround for early-stage concept models and form studies.

- No need for hard tooling, which keeps initial costs low for small quantities.

- Ability to produce complex or customized prototypes in one piece without assembly.

3D printing Rapid Prototyping covers several technologies such as FDM, SLA, SLS, MJF, and metal additive processes. Each technology has its own balance of cost, surface quality, accuracy, and material properties, so choosing the right additive Rapid Prototyping method for each project is critical.

Sheet metal Rapid Prototyping uses laser cutting, bending, stamping, and welding to create enclosures, brackets, chassis, and structural parts from metal sheets. For Rapid Prototyping of electronic housings, mechanical frames, automation equipment, and industrial cabinets, this method offers a very good balance of speed, strength, and cost.

Sheet metal Rapid Prototyping helps engineers:

- Test assembly and mounting interfaces in real equipment environments.

- Validate cooling, cable routing, and component layout inside enclosures.

- Optimize material thickness, reinforcements, and structural rigidity before tooling.

For OEM customers, combining sheet metal Rapid Prototyping with CNC machining and 3D printing at one supplier makes it easier to build full assemblies for testing and certification. This integrated Rapid Prototyping approach supports faster design validation and smoother transition into batch production.

Rapid injection molding uses simplified or soft tooling (often aluminum molds) to produce plastic parts in low to medium quantities for validation and pilot runs. This Rapid Prototyping method is especially useful when the final production process will also be injection molding and the customer needs parts very close to final products for testing.

Benefits of Rapid Prototyping with injection molding include:

- More realistic parts in terms of material, surface, and mechanical performance.

- Ability to test assembly, ergonomics, and durability with near-production components.

- A direct bridge from Rapid Prototyping to mass production by upgrading or replacing tools.

Because Rapid Prototyping with soft tooling has shorter lead times and lower costs than traditional steel molds, OEMs can afford to adjust designs between initial and final tools. This significantly reduces the risk that a single mold decision will lock in design issues for the entire product life.

Beyond the main methods, several supplementary Rapid Prototyping techniques help fill specific gaps between early design and production.

Vacuum casting, or urethane casting, is a Rapid Prototyping method where silicone molds are created from a master pattern and then used to cast small batches of polyurethane parts. It is particularly useful when projects require:

- Smooth surfaces similar to injection-molded parts.

- Small series (10–50 pieces) for marketing samples, user tests, or pilot runs.

- Rapid Prototyping of colored parts or parts with overmolding and inserts.

Vacuum casting Rapid Prototyping works well for enclosures, covers, cosmetic parts, and structural components that do not need the full mechanical strength of engineering plastics but still require good appearance.

In many real projects, no single method can deliver all the requirements. Hybrid Rapid Prototyping workflows may combine:

- 3D printed cores with CNC-machined interfaces.

- Sheet metal shells with plastic covers produced by vacuum casting.

- Machined metal bases with 3D printed ergonomic grips or soft-touch elements.

By combining processes, engineers can use Rapid Prototyping to build complex assemblies that are very close to final products in both function and appearance. This helps marketing, sales, and certification teams work with realistic samples long before full-scale production is ready.

Rapid Prototyping is widely used because it can transform the way companies design, test, and launch new products. For overseas brands working with a Chinese OEM partner, Rapid Prototyping brings several strategic advantages.

One of the most important advantages of Rapid Prototyping is speed: prototypes can be produced in days instead of weeks or months. Faster iterations allow design teams to test, learn, and adjust quickly, which shortens total development time and helps companies reach the market ahead of competitors.

By using Rapid Prototyping methods such as CNC machining and 3D printing, teams can create multiple design variants in parallel and choose the best version based on real testing. This Rapid Prototyping approach supports agile product development cycles rather than slow, linear workflows.

Rapid Prototyping helps reduce overall product development costs by eliminating the need for expensive production tooling at early stages. Instead of committing to long-lead steel molds or complex fixtures, teams can use Rapid Prototyping to validate concepts and catch design problems before making large investments.

Because Rapid Prototyping enables early detection of design flaws and usability issues, it reduces the chance of late-stage failures or redesigns that would be much more expensive. This means Rapid Prototyping not only saves money directly but also lowers the financial risk of launching new products.

Physical prototypes created through Rapid Prototyping improve communication between designers, engineers, management, and customers because everyone can see and touch the same object. Instead of trying to understand a 2D drawing or screen rendering, stakeholders can discuss a real model, which reduces misunderstandings and speeds up decisions.

For international OEM projects, Rapid Prototyping also helps bridge cultural and language gaps between overseas customers and manufacturing partners. The prototype becomes a shared reference point, making it easier to agree on geometry, tolerances, and functions before mass production.

Rapid Prototyping allows engineers to validate form, fit, and function step by step, starting from simple looks-like models and moving towards full functional prototypes. This staged Rapid Prototyping strategy allows each risk area—ergonomics, assembly, performance, durability—to be tested and optimized before committing to final design.

By using Rapid Prototyping processes that closely match production materials and manufacturing conditions, teams can run more realistic tests for mechanical strength, thermal resistance, and reliability. This leads to better-engineered products and fewer surprises after launch.

Because Rapid Prototyping reduces the cost and time for each iteration, teams can explore more design options and experiment with innovative ideas that would be too expensive with traditional methods. Rapid Prototyping encourages a culture of continuous improvement, where multiple variants can be quickly created, compared, and refined.

For OEMs serving different markets, Rapid Prototyping also makes it easier to customize products for specific customer groups or regions. Short runs with Rapid Prototyping allow brands to test customized features, collect feedback, and then decide whether to invest in full-scale production.

Even though Rapid Prototyping offers many benefits, it is not perfect and can create new problems if not used carefully. Understanding the disadvantages of Rapid Prototyping helps teams design better processes and avoid costly mistakes.

Many Rapid Prototyping methods do not support the full range of production materials, especially when using 3D printing. For example, some 3D printing technologies cannot reproduce the exact mechanical properties, surface finish, or heat resistance of final molded or machined parts.

If teams depend only on 3D printing Rapid Prototyping, they may overestimate part performance or miss problems that would only appear in production materials. To reduce this risk, Rapid Prototyping should combine methods like CNC machining and rapid molding when properties must be very close to final parts.

Additive Rapid Prototyping methods often produce visible layer lines, stepping, or rough surfaces that require post-processing. In some cases, dimensional accuracy or stability can be limited, especially for large parts or thin-wall structures made by low-cost 3D printing.

If these Rapid Prototyping limitations are not considered, teams may obtain misleading test results or need extra time for finishing operations. Choosing the right Rapid Prototyping method for each part and clearly defining tolerance expectations is essential to avoid quality issues.

Another disadvantage of Rapid Prototyping is psychological: customers or managers may see a prototype and assume it is almost the finished product. If they do not understand that Rapid Prototyping parts are still experimental and may differ from final production, they can be disappointed or make wrong decisions.

For example, a Rapid Prototyping model might show features that will not appear in the final product, or might lack final finishing, color, and branding. Clear communication about the purpose and limitations of each Rapid Prototyping stage is important to manage expectations.

When teams focus too heavily on a single prototype, they may neglect a broader analysis of system-level behavior or alternative solutions. Rapid Prototyping can encourage quick experiments, but it does not replace careful engineering, simulation, and verification of the entire product.

If Rapid Prototyping is used without a structured design process, there is a risk of moving forward with a concept that feels “good enough” in prototype form but is not optimized for cost, manufacturability, or maintenance. Balanced use of Rapid Prototyping together with robust engineering methods is necessary.

Some Rapid Prototyping technologies still involve relatively high equipment, material, or operational costs, especially for industrial-grade machines and specialized materials. While Rapid Prototyping can save money at the project level, early-stage budgets must still include these investments or service fees.

Rapid Prototyping also requires skilled personnel to prepare CAD data, set up machines, choose appropriate process parameters, and evaluate prototypes correctly. Without experienced engineers and technicians, Rapid Prototyping projects may waste time and resources instead of creating value.

Rapid Prototyping is most effective when used strategically at specific stages of the product lifecycle. Typical situations where Rapid Prototyping brings strong benefits include:

- Early concept validation and ergonomic mock-ups.

- Functional testing of mechanical assemblies and moving parts.

- Pre-production verification for assemblies, tolerances, and performance.

- Market testing with small batches and customized variants.

For overseas OEM buyers working with suppliers like Shangchen, Rapid Prototyping is especially valuable when launching new product lines, customizing existing platforms, or entering new markets where speed and flexibility are critical.

To maximize the advantages and reduce the disadvantages of Rapid Prototyping, teams should follow a few best practices.

- Define clear objectives for each Rapid Prototyping iteration: what exactly needs to be learned or validated.

- Choose Rapid Prototyping methods that match the test goal in terms of material, accuracy, and cost.

- Combine digital tools (CAD, simulation) with physical Rapid Prototyping to cover both virtual and real-world behavior.

- Communicate the stage and limitations of each prototype to stakeholders to avoid confusion.

- Document each Rapid Prototyping iteration, including changes, feedback, and test results, to support traceability.

- Work with an integrated Rapid Prototyping partner that can support the full journey from prototype to production.

An integrated manufacturing partner that offers CNC machining, 3D printing, sheet metal, and tooling in one place can coordinate all Rapid Prototyping steps and prepare a smooth path towards pilot runs and mass production. This type of Rapid Prototyping support is particularly attractive for overseas brands that want one point of contact for engineering, production, and logistics.

As a Chinese factory focused on Rapid Prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing, Shangchen is positioned to support international OEM customers through the entire development cycle. By combining multiple Rapid Prototyping processes under one roof, Shangchen can provide consistent quality and fast communication for global projects.

Typical Rapid Prototyping services at Shangchen can include:

- CNC machining Rapid Prototyping of metal and plastic parts with tight tolerances.

- 3D printing Rapid Prototyping for complex geometries and quick concept validation.

- Sheet metal Rapid Prototyping for enclosures, brackets, and structural components.

- Rapid mold making and short-run injection molding for near-production prototypes.

For overseas brands, wholesalers, and manufacturers, a partner like Shangchen makes it possible to progress from first design sketches to functional prototypes and then toward small-batch or mass production using a unified Rapid Prototyping strategy.

Rapid Prototyping has transformed modern product development by enabling fast, flexible, and cost-effective iterations from CAD to real parts. When used correctly, Rapid Prototyping reduces time-to-market, lowers development risks, and improves communication across global OEM projects.

However, Rapid Prototyping is not a magic solution: material limitations, surface quality issues, misinterpretation risks, and the need for skilled labor must be managed carefully. The most successful teams use Rapid Prototyping as a strategic tool inside a well-structured engineering process, combining CNC machining, 3D printing, sheet metal, and rapid molding to move from first idea to stable production with confidence.

For overseas brands working with Chinese OEM suppliers like Shangchen, Rapid Prototyping provides a powerful way to test ideas quickly, adapt to market feedback, and launch better products with less risk. By understanding both the advantages and disadvantages of Rapid Prototyping, companies can design smarter workflows and capture the full value of this modern manufacturing approach.

Contact us to get more information!

Rapid Prototyping is used to turn design ideas into physical or functional models quickly so teams can test form, fit, and function before investing in full production. It supports concept validation, ergonomic checks, mechanical testing, and pre-production verification for a wide variety of products, from consumer goods and electronics to industrial equipment and automotive parts.

No, Rapid Prototyping is much broader than 3D printing and also includes CNC machining, sheet metal fabrication, vacuum casting, and rapid injection molding. In many projects, 3D printing is used for early models, while CNC machining and molding support later-stage Rapid Prototyping when realistic materials, tight tolerances, and production-like properties are required.

Rapid Prototyping reduces costs by avoiding early investment in hard tooling and enabling quick detection of design errors before production. Shorter development cycles and fewer late-stage changes mean lower engineering hours and less scrap or rework across the project, which lowers the total cost of bringing a new product to market.

The main risks include relying on prototype materials that do not match final production, misinterpreting prototype performance, and focusing too narrowly on one design option. If Rapid Prototyping is not guided by clear objectives, realistic expectations, and experienced engineers, it can cause delays or lead to suboptimal design decisions that impact long-term product success.

Companies should choose a Rapid Prototyping partner that offers multiple processes, strong engineering support, and transparent communication about capabilities and limitations. An integrated supplier that combines CNC machining, 3D printing, sheet metal, vacuum casting, and tooling can deliver more consistent Rapid Prototyping results and a smoother path to mass production, especially for international OEM projects.

1. https://www.additive-x.com/blog/what-is-rapid-prototyping-the-advantages-disadvantages

2. https://dienamics.com.au/blog/pros-and-cons-of-rapid-prototyping-your-product/

3. https://musemind.agency/blog/advantages-and-disadvantages-rapid-prototyping

4. https://www.masterclass.com/articles/rapid-prototyping-guide

5. https://www.ltc-proto.com/blog/the-advantages-and-disadvantages-of-rapid-prototyping/

6. https://www.teameliteonline.com/rapid-prototyping-techniques-compared-injection-molding-3d-printing-and-cnc-machined-prototypes/

7. https://www.openbom.com/blog/rapid-prototyping-accelerating-new-product-development

8. https://www.ruiyi-cncmachining.com/advantages-and-disadvantages-of-fdm-rapid-prototyping-and-its-uses/

9. https://jiga.io/cnc-machining/cnc-prototyping/

10. https://www.sei.com/insights/article/achieving-faster-better-product-development-with-rapid-prototyping/

11. https://www.hubs.com/knowledge-base/what-is-rapid-prototyping/

12. https://www.fictiv.com/articles/cnc-vs-3d-printing-for-prototypes

13. https://digitalleadership.com/blog/prototyping/

14. https://blog.marianinc.com/blog/rapid-prototyping-methods

15. https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam