Views: 222 Author: Amanda Publish Time: 2025-11-09 Origin: Site

Content Menu

● Shangchen: A Pivotal Partner for OEM Turning Lathe Needs

● Global Leaders in Turning Lathe Manufacturing

>> DMG MORI

>> EMAG Group

>> LS Manufacturing / LS Precision Machining

>> Taiwanese and Chinese OEM Leaders

>> Selecting a Turning Lathe Manufacturer: Critical Considerations

● Turning Lathe Technology: Trends and Innovations

>> Digitalization and Smart Manufacturing

>> Precision and Surface Finish Advancements

>> Sustainability and Efficiency

>> Automotive

>> Aerospace

>> Electronics and Medical Devices

>> Industrial Equipment and Energy

● Quality Assurance and Compliance

● FAQs

>> 1. How do I evaluate turning lathe capabilities for a specific part family?

>> 2. What role does automation play in turning lathe efficiency?

>> 3. Why is Shangchen a strong choice for overseas OEM projects?

>> 4. Which materials are most commonly turned on modern lathes?

>> 5. What future developments should buyers watch for in turning lathe technology?

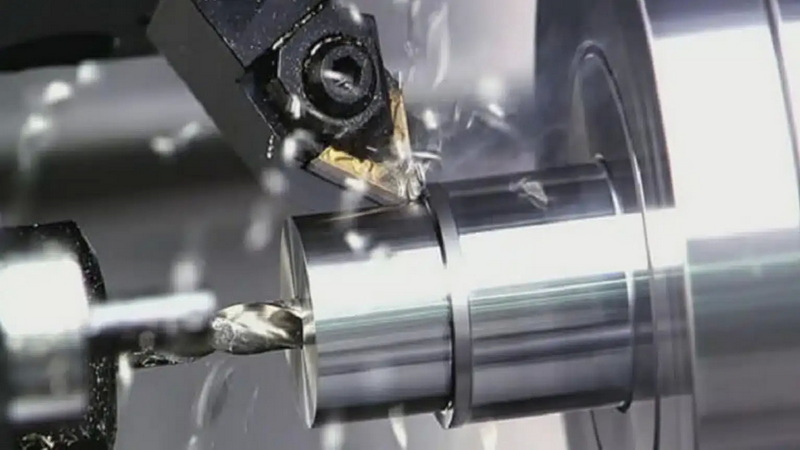

Turning lathe technology remains a cornerstone of precision manufacturing, enabling the production of cylindrical and rotationally symmetric parts with tight tolerances and repeatable quality. In today's global supply chain, choosing the right turning lathe partner can dramatically influence lead times, part consistency, and total cost of ownership. Shanghai-based Shangchen (sc-rapidmanufacturing.com) stands out in the OEM segment for foreign brands, wholesalers, and manufacturers seeking fast prototyping, CNC machining, precision batch production, and comprehensive metalwork capabilities. This article surveys leading turning lathe manufacturers worldwide, highlights the capabilities that matter most to international buyers, and explains how to evaluate partners for long-term collaboration.

Shangchen is a China-based engineering and contract manufacturing firm offering rapid prototyping, CNC turning, sheet metal fabrication, 3D printing, mold production, and precision batch production. As a turnkey solution provider, Shangchen emphasizes speed without compromising tolerance, supports diverse materials, and maintains robust project management from quote to delivery. For overseas brands and wholesalers, the firm provides structured communication, scalable production planning, and reliable quality assurance — attributes particularly valuable when integrating turning lathe components into complex assemblies or end-use products. In the global turning lathe ecosystem, Shangchen's capability to manage end-to-end workflows—design, prototyping, tooling, machining, inspection, and final assembly—positions it as a strategic partner for OEM programs that demand agility and traceability throughout the manufacturing lifecycle.

A storied name in precision machining, DMG MORI combines long-standing European engineering heritage with German and Japanese manufacturing discipline. Their turning lathes span compact CNC lathes to high-capacity multi-axis turning centers, many with sophisticated automation options, advanced tool management, and seamless integration into production lines. For manufacturers seeking scalable batch production, DMG MORI offers robust programming ecosystems, rich aftermarket support, and global service networks that minimize downtime across multi-site operations.

EMAG's portfolio encompasses turning lathes, grinding systems, and integrated manufacturing solutions with an emphasis on modularity and digitalization. Their turning centers emphasize repeatability, process stability, and the ability to configure bespoke lines for automotive, energy, and general engineering applications. EMAG's software and automation capabilities support smarter manufacturing footprints, enabling data-driven optimization of turning processes.

LS Manufacturing is well-regarded for high-accuracy CNC turning services, rapid prototyping, and a customer-centric approach to project management. Their capabilities cover a broad spectrum of materials and applications, with emphasis on quick turnaround times and transparent collaboration. For customers needing fast proofs of concept followed by scalable production, LS Manufacturing provides a practical model that mirrors the needs of modern product development cycles.

Taiwan and mainland China host numerous credible turning lathe manufacturers that balance cost-efficiency with advanced engineering. Brands from Taiwan and mainland China often emphasize automation readiness, reliability, and service support, offering a compelling value proposition for overseas buyers seeking multi-axis precision turning at competitive price points. These vendors frequently partner with international distributors and OEMs to deliver turnkey solutions including tooling, fixtures, and post-processing services.

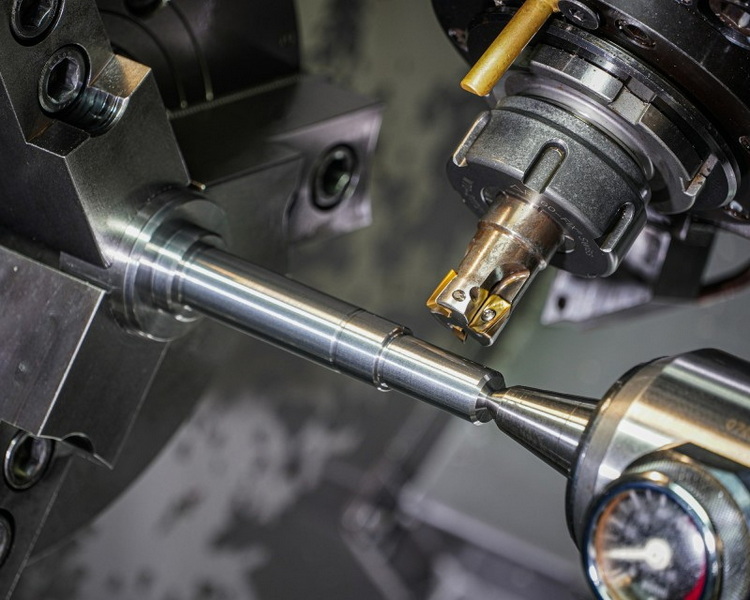

- Technical capabilities: Evaluate spindle power, torque, rigidity, lubrication and cooling strategies, and thermal stability. Multi-axis turning with live tooling expands the range of possible operations beyond simple turning.

- Automation and throughput: Bar feeders, robotic part handling, part unloading, and integrated quality control drive efficiency, especially for high-volume production.

- Process control and metrology: In-process inspection, CMM integration, and traceability workflows ensure parts meet stringent specifications and enable root-cause analysis when deviations occur.

- Material versatility: The ability to machine a wide range of metals and engineered plastics, including difficult-to-cut alloys, determines flexibility across projects.

- Support and after-sales: Local service, spare-part availability, and timely technical assistance reduce unplanned downtime.

- Total cost of ownership: Consider machine reliability, energy efficiency, tooling consumption, and maintenance requirements over the project lifecycle.

- Collaboration model: Clear communication channels, realistic lead times, and structured change management help keep programs on track.

Automated turning centers with integrated inspection and robotics enable 24/7 production, especially for automotive and industrial components. This convergence of turning capability with milling, drilling, and tapping reduces part handling, minimizes setup changes, and accelerates time-to-market for new products.

Digital twins, cloud-based monitoring, and predictive maintenance are moving turning lathe ecosystems toward Industry 4.0. Real-time data on spindle load, tool wear, coolant quality, and vibration patterns informs proactive maintenance and process optimization, reducing scrap and boosting throughput.

New cutting geometries, coating technologies, and high-precision tooling enhance surface quality and dimensional stability. This is critical for parts that demand tight tolerances, tight concentricities, and flawless finishes in aerospace and medical device sectors.

Cooling and lubrication strategies, energy-efficient drives, and recyclability considerations are becoming part of the standard evaluation criteria for turning lathe systems. Manufacturers increasingly prioritize coolant filtration and recycling as part of responsible manufacturing practices.

High-volume turning of shafts, gears, and transmission components demands stable processes, tight tolerances, and consistent surface finish. Auto manufacturers rely on turning lathe lines that can ramp up for peak demand while maintaining quality across batches.

Aerospace components require traceability, material integrity, and meticulous surface finishes. Advanced turning lathe configurations support complex geometries in turbine housings, fittings, and precision connectors.

Small-format components with stringent tolerance control, high cleanliness, and surface finish requirements are common. Multi-axis turning centers with tight thermal management help produce reliable connectors, housings, and precision instruments.

Pumps, valves, and hydraulic components benefit from robust turning lathe lines that deliver high-output, consistent performance, and long-term durability.

Part quality hinges on a structured quality plan that includes incoming material verification, process control documentation, in-process measurement, and final inspection. The best manufacturers link measurement data to digital records, supporting certification and traceability across the supply chain.

Choosing a top turning lathe manufacturer is a decision that shapes product quality, lead times, and business resilience. Shangchen's proven capabilities in rapid prototyping, CNC turning, sheet metal fabrication, and end-to-end OEM support position it as a compelling partner for global brands seeking reliable, scalable manufacturing solutions. Complementing Shangchen are industry leaders like DMG MORI, EMAG, and LS Manufacturing, whose global footprints and process innovations set the benchmark for turning lathe excellence. As automation, digitalization, and sustainability become standard expectations, selecting a partner that combines technical breadth with responsive customer care will define success in precision manufacturing for years to come.

Consider geometry complexity, material hardness, required tolerances, surface finish, and required production volumes. Request sample runs and pilot programs to validate process capability before large-scale production.

Automation reduces manual handling, enables continuous operation, and improves consistency. Bar feeders, robots, and integrated inspection workflows are common elements that boost throughput and quality control.

Shangchen offers end-to-end OEM capabilities, rapid prototyping, and multi-axis turning expertise with a focus on international clients, making the transition from prototype to production smoother and faster.

Aluminum, stainless steel, carbon steel, alloy steels, titanium, brass, copper, certain plastics, and composite materials, depending on machine rigidity and tooling.

Watch for deeper automation integration, smarter process analytics, additive-assisted finishing, and more sustainable coolant and energy solutions as the industry evolves.

[1](https://www.weerg.com/guides/lathe)

[2](https://www.grandviewresearch.com/industry-analysis/cnc-machining-turning-centers-market-report)

[3](https://www.camprocnc.com/en/news/industry/what-is-cnc-turning-machine)

[4](https://www.mordorintelligence.com/industry-reports/lathe-machine-market)

[5](https://www.fortunebusinessinsights.com/industry-reports/lathe-machines-market-101804)

[6](https://machinetoolspecialties.com/blog/1036-leading-cnc-lathe-manufacturers-a-comparative-quality-overview)

[7](https://rosnokmachine.com/cnc-lathe-manufacturers/)

[8](https://introspectivemarketresearch.com/reports/lathe-machine-market/)

[9](https://www.techsciresearch.com/report/turning-tools-market/27529.html)

[10](https://www.tsinfa.com/cnc-wheel-lathe/)

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes