Views: 222 Author: Amanda Publish Time: 2025-09-20 Origin: Site

Content Menu

>> Characteristics of Vacuum Casting

>> Characteristics of Injection Molding

● Key Differences Between Vacuum Casting and Injection Molding

● The Advantages of Vacuum Casting

● The Disadvantages of Vacuum Casting

● The Advantages of Injection Molding

● The Disadvantages of Injection Molding

>> Vacuum Casting Production Steps

>> Injection Molding Production Steps

● FAQ

>> 1. What materials are used in vacuum casting?

>> 2. How long does it take to make molds for vacuum casting vs injection molding?

>> 3. Can vacuum casting handle complex part geometries?

>> 4. What production volumes are suitable for each process?

>> 5. Why choose injection molding for mass production?

In the manufacturing world, choosing the most suitable production method can significantly influence cost, quality, and time-to-market. Two widely used processes for producing plastic parts are Vacuum Casting and Injection Molding. Although both create detailed and functional parts, their technologies, costs, production volumes, and material compatibilities vary greatly. This comprehensive article explores the nuances between vacuum casting and injection molding, detailing their advantages, drawbacks, and appropriate use cases to help manufacturers and OEMs make informed production choices.

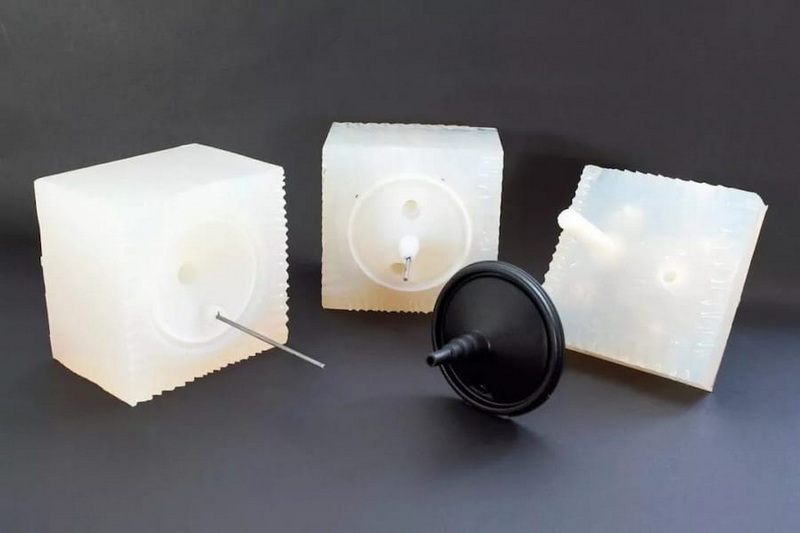

Vacuum casting is a process where liquid polyurethane resin is poured into a silicone mold positioned in a vacuum chamber. The vacuum removes trapped air bubbles, ensuring a smooth, defect-free surface. This method is especially favored for prototype development and limited production runs due to economical tooling and quick turnaround.

Vacuum casting molds are replicated from a master pattern (often created by 3D printing or CNC machining). The flexible silicone molds allow detailed replication of complex designs and textures while being cost-efficient for small batches typically ranging from 10 to a few hundred parts.

- Low-cost silicone molds replace expensive metal molds.

- Fast mold preparation and shorter lead times.

- Suitable for low to medium volume production.

- Good surface finish with some need for post-processing.

- Materials generally include polyurethane resins that can mimic various textures and appearances.

Injection molding is a manufacturing technique where molten plastic is injected under high pressure into a metal mold, typically made of hardened steel or aluminum. This process is designed for high-volume production and delivers parts with excellent dimensional accuracy and strong mechanical properties.

The metal molds are precision-machined to strict tolerances and can last for hundreds of thousands to millions of production cycles. Injection molding offers a broad material palette including engineering-grade thermoplastics and elastomers, catering to demanding performance requirements.

- High-cost, durable metal molds with long lifespans.

- Suited for mass production (thousands to millions of units).

- Fast cycle times and consistent replication.

- Wide material flexibility for functional and structural parts.

- Superior part precision and surface finish straight from the mold.

The following aspects highlight the core distinctions between these manufacturing methods:

| Feature | Vacuum Casting | Injection Molding |

| Mold Material | Silicone (flexible, low cost) | Metal (steel, aluminum - expensive) |

| Tooling Cost | Low | High |

| Setup Time | Days to a week | Weeks to months |

| Production Volume | Small to medium (up to hundreds) | Large scale (thousands to millions) |

| Material Choice | Polyurethane resins | Wide range of thermoplastics and elastomers |

| Dimensional Accuracy | Moderate (±0.3 mm) | High (±0.1 mm or better) |

| Surface Finish | Good, may require finishing | Excellent |

| Flexibility in Design | High, useful for prototypes | Lower, costly and time-consuming to alter molds |

| Ideal For | Prototyping, limited runs | Mass production of functional parts |

Vacuum casting has become popular for rapid prototyping and limited series production thanks to its many benefits:

- Low Tooling Costs: Silicone molds are inexpensive and faster to produce, making vacuum casting affordable for small batch production.

- Faster Lead Time: Mold creation and part production can start within days, supporting rapid iterations and quick time to market.

- Design Flexibility: Easy to produce complex geometries and replicate fine surface details.

- Good Surface Quality: The vacuum process removes air bubbles, leading to smooth, high-quality parts.

- Material Simulation: Polyurethane resins can mimic diverse material properties from rigid plastics to flexible rubbers.

- Minimal Setup Complexity: Efficient for projects requiring frequent design changes or pilot production.

Despite its usefulness, vacuum casting is not without limitations:

- Lower Durability of Molds: Silicone molds wear out quickly, lasting about 20–30 castings, creating higher costs for larger volumes.

- Material Constraints: Limited mainly to polyurethane resins, which might lack thermal and mechanical strength compared to injection-molded thermoplastics.

- Moderate Precision: Dimensional tolerances are less tight, which may be unsuitable for highly precise or functional parts.

- Longer Cycle Times: Each part is cast individually, making vacuum casting inefficient for very large runs.

- Weaker Mechanical Properties: Parts typically have 70–80% of the strength of injection molded parts.

Injection molding remains the go-to process for mass production due to several key strengths:

- Exceptional Precision and Consistency: Metal molds offer tighter tolerances and high repeatability, essential for complex and functional designs.

- Fast Production Speeds: Automated molding cycles produce thousands of parts per day, reducing cost per unit significantly.

- Robust Mold Durability: Metal molds endure extensive production runs without significant wear.

- Wide Material Range: Supports many high-performance plastics, including heat-resistant, impact-resistant, and flexible materials.

- Superior Mechanical Strength: Injection molded parts generally outperform vacuum cast parts in structural integrity and durability.

- Minimal Post-Processing Needed: Parts come out close to final finish, reducing labor and time.

However, injection molding is accompanied by drawbacks that can impact certain projects:

- High Initial Tooling Cost: Creating precise metal molds can cost tens of thousands and take several weeks or months.

- Long Mold Lead Time: Mold manufacturing delays project starts, slowing down prototyping phases.

- Inflexibility: Modifying metal molds is costly and slow, making it hard to iterate designs quickly.

- Not Economical for Small Runs: The high setup cost only pays off at large volume production, making it prohibitive for limited quantities or prototypes.

1. Master Pattern Creation: Using 3D printing or CNC machining to create a detailed master.

2. Silicone Mold Preparation: Silicone is poured over the master and cured to create a flexible mold.

3. Casting Resin Preparation: Polyurethane resin is mixed and degassed.

4. Vacuum Pouring: Resin is poured into the mold inside a vacuum chamber to eliminate bubbles.

5. Curing and Demolding: Parts are cured, removed, trimmed, and optionally polished or painted.

1. Clamping of Mold Halves: Mold is securely closed.

2. Injection of Molten Plastic: High-pressure injection fills the mold cavity.

3. Dwelling: Plastic settles inside the mold.

4. Cooling and Solidification: Mold is cooled to harden the plastic.

5. Mold Opening and Ejection: Mold opens and part is ejected using pins or plates.

6. Trimming and Finishing: Flash is removed as needed; parts may be ready for use immediately.

- Vacuum Casting: Ideal for functional prototypes, low-volume custom parts, complex geometry reproductions, and cosmetic or decorative elements. It suits industries such as consumer electronics, automotive prototyping, and medical device mockups.

- Injection Molding: Favored for manufacturing durable, high-volume parts like automotive components, household appliances, toys, packaging, and industrial parts requiring high strength and repeatability.

Deciding between vacuum casting and injection molding hinges on factors like volume, cost, material needs, design complexity, and timeline. Vacuum casting provides a flexible, low-cost path for rapid prototyping and small batch production with good surface finish and material simulation. Injection molding is best suited for mass production, offering superior precision, faster cycle times, and durable parts, though it requires substantial upfront investment and longer lead times. By understanding the strengths and limitations of both processes, manufacturers can align their production strategies with product requirements, balancing quality, cost, and delivery time effectively.

Vacuum casting mainly uses polyurethane resins that can replicate a spectrum of textures and mechanical properties but are generally less robust compared to thermoplastics used in injection molding.

Silicone molds for vacuum casting take days to a week, while injection molding metal molds require weeks to months to produce due to their complexity and durability requirements.

Yes, vacuum casting is well-suited for intricate details and textures due to the flexibility of silicone molds and the bubble-free casting process.

Vacuum casting is excellent for low-volume runs (10 to few hundred parts), whereas injection molding excels in large volume production starting from several hundreds to millions.

The durability of metal molds and rapid cycle times make injection molding economical for large quantities, providing consistent quality and tighter tolerances at scale.

[1](https://www.3erp.com/blog/vacuum-casting-vs-injection-molding/)

[2](https://xometry.pro/en/articles/vacuum-casting-vs-injection-molding/)

[3](https://engineeringproductdesign.com/vacuum-casting-vs-injection-moulding/)

[4](https://proleantech.com/vacuum-casting-vs-injection-molding/)

[5](https://www.xometry.com/resources/injection-molding/injection-molding-vs-vacuum-forming/)

[6](https://quickparts.com/gb/vacuum-casting-or-injection-moulding/)

[7](https://www.youtube.com/watch?v=JhE9ZelxxlQ)

[8](https://jlc3dp.com/blog/examining-and-differentiating-vacuum-casting-3d-printing-and-injection-moulding)

[9](https://www.zeal3dprinting.com.au/injection-moulding-vs-vacuum-casting-a-comparative-analysis/)

[10](https://www.pcbway.com/blog/Injection_Molding/Injection_molding_Vs_Vacuum_casting__how_to_choose.html)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal