Views: 222 Author: Amanda Publish Time: 2025-08-02 Origin: Site

Content Menu

● Introduction to Turning Lathe Technology in Europe

● Leading European Turning Lathe Manufacturers and Suppliers

>> EMCO

>> WEILER

>> Danobat

>> CMZ

>> Okuma Europe

>> ELMAG

>> HWACHEON

>> INDEX Group

● The Technological Edge: CNC and Automation in European Turning Lathes

● Factors to Consider When Selecting European Turning Lathe Manufacturers and Suppliers

● Broader Industry Applications Supported by European Turning Lathe Manufacturers

● Commitment to Sustainability and Environmental Responsibility

● FAQs

>> 1. What distinguishes European turning lathe manufacturers and suppliers from others?

>> 2. Are European turning lathes suitable for both small batch and mass production?

>> 3. How important is after-sales service when choosing a turning lathe manufacturer?

>> 4. Can European manufacturers customize lathes for specific industry needs?

>> 5. What are the current trends among top turning lathe manufacturers and suppliers in Europe?

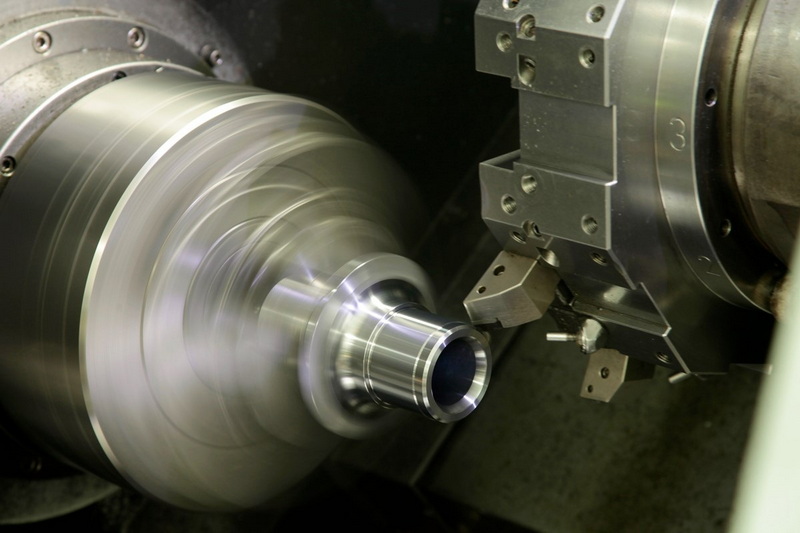

Europe has long been at the forefront of industrial machinery innovation, and its expertise in manufacturing and supplying turning lathes stands out globally. From high-precision CNC lathes for aerospace to robust manual lathes serving the energy sector, European turning lathe manufacturers and suppliers blend tradition, cutting-edge technology, and rigorous quality standards. This guide delves deep into the landscape of leading European turning lathe manufacturers and suppliers, highlighting their unique strengths, product offerings, and market advantages.

Turning lathes are the backbone of countless industries, including automotive, aerospace, energy, precision engineering, prototyping, and mass manufacturing. Europe, as a global manufacturing hub, is renowned for developing top-tier turning lathes and supporting technologies. Many of the world's most innovative, reliable, and high-precision lathes originate from the workshops and factories of Germany, the UK, Italy, Spain, and Austria.

Turning lathe manufacturers and suppliers in Europe focus on performance, precision, sustainability, and continuously evolving automation technologies. From traditional manual machines for specialized craftsmanship to the industry's most advanced CNC turning platforms, options abound for every production scale and requirement.

Headquartered in Austria, EMCO has earned its status as one of Europe's premier turning lathe manufacturers and suppliers. The company specializes in both conventional and CNC turning centers, vertical machining centers, and fully automated solutions. Renowned for product innovation, a broad range, and exceptional service, EMCO machines cater for both industrial production and advanced training applications. With over 75 years of experience, they provide fully customized, automated complete solutions for both turning and milling needs. EMCO's ability to integrate automation and training systems makes it a unique choice for a diverse range of customers, from educational institutions to large-scale manufacturers.

With a legacy spanning over 80 years, WEILER stands out as an iconic supplier of precision lathes for industries, educational facilities, and specialized workshops. Based in Germany, their product suite covers engine lathes, tool room lathes, servo engine lathes, cycle-controlled lathes, and cutting-edge CNC lathes. WEILER is synonymous with reliability, accuracy, and continuous technological advancement. Their machines are widely appreciated for their solid construction and the ability to handle complex machining processes with ease.

Located in Germany, Hager Maschinenbau is known for its robust and innovative turning lathes. They specialize in wood and metal lathes, sliding headstock lathes, and CNC options tailored for serial production. Hager's rich accessory programs make their product lines versatile, and their solutions are ideal for prototyping, contract production, and scale manufacturing. They offer both classic and custom machines, with a strong focus on quality and adaptability. Their commitment to efficiency and precision has made them a reliable partner for industries requiring high productivity coupled with customization.

A cornerstone in the UK's engineering landscape, Colchester Machine Tools has been producing renowned turning lathes since the 19th century and has continually evolved with technology. Their product lines range from robust manual lathes to advanced CNC systems, all supported by comprehensive aftersales and parts services. Their tech centers in Europe are hubs for demonstrations, training, and innovation. Colchester stands out for its emphasis on customer support and the durability of its machines, which remain favored in educational and industrial settings alike.

Based in Spain, Danobat focuses on manufacturing advanced turning lathes, CNC solutions, and precision robotics for machining. Their robust engineering, strong R&D, and commitment to automation have made them a preferred supplier for aerospace, automotive, and railway industries across Europe. Danobat's dedication to integrating robotics and smart manufacturing techniques positions it strongly within the Industry 4.0 landscape.

Operating for over 75 years, CMZ is a prominent Spanish manufacturer, offering a wide selection of CNC lathes specifically designed for high-volume production environments. Their commitment to quality, innovation, and customer-centricity has made CMZ a trusted name among European turning lathe manufacturers and suppliers. Their focus on scalability and repeatability appeals especially to manufacturers requiring consistent precision across large batches.

Okuma, with its European headquarters in Germany, brings Japanese engineering excellence to the European market. Their turning lathe offerings are distinguished by top-tier CNC controls, outstanding operational efficiency, and lifetime support. Okuma Europe is regarded for its full-circle approach to machine tool supply and maintenance. Their technology emphasizes adaptability, precision, and durability, supporting industries ranging from automotive to medical device manufacturing.

ELMAG is an Austrian-based supplier with a diversified range of turning lathes. Their catalog covers everything from ergonomically optimized small lathes to heavyweight, semi-automated professional models designed for industrial serial production. Their machines are favored for excellent ergonomics, enhanced safety features, and ease of use, making them suitable for both small workshops and large factories.

Serving the European market from Germany, HWACHEON combines traditional Korean craftsmanship with the latest technology, offering horizontal and vertical turning centers, CNC lathes, and multi-axis machine tools. Their commitment to durability, innovation, and customization makes them a formidable force among European turning lathe manufacturers and suppliers. Their machines are notable for precision engineering, high rigidity, and long-term reliability.

INDEX, based in Germany, specializes in multi-spindle turning machines and multifunctional production centers. As one of the leading turning lathe manufacturers and suppliers, INDEX's machines are tailored for fast, high-volume manufacturing, with advanced precision and flexibility. Their production platforms excel in industries where speed and accuracy are both critical, such as automotive components and electronics.

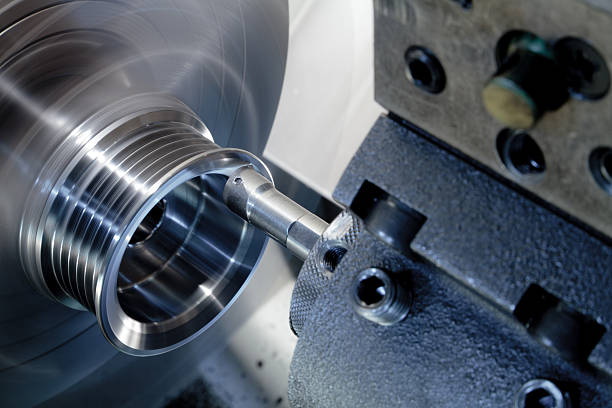

European turning lathe manufacturers and suppliers are global pioneers in CNC automation, integration of robotics, and digital production tracking. CNC technology enhances the precision, repeatability, and throughput of modern lathes, while modular automation options allow for seamless adaptation to changing production needs. Advanced motion control, smart sensors, and AI-powered diagnostics are increasingly common, enabling predictive maintenance and reducing machine downtime.

Key features include:

- Multi-axis capability: Allowing complex geometric shapes with greater detail and speed.

- Automated part loading/unloading systems: Increasing operational efficiency while reducing manual labor.

- Sophisticated control interfaces: Featuring user-friendly touchscreens and programming environments for quick setup and adaptation.

- Real-time production analytics: Offering insight into performance metrics, quality control, and throughput.

- Energy efficiency measures: Lowering operational costs and environmental impact.

- Integration with Industry 4.0 infrastructure: Facilitating seamless connectivity with factory-wide systems for optimized workflows.

These innovations collectively contribute to improved product quality, reduced lead times, and enhanced adaptability to variable production demands.

Choosing the right manufacturer or supplier from Europe's rich market requires careful consideration of several aspects:

- Product Range and Versatility: Ensure the supplier offers machines capable of handling the materials, precision levels, and batch sizes you require. Flexibility to upgrade or customize machines is an added advantage.

- After-Sales Support and Training: Comprehensive support, quick access to spare parts, and operator training programs reduce downtime and improve output quality.

- Customization Capabilities: Many industries demand specialized solutions; opting for suppliers offering tailor-made machines helps meet exact production needs.

- Certifications and Quality Standards: ISO, CE, and industry-specific standards confirm compliance and reliability.

- Technological Innovation and Future-Proofing: Invest with partners committed to continuous R&D, introducing smart features that keep your production lines competitive.

- Cost Considerations: Evaluate the total cost of ownership, including machine lifespan, maintenance expenses, and potential ROI, beyond just upfront purchase price.

The versatility of European turning lathe manufacturers and suppliers means their customers span diverse sectors:

- Automotive: High-speed, precision machining of engine components, transmission parts, and bespoke alloys.

- Aerospace: Complex geometries and lightweight materials requiring ultra-precise control and multi-axis turning.

- Medical Devices: Micrometer-precise components for surgical instruments and implants necessitating clean operation and tight tolerances.

- Energy: Heavy-duty lathes designed for turbine blades, shafts, and structural parts, focusing on durability and reliability.

- Electronics and Telecommunications: Miniature components produced with high repeatability on CNC lathes optimized for small batch sizes.

- General Engineering and Prototyping: Rapid prototyping capabilities offered by quick-change tooling and flexible programming.

European manufacturers frequently collaborate with clients to engineer bespoke solutions that meet tight deadlines and complex specifications, underlining the sector's responsiveness and customer orientation.

Many European turning lathe manufacturers and suppliers integrate sustainability into their operations and product development. This includes:

- Utilizing energy-efficient motors and systems.

- Designing machines for minimal waste generation.

- Incorporating recyclable materials and modular designs for upgrades rather than full replacements.

- Implementing closed-loop coolant and lubricant systems to minimize environmental impact.

- Applying Industry 4.0 technologies to optimize production efficiency, thus reducing energy consumption and material waste.

Such initiatives align with Europe's broader industrial policies aimed at fostering greener manufacturing processes.

Europe continues to set the global benchmark when it comes to the manufacture of high-quality turning lathes. From established giants like EMCO and WEILER to innovative players like CMZ and INDEX, European turning lathe manufacturers and suppliers exemplify reliability, advancement, and a customer-first philosophy. Whether seeking OEM solutions, rapid prototyping, or complex automated systems, brands from this region deliver unmatched choice and quality for international clients. The combination of tradition, innovation, and comprehensive support ensures European suppliers will remain essential partners for manufacturers worldwide. As demands for smarter, faster, and more sustainable production environments grow, Europe's turning lathe sector is poised for even greater relevance and success.

European turning lathe manufacturers and suppliers are known for their strict quality controls, state-of-the-art technology, and longstanding traditions of engineering excellence. They often lead the market in automation, precision, and customer-tailored solutions, emphasizing durability and innovation.

Absolutely. European suppliers provide a broad range of models from manual bench lathes designed for bespoke parts to large CNC lathes and multi-spindle machines capable of high-volume mass production. This versatility caters to startups, SMEs, and large industrial manufacturers alike.

After-sales service is crucial. It ensures ongoing machine performance through timely parts replacement, maintenance, and technical support. Reliable service reduces downtime, improves operational efficiency, and extends machine longevity, directly impacting production costs and quality.

Yes. Customization is a core strength among European turning lathe manufacturers and suppliers. Clients can order machines tailored to specific materials, precision levels, automation features, and production volumes, helping meet unique operational goals.

Key trends include increased automation, integration of Industry 4.0 technologies for real-time monitoring, energy-efficient operations, predictive maintenance, and the rising demand for flexible, modular production solutions that can quickly adapt to shifting market conditions.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal