Views: 222 Author: Amanda Publish Time: 2026-01-14 Origin: Site

Content Menu

● Why They Are Called “Rapid Prototyping Processes”

● Main Categories of Rapid Prototyping Processes

● Additive Manufacturing Rapid Prototyping

● Subtractive Rapid Prototyping: CNC Machining and Turning

● Sheet Metal Rapid Prototyping

● Casting and Molding Rapid Prototyping

● How Digital Models Drive Rapid Prototyping

● Typical Stages in a Rapid Prototyping Project

● Benefits of Rapid Prototyping for Global OEM Projects

● Rapid Prototyping and Low‑Volume Production

● Rapid Prototyping at Shangchen (CNC, Turning, Sheet Metal, 3D, Molding)

● Integrating Rapid Prototyping into Your Product Development

>> 1. What are the main types of rapid prototyping processes?

>> 2. How does rapid prototyping differ from traditional manufacturing?

>> 3. When should CNC machining be chosen for rapid prototyping?

>> 4. What advantages does vacuum casting offer in rapid prototyping?

>> 5. Why do international OEMs use Chinese factories for rapid prototyping?

Rapid prototyping is generally referred to as a group of digital manufacturing techniques used to quickly turn 3D CAD ideas into physical parts for design validation, functional testing, and low‑volume production. Rapid Prototyping allows engineering teams to build, test, and refine multiple design iterations in days instead of weeks, greatly accelerating time‑to‑market.[1][2]

Rapid prototyping is the collective name for methods that quickly fabricate a scale model or functional part directly from 3D computer‑aided design data, usually layer by layer or through fast CNC machining. It is defined as a group of techniques that use three‑dimensional CAD data to create a physical prototype for evaluation in the early and middle stages of product development.[3][1]

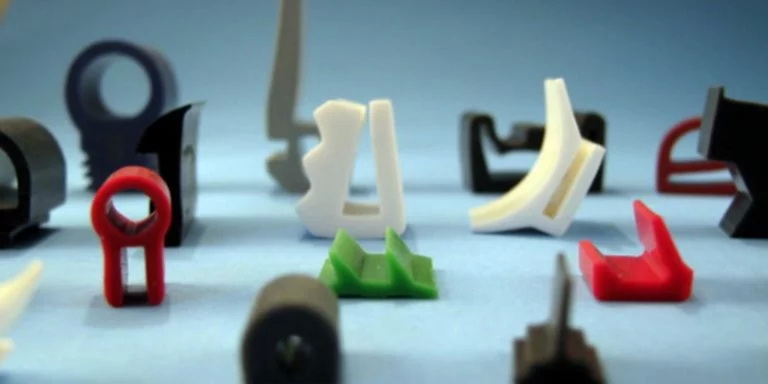

In practice, rapid prototyping covers processes such as CNC machining, 3D printing, vacuum casting, sheet metal fabrication, and soft tooling that can deliver usable parts in days with limited or no hard tooling. These rapid prototyping approaches are widely used across automotive, aerospace, medical devices, consumer electronics, and industrial equipment for both visual and functional models.[2][4]

Most rapid prototyping processes are referred to as additive or digital manufacturing methods that shorten the loop between design, prototype, testing, and refinement. Instead of waiting for complete tooling or full production lines, rapid prototyping lets designers build physical models throughout the development cycle and update the CAD model after each test.[1][2]

Because rapid prototyping emphasizes speed and agility, these processes prioritize short lead time, easy design modification, and flexible batch sizes rather than the lowest unit price at very high volumes. Teams can run several rapid prototyping routes in parallel—such as 3D printing for form, CNC for function, and vacuum casting for appearance—to make better decisions before committing to mass production.[4][2]

Most rapid prototyping processes can be grouped into several major categories that describe how material is added, removed, or formed. Understanding these categories helps engineers select the most suitable rapid prototyping method for each project stage and each part geometry.[5][6]

- Additive manufacturing (3D printing) rapid prototyping

- Subtractive rapid prototyping using CNC machining and turning

- Sheet metal rapid prototyping and fabrication

- Casting and molding rapid prototyping such as vacuum casting and rapid tooling

- Hybrid rapid prototyping that combines several of the above paths in one workflow

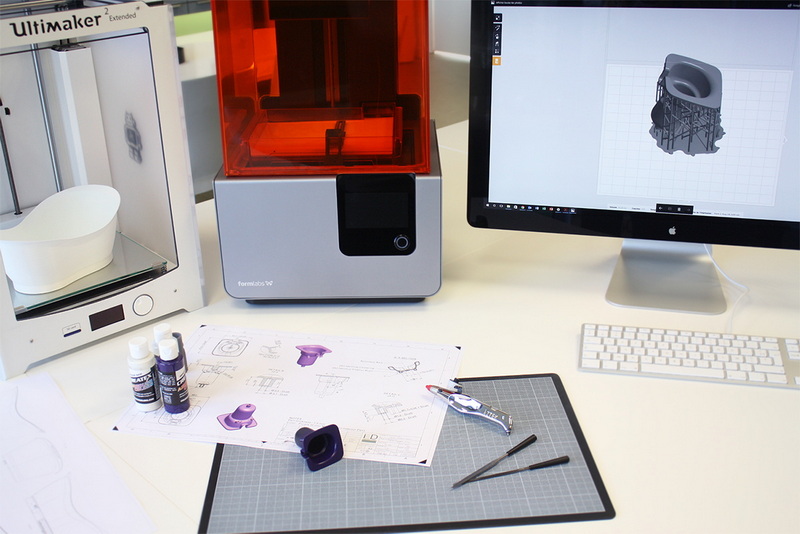

Additive manufacturing rapid prototyping builds parts layer by layer from a digital model, and today 3D printing is the most recognized technique in this category. These rapid prototyping technologies are ideal for complex geometries, internal channels, organic shapes, and lightweight lattice structures that are difficult or impossible to machine.[7][1]

Common 3D printing rapid prototyping processes include selective laser sintering, stereolithography, fused deposition modeling, HP Multi Jet Fusion, and direct metal laser sintering, each with different levels of accuracy, surface finish, and material compatibility. Engineers often start rapid prototyping projects with these methods for concept models, ergonomic studies, assembly checks, and early functional tests using plastics or metals.[5][7]

3D printing rapid prototyping is also valuable for design exploration because it allows designers to quickly compare multiple geometry options without major set‑up changes. This makes additive rapid prototyping a powerful tool not only for engineering, but also for marketing teams who need physical mockups for internal presentations, exhibitions, and user research.[7][1]

Subtractive rapid prototyping removes material from solid stock using CNC machining centers and lathes to achieve accurate, production‑like parts. CNC rapid prototyping is particularly valuable when prototypes must be produced from real engineering plastics or metals, delivering parts with high precision and consistent mechanical performance.[8][4]

For many projects, rapid prototyping with CNC milling and CNC turning can provide small batches of components in less than ten days, giving teams enough time to validate fit, function, and durability before investing in steel molds. Because programs and fixturing can be updated quickly, CNC rapid prototyping also supports multiple design iterations with controlled cost, especially in the critical pre‑tooling phase.[6][5]

Another advantage of CNC rapid prototyping is that it closely mirrors production machining strategies, which helps engineers identify tolerance stacks, assembly issues, and tooling access problems early. When combined with 3D printing rapid prototyping for early concept work, CNC can form the backbone of a robust verification and validation stage, particularly for mechanical and structural components.[4][8]

Sheet metal rapid prototyping uses cutting, punching, laser profiling, bending, and welding operations to make thin‑walled parts, brackets, and enclosures quickly from flat metal sheet. This rapid prototyping approach is ideal when designers need early samples of housings, chassis, or structural components in their final metal material while keeping tooling costs low.[9][5]

China has developed a strong ecosystem of sheet metal rapid prototyping manufacturers capable of fast‑turn projects with high dimensional precision and a wide range of materials and finishes. These rapid prototyping services typically include design optimization for manufacturability, material recommendations, bending and joining processes, and surface treatments such as powder coating and anodizing to create production‑like prototypes.[9]

Because sheet metal rapid prototyping shares many steps with mass production fabrication, it is a practical way to validate assembly clearances, thermal behavior, and mounting strategies in real operating conditions. Product teams often combine sheet metal rapid prototyping for external housings with CNC or 3D printing rapid prototyping for internal modules, resulting in complete prototype builds that closely represent the final product.[5][9]

Casting and molding rapid prototyping processes replicate parts using temporary or soft tooling, providing near‑production parts without the full cost of hardened steel molds. One widely used rapid prototyping method is vacuum casting, where a silicone mold is created from a master model and then filled with polyurethane or similar resin under vacuum to produce high‑quality replicas.[10][4]

Vacuum casting rapid prototyping is particularly well suited for visual prototypes, functional tests, and marketing samples that require surface quality, color, and texture very close to injection‑molded parts. Although vacuum casting is slower than 3D printing or CNC machining for a single unit, it becomes efficient for small series of 10–50 pieces, making it a popular bridge between prototypes and pilot production.[8][4]

Another key member of this family is rapid tooling or rapid injection molding, where simplified or soft tools are made quickly to mold small batches in the final production resin. This rapid prototyping technique allows engineers to check warpage, shrinkage, and long‑term material performance using real molding conditions before committing to large multi‑cavity tools.[4]

All rapid prototyping processes depend on 3D CAD models as the single source of truth, which are converted into formats such as STL or native CAM files for downstream manufacturing. Once the model is prepared, engineers can select a rapid prototyping process, generate toolpaths or layer slices, and simulate the build digitally to predict potential problems.[6][10]

Rapid prototyping workflows usually follow an iterative loop of design, prototype fabrication, testing, and refinement, repeated until the design satisfies technical performance, usability, and cost constraints. This digital‑first approach makes rapid prototyping extremely efficient because changes in geometry, tolerances, or materials can be implemented directly in the CAD model and propagated to all selected processes.[11][1]

Modern software platforms further extend rapid prototyping by offering integrated design, simulation, and manufacturing preparation in one environment, which reduces file translation errors and speeds up decision‑making. For many companies, this end‑to‑end digital chain is now the backbone of their rapid prototyping and new product introduction strategy.[2]

A structured rapid prototyping project usually moves through a series of stages that gradually increase part realism and testing depth. While every company tailors the details, the following pattern is common in modern hardware development.[1][2]

- Concept validation: Use 3D printing rapid prototyping to explore basic shapes and user interaction with minimal cost and lead time.[1]

- Functional testing: Shift to CNC rapid prototyping or stronger 3D printing materials to evaluate mechanical performance, assembly, and environmental behavior.[7]

- Design refinement: Iterate geometry, wall thickness, and interface details using a mix of rapid prototyping methods, often including sheet metal and turning.[5]

- Pre‑production: Apply vacuum casting or rapid tooling to obtain production‑like parts in small quantities for certification, marketing, and pilot runs.[4]

At each step, feedback from prototypes informs design changes, and the rapid prototyping cycle repeats until the team is confident enough to invest in full tooling and process validation. This staged approach helps organizations control risk while leveraging the strengths of different rapid prototyping technologies.[11][2]

Rapid prototyping delivers several strategic benefits for international OEM brands, wholesalers, and manufacturers working with overseas partners. First, rapid prototyping compresses development time by allowing design teams to validate multiple concepts and variants in parallel, rather than sequentially.[2][5]

Second, rapid prototyping reduces project risk by catching design errors, assembly conflicts, and performance issues before expensive production tooling is cut. Early detection through rapid prototyping also improves cost forecasts and supports better sourcing decisions, since suppliers can quote based on realistic, tested designs.[3][2]

Third, rapid prototyping supports customized products, short life‑cycle items, and low‑volume demand, which are increasingly common in industrial and consumer markets. For many OEMs, a well‑organized rapid prototyping program becomes a competitive differentiator, enabling faster response to customer requests and market changes.[2][4]

As technologies mature, the boundary between rapid prototyping and low‑volume production is becoming less rigid. Many of the same rapid prototyping processes—CNC machining, sheet metal fabrication, 3D printing, and vacuum casting—are now used not only for prototypes but also for bridge manufacturing and after‑market parts.[4][5]

This shift allows companies to delay investment in full tooling until demand is clear, using rapid prototyping equipment as flexible, digital production capacity. For example, a series of custom or regional product variants can be supplied directly from rapid prototyping lines, while high‑volume global versions move to traditional mass production.[2][4]

In addition, finishes such as polishing, painting, anodizing, and plating can be integrated with rapid prototyping workflows, producing parts whose cosmetic appearance is suitable for end customers. This combination of rapid prototyping flexibility and near‑production quality is particularly attractive for startups, pilot projects, and high‑mix manufacturing environments.[12][13]

As a China‑based factory, Shangchen focuses on rapid prototyping and precision low‑volume production using an integrated set of processes suitable for diverse industrial sectors. Core capabilities include CNC machining, CNC turning, sheet metal fabrication, 3D printing, and mold manufacturing to support OEM rapid prototyping projects from early concept to pre‑series and trial builds.[12]

For overseas brands, wholesalers, and manufacturers, this combination of rapid prototyping services makes it possible to consolidate multiple part types and processes into one supplier, simplifying communication and project management. By coordinating machining, forming, casting, and molding under one roof, Shangchen can align rapid prototyping activities with the eventual mass production strategy.[13][12]

Experienced engineering teams provide DFM feedback and material recommendations during rapid prototyping so that parts are designed from the start with realistic tolerances, draft angles, and cost structures. Whether the requirement is a single verification prototype or a small batch of pilot parts, rapid prototyping with a versatile partner helps international customers achieve short lead times and stable quality.[13][6]

To extract full value from rapid prototyping, companies should embed these processes into their product development framework rather than using them only in emergencies. A typical roadmap begins with conceptual 3D printing rapid prototyping, transitions to CNC or sheet metal rapid prototyping for mechanical validation, and then adopts vacuum casting or rapid tooling for pre‑production evaluation.[7][2]

Working with an experienced rapid prototyping partner helps optimize material selection, tolerance zoning, and part splitting, which in turn reduces redesigns after tooling. Feedback from rapid prototyping can also be used to refine documentation, assembly instructions, and testing procedures before ramp‑up, making mass production launches smoother and more predictable.[6][2]

For global OEMs, integrating rapid prototyping into cross‑border collaboration is especially important, because physical samples often serve as a common reference between design centers and manufacturing plants in different countries. When this rapid prototyping collaboration is supported by clear digital data exchange and quality standards, it contributes directly to better products and stronger supplier relationships.[13][2]

Most rapid prototyping processes are referred to as additive and digital manufacturing techniques that transform CAD models into physical parts quickly for design validation, testing, and low‑volume production. From 3D printing and CNC machining to sheet metal fabrication, vacuum casting, and rapid tooling, rapid prototyping now forms a central pillar of modern engineering workflows for global OEMs.[1][7]

By combining multiple rapid prototyping technologies in one facility, providers such as integrated Chinese factories help international customers shorten development cycles, manage technical risk, and prepare designs for efficient mass production. When applied strategically from concept through pre‑series stages, rapid prototyping is more than a set of tools; it is a systematic approach that delivers speed, flexibility, and competitive advantage in fast‑moving industrial markets.[12][2]

The main rapid prototyping process families are additive manufacturing, subtractive CNC machining and turning, sheet metal fabrication, and casting or molding techniques such as vacuum casting and rapid tooling. Within additive rapid prototyping, widely used methods include selective laser sintering, stereolithography, fused deposition modeling, HP Multi Jet Fusion, and direct metal laser sintering, each serving different accuracy and material needs.[5][4]

Traditional manufacturing is optimized for high volumes and low per‑unit cost, which typically requires expensive and time‑consuming hard tooling before production can start. Rapid prototyping focuses on speed and flexibility, using processes that need little or no permanent tooling so that small batches and design changes can be produced quickly at acceptable cost.[3][1]

CNC machining is ideal for rapid prototyping when tight tolerances, high strength, and real production materials such as aluminum, steel, or engineering plastics are required. It is also the preferred rapid prototyping option when parts must withstand demanding mechanical loads or when precise mating surfaces and threads are critical for final assembly.[8][4]

Vacuum casting rapid prototyping allows small batches of near‑production parts to be produced using silicone molds at a fraction of the cost and lead time of full steel injection tools. These rapid prototyping parts usually provide excellent surface quality, color options, and tactile feel, making them well suited for functional testing, user trials, and marketing demonstrations before mass production.[8][4]

International OEMs often choose Chinese factories for rapid prototyping because of their broad process capabilities, competitive pricing, and fast delivery times. Experienced Chinese rapid prototyping suppliers offer integrated services such as CNC machining, sheet metal fabrication, 3D printing, and casting, together with engineering support and global logistics, which simplifies sourcing for overseas customers.[9][13]

[1](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[2](https://www.autodesk.com/solutions/rapid-prototyping)

[3](https://en.wikipedia.org/wiki/Rapid_prototyping)

[4](https://www.3erp.com/manufacturing-technology/rapid-prototyping/)

[5](https://xometry.eu/en/rapid-prototyping/)

[6](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

[7](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[8](https://www.hlhprototypes.com/what-are-the-different-types-of-rapid-prototyping/)

[9](https://ecoreprap.com/blog/top-sheet-metal-prototyping-manufacturers-in-china/)

[10](https://www.techniwaterjet.com/what-is-rapid-prototyping-process-stages-types-and-tools/)

[11](https://www.figma.com/resource-library/what-is-rapid-prototyping/)

[12](https://www.sgproto.com/product-page/china-oem-factory-for-customized-sheet-metal-fabrication)

[13](https://firstpart.com)

content is empty!