Views: 222 Author: Amanda Publish Time: 2025-09-24 Origin: Site

Content Menu

>> The Die Casting Process Overview

● Key Differences Between Vacuum Casting and Die Casting

>> Mechanical Properties and Applications

● Advantages of Vacuum Casting

>> Die Casting

>> Vacuum Casting Process Breakdown

>> Die Casting Process Breakdown

● Innovations and Hybrid Technologies

● Choosing the Right Process for Your Project

● Environmental Considerations

● Summary

● FAQ

>> 1. What materials are used in vacuum casting?

>> 2. Can vacuum casting replace die casting for large production?

>> 3. How does vacuum die casting improve part quality?

>> 4. What is the lead time for vacuum casting parts?

>> 5. Are complex shapes possible with both processes?

In the complex world of manufacturing, choosing the most suitable casting technique is crucial for achieving optimal product quality, cost-efficiency, and delivery timelines. Among the many available manufacturing processes, Vacuum Casting and Die Casting are two prominent methods, each tailored for unique applications and production volumes. This comprehensive article explores the essential differences between these two casting techniques, examines their processes, materials, applications, and benefits, and guides manufacturers and product developers toward informed decisions for their projects.

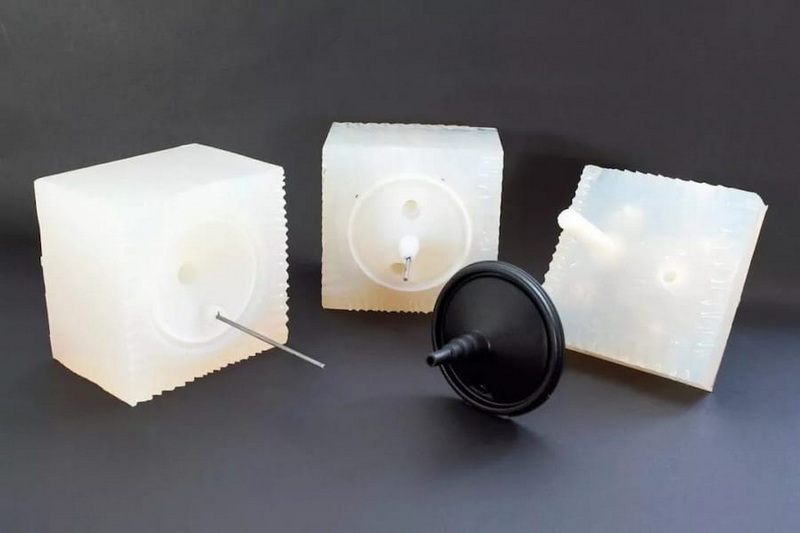

Vacuum casting is a highly specialized process ideal for rapid prototyping and low-volume production of parts with intricate details and smooth surface finishes. It involves using a vacuum to draw liquid casting materials, usually polyurethane or similar resins, into flexible silicone molds. This vacuum extraction minimizes air bubbles and porosity, yielding high-fidelity replicas of original master models.

The process starts with the creation of a master prototype, which can be produced via CNC machining or 3D printing. This master model is encapsulated in liquid silicone to form a mold that cures into a flexible, reusable casting mold. When ready for production, the molded silicone is placed inside a vacuum chamber. Casting resin is poured in, and the vacuum pulls the resin into all areas of the mold while removing trapped air to avoid defects.

The vacuum environment contributes to a smooth, bubble-free surface and precise detail capture, which is critical for parts used in functional testing, design validation, or market sampling.

Die casting is a metal casting process designed for high-volume production of complex metal parts. It involves injecting molten metal, typically aluminum, zinc, or magnesium, into a steel mold known as a die under high pressure. The process is capable of producing parts with excellent dimensional accuracy, thin walls, and strong mechanical properties.

Molten metal is transferred to a shot chamber, either via a plunger in hot-chamber machines or manually using a ladle in cold-chamber setups. The mold die cavity is often equipped with cooling channels to accelerate solidification while maintaining part accuracy. Optionally, in vacuum die casting—a variant—the die cavity is evacuated of air before metal injection, significantly reducing porosity and enhancing the mechanical quality of the final casting.

Once the molten metal solidifies and cools, the die opens, and ejector pins push the finished component out for further finishing as needed.

Vacuum casting predominantly uses liquid resins such as polyurethane and silicone molds, which can be reused approximately 15 to 20 times per mold. Die casting, in contrast, employs molten metals injected into robust steel molds engineered to endure thousands or even millions of cycles.

Vacuum casting is economically advantageous for short runs, prototype batches, or low-volume production where flexibility and speed are paramount. The tooling costs are minimal compared to die casting, which requires high upfront investment in steel tooling but becomes highly cost-efficient for large-scale manufacturing.

Both processes produce parts with excellent surface finishes; vacuum casting tends to excel in replicating master model details and textures, while die casting ensures smooth metallic surfaces with consistent high tolerances.

Die cast parts possess superior mechanical strength, thermal resistance, and dimensional stability due to metal materials. Vacuum cast resin parts, while less strong, offer versatility in coloration, flexibility, and material properties suited for functional prototypes and cosmetic parts.

- Rapid Turnaround: Capable of producing high-quality prototypes in about one week.

- High Detail Accuracy: Captures intricate surface features and textures faithfully.

- Cost-effective Tooling: Low initial investment leveraging silicone molds instead of steel.

- Material Versatility: Allows a variety of resin formulations, offering different color and flexibility options.

- Ideal for Design Iterations: Enables quick modifications during product development.

- High-Volume Efficiency: Suitable for large production runs with consistent quality.

- Material Strength: Produces durable, lightweight metal parts.

- Precision and Thin Walls: Enables tight tolerances and complex geometries.

- Reduced Porosity Through Vacuum Die Casting: Optional vacuum process reduces defects, improving weldability and strength.

- Fast Cycle Times: Automated machinery reduces per-part production time in mass manufacturing.

- Prototype parts for functional and visual testing.

- Demonstration models and market samples.

- Small-batch production of plastic components.

- Components needing complex material layering or coloring.

- Medical device housings requiring smooth surface finishes.

- Automotive parts like engine brackets and housings.

- Electronic casings and heat sinks.

- Industrial power tools and machinery components.

- Aerospace metal structures.

- Consumer goods requiring durable metal finishes.

1. Master Model Preparation: The prototype master, often CNC machined or 3D printed, serves as the reference for mold creation.

2. Silicone Mold Formation: Silicone liquid is poured around the master model and cured, producing a flexible mold.

3. Casting Material Preparation: Polyurethane resin or similar materials are mixed and prepared.

4. Vacuum Chamber Casting: The silicone mold is placed in a vacuum chamber; resin is poured in and vacuumed to remove air bubbles.

5. Curing and Demolding: The resin is cured, typically in an oven, and the cast part is removed. Each mold can be reused for about 20 cycles.

6. Post-Processing: Parts may undergo finishing processes like sanding, painting, or assembly.

1. Metal Melting: The alloy, such as aluminum, is melted in large furnaces maintaining precise temperature control.

2. Transfer to Shot Chamber: Molten metal is transferred to the shot chamber via plunger (hot chamber) or ladle (cold chamber).

3. Vacuum Creation (optional): A vacuum pump evacuates air from the die cavity.

4. High-Pressure Injection: Molten metal is injected into the die cavity at high pressure to fill intricate mold shapes.

5. Cooling and Solidification: Controlled cooling channels solidify the metal rapidly, maintaining shape.

6. Die Opening and Ejection: The die opens; ejector pins push the cooled casting out.

7. Finishing: Castings may undergo machining, surface treatment, or assembly.

Recent advancements have introduced hybrid technologies combining aspects of vacuum and traditional die casting. For example, vacuum die casting uses vacuum systems to evacuate air and gases from die cavities before metal injection. This creates near-gas-free castings, significantly reducing porosity and improving mechanical properties, such as weldability and heat treatment outcomes.

Several factors influence choosing vacuum casting or die casting:

- Production Volume: Low volume or prototypes favor vacuum casting; mass production suits die casting.

- Material Needs: For metal parts with strength requirements, die casting is preferred; plastic or resin parts align with vacuum casting.

- Budget Constraints: Lower upfront tooling costs favor vacuum casting.

- Design Complexity: Both offer complexity benefits, but vacuum casting excels in fine surface details for plastics.

- Delivery Time: Vacuum casting provides quicker turnaround for prototyping purposes.

Vacuum casting consumes less energy and produces less waste when compared to metal die casting. Though both methods generate scrap material (silicone molds in vacuum casting, metal cut-offs in die casting), recycling and reuse options differ. Manufacturers increasingly weigh environmental impact alongside performance and cost.

Both Vacuum Casting and Die Casting hold crucial roles in modern manufacturing. Vacuum casting shines in prototype development and small-scale manufacturing of plastic parts with superior surface fidelity and rapid turnaround. Die casting, particularly when combined with vacuum die casting technology, meets the demands for high-volume, precise, and durable metal components with excellent mechanical properties. Understanding these processes helps industries make informed choices, balancing quality, cost, and production needs for optimal product outcomes.

Vacuum casting primarily uses polyurethane resins or similar plastics, enabling flexible, rigid, or transparent parts with various colors and finishes.

Vacuum casting is not typically suitable for mass production due to mold durability and slower cycle times. Die casting remains preferred for high-volume, metal parts.

By evacuating air and gases before injection, vacuum die casting reduces porosity, improves surface finish, strengthens weldability, and enables thinner wall castings.

Vacuum casting parts generally take around 5–7 days, making it a fast option for prototypes and small batches.

Yes. Vacuum casting is excellent for reproducing detailed plastic parts, while die casting facilitates complex metal part geometries with tight tolerances.

[1](https://www.xometry.com/resources/casting/vacuum-die-casting/)

[2](https://www.rtprototype.com/what-is-the-difference-between-vacuum-forming-and-vacuum-die-casting/)

[3](https://asuzac-acm.com/die-casting-and-vacuum-casting/)

[4](https://www.linkedin.com/posts/asuzac-acm_die-casting-vs-vacuum-casting-a-comprehensive-activity-7328282943494205440-a53C)

[5](https://leadrp.net/blog/overview-of-vacuum-casting/)

[6](https://proleantech.com/types-of-casting/)

[7](https://xometry.pro/en/articles/vacuum-casting-vs-injection-molding/)

[8](https://www.rapiddirect.com/blog/casting-vs-machining-which-one-to-choose/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal