Views: 222 Author: Amanda Publish Time: 2025-11-11 Origin: Site

Content Menu

● Versatility of Turning Lathe Technology

>> Typical Turning Lathe Applications

>> Core Lathe Turning Operations

● The Turning Lathe vs Lathe Turning Distinction

● Detailed Lathe Turning Workflow

>> 3. Inspection & Quality Control

>> CNC Turning

>> Polygonal and Spherical Turning

● Material Considerations in Turning Lathe Operations

● Surface Finish and Tolerance Optimization

● Design for Manufacturability in Lathe Turning

● From Prototyping to Production: Scaling with Turning Lathe Technology

● Common Challenges in Lathe Turning

● Industry Trends in Turning Lathe Technology

>> 1. What is the difference between a turning lathe and lathe turning?

>> 2. Are all lathes suitable for CNC turning?

>> 3. What materials can be processed via lathe turning?

>> 4. How do coolant systems affect lathe turning results?

>> 5. Why has CNC technology revolutionized turning lathe manufacturing?

Manufacturing excellence hinges on precision, terminology, and the selection of appropriate tools—especially when it comes to cylindrical component fabrication. Two phrases often encountered in the machining world, "turning lathe" and "lathe turning," summarize the essentials of one of the oldest and most widely applied manufacturing processes. While they seem interchangeable, these terms represent distinct concepts, practices, and machinery in modern OEM and rapid manufacturing industries. In this detailed guide, discover how turning lathe technology shapes today's markets, the nuances of lathe turning processes, and the impact of proper terminology on your next precision engineering project.[1][10][11]

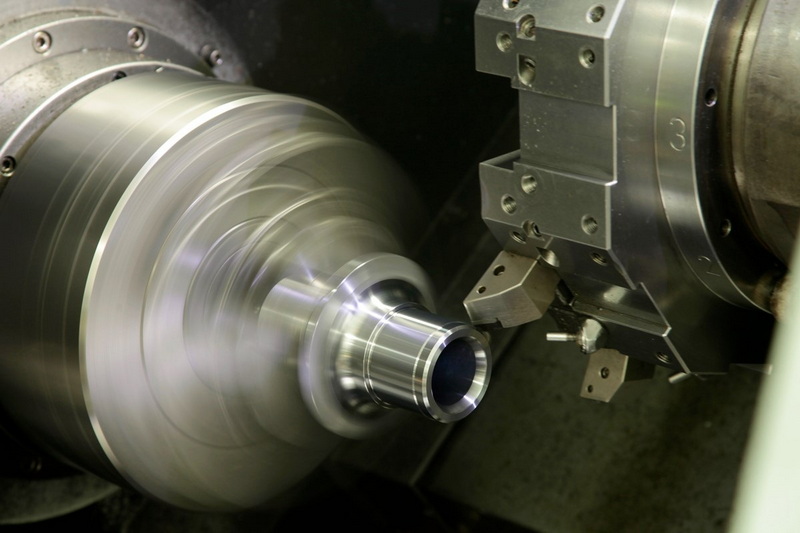

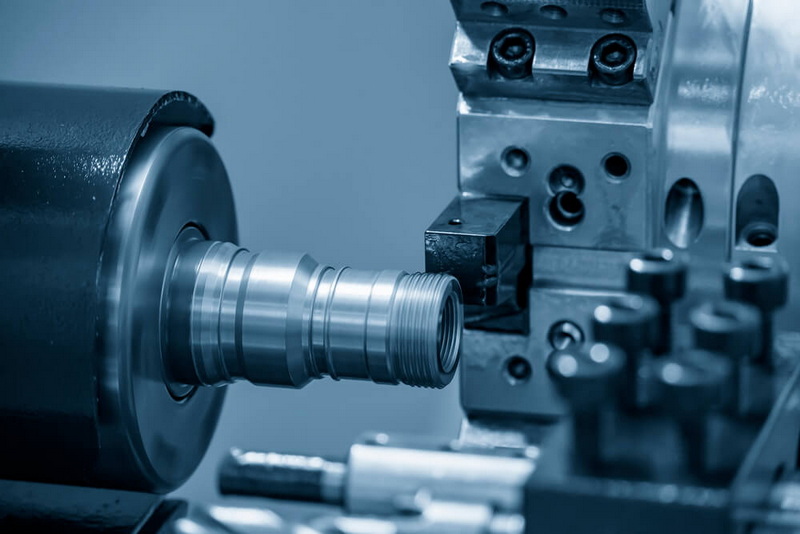

A turning lathe is a specialized machine tool designed to hold, rotate, and precisely shape material—usually metal, plastic, or even wood—by removing unwanted material through various cutting operations. Over centuries of industrial evolution, the turning lathe has remained essential for producing components requiring rotational symmetry and high dimensional accuracy.

- Headstock: Contains the spindle that rotates the workpiece.[4]

- Tailstock: Supports and aligns longer workpieces for increased accuracy.[4]

- Chuck: Clamps and holds the workpiece securely in position.[4]

- Carriage & Tool Post: Provides stable movement and positioning of the cutting tool.[4]

- Bed: Forms the backbone, ensuring parallel alignment for machining.[4]

Turning lathes can be manual or CNC-controlled, with each variant designed for particular tasks and volumes. CNC (Computer Numerical Control) turning lathes have dramatically improved the quality, speed, and repeatability of modern manufacturing, enabling the automated production of parts with complex geometries and tight tolerances.[6][11][12]

- Precision shafts and bushings for aerospace.

- Axles, drive pulleys, and fasteners in automotive manufacturing.

- Custom connectors for electronics.

- Surgical implants and high-performance medical components.[12][13]

Lathe turning is the process performed using a turning lathe, where a single-point cutting tool advances along the length or diameter of a rotating workpiece. The objective is to shape, reduce, or refine the external or internal surfaces to exact specifications.

- Turning: Reduces diameter to required size—main process in lathe machining.[1]

- Facing: Produces flat surfaces perpendicular to rotation axis.[1]

- Boring: Enlarges inner diameters for precision holes.[5]

- Grooving/Parting: Cuts localized slots or segments from the raw material.[5]

- Thread Cutting: Essential for screws, bolts, and joining components.[5][1]

- Knurling: Imprints textured grip patterns on cylindrical surfaces.[5]

- Taper Turning: Generates a gradual change in diameter, vital for tool shanks or mating parts.[2][1]

- Chamfering: Creates beveled edges for finishing steps.[1]

| Feature | Turning Lathe | Lathe Turning |

|---|---|---|

| Definition | The physical machine tool used for rotation and cutting | The machining process performed on that machine |

| Core Concept | Focused on equipment and setup | Focused on operational method and execution |

| Application | Manual, CNC lathes, turret lathes, specialty lathes | Turning, facing, boring, threading, knurling |

| Practical Use | Describes the hardware | Describes the activity/process |

"Turning lathe" references the machinery itself, while "lathe turning" is the manufacturing operation. Both are inseparable in modern production, yet clarity improves communication and ensures optimal process selection.[2][6][1]

- Material Selection: Metals (steel, aluminum, copper, titanium), plastics, ceramics, and composites.[6]

- Tooling Choice: Selected for roughing, finishing, threading, parting, grooving, and more.[6][1]

- Machine Setup: Mount workpiece using chuck or centers; set spindle speed, feed rate, and depth of cut for material and geometry.[4]

- Spindle Engagement: Motor powers rotation; precise clamping ensures concentricity.[4]

- Tool Positioning: Cutting tool engages at exact location, maintaining clearance and programming or manual position.[4]

- Cutting Process: Tool removes material layer-by-layer, generating chips and achieving dimensional accuracy aided by coolant and chip breakers.[4]

- In-Process Measurement: Callipers, micrometers, digital probes check dimensions mid-process.[6][4]

- Final Verification: Finished components are inspected for dimensional fidelity, surface finish, and functional requirements, followed by post-processing if needed.

CNC turning integrates digital controls for full automation, multi-axis motion, and extremely fine tolerances. Complex programmed movements allow production of sculpted contours, multi-featured profiles, and high-volume repeatability without manual intervention.[12][6]

Modern CNC lathes enable polygonal turning (geometrically accurate non-cylindrical profiles) and true spherical generation, ideal for innovative product shapes in the automotive, aerospace, and consumer goods industries.[2]

Turning lathes accommodate a diverse array of materials, each with unique machining behaviors:

- Ferrous Metals: Alloy steels, carbon steels, cast iron for rugged industrial parts.[1][6]

- Non-Ferrous Metals: Aluminum, copper, brass, magnesium for lighter-weight or corrosion-resistant applications.[6]

- Plastics and Composites: Useful in prototyping, low-stress components, and electronics.[6]

- Specialty Materials: Ceramics and thermosets require specialized tooling and slow feed rates for intricate, brittle features.[6]

Each material demands proper spindle speeds, feed rates, and cutting tool materials—typically carbide, high-speed steel, or ceramics—to achieve optimal results.

The quality of a turned part depends not only on dimensional accuracy but also on surface finish—a crucial factor in the end-use and aesthetic appeal of the product.

- Finish Turning: Final passes with fine tools produce smooth, polished surfaces within microns of tolerance.[3][6]

- Coolant and Chip Management: Efficient cooling and chip evacuation enhance surface quality and tool life.[4]

Turning lathes equipped for finish turning and supported by diligent inspection deliver components that meet stringent OEM quality specifications.

OEM clients and designers should consider key principles in part geometry to maximize efficiency and quality in the turning lathe process:

- Avoid Excessive Undercuts: Maintain symmetry for best stability and accuracy during turning.[8]

- Include Chamfers and Fillets: Facilitate tool transition between surfaces and improve finished part strength.[8]

- Preview Thread Depths and Diameters: Ensure compatibility with downstream assembly requirements.[8]

- Standardize Feature Sizes Where Possible: Utilize standard diameters and tolerances to minimize cost and streamline production.[8]

Collaborating with experienced turning lathe specialists elevates project outcomes by leveraging best practices for manufacturability.

Turning lathe technology excels in both rapid prototyping and large-scale production. For custom development, it enables quick turnaround on test parts with vital performance features. In serial manufacturing, automated turning centers output thousands of precisely matched components with minimal variance.

Industries served:

- Automotive: Crankshafts, axles, pistons, and bushings.

- Aerospace: Special alloys and ultra-tight tolerances.

- Medical: Surgical tools, implants, and diagnostic housing.

- Electronics: High-precision connectors and sensor bodies.[13][12][1]

OEM partners turn to premium turning lathe shops to achieve reliable, scalable, and innovative results in a competitive international landscape.

Despite its universality, lathe turning presents several technical challenges:

- Tool Wear: High cutting speeds and tough materials accelerate tool degradation—modern turning lathe operations require routine monitoring and replacement.

- Machining Vibration: Imbalanced workpieces or aggressive feeds provoke vibration, risking part accuracy and surface finish.

- Chip Management: Efficient removal and containment of chips prevent tool breakage and thermal buildup, ensuring consistent turning quality.

- Programming Complexity (CNC): Multi-axis CNC turning requires advanced programming skills to unlock the full capability of the equipment.

Addressing these issues through improved design, updated tool paths, and ongoing operator training maximizes manufacturing success.

Automation, digitalization, and material advancement are reshaping the world of turning lathe machining:

- Smart Factories: Integrated sensors monitor tool wear, quality metrics, and production status in real time.

- Multi-Process Centers: Hybrid machines combine turning, milling, and drilling—minimizing cycle time and maximizing versatility.

- Eco-Friendly Machining: Water-based coolants and optimized chip recycling can reduce environmental impact.

- Advanced Tooling Materials: New ceramics and coated carbides extend tool life and enable faster, cleaner cuts.

Manufacturers that invest in modern turning lathe systems continue to outperform competitors through innovation and agility.

Mastering the distinctions and complexities between "turning lathe" and "lathe turning" delivers immense advantages for those engaged in precision manufacturing, rapid prototyping, and OEM product development. Recognizing the interplay between advanced equipment, process methodologies, material selection, and best practices ensures that every turned component meets both customer expectations and global engineering standards. Turning lathe technology remains at the heart of the world's manufacturing momentum—crafting everything from prototype shafts to aerospace-critical components and driving innovation in the digital production era.[13][12][1][6]

A turning lathe is the machine itself, while lathe turning is the process of shaping material using that machine. The former refers to the hardware, the latter to the operation performed.[1][6]

Not all lathes are CNC compatible; CNC lathes are specifically designed for automated, programmable operations, while manual lathes rely on skilled operators.[11][6]

The process is versatile enough for metals (steel, aluminum, copper, titanium), plastics, and specialty composites, with the right selection of cutting tools and machine settings.[1][6]

Proper coolant delivery during turning lathe operations reduces heat buildup, extends tool life, and improves the surface finish of machined components.[4]

CNC technology allows for high precision, consistent repeatability, fast cycle times, and complex multi-axis machining—all essential for modern automated manufacturing.[11][12]

[1](https://turntechprecision.com/clueless-machinist/2020/8/25/10-machining-operations-performed-on-a-lathe)

[2](https://cncpartsxtj.com/es/brief-guide-to-lathe-turning-operations/)

[3](https://openoregon.pressbooks.pub/manufacturingprocesses45/chapter/unit-4-turning/)

[4](https://cncwmt.com/qa/how-does-a-lathe-work/)

[5](https://waykenrm.com/blogs/types-of-turning-operations/)

[6](https://www.xometry.com/resources/machining/what-is-turning-in-machining/)

[7](https://rosnokmachine.com/how-to-operate-a-lathe/)

[8](https://www.makerverse.com/resources/cnc-machining-guides/best-practices-designing-for-cnc-turning/)

[9](https://www.xavier-parts.com/turning-parts-manufacturing-guide/)

[10](https://en.wikipedia.org/wiki/Turning)

[11](https://cncwmt.com/qa/turning-center-vs-lathe-choosing-the-right-machine/)

[12](https://www.wevolver.com/article/what-is-cnc-turning)

[13](https://www.yashmachine.com/blog/applications-of-lathe-machines-in-workshop-environments/)

content is empty!