Views: 222 Author: Amanda Publish Time: 2025-11-13 Origin: Site

Content Menu

● Understanding the Turning Lathe

>> Basic Operation and Structure

● Comparing Accuracy and Precision

>> Vibration and Deflection Control

● Machining Complexity and Cycle Time

>> Ideal Jobs for Turning Lathes

>> Perfect Fit for Swiss Lathes

● Efficiency, Automation, and Cost

● FAQ

>> 1. What are the main structural differences between a turning lathe and a Swiss lathe?

>> 2. Which machine offers better accuracy and for what applications?

>> 3. Can both machines handle the same materials?

>> 4. What are the cost and operational differences?

>> 5. How do Swiss lathes reduce cycle time and labor?

In the modern manufacturing landscape, choosing the right machine tool is crucial for balancing cost, precision, and efficiency—especially for businesses specializing in OEM services across industries like automotive, aerospace, electronics, and medical technology. The debate between turning latheand Swiss lathe solutions is particularly intense when the core concern is dimensional accuracy. Both technologies offer unique advantages, and the choice depends on part complexity, production volume, material, and investment goals. This article provides an in-depth comparison of the two, focusing on their structure, working principles, accuracy, operational pros and cons, and ideal applications, to help you make informed decisions for high-precision manufacturing.[1][3][5][6]

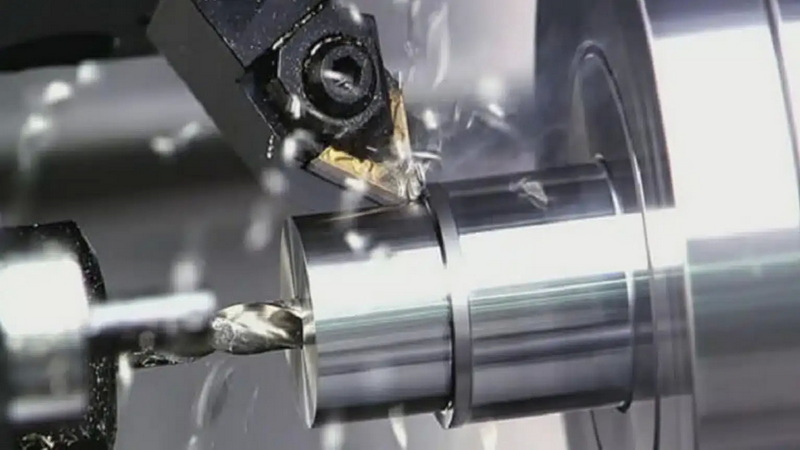

A turning lathe, also called a conventional or CNC turning lathe, is among the most fundamental machines in the realm of subtractive manufacturing. Used for centuries and now highly automated, the turning lathe operates by securing a workpiece in a chuck or collet, rotating it at high speeds, and applying a stationary cutting tool to remove unwanted material.

- Fixed Headstock: The core feature is its fixed headstock, providing a stable base for clamping the workpiece.

- Versatility: Turning lathes handle a variety of metals and plastics, producing parts with cylindrical symmetry, such as shafts, bushings, and pulleys.

- CNC Options: Modern CNC turning lathes integrate computerized controls for highly repeatable pathways, reducing human error and improving productivity.

- Axes and Tools: Typically configured with 2–4 axes, suitable for variants like roughing, finishing, facing, grooving, drilling, and threading.[6][10]

- Batch Suitability: Ideal for prototyping, custom parts, and low-to-medium volume production where part size and geometry are moderate to large.

A Swiss lathe—often called a Swiss-type or sliding headstock lathe—was originally developed for watchmaking, but today, it is the machine of choice for ultra-high precision and micro-scale manufacturing challenges.

- Sliding Headstock and Guide Bushing: Swiss lathes guide bar stock through a sliding headstock and a close-fitting guide bushing, supporting the workpiece within a fraction of a millimeter of the cutting tool.

- Multiple Axes: Capable of 7–13 axes and multiple tool turrets, Swiss lathes can perform complex machining steps simultaneously.[5][1]

- Support for Long, Thin Parts: Their powerful support minimizes vibration and deflection, making it possible to achieve precise results on long, slender, or extremely intricate components.

- Automation: Automatic bar feeders and high tool capacity allow for continuous operation and minimal operator intervention, favoring high-volume production runs.

- Turning Lathe: Typical attainable tolerances are around ±0.01 mm—excellent for most medium-to-large parts and general industrial applications.[5]

- Swiss Lathe: Swiss machines routinely hold micron-level tolerances (up to ±0.001 mm), essential for medical, aerospace, and electronics industries where dimensional integrity is critical over long or slender geometries.[1][5]

- Turning Lathe: As the length-to-diameter ratio increases (typically beyond 4:1), standard turning lathes are vulnerable to part deflection and vibration, which can compromise surface finish and dimensional accuracy—especially on longer, thinner parts.[6][1][5]

- Swiss Lathe: By maintaining constant proximity between the tool and guide bushing, Swiss lathes virtually eliminate these issues, yielding consistent results no matter the part's slenderness.[1][5]

- Turning Lathe: Capable of achieving commercial surface finishes (Ra 0.8–1.6 μm), sufficient for most non-critical applications.[1]

- Swiss Lathe: Can produce much smoother finishes (Ra 0.16 μm), eliminating or reducing secondary finishing operations.[5][1]

- Turning Lathe: Typically machines one feature at a time, changing tools between operations.

- Swiss Lathe: Performs multiple machining operations in parallel due to its multiple tools and axes, significantly reducing cycle times for complex parts.[5]

Swiss lathes often integrate turning, milling, drilling, and threading in a single setup, allowing for true "done-in-one" manufacturing. Turning lathes, while versatile, generally require part transfers or multiple setups for similar levels of complexity.[6][5]

- Large, simple shafts, collars, flanges, and general-purpose cylindrical components.

- Automotive drive components, pump rotors, and industrial rollers.

- Profitable for short-to-medium production runs or frequent part changes due to simple setup and lower upfront cost.[6]

- Surgical and dental screws, medical device components.

- Aerospace fuel nozzles, electrical connectors, micro fasteners.[1][5]

- High-volume production of intricate, miniature, or long slender parts where micrometer-level precision is vital.

- Machining expensive alloys or heat-sensitive materials where material savings and tight tolerance are priorities.

- Turning Lathe: Excellent for aluminum, mild and stainless steels, brass, and engineering plastics. Parts are typically larger and more robust, where small deflections can be tolerated.[5][1]

- Swiss Lathe: Especially well-suited for titanium, Inconel, cobalt-chrome, and medical or electronics-grade stainless steel, allowing complex machining of small diameters with tough alloys.[5]

- Turning Lathe: Uses water-based coolants that are more cost-effective and easier to maintain but less efficient in heat management.[2]

- Swiss Lathe: Employs oil-based coolants, improving precision by reducing thermal expansion but necessitating more stringent fire safety and cooling controls.[2]

- Turning Lathe: Faster for parts with simple geometries or large dimensions. Lower operator skill requirements.

- Swiss Lathe: More expensive to acquire and set up, but operational savings are realized in cycle time, reduced rework, and labor for high-volume, high-precision production.[7][1][5]

Swiss-type turning's segmental machining utilizes material more efficiently—especially important for precious alloys—whereas turning lathes may generate more waste when working with long, thin parts.[5]

- Swiss turning excels in accuracy, repeatability, and handling complex, small-diameter work.

- Turning lathes are unmatched in versatility and cost-effectiveness for larger, simpler parts.

Manufacturers deciding between a turning lathe and a Swiss lathe must weigh:

- Tolerance and finish requirements

- Part geometry and length-to-diameter ratio

- Project volume and changeover frequency

- Material characteristics

- Available capital investment

For custom or low-medium runs of larger-diameter, less intricate parts, a turning lathe is the pragmatic workhorse. For miniature components, tight tolerances, all-in-one cycle operations, and best-in-class surface quality, Swiss lathes are the proven leaders.[7][6][1][5]

Selecting between a turning lathe and a Swiss lathe means matching your manufacturing needs to technological strengths. Turning lathes offer robust performance and flexibility for most industrial jobs, but Swiss lathes push the limits of accuracy and efficiency, making them essential for industries such as medical, electronics, and aerospace, where precision is non-negotiable. Investing in the right machine tool unlocks faster production, reduced costs, and superior product quality—empowering manufacturers in an increasingly competitive global market.[3][7][6][1][5]

Turning lathes use a fixed headstock and clamp the workpiece at one or both ends, while Swiss lathes employ a sliding headstock and guide bushing to support the workpiece close to the cutting tool, especially suitable for long, thin components.[6][1]

Swiss lathes provide higher accuracy—down to the micrometer level—making them the preferred choice for medical implants, aerospace parts, and electronic connectors. Turning lathes offer strong performance for less demanding tolerances.[7][1][6][5]

Both can process metals and engineering plastics, but Swiss lathes excel with difficult alloys and small-diameter bars, while turning lathes are best for broader diameters and more common industrial materials.[6][5]

Turning lathes are less costly to acquire and maintain, optimal for custom work and flexible applications. Swiss lathes require higher initial investment but deliver cost savings for mass-producing intricate, high-precision components.[3][7][1][5]

Swiss lathes offer simultaneous multi-tool machining, automatic bar feeding, and fewer secondary processes, greatly shortening cycle time and labor demands compared to conventional lathes.[7][6][5]

[1](https://cncwmt.com/qa/swiss-turning-vs-conventional-cnc-what-are-the-differences/)

[2](https://turntechprecision.com/clueless-machinist/2020/6/11/5-key-differences-between-conventional-cnc-turning-and-swiss-type-turning)

[3](https://vesciomfg.com/swiss-cnc-machining-vs-conventional-cnc-lathe-turning-services/)

[4](https://www.reddit.com/r/CNC/comments/ud0oeb/cnc_y_lathe_vs_swiss_lathe_let_the_fight_begin/)

[5](https://fractory.com/swiss-machining-explained/)

[6](https://www.jecompanies.com/blog/the-difference-between-a-conventional-mazak-lathe-and-a-swiss-turning-machine)

[7](https://www.zintilon.com/blog/cnc-swiss-lathe-vs-cnc-lathe/)

[8](https://www.matterhackers.com/articles/understanding-swiss-lathes-precision-machining-for-complex-parts)

[9](https://www.youtube.com/watch?v=EPyKVjuFd5g)

[10](https://staubinc.com/news/a-guide-to-cnc-lathe-machining-processes-applications-benefits/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal