Views: 222 Author: Amanda Publish Time: 2025-07-13 Origin: Site

Content Menu

>> Key Benefits of Vacuum Casting

● The Vacuum Casting Process in Detail

● Applications of Vacuum Casting

● Top Vacuum Casting Manufacturers and Suppliers in Spain

>> Soluciones Globales y Gestión de Compras, S.L.

● Leading Vacuum Casting Service Providers

>> ProtoSpain

>> Ineo

>> Advanced Manufacturing Barcelona

>> Proto&Go

● The Competitive Edge of Spanish Vacuum Casting Manufacturers and Suppliers

● Choosing the Right Vacuum Casting Manufacturer or Supplier

● Advantages of Partnering with Spanish Vacuum Casting Manufacturers and Suppliers

● Frequently Asked Questions (FAQ)

>> 1. What is vacuum casting and how does it differ from other casting methods?

>> 2. What materials can be used in vacuum casting?

>> 3. How long does it take to produce parts using vacuum casting?

>> 4. What are the typical applications for vacuum casting?

>> 5. How do I choose the best vacuum casting manufacturer or supplier in Spain?

Vacuum casting has emerged as a leading technology for rapid prototyping and low-volume production, offering exceptional precision, material versatility, and surface finish. Spain, with its robust manufacturing sector and innovative engineering talent, is home to some of the most reputable vacuum casting manufacturers and suppliers in Europe. This article provides a comprehensive overview of the top vacuum casting manufacturers and suppliers in Spain, exploring their capabilities, services, and the unique advantages they bring to the industry. Whether you are a brand owner, wholesaler, or production manager seeking reliable OEM partners, this guide will help you navigate the Spanish vacuum casting market.

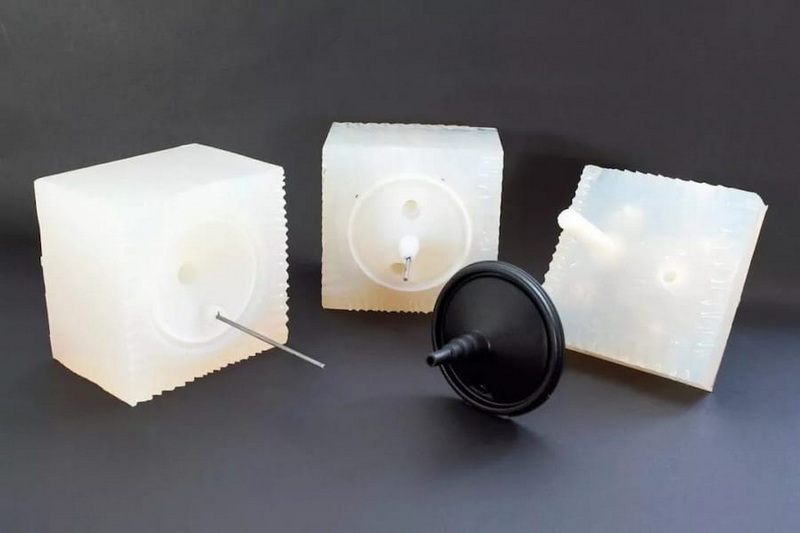

Vacuum casting is a manufacturing process that utilizes silicone molds and vacuum technology to produce high-quality plastic or resin parts. The process begins with the creation of a master pattern, typically made using 3D printing or CNC machining. This pattern is then encased in silicone to form a mold. Under vacuum, liquid resin is poured into the mold, ensuring that every detail is captured and air bubbles are eliminated. The result is a precise replica of the master pattern, ideal for prototypes, functional testing, and small batch production.

- High Precision: Achieves intricate details and complex geometries.

- Material Flexibility: Supports a wide range of polyurethane resins, including transparent, flexible, and high-temperature resistant materials.

- Cost-Effective for Short Runs: Perfect for low to medium volume production without the high costs of traditional tooling.

- Fast Turnaround: Rapid mold creation and part replication.

- Superior Surface Finish: Produces smooth, ready-to-use parts.

1. Master Pattern Creation

The process starts with the creation of a master pattern, which serves as the original model for the part. This master is typically produced using advanced 3D printing technologies or precision CNC machining, allowing for complex geometries and fine details. The master pattern is finished to the desired surface quality, often polished or painted to ensure the mold captures every nuance.

2. Silicone Mold Making

Once the master pattern is ready, it is encased in liquid silicone rubber. The silicone cures around the master, forming a flexible, durable mold. This mold can be used repeatedly to produce multiple parts, making it highly efficient for short to medium production runs.

3. Vacuum Casting

The silicone mold is placed inside a vacuum chamber. Liquid polyurethane resin is mixed and degassed to remove air bubbles, then poured into the mold under vacuum conditions. The vacuum environment ensures that the resin fills every cavity of the mold without trapping air, resulting in defect-free parts with excellent surface finish.

4. Curing and Demolding

After the resin is poured, the mold is heated to cure the material. Once cured, the part is carefully removed from the silicone mold. The flexible nature of the silicone allows for easy demolding without damaging delicate features.

5. Post-Processing

The cast parts can undergo various post-processing steps such as trimming excess material, sanding, painting, plating, or assembly depending on the application requirements. These finishing touches enhance the appearance and functionality of the final product.

Vacuum casting is widely used across industries due to its versatility and ability to produce functional parts rapidly and cost-effectively.

- Automotive Prototypes: Vacuum casting is ideal for manufacturing dashboard components, housings, and functional prototypes that require high precision and fine surface finishes. It allows automotive designers to test form, fit, and function before committing to mass production.

- Medical Devices: The process is used to create ergonomic models, transparent parts, and casings for medical instruments. Vacuum casting can utilize biocompatible and FDA-approved resins suitable for medical applications.

- Consumer Products: From electronic enclosures to buttons and handles, vacuum casting enables rapid production of consumer goods prototypes and short-run products that closely mimic injection-molded parts.

- Aerospace: Lightweight structural models, test fixtures, and functional components can be produced with vacuum casting, helping aerospace engineers validate designs and materials.

- Industrial Equipment: Custom gears, levers, and machine parts are produced with high accuracy, enabling manufacturers to test and optimize equipment before large-scale production.

Spain's vacuum casting industry is characterized by a blend of established foundries and agile prototyping firms. Below is a curated list of leading vacuum casting manufacturers and suppliers, each with unique strengths and service offerings.

Located in Madrid, Intrum España is a versatile foundry specializing in vacuum casting alongside centrifugal casting, lost-foam casting, and shell molding. Serving aerospace, commercial, and military sectors, Intrum offers ferrous and non-ferrous castings with additional services such as painting, plating, and assembly. Their comprehensive capabilities make them a strong partner for complex OEM projects requiring high-quality vacuum cast parts.

Based in Albacete, this company excels in rapid prototyping, injection tooling, fixture fabrication, and vacuum casting. They focus on industrial sourcing and cost optimization, providing OEM clients with efficient project management and competitive pricing. Their expertise is particularly valuable for brands seeking to streamline procurement and manufacturing processes.

Operating out of Barcelona, Eines CANELA is recognized as one of Spain's largest rapid prototyping service bureaus. Their specialties include shell casting, laboratory quality checks, heat treatment, machining, and vacuum casting. Their precision short-run production capabilities cater to industries demanding tight tolerances and consistent quality.

Located in Valladolid, Saeta Die Casting offers high-pressure die casting and vacuum casting services, producing tool steel and cobalt alloy castings. They serve the automotive and industrial machinery sectors, providing durable and high-performance parts with excellent surface finishes.

Valencia-based GRUPO GEISPEN specializes in aluminum and stainless steel casting, high-pressure die casting, and vacuum casting. Their in-house tooling, machining, and assembly capabilities allow them to deliver turnkey solutions for clients requiring end-to-end manufacturing services.

With over a century of experience, Ayamar Nautico in Huelva focuses on bronze, nickel, and duplex alloy castings, complemented by vacuum casting services. Their longstanding expertise in metalworking and casting makes them a trusted supplier for demanding industrial applications.

Sermadiesel, located in Murcia, provides a broad range of casting services including stainless steel, cobalt alloy, tool steel, bronze/brass, nickel alloy, duplex alloy castings, and vacuum casting. Their diverse material portfolio supports various industries with complex requirements.

ProtoSpain offers rapid prototyping, vacuum casting, silicone molding, and short-run production. Their fast turnaround and high-quality surface finishes make them a preferred choice for clients needing quick yet precise parts. They support a wide range of resin materials suitable for various applications.

Ineo specializes in rapid manufacturing of parts using silicone molds and vacuum casting for pre-series and low-volume production. They provide a variety of finishes including painted, chrome, tinted, and metallic, catering to aesthetic and functional demands.

This firm focuses on polyurethane resin parts, stereolithography patterns, and FDA-approved materials for food-related applications. Their expertise makes them an excellent partner for projects requiring stringent material compliance and quality.

Proto&Go is known for silicone molding and vacuum casting services tailored for prototypes and small series production. Their customer-centric approach ensures tailored solutions and responsive communication.

Spanish vacuum casting manufacturers and suppliers are recognized for their technical expertise, customer-centric approach, and advanced facilities. They offer:

- Customization: Tailored solutions for unique project requirements, including specialized materials and finishes.

- Quality Assurance: Rigorous quality control and certification processes ensure consistent part quality.

- Innovation: Adoption of the latest materials, 3D printing technologies, and process improvements.

- Sustainability: Many companies implement eco-friendly practices, including material recycling and energy-efficient operations.

- Multisector Experience: Serving automotive, aerospace, medical, consumer goods, and industrial sectors with diverse expertise.

Selecting the right partner is critical to the success of your project. Consider the following factors when evaluating vacuum casting manufacturers and suppliers in Spain:

- Experience and Track Record: Review their portfolio and client testimonials to assess industry expertise.

- Material and Process Capabilities: Confirm they can work with your required materials and finishes.

- Quality Standards: Check for certifications such as ISO 9001 or industry-specific approvals.

- Lead Time and Capacity: Ensure they can meet your production schedule and volume needs.

- Customer Support: Opt for companies that provide technical consultation, transparent communication, and after-sales service.

- Proximity to European Markets: Reduced shipping times and easier logistics.

- Language and Cultural Alignment: Facilitates smoother communication and collaboration.

- Strong Engineering Talent: Access to skilled technicians and innovative problem solvers.

- Competitive Pricing: Cost-effective solutions without compromising quality.

- Integrated Services: Many suppliers offer turnkey solutions including design, prototyping, casting, machining, and assembly.

Spain stands out as a hub for vacuum casting manufacturers and suppliers, offering world-class expertise, advanced technology, and a commitment to quality. Whether you need rapid prototypes, functional parts, or low-volume production, Spanish vacuum casting companies deliver reliable, high-precision solutions tailored to your needs. By leveraging their capabilities, international brands and OEMs can accelerate product development, reduce costs, and bring innovative products to market faster. The combination of technical proficiency, customer focus, and strategic location makes Spain an ideal destination for vacuum casting services.

Vacuum casting is a process that uses silicone molds and vacuum technology to produce high-quality resin or plastic parts. Unlike traditional casting, vacuum casting eliminates air bubbles and achieves finer detail, making it ideal for prototypes and small batch production.

A wide range of polyurethane resins can be used, including transparent, flexible, high-temperature resistant, and food-grade materials. The choice depends on the application and desired properties.

Production times vary based on part complexity and quantity, but vacuum casting is known for its fast turnaround. Simple parts can often be delivered within a few days, while larger or more complex projects may take a week or more.

Vacuum casting is commonly used for automotive prototypes, medical device housings, consumer product enclosures, aerospace models, and industrial components requiring high precision and excellent surface finish.

Consider the company's experience, material and process capabilities, quality assurance, lead time, and customer support. Requesting samples and reviewing past projects can also help ensure a good fit for your needs.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal