Views: 222 Author: Amanda Publish Time: 2025-11-23 Origin: Site

Content Menu

● The Basic CNC Machining Workflow

>> Step 2: CAM Programming and Toolpath Generation

>> Step 4: Machining Execution

>> Step 5: Inspection and Finishing

● Main Types of CNC Machining Processes

>> CNC Milling

>> CNC Turning

>> CNC Grinding

>> EDM and Other Specialized CNC Processes

● CNC Machine Structure and Key Components

● Materials Commonly Used in CNC Machining

>> Metals

>> Plastics

● CNC Machining Tolerances and Surface Finishes

● CNC Machining for Prototypes and Low-Volume Production

● CNC Machining in Integrated Manufacturing

● Quality Control in CNC Machining

● Cost Factors in CNC Machining

● FAQ

>> 1. How does CNC machining differ from manual machining?

>> 2. What industries benefit most from CNC machining?

>> 3. How should a part be designed for CNC machining?

>> 4. Is CNC machining suitable for both prototypes and mass production?

>> 5. How long does it take to receive CNC machined parts?

CNC machining is one of the most important and reliable technologies in modern manufacturing, enabling the production of highly precise parts at scale. It transforms digital designs into real components by controlling machine tools with computer programs instead of manual operation. For global OEM customers who demand accuracy, repeatability, and short lead times, CNC machining is often the first-choice process.

CNC machining, short for Computer Numerical Control machining, is a subtractive manufacturing process that removes material from a solid block (the workpiece) using cutting tools controlled by a computer. A CNC system executes programmed instructions to move tools along defined paths so that the final part matches a digital 2D or 3D model.

Unlike manual machining, CNC machining follows pre-programmed toolpaths with consistent speeds, feeds, and cutting depths. This allows manufacturers to produce complex geometries, tight tolerances, and high-quality surfaces with minimal human error. For OEM projects, CNC machining offers both flexibility for custom parts and stability for recurring production orders.

The CNC machining workflow moves from design to finished part through a digital-to-physical pipeline. Although every project is unique, the general steps are similar across industries and applications.

The process begins with a CAD (Computer-Aided Design) model that defines the part's dimensions, tolerances, and geometric features. Engineers or product designers create a 2D drawing or 3D solid model using professional CAD software. Good design practice for CNC machining considers manufacturability, including wall thickness, radii, hole sizes, and tool access.

For OEM partners, this stage is often a collaboration between the customer's engineering team and the machining supplier. Feedback on design for manufacturability (DFM) helps optimize the CAD model to reduce cost and machining time without compromising function.

Once a CAD model is complete, it is transferred into CAM (Computer-Aided Manufacturing) software. CAM software defines how CNC machining will actually create the part by generating:

- Toolpaths for each cutting operation

- Cutting tools to be used for different features

- Spindle speeds and feed rates

- Cutting depths and passes

- Entry and exit strategies to protect surface finish

The CAM system converts all this information into a CNC program, most commonly written in G-code and M-code. The code instructs the machine how to move, how fast to rotate the spindle, when to switch tools, and when to start or stop auxiliary functions such as coolant.

In the setup phase, machinists prepare the CNC machining equipment to execute the program correctly. Setup usually includes:

- Mounting the raw material on the worktable, chuck, or fixture

- Zeroing or “touching off” to establish work coordinate systems

- Installing and measuring cutting tools in their holders

- Configuring tool offsets and length compensation

- Verifying coolant lines and chip evacuation systems

Proper setup is critical for accurate CNC machining, especially when tight tolerances or multi-face machining are required. For batch or mass production, dedicated fixtures and jigs are often designed to reduce setup time and guarantee repeatability from part to part.

After the setup is complete, the CNC machining program is loaded and executed. The controller reads the code line by line and drives the machine's servomotors and spindle according to the instructions. Typical operations include facing, contouring, pocketing, drilling, threading, and more.

During machining, the operator monitors the process, checking tool wear, cutting performance, and chip removal. For complex or high-value parts, a dry run or simulation is often performed first to verify toolpaths, avoid collisions, and ensure the CNC machining sequence behaves as expected.

When machining is complete, parts go through inspection using calipers, micrometers, gauges, CMM (coordinate measuring machines), or optical systems. Dimensional accuracy, geometric tolerances, surface roughness, and critical features are checked against the drawing.

If required, additional finishing processes can be applied after CNC machining, such as:

- Deburring and edge smoothing

- Sandblasting or polishing

- Anodizing, plating, or painting

- Heat treatment for enhanced mechanical properties

This combination of CNC machining and secondary finishing delivers parts that are ready for assembly or end use.

Different CNC machining processes are used according to part geometry, material, and functional requirements. Understanding each type helps OEM customers choose the right method for their project.

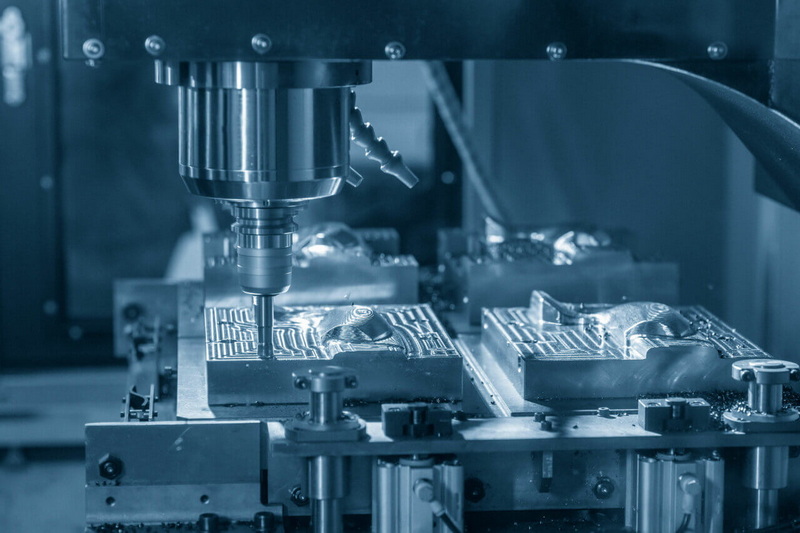

CNC milling is the most common CNC machining process. A rotating multi-point cutting tool removes material from a stationary or slowly moving workpiece. The machine typically moves the tool along three linear axes (X, Y, Z), and many advanced machining centers also use rotary axes (A, B) for 4-axis and 5-axis milling.

CNC milling is ideal for:

- Prismatic parts with flat faces and complex contours

- Pockets, slots, and cavities

- Enclosures, brackets, plates, and housings

- Precision surfaces and intricate 3D shapes

For demanding OEM applications, multi-axis CNC milling allows machining of difficult parts in fewer setups, improving accuracy and reducing production time.

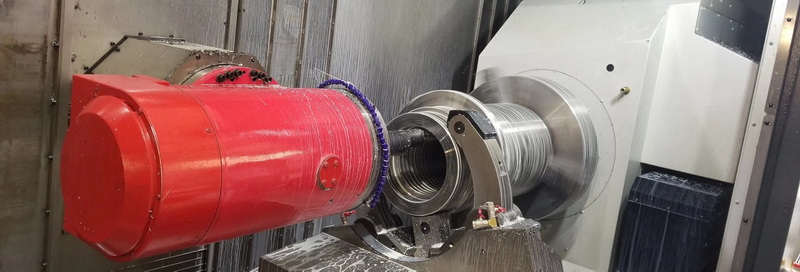

CNC turning is performed on lathes or turning centers where the workpiece rotates at high speed while a stationary cutting tool removes material. This CNC machining process is best suited to rotationally symmetric parts.

Typical CNC turning applications include:

- Shafts, pins, and axles

- Bushings, couplings, and collars

- Threads, tapers, and grooves

Advanced turning centers often combine milling capabilities, allowing cross-holes, flats, and other features to be machined in a single setup. For precision cylindrical components required in automotive, hydraulics, and mechanical assemblies, CNC turning is the core solution.

CNC drilling uses rotating drill bits to create circular holes with controlled position, depth, and diameter. In many machining centers, drilling, counterboring, and reaming are combined with milling operations in one cycle.

Threaded holes are produced using:

- Tapping (for cutting or forming threads)

- Thread milling (using a helical toolpath)

Because CNC machining controls position and depth accurately, drilling and tapping on a CNC machine offers better consistency than manual operations, especially when many holes are needed on complex parts.

CNC grinding uses abrasive wheels to achieve fine surface finishes and extremely tight dimensional tolerances. It is often used as a finishing CNC machining step when rough milling or turning can't meet the final accuracy or surface roughness required.

Common uses include:

- Hardened steel components

- Precision shafts and bearing seats

- Mating surfaces in tooling and molds

Although slower than rough machining, CNC grinding ensures critical components meet stringent performance requirements.

For very hard materials or extremely complex internal features, Electrical Discharge Machining (EDM) can complement CNC machining. EDM removes material through controlled electrical discharges and is especially valuable in mold making and toolmaking.

Other CNC-controlled processes that may integrate with CNC machining include:

- CNC routing for plastics, composites, and wood

- CNC sawing for cutting raw stock to size

- CNC honing for final surface refinement inside holes

Combining these technologies under one roof offers OEM customers more flexibility and shorter overall lead times.

For CNC machining to operate accurately and reliably, each component of the machine plays a specific role.

- Machine frame and guideways: Provide stiffness, stability, and precise motion.

- Spindle: Holds and rotates cutting tools or workpieces at controlled speeds.

- Drive motors and ball screws: Convert electronic commands into smooth, accurate linear or rotary motion.

- Tool magazine and automatic tool changer (ATC): Store multiple tools and switch them automatically during a CNC machining cycle.

- Control panel and controller: Input and interpret programs, handle real-time interpolation, and coordinate all axis movements.

- Coolant system and chip conveyor: Manage heat, lubricate tools, and remove chips to maintain cutting efficiency and part quality.

The synergy between these components is what allows CNC machining to achieve high precision under continuous industrial operation.

One of the strengths of CNC machining is compatibility with a wide range of materials. Choosing the right material depends on mechanical performance, environment, weight, cost, and appearance.

- Aluminum: Lightweight, corrosion-resistant, excellent machinability, widely used for enclosures, brackets, and structural parts.

- Stainless Steel: High strength and corrosion resistance for food, medical, and marine environments.

- Carbon and Alloy Steels: Used when high strength, wear resistance, or heat treatment is required.

- Brass and Copper: Good electrical and thermal conductivity for connectors, terminals, and heat sinks.

- Titanium: High strength-to-weight ratio and biocompatibility, popular in aerospace and medical sectors.

- ABS, PC, PA, POM, PEEK and others: Used for lightweight structural components, housings, fixtures, and functional prototypes.

For OEM clients, CNC machining provides both functional prototypes and end-use parts directly in production-grade materials, which is critical for performance validation and real-world testing.

A key advantage of CNC machining is its ability to achieve precise tolerances and consistent finishes. Typical general tolerances for standard parts are often within a few hundredths of a millimeter, and tighter tolerances are possible when design and setup are optimized.

Surface finish can be adjusted through:

- Choice of cutting tools and toolpaths

- Cutting parameters such as feed and speed

- Secondary processes like polishing, blasting, or grinding

By matching tolerance and finish levels to the functional needs of each feature, CNC machining balances performance and cost effectively.

For product development, CNC machining plays a vital role in transforming ideas into physical prototypes that can be tested and refined. Compared with many forming methods, CNC machining:

- Uses production-grade materials early in the development cycle

- Produces high-strength, functional prototypes

- Maintains consistent dimensions across design iterations

When demand grows beyond a few units but doesn't yet justify full tooling investment, CNC machining is ideal for low-volume production. It can deliver dozens, hundreds, or even thousands of parts while keeping flexibility for design changes and engineering improvements.

For international OEM partners, this bridge between prototyping and mass production allows faster time-to-market and lower overall risk.

Modern factories often combine CNC machining with other processes to offer turnkey manufacturing solutions.

- Sheet metal fabrication + CNC machining: Bending and laser cutting create the basic shell, and CNC machining adds precise details such as critical holes, threads, and machined edges.

- 3D printing + CNC machining: Additive manufacturing produces complex shapes quickly, then CNC machining refines interfaces, sealing surfaces, and high-precision features.

- Mold making + CNC machining: Steel or aluminum blocks are machined into mold cavities, which are later used for injection molding or die casting. CNC machining ensures the mold meets dimensional and surface quality requirements.

This integrated approach allows OEM clients to handle rapid prototyping, pilot runs, and stable production within a single supply chain.

Serious CNC machining for global customers always includes a strong quality control system. Typical practices include:

- Incoming inspection of raw materials

- In-process checks during machining

- Final inspection with calibrated measuring equipment

- Documentation of inspection reports and traceability

For high-precision projects, statistical process control (SPC) and capability studies may be implemented to ensure CNC machining processes remain stable over time. Consistent quality builds trust and long-term cooperation between machining suppliers and OEM customers.

Understanding what drives cost helps customers design more economical parts without sacrificing performance. Main cost factors include:

- Material type and stock size

- Complexity of geometry and number of setups

- Tolerance and surface finish requirements

- Quantity and repeat orders

- Need for custom fixtures or special tools

By discussing these aspects early, engineers can optimize parts for CNC machining and find the right balance between design ambition and budget.

CNC machining is a powerful, flexible, and precise manufacturing technology that converts digital designs into real-world components with remarkable accuracy. From 3D CAD modeling and CAM programming to machine setup, machining execution, and quality inspection, every stage in the CNC machining workflow supports consistent, repeatable results for complex parts and demanding applications.

Across industries such as automotive, aerospace, medical, robotics, and electronics, CNC machining enables both rapid prototyping and stable production in metals and engineering plastics. When integrated with complementary services like sheet metal fabrication, 3D printing, and mold making, CNC machining becomes a central element in a complete OEM manufacturing solution. For international customers looking for reliable partners, working with an experienced CNC machining factory ensures on-time delivery, dependable quality, and a smoother path from concept to market.

CNC machining uses computer-controlled programs to move tools and workpieces along precise paths, while manual machining relies on direct human control of levers and handwheels. Because of this automation, CNC machining offers better repeatability, higher productivity, and the ability to produce more complex shapes than manual methods.

Industries that require precise, reliable components made from metals or engineering plastics benefit the most from CNC machining. These include automotive, aerospace, medical devices, industrial equipment, consumer electronics, robotics, and energy, where tight tolerances and consistent quality are critical.

A part designed for CNC machining should respect reasonable wall thicknesses, avoid extremely deep and narrow pockets, and include fillets that match typical tool sizes where possible. Designers also need to consider tool access, clamping surfaces, and clear dimensions and tolerances so that the CNC machining process can be both efficient and cost-effective.

Yes, CNC machining is ideal for functional prototypes because it uses real materials and can deliver highly accurate parts quickly. With the right fixtures and process optimization, the same CNC machining setups can also support small to medium production volumes, and sometimes larger batches depending on the part and scheduling.

Lead time for CNC machined parts depends on the complexity of the design, the material, the required quantity, and the finishing processes. Simple prototypes can often be delivered in a short time, while more complex assemblies or large batch orders may require longer schedules to allow for programming, tooling, machining, finishing, and inspection.

[1](https://geomiq.com/cnc-machining-guide/)

[2](https://astromachineworks.com/what-is-cnc-machining/)

[3](https://www.goodwin.edu/enews/what-is-cnc/)

[4](https://www.3erp.com/manufacturing-technology/cnc-machining/)

[5](https://www.pickenstech.org/blog/what-is-a-cnc-machine/)

[6](https://gab.wallawalla.edu/~ralph.stirling/classes/engr480/examples/nvx/NVX/Helpful%20Docs/CNC_Machining_The_Complete_Engineering_Guide.pdf)

[7](https://www.youtube.com/watch?v=lEyNWtM6MW4)

[8](https://www.protolabs.com/resources/guides-and-trend-reports/cnc-machining-for-prototypes-and-low-volume-production-parts/)

[9](https://academy.titansofcnc.com/files/Fundamentals_of_CNC_Machining.pdf)

[10](https://cst.princeton.edu/studiolab/equipment/cnc-milling)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam